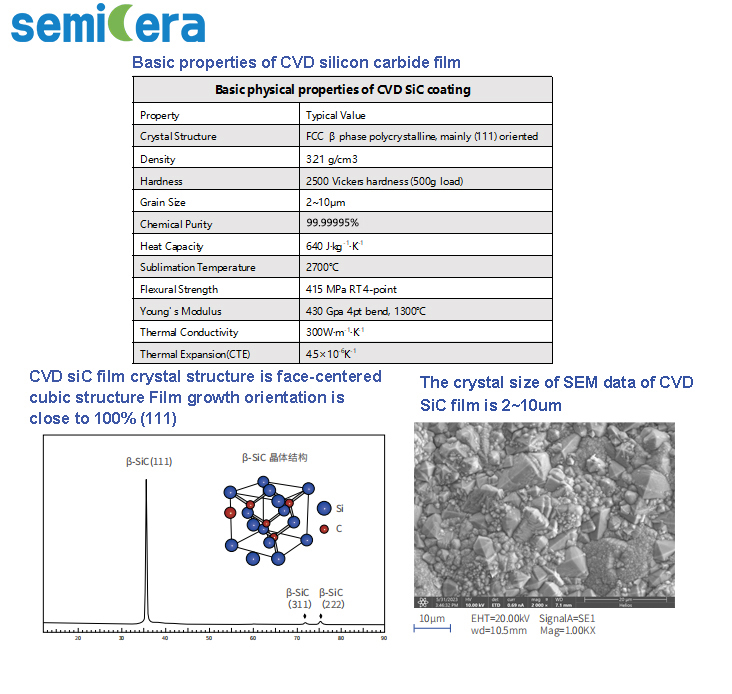

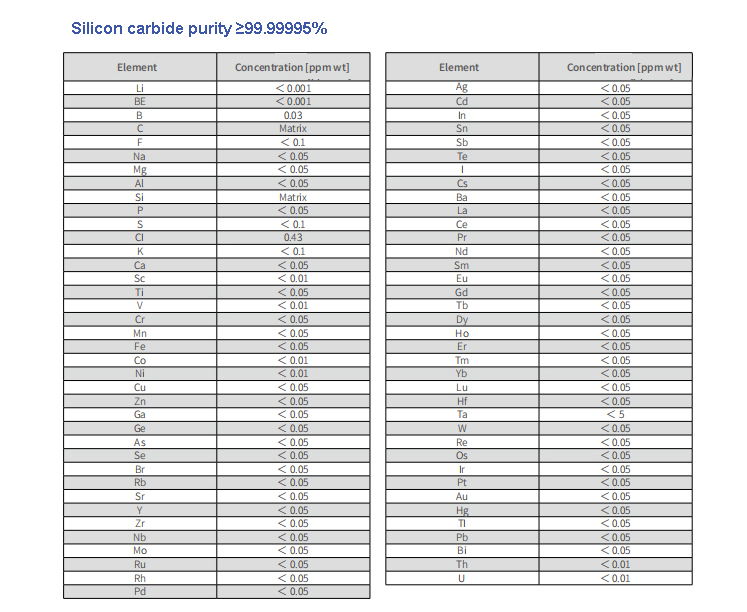

IRingi ze-CVD Silicon Carbide(SiC) ezibonelelwa yiSemicera ngamacandelo aphambili kwi-semiconductor etching, inqanaba elibalulekileyo ekwenzeni isixhobo se-semiconductor. Ukuqulunqwa kwezi CVD Silicon Carbide (SiC) Izangqa ziqinisekisa isakhiwo esinqabileyo kunye nesigxina esinokumelana neemeko ezinzima zenkqubo yokubhala. Ukufakwa komphunga weChemical kunceda ukwenza ubunyulu obuphezulu, obufanayo kunye noxineneyo lwe-SiC, inika amakhonkco amandla agqwesileyo omatshini, ukuzinza kwe-thermal kunye nokumelana nomhlwa.

Njengento ephambili kwimveliso ye-semiconductor, i-CVD Silicon Carbide (SiC) Izindandatho zisebenza njengesithintelo sokukhusela ukukhusela ingqibelelo yee-chips ze-semiconductor. Uyilo lwayo oluchanekileyo luqinisekisa ukubethelwa okufanayo kunye nokulawulwayo, okunceda ekwenziweni kwezixhobo ze-semiconductor ezinzima kakhulu, ukubonelela ukusebenza okuphuculweyo kunye nokuthembeka.

Ukusetyenziswa kwezinto ze-CVD SiC ekwakhiweni kwamakhonkco kubonisa ukuzibophezela kumgangatho kunye nokusebenza kwimveliso ye-semiconductor. Esi sixhobo sineempawu ezizodwa, kubandakanywa ukuguquguquka okuphezulu kwe-thermal, ukungahambi kakuhle kweekhemikhali, kunye nokuguga kunye nokuxhathisa ukubola, okwenza i-CVD Silicon Carbide (SiC) Iringi ibe yinto eyimfuneko ekufuneni ukuchaneka kunye nokusebenza kakuhle kwiinkqubo ze-semiconductor etching.

I-Semicera's CVD Silicon Carbide (SiC) Iringi imele isisombululo esiphezulu kwinkalo yokwenziwa kwe-semiconductor, kusetyenziswa iimpawu ezizodwa zomphunga wekhemikhali ofakwe kwi-silicon carbide ukuze kuphunyezwe iinkqubo ezithembekileyo neziphezulu zokuhombisa, ukukhuthaza ukuqhubela phambili kobugcisa be-semiconductor. Sizibophelele ekuboneleleni abathengi ngeemveliso ezigqwesileyo kunye nenkxaso yobuchwephesha bobuchwephesha ukuhlangabezana neemfuno zeshishini le-semiconductor kwizisombululo ezikumgangatho ophezulu nezisebenzayo.

✓Umgangatho ophezulu kwimarike yaseTshayina

✓Inkonzo entle rhoqo kuwe, 7*24 iiyure

✓Umhla omfutshane wokuhanjiswa

✓I-MOQ encinci yamkelekile kwaye yamkelwe

✓Iinkonzo ezilungiselelwe wena

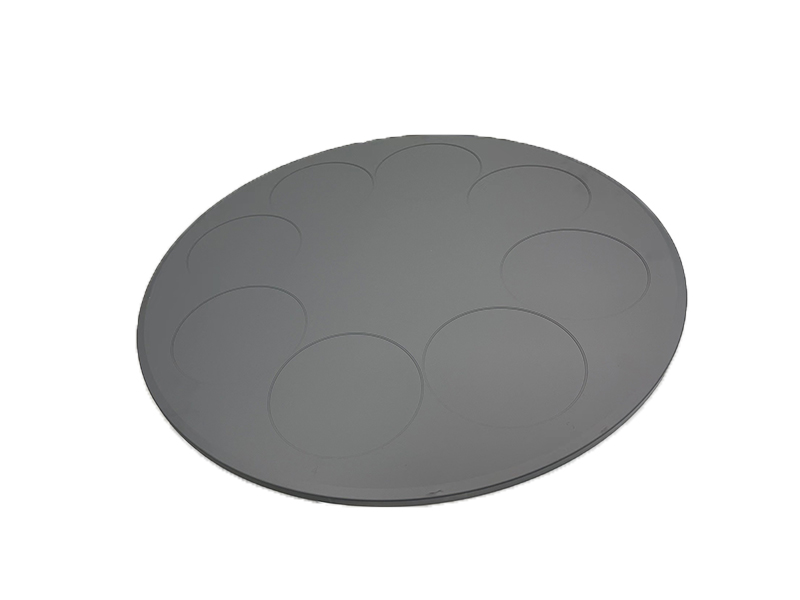

Epitaxy Growth Susceptor

I-silicon / i-silicon carbide wafers kufuneka ihambe kwiinkqubo ezininzi eziza kusetyenziswa kwizixhobo zombane. Inkqubo ebalulekileyo yi-silicon / i-sic epitaxy, apho i-silicon / i-sic wafers iqhutyelwa kwisiseko segraphite. Izibonelelo ezikhethekileyo zeSemicera's silicon carbide-coated-coated graphite base ibandakanya ukucoceka okuphezulu kakhulu, ukutyabeka okufanayo, kunye nobomi benkonzo ende kakhulu. Kananjalo banokumelana neekhemikhali eziphezulu kunye nokuzinza kwe-thermal.

Ukuveliswa kweChip ye-LED

Ngethuba lokugquma okubanzi kwe-reactor ye-MOCVD, isiseko seplanethi okanye umthwali uhambisa i-wafer substrate. Ukusebenza kwezinto ezisisiseko kunempembelelo enkulu kumgangatho wokugquma, nto leyo echaphazela izinga le-scrap ye-chip. Isiseko seSemicera's silicon carbide-coated base sonyusa ukusebenza kakuhle kweewafers ze-LED ezikumgangatho ophezulu kunye nokunciphisa ukutenxa kobude bamaza. Sikwabonelela ngezixhobo ezongezelelweyo zegraphite kuzo zonke iireactor zeMOCVD ezisetyenziswayo ngoku. Sinako ukunxiba phantse naliphi na icandelo nge-silicon carbide coating, nokuba i-diameter yecandelo ifikelela kwi-1.5M, sisenokwambatha ngesilicon carbide.

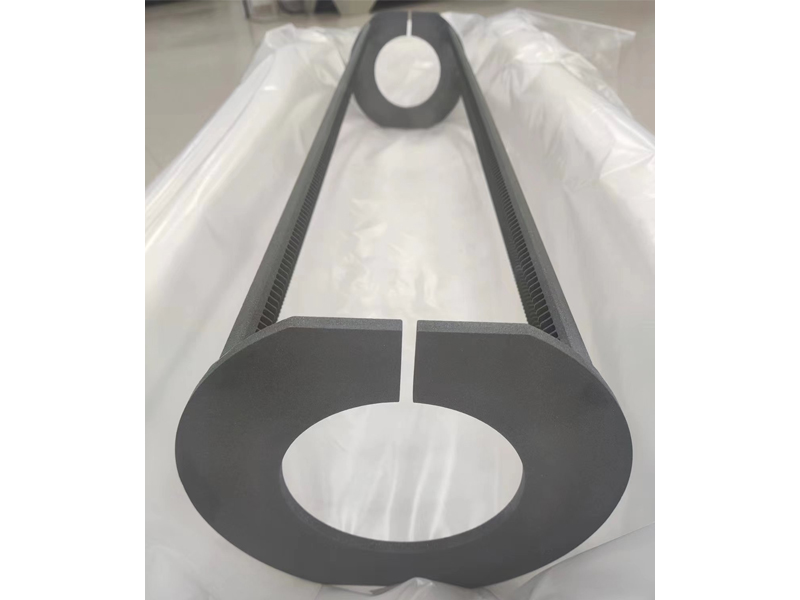

Ummandla weSemiconductor, Inkqubo ye-Oxidation Diffusion, njl.

Kwinkqubo ye-semiconductor, inkqubo yokwandiswa kwe-oxidation ifuna ukucoceka okuphezulu kwemveliso, kwaye kwi-Semicera sinikezela ngeenkonzo zesiko kunye ne-CVD yokwambathisa uninzi lweengxenye ze-silicon carbide.

Lo mfanekiso ulandelayo ubonisa i-silicon carbide slurry esekwe ngokurhabaxa ye-Semicea kunye ne-silicon carbide furnace tyhubhu ecocwe kwi-100.0-kwinqanabaengenathuliigumbi. Abasebenzi bethu basebenza ngaphambi kokulala. Ukucoceka kwe-silicon carbide yethu kunokufikelela kwi-99.99%, kwaye ukucoceka kwe-sic coating kukhulu kune-99.99995%.

I-Silicon Carbide Paddle eluhlaza kunye ne-SiC Process Tube ekuCocini

ISilicon Carbide Wafer Boat CVD SiC Coated