CVD SiC Coating

Silicon carbide(SiC) epitaxy

I-tray ye-epitaxial, ebambe i-substrate ye-SiC yokukhulisa i-SiC epitaxial slice, ibekwe kwigumbi lokuphendula kwaye iqhagamshelane ngokuthe ngqo ne-wafer.

Inxalenye engaphezulu yesiqingatha senyanga sisithwali sezinye izixhobo zegumbi lokuphendula lezixhobo ze-Sic epitaxy, ngelixa isiqingatha senyanga esisezantsi siqhagamshelwe kwityhubhu yequartz, sazisa igesi ukuqhuba isiseko se-susceptor ukujikeleza.zinolawulo lobushushu kwaye zifakwe kwigumbi lokusabela ngaphandle kokudibana ngokuthe ngqo ne-wafer.

Si epitaxy

I-tray, ebambe i-Si substrate yokukhulisa i-Si epitaxial slice, ibekwe kwigumbi lokuphendula kwaye iqhagamshelane ngqo ne-wafer.

Isangqa sokufudumala sifumaneka kwindandatho yangaphandle ye-Si epitaxial substrate tray kwaye isetyenziselwa ukulinganisa kunye nokufudumeza.Ifakwe kwigumbi lokuphendula kwaye ayiqhagamshelani ngqo ne-wafer.

I-epitaxial susceptor, ebambe i-Si substrate yokukhulisa i-Si epitaxial slice, ibekwe kwigumbi lokuphendula kwaye iqhagamshelane ngqo ne-wafer.

I-Epitaxial barrel yizona zinto zibalulekileyo ezisetyenziswa kwiinkqubo ezahlukeneyo zokuvelisa i-semiconductor, ezisetyenziswa ngokubanzi kwizixhobo ze-MOCVD, ezinozinzo oluhle kakhulu lwe-thermal, ukuxhathisa imichiza kunye nokumelana nokunxiba, kukulungele kakhulu ukusetyenziswa kwiinkqubo zokushisa okuphezulu.Iqhagamshela iiwafa.

| 重结晶碳化硅物理特性 Iimpawu ezibonakalayo zeRecrystallized Silicon Carbide | |

| 性质 / Ipropati | 典型数值 / Ixabiso eliqhelekileyo |

| 使用温度 / Ubushushu bokusebenza (°C) | 1600°C (neoksijini), 1700°C (ukunciphisa okusingqongileyo) |

| SiC 含量 / umxholo weSiC | > 99.96% |

| 自由 Si 含量 / Isiqulatho sasimahla seSi | <0.1% |

| 体积密度 / Ubuninzi bobuninzi | 2.60-2.70 g / cm3 |

| 气孔率 / I-porosity ebonakalayo | < 16% |

| 抗压强度 / Amandla oxinzelelo | > 600 MPa |

| 常温抗弯强度 / Amandla okugoba okubandayo | 80-90 MPa (20°C) |

| 高温抗弯强度 Amandla okugoba ashushu | 90-100 MPa (1400°C) |

| 热膨胀系数 / Ukwandiswa kweThermal @1500°C | 4.70 10-6/°C |

| 导热系数 / Thermal conductivity @1200°C | 23 W/m•K |

| 杨氏模量 / Imodyuli Elastiki | 240 GPA |

| 抗热震性 / Ukuxhathisa ukothuka kweThermal | Ulunge kakhulu |

| 烧结碳化硅物理特性 Iimpawu ezibonakalayo zeSintered Silicon Carbide | |

| 性质 / Ipropati | 典型数值 / Ixabiso eliqhelekileyo |

| 化学成分 / Ukwakhiwa kwemichiza | SiC>95%, Si<5% |

| 体积密度 / Ubuninzi bobuninzi | >3.07 g/cm³ |

| ILogo Simahla Akukho mlinganiselo Ipapashwe ngu- porosity | <0.1% |

| 常温抗弯强度 / iModulus yokugqabhuka kwi-20℃ | 270 MPa |

| 高温抗弯强度 / iModulus yokugqabhuka kwi-1200℃ | 290 MPa |

| 硬度 / Ukuqina kwi-20℃ | 2400 Kg/mm² |

| 断裂韧性 / Ukuqina kokwaphuka kwi-20% | 3.3 MPa · m1/2 |

| 导热系数 / Thermal Conductivity kwi-1200℃ | 45 w/m .K |

| 热膨胀系数 / Ukwandiswa kweThermal kwi-20-1200℃ | 4.5 1 × 10 -6/℃ |

| 最高工作温度 / Max.ubushushu bokusebenza | 1400℃ |

| 热震稳定性 / Ukumelana nokothuka kwe-Thermal kwi-1200℃ | Kulungile |

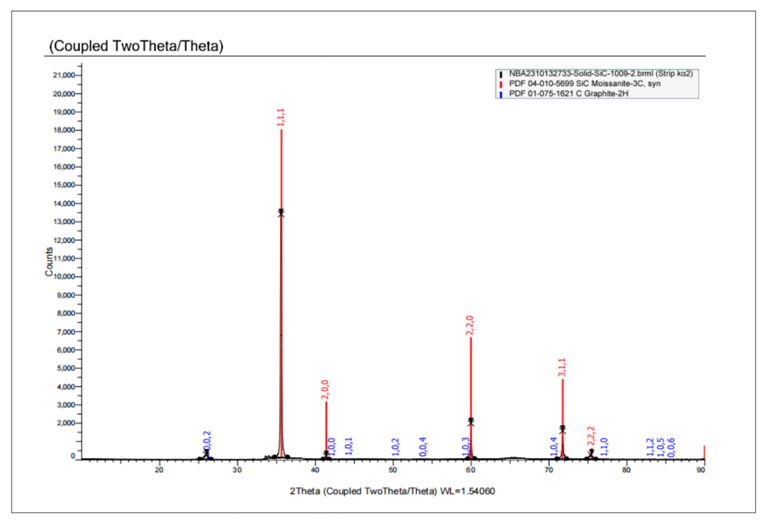

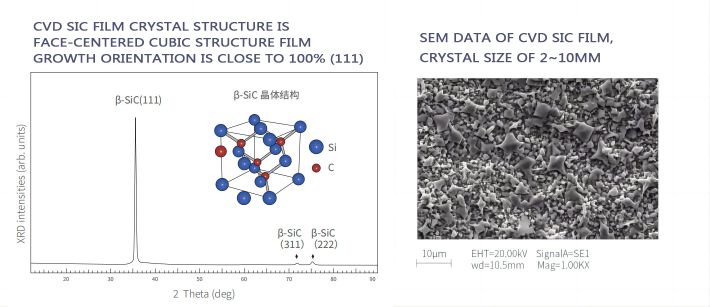

| CVD SiC 薄膜基本物理性能 Iimpawu ezibonakalayo ezisisiseko zeefilimu ze-CVD SiC | |

| 性质 / Ipropati | 典型数值 / Ixabiso eliqhelekileyo |

| 晶体结构 / Crystal Structure | I-FCC β isigaba se-polycrystalline, ikakhulu (i-111) ejoliswe kuyo |

| 密度 / Ubuninzi | 3.21 g/cm³ |

| 硬度 / Ubunzima 2500 | 维氏硬度 (500g umthwalo) |

| 晶粒大小 / Grain SiZe | 2 ~ 10μm |

| 纯度 / Ucoceko lweMichiza | 99.99995% |

| 热容 / Umthamo wobushushu | 640 J·kg-1·K-1 |

| 升华温度 / Ubushushu bokunciphisa | 2700℃ |

| 抗弯强度 / Amandla e-Flexural | 415 MPa RT 4-point |

| 杨氏模量 / Young's Modulus | 430 Gpa 4pt bend, 1300℃ |

| 导热系数 / Thermal Conductivity | 300Wm-1·K-1 |

| 热膨胀系数 / Ukwandiswa kweThermal(CTE) | 4.5×10-6 K -1 |

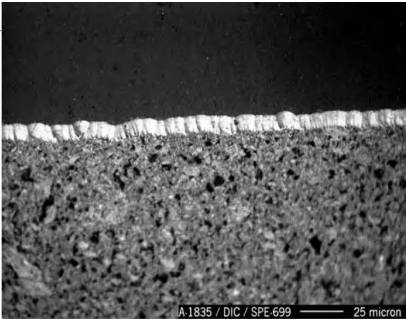

I-Pyrolytic Carbon Coating

Iimpawu eziphambili

Umphezulu uxinene kwaye awunazo iipores.

Ukucoceka okuphezulu, umxholo wokungcola ngokupheleleyo <20ppm, umoya omhle.

Ukumelana nobushushu obuphezulu, amandla anyuka ngokunyuka kobushushu bokusetyenziswa, ukufikelela kwelona xabiso liphezulu kwi-2750 ℃, i-sublimation kwi-3600 ℃.

Imodyuli ye-elastic esezantsi, ukuhanjiswa okuphezulu kwe-thermal, i-coefficient yokwandisa i-thermal ephantsi, kunye nokuchasana kokuthotywa kwe-thermal.

Ukuzinza kweekhemikhali ezilungileyo, ukumelana ne-asidi, i-alkali, ityuwa, kunye ne-organic reagents, kwaye ayinayo impembelelo kwisinyithi esityhidiweyo, i-slag, kunye nezinye izinto ezidliwayo.Ayifaki i-oxidize kakhulu kwi-atmosfera engaphantsi kwe-400 C, kwaye izinga le-oxidation linyuka kakhulu kwi-800 ℃.

Ngaphandle kokukhupha nayiphi na igesi kumaqondo obushushu aphezulu, inokugcina ivacuum eyi-10-7mmHg malunga ne-1800°C.

Isicelo semveliso

I-crucible enyibilikayo yokunyuka komphunga kwishishini le-semiconductor.

Amandla aphezulu esango letyhubhu ye-elektroniki.

Ibrashi enxibelelana nesilawuli sombane.

Graphite monochromator for X-reyi kunye neutron.

Iimilo ezahlukeneyo ze-graphite substrates kunye ne-atom yokufunxa ityhubhu yokugquma.

Ifuthe le-pyrolytic carbon coating phantsi kwe-500X microscope, kunye nomphezulu oqinileyo kunye notywiniweyo.

I-CVD Tantalum Carbide Coating

Ukwaleka kwe-TaC sisizukulwana esitsha sokumelana nobushushu obuphezulu, enozinzo olungcono lobushushu obuphezulu kuneSiC.Njengengubo enganyangekiyo ku-corrosion, i-anti-oxidation coating kunye ne-resistant-resistant coating, inokusetyenziswa kwindawo engaphezulu kwe-2000C, isetyenziswa ngokubanzi kwindawo ye-aerospace yobushushu obuphezulu bobushushu obuphezulu, isizukulwana sesithathu semiconductor enye indawo yokukhula yekristale.

| 碳化钽涂层物理特性物理特性 Iipropati ezibonakalayo ze-TAC ukutyabeka | |

| 密度/ Ubuninzi | 14.3 (g/cm3) |

| 比辐射率 /Specific emissivity | 0.3 |

| 热膨胀系数/ Ukwandiswa kwe-Thermal coefficient | 6.3 10/K |

| 努氏硬度 /Ubunzima (HK) | 2000 HK |

| 电阻/ Ukuchasa | 1x10-5 Ohm * cm |

| 热稳定性 /Thermal uzinzo | <2500℃ |

| 石墨尺寸变化/Ubungakanani botshintsho lweGrafite | -10 ~ -20um |

| 涂层厚度/Ubukhulu bokugquma | ≥220um ixabiso eliqhelekileyo (35um±10um) |

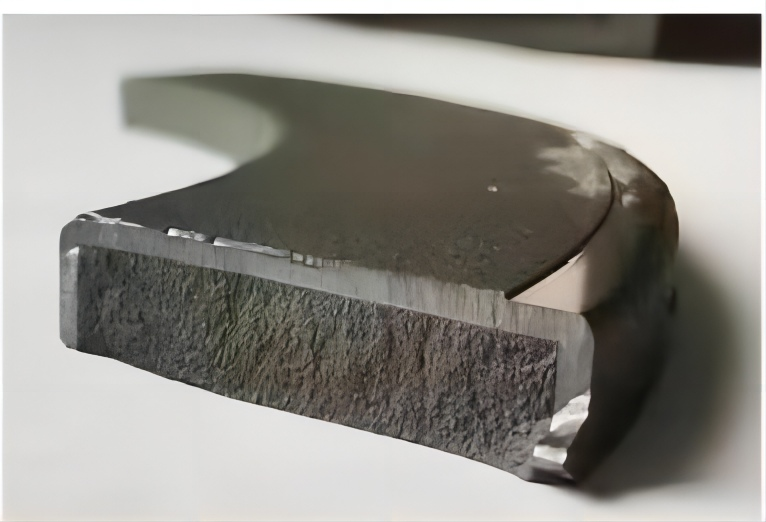

I-Silicon Carbide (CVD SiC)

Iinxalenye eziqinileyo zeCVD SILICON CARBIDE zibonwa njengolona khetho luphambili lweRTP/EPI amakhonkco kunye neziseko kunye neplasma etch cavity amalungu asebenza kwinkqubo ephezulu efunekayo ubushushu bokusebenza (> 1500 ° C), iimfuno zococeko ziphezulu kakhulu (> 99.9995%) kwaye ukusebenza kuhle ngakumbi xa iikhemikhali zokumelana netol ziphezulu kakhulu.Ezi zixhobo aziqukethe izigaba zesibini kumda wokudla okuziinkozo, ngoko ke amacandelo e-il avelisa amasuntswana ambalwa kunezinye izinto.Ukongeza, la macandelo anokucocwa usebenzisa i-HF/HCI eshushu ngokuthotywa okuncinci, okubangela amasuntswana ambalwa kunye nobomi benkonzo obude.