Semicera's self-uphuhlisoInxalenye yeSiC Ceramic Sealyenzelwe ukuhlangabezana nemigangatho ephezulu yokwenziwa kwesemiconductor yanamhlanje. Le nxalenye yokutywina isebenzisa ukusebenza okuphezului-silicon carbide (SiC)izinto eziphathekayo ezinokumelana nokunxiba okugqwesileyo kunye nokuzinza kweekhemikhali zokuqinisekisa ukusebenza ngokugqwesileyo kokutywinwa kwiindawo ezigqithisileyo. Idityaniswe neialuminiyam oxide (Al2O3)kwayei-silicon nitride (Si3N4), le nxalenye isebenza kakuhle kwizicelo eziphezulu zokushisa kwaye inokuthintela ngokufanelekileyo igesi kunye nokuvuza kwamanzi.

Xa isetyenziswe ngokubambisana nezixhobo ezifanaizikhephe ezisicabakunye nabathwali be-wafer, i-Semicera'sInxalenye yeSiC Ceramic Sealinokuphucula kakhulu ukusebenza kakuhle kunye nokuthembeka kwenkqubo iyonke. Ukumelana nobushushu obuphezulu kunye nokumelana nokubola kwenza kube yinto ebaluleke kakhulu kwimveliso ye-semiconductor echanekileyo, eqinisekisa uzinzo kunye nokhuseleko ngexesha lenkqubo yokuvelisa.

Ukongeza, uyilo lwale nxalenye yokutywina iphuculwe ngokucophelela ukuze kuqinisekiswe ukuhambelana nezixhobo ezahlukeneyo, okwenza kube lula ukuyisebenzisa kwimigca eyahlukeneyo yokuvelisa. Iqela le-R&D le-Semicera liyaqhubeka nokusebenza nzima ukukhuthaza ukutsha kwezobuchwepheshe ukuqinisekisa ukukhuphisana kweemveliso zayo kushishino.

Ukukhetha iSemicera'sInxalenye yeSiC Ceramic Seal, uya kufumana indibaniselwano yokusebenza okuphezulu kunye nokuthembeka, kukunceda ufezekise iinkqubo ezisebenzayo zokuvelisa kunye nomgangatho obalaseleyo wemveliso. I-Semicera isoloko izibophelele ekuboneleleni abathengi ngezona zisombululo ze-semiconductor kunye neenkonzo zokukhuthaza uphuhliso oluqhubekayo kunye nenkqubela phambili yoshishino.

✓Umgangatho ophezulu kwimarike yaseTshayina

✓Inkonzo entle rhoqo kuwe, 7*24 iiyure

✓Umhla omfutshane wokuhanjiswa

✓I-MOQ encinci yamkelekile kwaye yamkelwe

✓Iinkonzo ezilungiselelwe wena

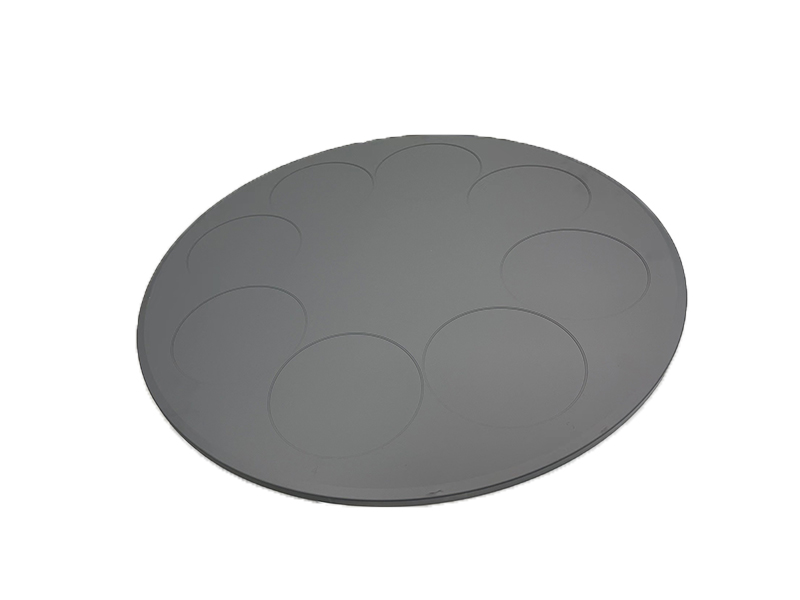

Epitaxy Growth Susceptor

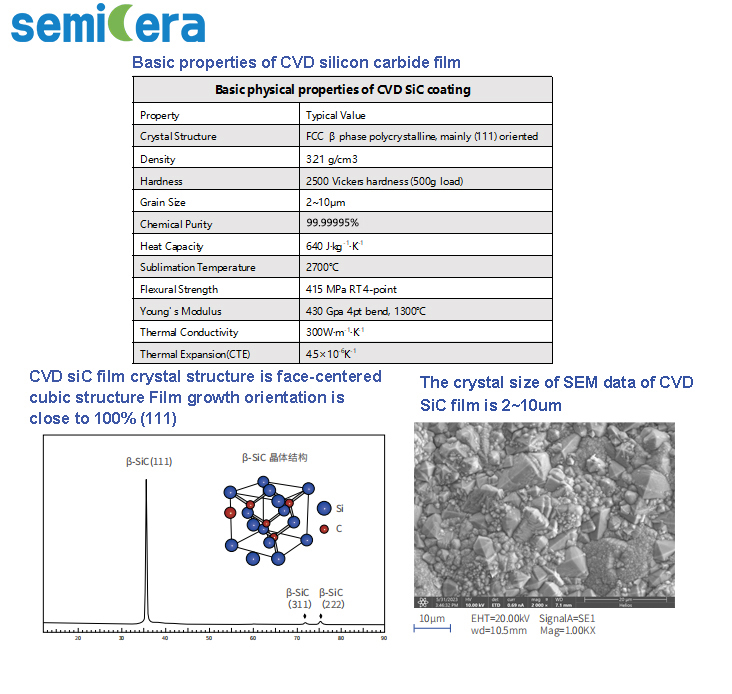

I-silicon / i-silicon carbide wafers kufuneka ihambe kwiinkqubo ezininzi eziza kusetyenziswa kwizixhobo zombane. Inkqubo ebalulekileyo yi-silicon / i-sic epitaxy, apho i-silicon / i-sic wafers iqhutyelwa kwisiseko segraphite. Izibonelelo ezikhethekileyo zeSemicera's silicon carbide-coated-coated graphite base ibandakanya ukucoceka okuphezulu kakhulu, ukutyabeka okufanayo, kunye nobomi benkonzo ende kakhulu. Kananjalo banokumelana neekhemikhali eziphezulu kunye nokuzinza kwe-thermal.

Ukuveliswa kweChip ye-LED

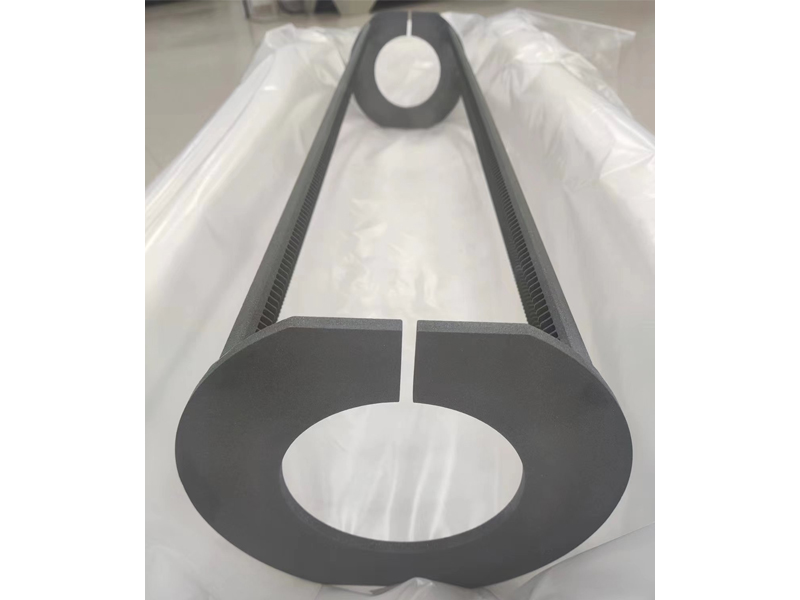

Ngethuba lokugquma okubanzi kwe-reactor ye-MOCVD, isiseko seplanethi okanye umthwali uhambisa i-wafer substrate. Ukusebenza kwezinto ezisisiseko kunempembelelo enkulu kumgangatho wokugquma, nto leyo echaphazela izinga le-scrap ye-chip. Isiseko seSemicera's silicon carbide-coated base sonyusa ukusebenza kakuhle kweewafers ze-LED ezikumgangatho ophezulu kunye nokunciphisa ukutenxa kobude bamaza. Sikwabonelela ngezixhobo ezongezelelweyo zegraphite kuzo zonke iireactor zeMOCVD ezisetyenziswayo ngoku. Sinako ukunxiba phantse naliphi na icandelo nge-silicon carbide coating, nokuba i-diameter yecandelo ifikelela kwi-1.5M, sisenokwambatha ngesilicon carbide.

Ummandla weSemiconductor, Inkqubo ye-Oxidation Diffusion, njl.

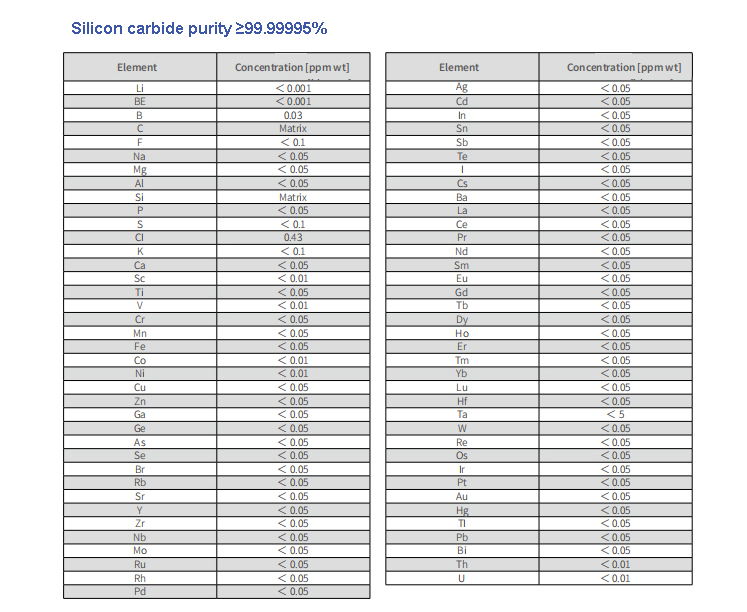

Kwinkqubo ye-semiconductor, inkqubo yokwandiswa kwe-oxidation ifuna ukucoceka okuphezulu kwemveliso, kwaye kwi-Semicera sinikezela ngeenkonzo zesiko kunye ne-CVD yokwambathisa uninzi lweengxenye ze-silicon carbide.

Lo mfanekiso ulandelayo ubonisa i-silicon carbide slurry esekwe ngokurhabaxa ye-Semicea kunye ne-silicon carbide furnace tyhubhu ecocwe kwi-100.0-kwinqanabaengenathuliigumbi. Abasebenzi bethu basebenza ngaphambi kokulala. Ukucoceka kwe-silicon carbide yethu kunokufikelela kwi-99.99%, kwaye ukucoceka kwe-sic coating kukhulu kune-99.99995%.

I-Silicon Carbide Paddle eluhlaza kunye ne-SiC Process Tube ekuCocini

ISilicon Carbide Wafer Boat CVD SiC Coated

-

Ubushushu obuphezulu bokumelana nesilicon carbide cera...

-

I-Corrosion kunye ne-silico exhathisa ubushushu obuphezulu...

-

ISilicon yeCarbide yokuNxina okuPhezulu kweCeramic Li...

-

I-silicon enganyangekiyo kwi-silicon carbide ceramic saggar

-

Amakhonkco okutywina e-SiC

-

Ukunxiba okuphezulu ukumelana ne-silicon carbide saggar