Okwangoku, isizukulwana sesithathu se-semiconductors silawulwai-silicon carbide. Kwixabiso leendleko zezixhobo zayo, i-substrate i-akhawunti ye-47%, kunye ne-epitaxy i-akhawunti ye-23%. Ezi zimbini kunye akhawunti malunga 70%, eyona nxalenye ibalulekileyoi-silicon carbideisixhobo sokwenza izixhobo.

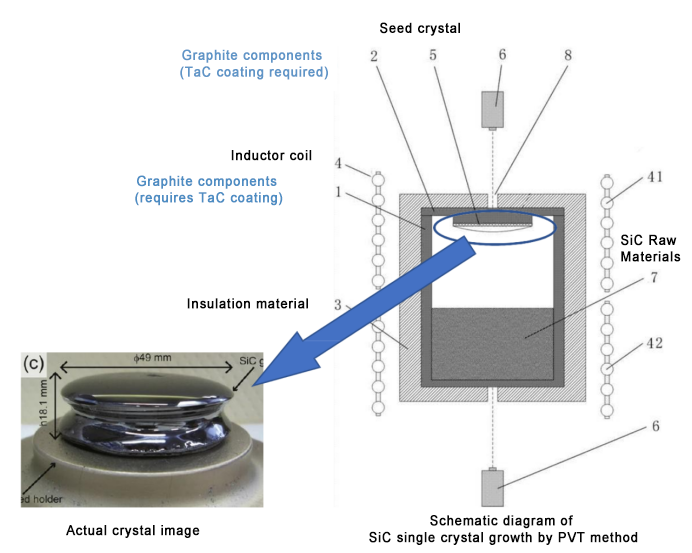

Indlela esetyenziswa ngokuqhelekileyo ukulungiselelai-silicon carbideIikristale enye yindlela ye-PVT (ukuthutha umphunga womzimba). Umgaqo kukwenza izinto eziluhlaza kwindawo yobushushu obuphezulu kunye nekristale yembewu kwindawo ephantsi kakhulu. Izinto eziluhlaza kwiqondo lokushisa eliphezulu zibola kwaye zivelise ngokuthe ngqo izinto zesigaba segesi ngaphandle kwesigaba solwelo. Ezi zinto zesigaba segesi zithuthelwa kwikristale yembewu phantsi komqhubi we-axial ubushushu begradient, kwaye i-nucleate kwaye ikhule kwikristale yembewu ukwenza i-silicon carbide crystal enye. Okwangoku, iinkampani zangaphandle ezifana neCree, II-VI, SiCrystal, Dow kunye neenkampani zasekhaya ezifana neTianyue Advanced, Tianke Heda, kunye neCentury Golden Core zonke zisebenzisa le ndlela.

Kukho iifom ze-crystal ezingaphezu kwe-200 ze-silicon carbide, kwaye ulawulo oluchanekileyo luyafuneka ukuvelisa ifom ye-crystal efunekayo (i-mainstream yi-4H ye-crystal form). Ngokutsho kweprospectus ye-Tianyue Advanced, imveliso ye-crystal yenkampani kwi-2018-2020 kunye ne-H1 2021 yayiyi-41%, 38.57%, 50.73% kunye ne-49.90% ngokulandelanayo, kunye nezivuno ze-substrate zazingama-72.61%, 5, 7% kunye ne-7%. ngokulandelelanayo. Isivuno esipheleleyo sithetha nje ngama-37.7% kuphela. Ukuthatha indlela ye-PVT eqhelekileyo njengomzekelo, isivuno esiphantsi sibangelwa ikakhulu kobu bunzima bulandelayo kulungiselelo lwe-SiC substrate:

1. Ubunzima bokulawula intsimi yokushisa: Iintsimbi ze-crystal ze-SiC kufuneka ziveliswe kubushushu obuphezulu be-2500 ℃, ngelixa iikristale ze-silicon zifuna kuphela i-1500 ℃, ngoko ke kufuneka iziko ezikhethekileyo ze-crystal enye, kwaye ubushushu bokukhula bufuna ukulawulwa ngokuchanekileyo ngexesha lemveliso. , ekunzima kakhulu ukuyilawula.

2. Isantya sokuvelisa esicothayo: Izinga lokukhula kwezinto ze-silicon zendabuko yi-300 mm ngeyure, kodwa i-silicon carbide i-crystals enye inokukhula kuphela i-400 microns ngeyure, ephantse ibe ngamaxesha angama-800 umahluko.

3. Iimfuno eziphezulu zeeparamitha ezilungileyo zemveliso, kunye nesivuno sebhokisi emnyama kunzima ukulawula ngexesha: Iiparamitha eziphambili ze-SiC wafers ziquka ubuninzi be-microtube, ubuninzi be-dislocation, resistivity, warpage, roughness surface, njl. Ngexesha lokukhula kwekristale Kuyimfuneko ukulawula ngokuchanekileyo iiparamitha ezinje ngesilicon-carbon ratio, ukukhula kweqondo lobushushu, izinga lokukhula kwekristale, kunye noxinzelelo lokuhamba komoya. Ngaphandle koko, ukufakwa kwe-polymorphic kunokwenzeka ukuba kwenzeke, kubangele iikristale ezingafanelekanga. Kwibhokisi elimnyama le-graphite crucible, akunakwenzeka ukujonga imeko yokukhula kwekristale ngexesha langempela, kunye nokulawulwa kwentsimi ye-thermal echanekileyo, ukuhambelana kwezinto kunye nokuqokelela amava kuyadingeka.

4. Ubunzima bokwandiswa kwekristale: Ngaphantsi kwendlela yokuthutha isigaba segesi, iteknoloji yokwandisa i-SiC crystal ukukhula inzima kakhulu. Njengoko ubungakanani bekristale bukhula, ubunzima bayo bokukhula bukhula ngokukhawuleza.

5. Ngokuqhelekileyo isivuno esiphantsi: Isivuno esiphantsi kakhulu siqulunqwe ngamakhonkco amabini: (1) i-Crystal rod isivuno = i-semiconductor-grade crystal rod output / (semiconductor-grade crystal rod output + non-semiconductor-grade crystal rod output) × 100%; (2) Imveliso yesubstrate = imveliso yesubstrate esemgangathweni/(imveliso yesubstrate esemgangathweni + imveliso yesubstrate engafanelekanga) × 100%.

Ekulungiseleleni umgangatho ophezulu kunye nesivuno esiphezului-silicon carbide substrates, ingundoqo idinga izinto ezingcono zentsimi ye-thermal ukulawula ngokuchanekileyo ubushushu bemveliso. Iikiti ze-thermal crucible kits ngoku ezisetyenziswayo ngoku ubukhulu becala ziyi-high-purity-high-purity graphite structural parts, ezisetyenziselwa ukufudumeza nokunyibilikisa umgubo wekhabhoni kunye nomgubo wesilicon kwaye uhlale ushushu. Izixhobo zegraphite zineempawu zamandla athile aphezulu kunye nemodyuli ethile, ukuxhathisa ukothuka kwe-thermal kunye nokuxhathisa ukubola, kodwa zineziphene zokuba i-oxidized ngokulula kwiindawo ezinobushushu obuphezulu be-oksijini, ingaxhathisi i-ammonia, kunye nokunganyangeki kakuhle komkrwelo. Kwinkqubo ye-silicon carbide ukukhula kwekristale enye kunyei-silicon carbide epitaxial waferimveliso, kunzima ukuhlangabezana neemfuno ezingqongqo zabantu zokusetyenziswa kwemathiriyeli yegraphite, ethintela ngokunzulu uphuhliso kunye nokusetyenziswa okusebenzayo. Ngoko ke, iingubo eziphakamileyo zokushisa ezifana ne-tantalum carbide sele ziqalile ukuvela.

2. Iimpawu zeTantalum Carbide Coating

I-taC ceramic inendawo yokunyibilika ukuya kuthi ga kwi-3880℃, ubunzima obuphezulu (Mohs hardness 9-10), i-thermal conductivity enkulu (22W · m-1 · K−1), amandla amakhulu okugoba (340-400MPa), kunye nokwandiswa kwe-thermal encinci. i-coefficient (6.6×10−6K−1), kwaye ibonisa uzinzo oluhle kakhulu lwe-thermochemical kunye neempawu ezibalaseleyo zomzimba. Inokuhambelana kakuhle kweekhemikhali kunye nokuhambelana nomatshini kunye negraphite kunye neC / C izinto ezidibeneyo. Ke ngoko, ukugquma kwe-TaC kusetyenziswa kakhulu kukhuseleko lobushushu kwi-aerospace, ukukhula kwekristale enye, i-elektroniki yamandla, kunye nezixhobo zonyango.

TaC-coatedigraphite inokumelana nokukhula kweekhemikhali ezingcono kunegraphite engenanto okanye igraphite ene-SiC-coated, ingasetyenziswa ngokuzinzileyo kumaqondo obushushu aphezulu angama-2600 °, kwaye ayisebenzi ngezinto ezininzi zetsimbi. Yeyona nto intle yokwaleka kwisizukulwana sesithathu semiconductor yokukhula kwekristale enye kunye neemeko zokuhombisa. Inokuphucula kakhulu ukulawulwa kweqondo lokushisa kunye nokungcola kwinkqubo kunye nokulungiselelaiiwafers ze-silicon carbide ezikumgangatho ophezulukwaye ezinxulumeneiipaxial wafers. Kufanelekile ngokukodwa ukukhulisa i-GaN okanye i-AlN i-crystals enye enezixhobo ze-MOCVD kunye nokukhulisa i-crystals ye-SiC enye enezixhobo ze-PVT, kwaye umgangatho weekristale ezikhulileyo ziphuculwe kakhulu.

III. Izinto ezilungileyo zeTantalum Carbide Coated Devices

Ukusetyenziswa kweTantalum Carbide TaC coating kunokusombulula ingxaki ye-crystal edge defects kunye nokuphucula umgangatho wokukhula kwekristale. Ngomnye wezalathiso ezingundoqo "zokukhula ngokukhawuleza, ukukhula ngokutyeba, kunye nokukhula ixesha elide". Uphando lwamashishini lukwabonise ukuba iTantalum Carbide Coated Graphite Crucible inokufikelela kubushushu obufanayo, ngaloo ndlela ibonelela ngolawulo olugqwesileyo lwenkqubo yeSiC yokukhula kwekristale enye, ngaloo ndlela inciphisa kakhulu amathuba okubunjwa kwepolycrystalline kumda weekristale zeSiC. Ukongeza, iTantalum Carbide Graphite Coating ineengenelo ezimbini eziphambili:

(I) Ukunciphisa iziphene zeSiC

Ngokumalunga nokulawula i-SiC enye i-crystal defects, ngokuqhelekileyo kukho iindlela ezintathu ezibalulekileyo. Ukongeza ekuphuculeni iiparitha zokukhula kunye nezixhobo eziphezulu zomthombo (ezifana ne-SiC source powder), usebenzisa i-Tantalum Carbide Coated Graphite Crucible inokuphinda ifikelele umgangatho omhle we-crystal.

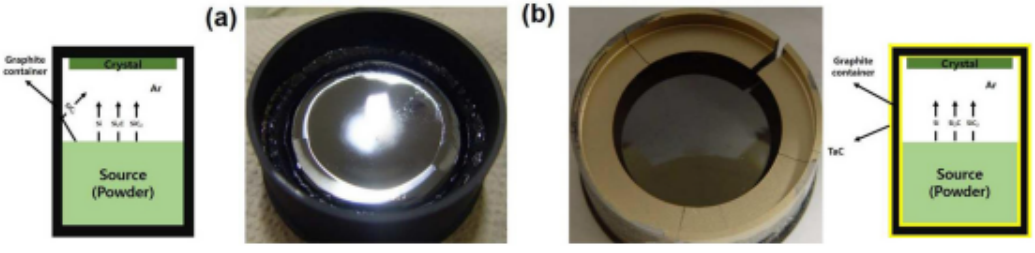

Umzobo we-Schematic crucible yegraphite (a) kunye ne-TAC coated crucible (b)

Ngokophando olwenziwa yiYunivesithi yaseMpuma Yurophu eKorea, ukungcola okuphambili ekukhuleni kwekristale ye-SiC yinitrogen, kwaye i-tantalum carbide coated graphite crucibles inokunciphisa ngokufanelekileyo ukufakwa kwenitrogen yeekristale ze-SiC, ngaloo ndlela kuncitshiswe ukuveliswa kweziphene ezinje ngemicropipes kunye nokuphucula ikristale. umgangatho. Uphononongo lubonise ukuba phantsi kweemeko ezifanayo, i-carrier concentrations ye-SiC wafers ekhulile kwi-graphite crucibles kunye ne-TAC coated crucibles malunga ne-4.5 × 1017 / cm kunye ne-7.6 × 1015 / cm, ngokulandelanayo.

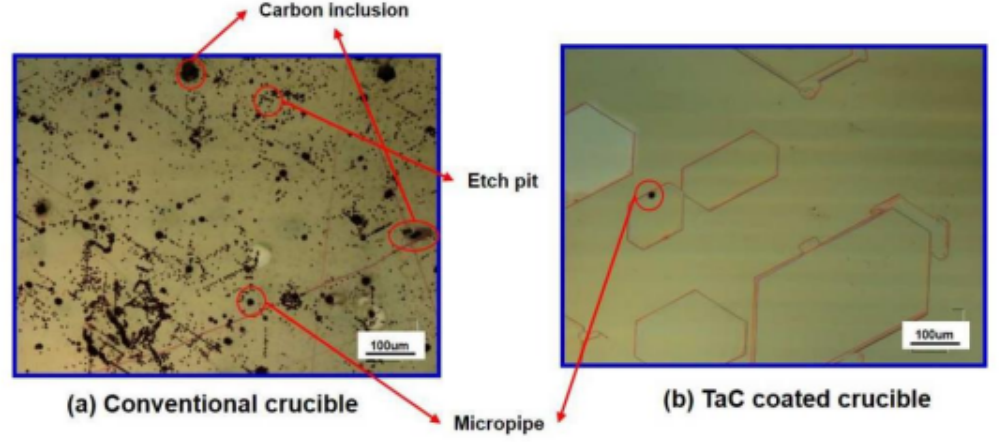

Ukuthelekiswa kweziphene kwi-SiC enye iikristale ezikhule kwii-graphite crucibles eziqhelekileyo (a) kunye ne-TAC coated crucibles (b)

(II) Ukuphucula ubomi be-graphite crucibles

Okwangoku, iindleko ze-crystals ze-SiC ziye zahlala ziphakamileyo, apho iindleko ze-graphite consumables akhawunti malunga ne-30%. Isitshixo ekunciphiseni iindleko zegraphite consumables kukwandisa ubomi bayo benkonzo. Ngokutsho kwedatha evela kwiqela lophando laseBrithani, i-tantalum carbide coatings inokwandisa ubomi benkonzo yamacandelo egraphite nge-30-50%. Ngokwalolu balo, ukutshintsha kuphela i-tantalum carbide coated graphite kunokunciphisa iindleko ze-crystals ze-SiC nge-9% -15%.

4. Inkqubo yokulungiselela ukutyabeka kweTantalum carbide

Iindlela zokulungiselela ukugquma kwe-TaC zinokwahlulwa zibe ngamacandelo amathathu: indlela yesigaba esiqinileyo, indlela yesigaba solwelo kunye nendlela yesigaba segesi. Indlela yesigaba esiqinileyo ibandakanya indlela yokunciphisa kunye nendlela yekhemikhali; indlela yesigaba solwelo ibandakanya indlela yetyuwa etyhidiweyo, indlela ye-sol-gel (i-Sol-Gel), indlela ye-slurry-sintering, indlela yokutshiza i-plasma; indlela yesigaba segesi ibandakanya ukubekwa komphunga kwiikhemikhali (CVD), ukungena kwikhemikhali yomphunga (CVI) kunye nokubekwa komphunga womzimba (PVD). Iindlela ezahlukeneyo zineengenelo kunye nezingeloncedo zazo. Phakathi kwazo, i-CVD yindlela esele ikhulile kwaye isetyenziswa ngokubanzi ekulungiseni i-TaC yokwambathisa. Ngophuculo oluqhubekayo lwenkqubo, iinkqubo ezintsha ezifana nokubeka umphunga wekhemikhali ngocingo olushushu kunye ne-ion beam encediswa yikhemikhali yokubeka umphunga ziye zaphuhliswa.

I-TaC yokwambathisa i-carbon-based modified materials iquka ikakhulu igraphite, carbon fiber, kunye necarbon/carbon composite materials. Iindlela zokulungiselela i-TaC yokwambathisa kwigraphite ziquka ukutshiza ngeplasma, i-CVD, i-slurry sintering, njl.

Izinto ezilungileyo zendlela ye-CVD: Indlela ye-CVD yokulungisa i-TaC yokwambathisa isekelwe kwi-tantalum halide (TaX5) njengomthombo we-tantalum kunye ne-hydrocarbon (CnHm) njengomthombo wekhabhoni. Phantsi kweemeko ezithile, ziboliswa zibe ngu-Ta no-C ngokulandelelanayo, kwaye emva koko sabelane ngokunye ukuze kufumaneke iileyiti ze-TaC. Indlela ye-CVD inokuqhutyelwa kwiqondo lokushisa eliphantsi, elinokuthi ligweme iziphene kunye nokunciphisa iimpawu zomatshini ezibangelwa ukulungiswa kobushushu obuphezulu okanye unyango lweengubo ukuya kwinqanaba elithile. Ukubunjwa kunye nokwakheka kwengubo kuyalawuleka, kwaye ineenzuzo zokucoceka okuphezulu, ukuxinana okuphezulu, kunye nobukhulu obufanayo. Okona kubalulekileyo, ukwakheka kunye nokwakheka kweengubo ze-TaC ezilungiselelwe yi-CVD zinokuyilwa kwaye zilawuleke ngokulula. Yindlela esele ikhulile ngokwentelekiso kwaye isetyenziswa ngokubanzi ekulungiseni i-TaC ekumgangatho ophezulu.

Imiba ephambili enempembelelo yale nkqubo ibandakanya:

A. Izinga lokuhamba kwegesi (umthombo we-tantalum, igesi ye-hydrocarbon njengomthombo wekhabhoni, igesi ethwala, igesi ye-dilution Ar2, ukunciphisa igesi ye-H2): Utshintsho kwisantya sokuhamba kwegesi kunempembelelo enkulu kwintsimi yobushushu, intsimi yoxinzelelo, kunye nentsimi yokuhamba kwegesi Igumbi lokuphendula, elikhokelela kutshintsho ekubunjweni, kwisakhiwo, kunye nokusebenza kwengubo. Ukonyusa izinga lokuhamba kwe-Ar kuya kuthoba isantya sokukhula kwengubo kunye nokunciphisa ubungakanani beenkozo, ngelixa i-molar mass ratio ye-TaCl5, i-H2, kunye ne-C3H6 ichaphazela ukubunjwa kokugquma. Umlinganiselo we-molar we-H2 ukuya kwi-TaCl5 ngu (15-20):1, ofaneleke ngakumbi. Umlinganiselo wemolar we-TaCl5 ukuya kwi-C3H6 ngokwethiyori usondele kwi-3:1. Ukugqithisa kwe-TaCl5 okanye i-C3H6 kuya kubangela ukubunjwa kwe-Ta2C okanye i-carbon yamahhala, echaphazela umgangatho we-wafer.

B. Ubushushu bendawo: Okukhona ubushushu bokubekwa buphezulu, kokukhona ukukhawuleza kwesantya sokubekelwa, kokukhona bukhulu ubungakanani beenkozo, kwaye kokukhona inyameko irhabaxa. Ukongeza, iqondo lobushushu kunye nesantya sokubola kwe-hydrocarbon ibe yi-C kunye ne-TaCl5 yokubola ibe ngu-Ta zahlukile, kwaye u-Ta no-C kunokwenzeka ukuba benze i-Ta2C. Ubushushu bunempembelelo enkulu ekugqumeni kweTaC imathiriyeli yekhabhoni elungisiweyo. Njengoko ukushisa kwe-deposition kwandisa, izinga lokubeka liyanda, ubukhulu be-particle buyanda, kwaye i-particle shape ishintsha ukusuka kwi-spherical ukuya kwi-polyhedral. Ukongeza, okukhona iqondo lobushushu liphezulu, kokukhona ukubola kwe-TaCl5 kukhawuleza, kokukhona i-C encinci isimahla, kokukhona uxinzelelo olukhulu kwi-coating, kunye nokuqhekeka kuya kuveliswa ngokulula. Nangona kunjalo, ubushushu obuphantsi bokubekwa buya kukhokelela ekusebenzeni kakuhle kokubekwa kwe-coating, ixesha elide lokubeka, kunye neendleko eziphezulu zezinto ezikrwada.

C. Uxinzelelo lwe-Deposition: Uxinzelelo lwe-deposition luhambelana ngokusondeleyo namandla akhululekile omhlaba wezinto eziphathekayo kwaye luya kuchaphazela ixesha lokuhlala kwegesi kwigumbi lokuphendula, ngaloo ndlela lichaphazela isantya se-nucleation kunye nobukhulu be-particle ye-coating. Njengoko uxinzelelo lwe-deposition lukhula, ixesha lokuhlala kwegesi liba lide, i-reactants inexesha elingakumbi lokufumana i-nucleation reactions, izinga lokuphendula liyenyuka, amaqhekeza abe mkhulu, kwaye i-coating iba nkulu; ngokuchaseneyo, njengoko uxinzelelo lwe-deposit luyancipha, ixesha lokuhlala legesi yokusabela lifutshane, izinga lokusabela liyancipha, amasuntswana abe mancinci, kwaye isambatho sincinci, kodwa uxinzelelo lwe-deposition lunempembelelo encinane kwisakhiwo sekristale kunye nokwakhiwa kwengubo.

V. Umkhwa woPhuhliso lwe-tantalum carbide coating

Ukwandiswa kwe-thermal coefficient ye-TaC (6.6×10−6K−1) yahluke ngandlel' ithile kuleyo yemathiriyeli esekwe kwikhabhoni efana negraphite, carbon fiber, kunye ne-C/C composite imathiriyeli, nto leyo eyenza inqanaba elinye i-TaC yokwambathisa ithande ukuqhekeka kwaye ukuwa. Ukuze kuphuculwe ngakumbi ukunyanzeliswa kwe-ablation kunye ne-oxidation, ukuzinza komatshini wobushushu obuphezulu, kunye nobushushu obuphezulu bekhemikhali yokumelana nokubola kwe-TaC, abaphandi baye baqhuba uphando kwiinkqubo zokugquma ezifana neenkqubo zokugquma, iinkqubo zokugquma eziqinileyo, kunye negradient. iinkqubo zokugquma.

Inkqubo yokwaleka edibeneyo kukuvala iintanda zengubo enye. Ngesiqhelo, ezinye izinto zokugquma zingeniswa kumphezulu okanye umaleko wangaphakathi we-TaC ukwenza inkqubo yokwaleka edityanisiweyo; Isisombululo esiluqilima esomeleza inkqubo yokugquma i-HfC, i-ZrC, njl. I-Hf (Ta) C yokugquma ayinakuqhekeka kwaye inokubambelela kakuhle kwizinto ezidibeneyo zeC / C. I-coating inomsebenzi obalaseleyo wokuchasana nokukhupha; Inkqubo yokwaleka ngokuthambeka kwenkqubo yokwaleka ibhekiselele kuxinaniso lwecandelo lokutyabeka ecaleni kobunzima bayo. Isakhiwo sinokunciphisa uxinzelelo lwangaphakathi, ukuphucula ukungahambi kakuhle kwe-coefficients yokwandisa i-thermal, kwaye ugweme ukuqhekeka.

(II) Iimveliso zesixhobo sokugquma iTantalum carbide

Ngokwezibalo kunye noqikelelo lwe-QYR (Hengzhou Bozhi), intengiso ye-tantalum carbide coating ye-world in 2021 yafikelela kwi-US$1.5986 yezigidi (ngaphandle kwemveliso ye-tantalum carbide yokwambathisa), kwaye isesekuqaleni. izigaba zophuhliso loshishino.

1. Iiringi zokwandiswa kwekristale kunye neecrucibles ezifunekayo ekukhuleni kwekristale: Ngokusekwe kwiziko lokukhula kwekristale ezingama-200 kwishishini ngalinye, isabelo sentengiso yezixhobo ezigqunywe nge-TaC ezifunwa ziinkampani ezingama-30 zokukhula kwekristale malunga ne-4.7 yeebhiliyoni zeeyuan.

2. Iitreyi ze-TaC: Itreyi nganye inokuthwala iiwafer ezi-3, itreyi nganye ingasetyenziswa inyanga enye, kwaye itreyi enye iyatyiwa kwiiwafer ezili-100. Ii-wafers ezizigidi ezi-3 zifuna iitreyi ze-TaC ezingama-30,000, itreyi nganye imalunga namaqhekeza angama-20,000, kwaye malunga nezigidi ezingama-600 ziyafuneka ngonyaka ngamnye.

3. Ezinye iimeko zokunciphisa ikhabhoni. Ezifana ne-high-temperature lining ye-furnace, i-nozzle ye-CVD, imibhobho yesithando somlilo, njl., malunga ne-100 yezigidi.

Ixesha lokuposa: Jul-02-2024