2. Inkqubo yoMfuniselo

2.1 Ukunyangwa kweFilimu encamathelayo

Kwaphawulwa ukuba ukwenza ngokuthe ngqo ifilimu yekhabhoni okanye ukudibanisa kunye nephepha legraphiteIifafa zeSiCiqatywe ngencangathi kukhokelele kwimiba emininzi:

1. Ngaphantsi kweemeko ze-vacuum, ifilimu yokubambelelaIifafa zeSiCyavelisa inkangeleko efana nesikali ngenxa yokukhutshwa komoya okubalulekileyo, okukhokelele kwi-porosity yomhlaba. Oku kuthintele i-adhesive layers ekubopheni ngokufanelekileyo emva kwe-carbonization.

2. Ngexesha lokudibanisa, iiqhekezana lesonkakufuneka ibekwe kwiphepha legraphite ngexesha elinye. Ukuba ukubekwa kwakhona kuyenzeka, uxinzelelo olungalinganiyo lunokunciphisa ukufana okuncamathelayo, kube nefuthe elibi kwikhwalithi yokudibanisa.

3. Kwimisebenzi ye-vacuum, ukukhululwa komoya kwi-adhesive layer kubangele ukuxubha kunye nokwakhiwa kwee-voids ezininzi ngaphakathi kwefilimu yokunamathela, okubangelwa iziphene zokubopha. Ukujongana nale miba, ukomisa kwangaphambili i-adhesive kwiyewaferumphezulu wokudibanisa usebenzisa ipleyiti eshushu emva kokuba i-spin-coating iyacetyiswa.

2.2 Inkqubo yeCarbonization

Inkqubo yokwenza ifilimu yekhabhoni kwiSiC seed imbewukunye nokuyibophelela kwiphepha legraphite kufuna i-carbonization ye-adhesive layer kwiqondo lokushisa elithile ukuqinisekisa ukudibanisa okuqinileyo. I-carbonization engaphelelanga ye-adhesive layer ingakhokelela ekuqhekekeni kwayo ngexesha lokukhula, ukukhulula ukungcola okuchaphazela umgangatho wokukhula kwe-crystal. Ke ngoko, ukuqinisekisa ukuba i-carbonization epheleleyo yomaleko wokuncamathelisa ibalulekile kwi-high-density bonding. Olu pho nonongo luhlola umphumo wokushisa kwi-adhesive carbonization. Umaleko ofanayo we-photoresist wasetyenziswa kwiiqhekezana lesonkaumphezulu kwaye ibekwe kwiziko ityhubhu phantsi kwe-vacuum (<10 Pa). Iqondo lokushisa liphakanyiswe kumanqanaba amiselweyo (400 ℃, 500 ℃, kunye ne-600 ℃) kwaye igcinwe kwiiyure ze-3-5 ukufezekisa i-carbonization.

Imilingo ibonisiwe:

Kwi-400 ℃, emva kweeyure ze-3, ifilimu yokunamathela ayizange i-carbonize kwaye ibonakala ibomvu ebomvu; akukho tshintsho lubalulekileyo luye lwabonwa emva kweeyure ze-4.

Kwi-500℃, emva kweeyure ze-3, ifilimu yajika yaba mnyama kodwa yasasaza ukukhanya; akukho tshintsho lubalulekileyo emva kweeyure ze-4.

Kwi-600 ℃, emva kweeyure ze-3, ifilimu yajika yaba mnyama ngaphandle kokuhanjiswa kokukhanya, ebonisa i-carbonization epheleleyo.

Ke ngoko, ubushushu obufanelekileyo bokudibanisa kufuneka bube ≥600℃.

2.3 Inkqubo ye-Adhesive Application

Ukufana kwefilimu yokubambelela kuyisalathisi esibalulekileyo sokuvavanya inkqubo yesicelo sokubambelela kunye nokuqinisekisa umgca wokudibanisa okufanayo. Eli candelo liphonononga esona santya siphezulu sokujikeleza kunye nexesha lokugquma kwiingqimba ezahlukeneyo zefilimu encamathelayo. Ukufana

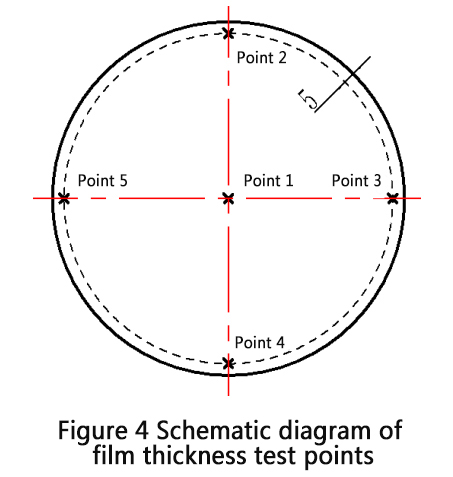

Ubukhulu befilimu buchazwa njengomlinganiselo wobuncinci befilimu ubukhulu be-Lmin ukuya kubukhulu befilimu ye-Lmax ngaphezu kwendawo eluncedo. Amanqaku amahlanu kwi-wafer akhethwe ukulinganisa ubukhulu befilimu, kwaye ukufana kubalwe. Umzobo 4 ubonisa iindawo zokulinganisa.

Kunxunguphalo olunoxinano oluphezulu phakathi kwewafer ye-SiC kunye nezixhobo zegraphite, ubukhulu befilimu encamathelayo ekhethwayo yi-1-5 µm. Ubukhulu befilimu obuyi-2 µm bukhethiwe, busebenza kuzo zombini ulungiselelo lwefilimu yekhabhoni kunye nenkqubo yokudibanisa iphepha le-wafer/graphite. Iiparamitha ezichanekileyo ze-spin-coating ze-adhesive carbonizing zi-15 s kwi-2500 r / min, kunye ne-adhesive bonding, i-15 s kwi-2000 r / min.

2.4 Inkqubo yoBonding

Ngexesha lokudityaniswa kwesiqwenga se-SiC kwiphepha legraphite / igraphite, kubalulekile ukuphelisa ngokupheleleyo umoya kunye neegesi eziphilayo eziveliswa ngexesha le-carbonization ukusuka kumaleko okudibanisa. Ukupheliswa kwerhasi engaphelelanga kubangela i-voids, ekhokelela kwi-non-dense bonding layer. Umoya kunye neegesi eziphilayo zinokukhutshwa kusetyenziswa impompo yeoli yomatshini. Ekuqaleni, ukusebenza okuqhubekayo kompompo womatshini kuqinisekisa ukuba igumbi lokucoca lifikelela kumda walo, livumela ukukhutshwa komoya okupheleleyo kwi-bonding layer. Ukunyuka kweqondo lokushisa ngokukhawuleza kunokuthintela ukupheliswa kwegesi ngexesha elifanelekileyo ngexesha le-carbonization ephezulu yobushushu, ukwenza i-voids kwi-bonding layer. Iimpawu zokuncamathelisa zibonisa ukuphuma okubalulekileyo kwi-≤120℃, kuzinza ngaphezu kobu bushushu.

Uxinzelelo lwangaphandle lusetyenziswa ngexesha lokudibanisa ukunyusa ubuninzi befilimu yokubambelela, ukuququzelela ukuxoshwa komoya kunye ne-organic gases, okubangelwa umgca we-bonding ephezulu.

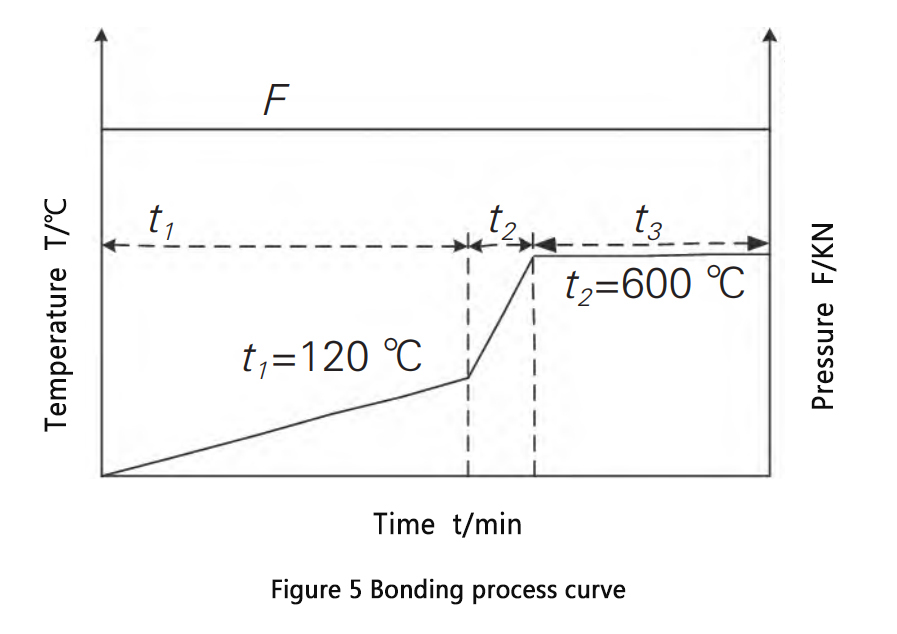

Isishwankathelo, i-curve yenkqubo yokudibanisa eboniswe kuMfanekiso 5 yaphuhliswa. Phantsi koxinzelelo oluthile, ubushushu bunyuselwa kubushushu obuphumayo (~120℃) kwaye bubanjwe de kugqitywe ukukhupha umoya. Emva koko, iqondo lokushisa linyuswa kwiqondo lokushisa le-carbonization, ligcinwe ixesha elifunekayo, lilandelwa ukupholisa kwendalo kwiqondo lokushisa, ukukhutshwa koxinzelelo, kunye nokususwa kwe-wafer edibeneyo.

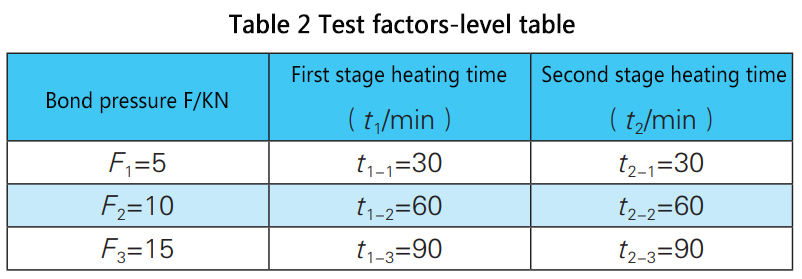

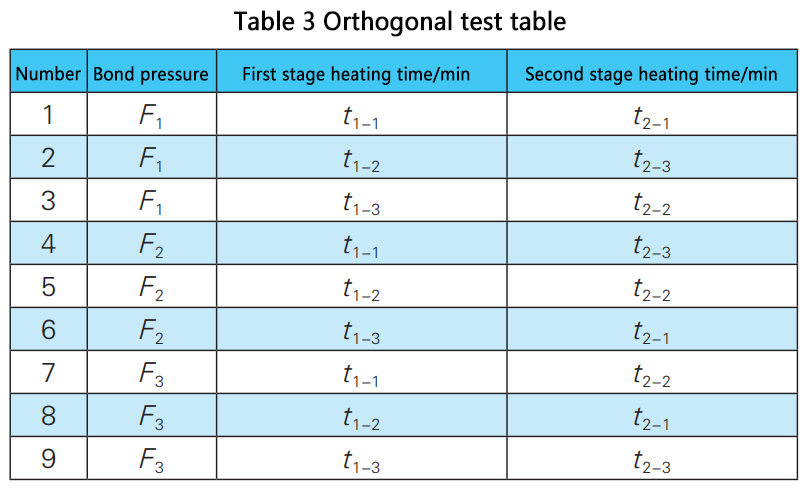

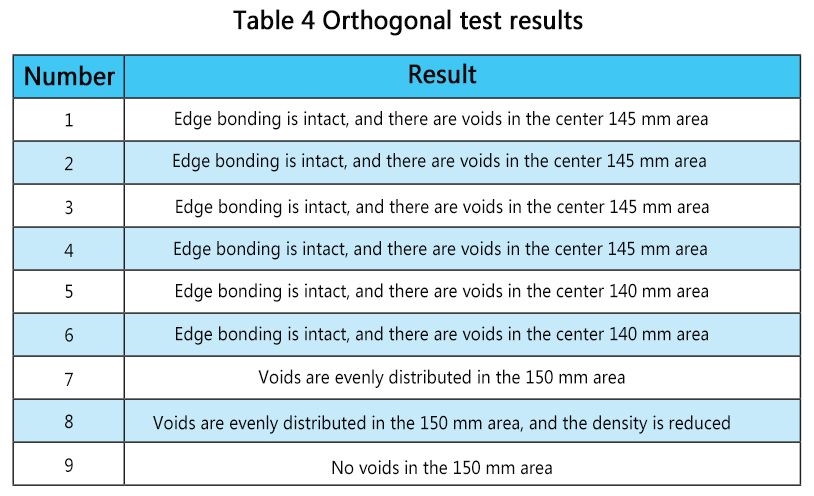

Ngokutsho kwecandelo 2.2, ifilimu enamathelayo kufuneka ifakwe i-carbonized kwi-600 ℃ ngaphezu kweeyure ze-3. Ngoko ke, kwinkqubo yokudibanisa ijika, i-T2 imiselwe kwi-600 ℃ kunye ne-t2 kwiiyure ze-3. Amanani awona maxabiso enkqubo yokudibanisa, egqitywe ngokusebenzisa iimvavanyo ze-orthogonal ezifunda imiphumo yoxinzelelo lwe-bonding, ixesha lokuqala lokufudumeza i-t1, kunye nexesha lesibini lokufudumeza i-t2 kwiziphumo zokudibanisa, ziboniswa kwiiThebhile 2-4.

Iziphumo zibonisiwe:

Kuxinzelelo lwe-bonding ye-5 kN, ixesha lokufudumala libe nefuthe elincinci kwi-bonding.

Kwi-10 kN, indawo engenanto kwi-bonding layer yehla ngokufudumeza okude kwenqanaba lokuqala.

Kwi-15 kN, ukwandisa ukufudumeza kwinqanaba lokuqala kunciphisa kakhulu i-voids, ekugqibeleni kupheliswe.

Ixesha lesibini lokufudumala ixesha lokufudumala kwi-bonding lalingabonakali kwiimvavanyo ze-orthogonal. Ukulungisa uxinzelelo lwe-bonding kwi-15 kN kunye nexesha lokuqala lokufudumeza kwi-90 min, amaxesha okufudumeza okwesibini kwi-30, i-60, kunye ne-90 min yonke ibangele i-void-free dense bonding layers, ebonisa ixesha lokufudumeza kwenqanaba lesibini. impembelelo encinci kwi-bonding.

Amanani afanelekileyo kwi-curve yenkqubo yokudibanisa: uxinzelelo lwe-bonding 15 kN, ixesha lokuqala lokufudumeza i-90 min, ubushushu benqanaba lokuqala 120 ℃, ixesha lesibini lokufudumeza i-30 min, iqondo lesibini le-600 ℃, kunye nexesha lesibini lokubamba. iiyure ezi-3.

Ixesha lokuposa: Jun-11-2024