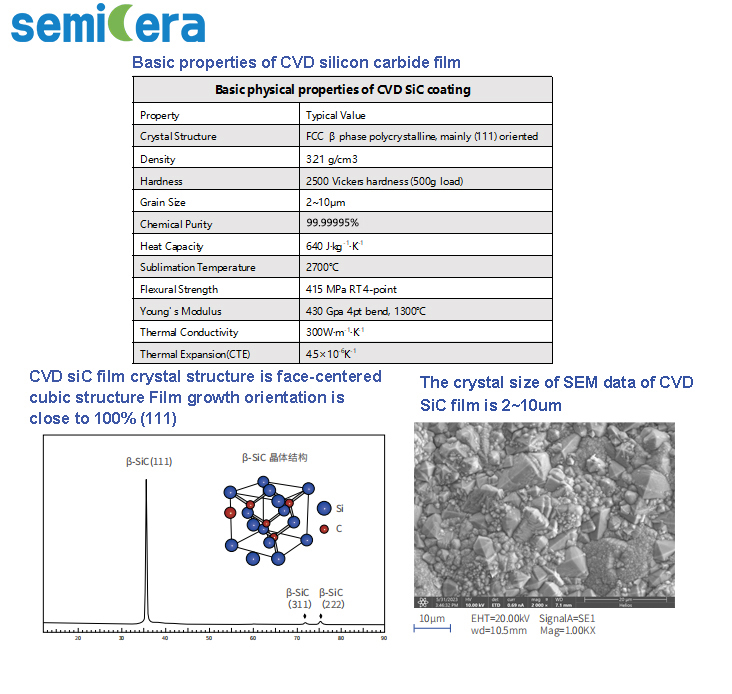

GxininisaCVD SiC Ringyi-silicon carbide (SiC) imathiriyeli yeringi elungiswe yi-Focus Chemical Vapor Deposition (Focus CVD) iteknoloji.

GxininisaCVD SiC Ringineempawu ezininzi zokusebenza ezisemagqabini. Okokuqala, inobunzima obuphezulu, indawo ephezulu yokunyibilika kunye nokumelana nobushushu obuphezulu, kwaye inokugcina uzinzo kunye nokunyaniseka kwesakhiwo phantsi kweemeko zokushisa ezigqithisileyo. Okwesibini, GxininisaCVD SiC Ringinozinzo olugqwesileyo lweekhemikhali kunye nokumelana nomhlwa, kwaye inokumelana okuphezulu nemithombo yeendaba ezonakalisayo njengeeasidi kunye neealkali. Ukongeza, ikwanayo ne-thermal conductivity egqwesileyo kunye namandla omatshini, afanelekile kwiimfuno zesicelo kwiqondo lokushisa eliphezulu, uxinzelelo oluphezulu kunye neendawo ezinobungozi.

GxininisaCVD SiC Ringisetyenziswa kakhulu kwiinkalo ezininzi. Ihlala isetyenziselwa ukuhlukaniswa kwe-thermal kunye nokukhusela izixhobo zokushisa eziphezulu, ezifana neziko lobushushu obuphezulu, izixhobo ze-vacuum kunye ne-reactors zamakhemikhali. Ukongeza, GxininisaCVD SiC Ringingasetyenziselwa kwi-optoelectronics, ukuveliswa kwe-semiconductor, umatshini ochanekileyo kunye ne-aerospace, ukubonelela ngokunyamezela okuphezulu kokusingqongileyo kunye nokuthembeka.

✓Umgangatho ophezulu kwimarike yaseTshayina

✓Inkonzo entle rhoqo kuwe, 7*24 iiyure

✓Umhla omfutshane wokuhanjiswa

✓I-MOQ encinci yamkelekile kwaye yamkelwe

✓Iinkonzo ezilungiselelwe wena

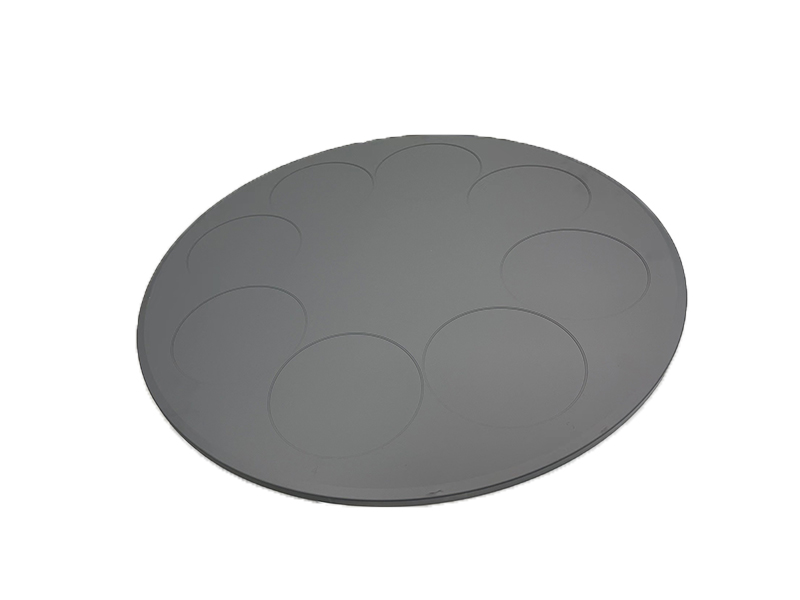

Epitaxy Growth Susceptor

I-silicon / i-silicon carbide wafers kufuneka ihambe kwiinkqubo ezininzi eziza kusetyenziswa kwizixhobo zombane. Inkqubo ebalulekileyo yi-silicon / i-sic epitaxy, apho i-silicon / i-sic wafers iqhutyelwa kwisiseko segraphite. Izibonelelo ezikhethekileyo zeSemicera's silicon carbide-coated-coated graphite base ibandakanya ukucoceka okuphezulu kakhulu, ukutyabeka okufanayo, kunye nobomi benkonzo ende kakhulu. Kananjalo banokumelana neekhemikhali eziphezulu kunye nokuzinza kwe-thermal.

Ukuveliswa kweChip ye-LED

Ngethuba lokugquma okubanzi kwe-reactor ye-MOCVD, isiseko seplanethi okanye umthwali uhambisa i-wafer substrate. Ukusebenza kwezinto ezisisiseko kunempembelelo enkulu kumgangatho wokugquma, nto leyo echaphazela izinga le-scrap ye-chip. Isiseko seSemicera's silicon carbide-coated base sonyusa ukusebenza kakuhle kweewafers ze-LED ezikumgangatho ophezulu kunye nokunciphisa ukutenxa kobude bamaza. Sikwabonelela ngezixhobo ezongezelelweyo zegraphite kuzo zonke iireactor zeMOCVD ezisetyenziswayo ngoku. Sinako ukunxiba phantse naliphi na icandelo nge-silicon carbide coating, nokuba i-diameter yecandelo ifikelela kwi-1.5M, sisenokwambatha ngesilicon carbide.

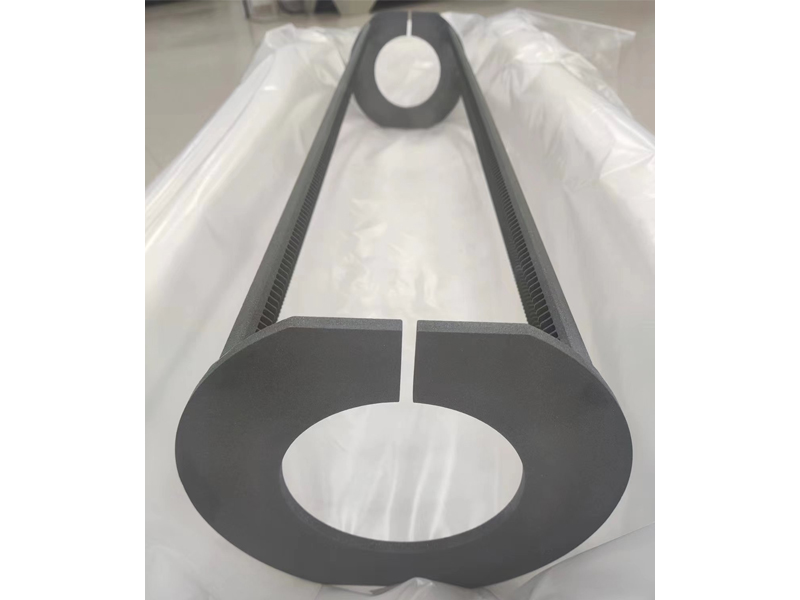

Ummandla weSemiconductor, Inkqubo ye-Oxidation Diffusion, njl.

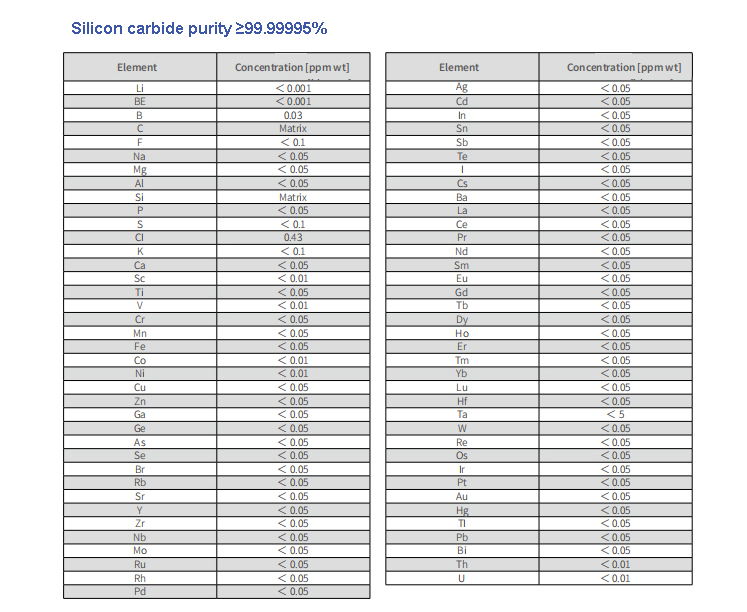

Kwinkqubo ye-semiconductor, inkqubo yokwandiswa kwe-oxidation ifuna ukucoceka okuphezulu kwemveliso, kwaye kwi-Semicera sinikezela ngeenkonzo zesiko kunye ne-CVD yokwambathisa uninzi lweengxenye ze-silicon carbide.

Lo mfanekiso ulandelayo ubonisa i-silicon carbide slurry esekwe ngokurhabaxa ye-Semicea kunye ne-silicon carbide furnace tyhubhu ecocwe kwi-100.0-kwinqanabaengenathuliigumbi. Abasebenzi bethu basebenza ngaphambi kokulala. Ukucoceka kwe-silicon carbide yethu kunokufikelela kwi-99.99%, kwaye ukucoceka kwe-sic coating kukhulu kune-99.99995%.

I-Silicon Carbide Paddle eluhlaza kunye ne-SiC Process Tube ekuCocini

ISilicon Carbide Wafer Boat CVD SiC Coated