I-Solid Silicon Carbide (i-SiC) i-Etching Rings enikezelwa yi-Semicera yenziwe nge-Chemical Vapor Deposition (CVD) indlela kwaye ziziphumo ezibalaseleyo kwintsimi yezicelo zenkqubo yokuchaneka. Ezi I-Silicon Silicon Carbide (SiC) Etching Rings zaziwa ngobulukhuni bazo obubalaseleyo, ukuzinza kwe-thermal kunye nokuxhathisa ukubola, kunye nomgangatho ophezulu wezinto ezibonakalayo uqinisekiswa yi-CVD synthesis.

Eyilwe ngokukodwa kwiinkqubo ze-etching, i-Solid Silicon Carbide (i-SiC) i-Etching Rings 'isakhiwo esinqabileyo kunye neempawu zezinto ezizodwa zidlala indima ebalulekileyo ekufezekiseni ukuchaneka nokuthembeka. Ngokungafaniyo nezixhobo zemveli, icandelo le-SiC elomeleleyo linokuqina okungenakulinganiswa kunye nokumelana nokunxiba, oko kuyenza ibe yinto ebaluleke kakhulu kumashishini afuna ukuchaneka kunye nobomi obude.

I-Solid Silicon Carbide yethu (i-SiC) ye-Etching Rings ichanekileyo yenziwe kwaye ilawulwa umgangatho ukuqinisekisa ukusebenza kwayo okuphezulu kunye nokuthembeka. Nokuba kukwimveliso ye-semiconductor okanye kwezinye iindawo eziyeleleneyo, ezi I-Solid Silicon Carbide (SiC) I-Etching Rings inokubonelela ngokusebenza okuzinzileyo kunye neziphumo ezigqwesileyo zokurhweba.

Ukuba unomdla kwi-Solid Silicon Carbide (SiC) Etching Ring yethu, nceda uqhagamshelane nathi. Iqela lethu liya kukubonelela ngolwazi oluneenkcukacha lwemveliso kunye nenkxaso yobuchwephesha bobugcisa ukuhlangabezana neemfuno zakho. Sijonge phambili ekusekeni intsebenziswano yexesha elide nawe kunye nokukhuthaza ngokudibeneyo uphuhliso lweshishini.

✓Umgangatho ophezulu kwimarike yaseTshayina

✓Inkonzo entle rhoqo kuwe, 7*24 iiyure

✓Umhla omfutshane wokuhanjiswa

✓I-MOQ encinci yamkelekile kwaye yamkelwe

✓Iinkonzo ezilungiselelwe wena

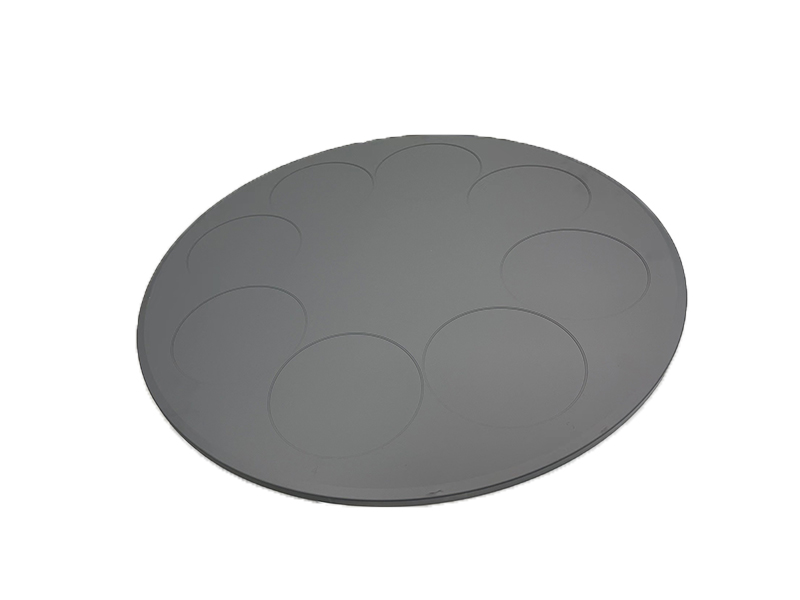

Epitaxy Growth Susceptor

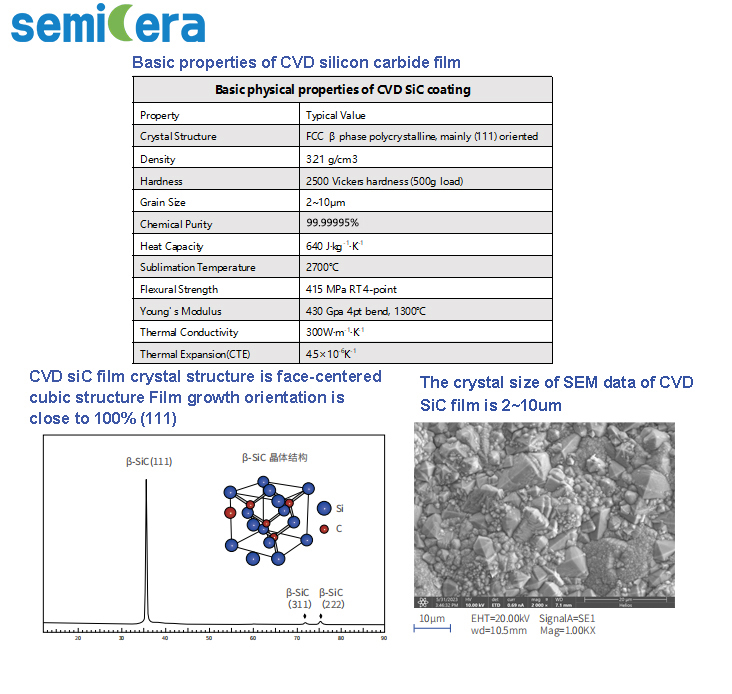

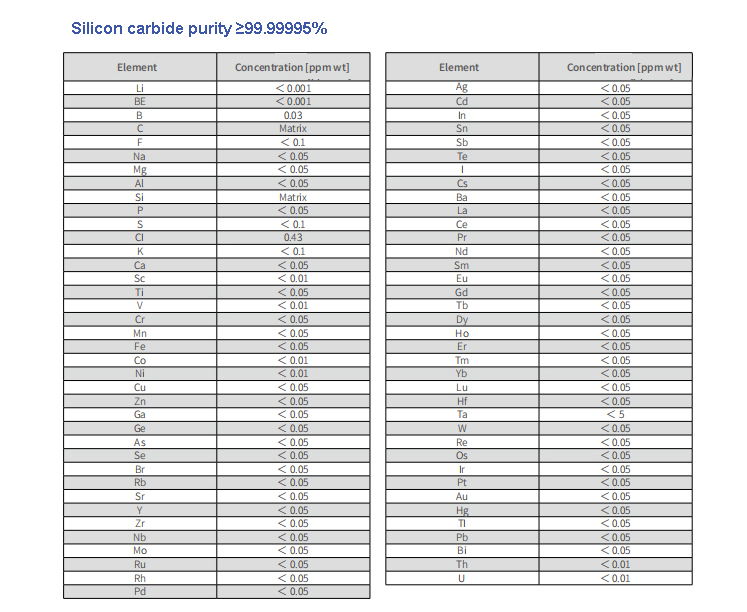

I-silicon / i-silicon carbide wafers kufuneka ihambe kwiinkqubo ezininzi eziza kusetyenziswa kwizixhobo zombane. Inkqubo ebalulekileyo yi-silicon / i-sic epitaxy, apho i-silicon / i-sic wafers iqhutyelwa kwisiseko segraphite. Izibonelelo ezikhethekileyo zeSemicera's silicon carbide-coated-coated graphite base ibandakanya ukucoceka okuphezulu kakhulu, ukutyabeka okufanayo, kunye nobomi benkonzo ende kakhulu. Kananjalo banokumelana neekhemikhali eziphezulu kunye nokuzinza kwe-thermal.

Ukuveliswa kweChip ye-LED

Ngethuba lokugquma okubanzi kwe-reactor ye-MOCVD, isiseko seplanethi okanye umthwali uhambisa i-wafer substrate. Ukusebenza kwezinto ezisisiseko kunempembelelo enkulu kumgangatho wokugquma, nto leyo echaphazela izinga le-scrap ye-chip. Isiseko seSemicera's silicon carbide-coated base sonyusa ukusebenza kakuhle kweewafers ze-LED ezikumgangatho ophezulu kunye nokunciphisa ukutenxa kobude bamaza. Sikwabonelela ngezixhobo ezongezelelweyo zegraphite kuzo zonke iireactor zeMOCVD ezisetyenziswayo ngoku. Sinako ukunxiba phantse naliphi na icandelo nge-silicon carbide coating, nokuba i-diameter yecandelo ifikelela kwi-1.5M, sisenokwambatha ngesilicon carbide.

Ummandla weSemiconductor, Inkqubo ye-Oxidation Diffusion, njl.

Kwinkqubo ye-semiconductor, inkqubo yokwandiswa kwe-oxidation ifuna ukucoceka okuphezulu kwemveliso, kwaye kwi-Semicera sinikezela ngeenkonzo zesiko kunye ne-CVD yokwambathisa uninzi lweengxenye ze-silicon carbide.

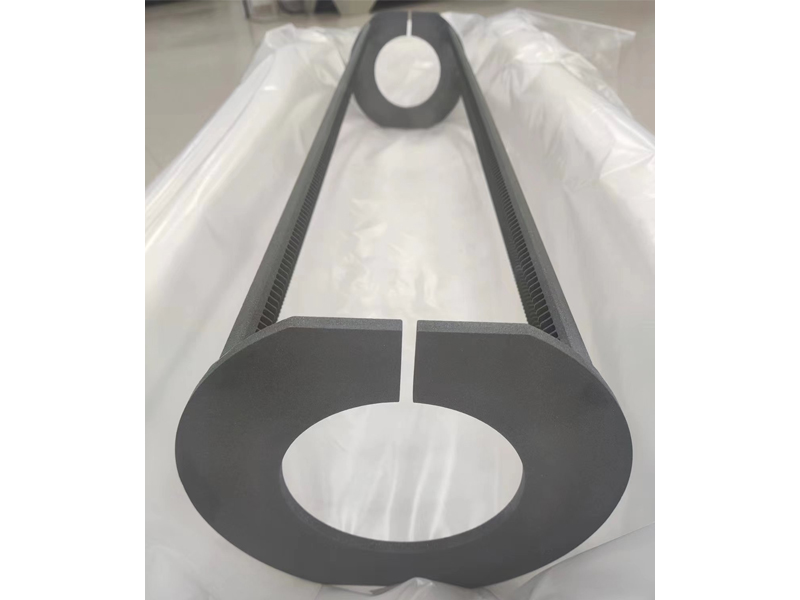

Lo mfanekiso ulandelayo ubonisa i-silicon carbide slurry esekwe ngokurhabaxa ye-Semicea kunye ne-silicon carbide furnace tyhubhu ecocwe kwi-100.0-kwinqanabaengenathuliigumbi. Abasebenzi bethu basebenza ngaphambi kokulala. Ukucoceka kwe-silicon carbide yethu kunokufikelela kwi-99.99%, kwaye ukucoceka kwe-sic coating kukhulu kune-99.99995%.

I-Silicon Carbide Paddle eluhlaza kunye ne-SiC Process Tube ekuCocini

ISilicon Carbide Wafer Boat CVD SiC Coated