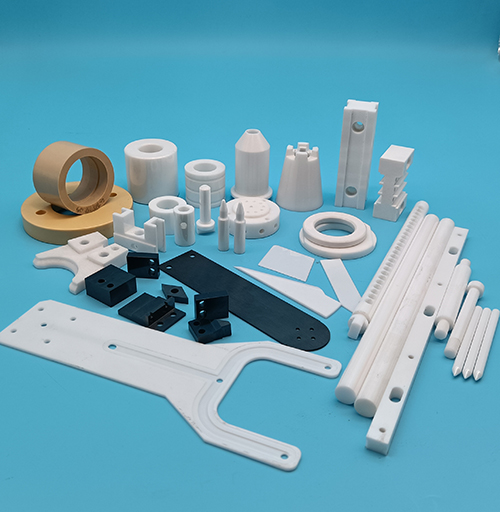

I-Zirconia yimpahla enegunya eliphezulu lomatshini kunye nokuqina kwe-fracture kwiqondo lokushisa. I-zirconia yethu (i-ZrO2) yongezwa kunye ne-3mol% Y2O3 i-zirconia esisigxina (i-PSZ). Ngenxa yokuba i-particle diameter ye-PSZ incinci, inokucutshungulwa ngokuchaneka okuphezulu, kwaye ukusetyenziswa kwayo kwiindawo ezichanekileyo ze-machining ezifana nokubumba kuyanda. Ukongeza, ingasetyenziselwa izixhobo zoshishino, iinxalenye ze-optical connector kunye nesixhobo sokutyumza esiphakathi. Ukuqina okuphezulu kwe-PSZ kungasetyenziselwa ukwenza imithombo ekhethekileyo, kwaye isetyenziswa ngokubanzi kwiimela ze-ceramic zasekhaya, i-slicer kunye nezinye iindawo.

Iimpahla zeMathiriyeli

| Into | 95% iAlumina | 99% iAlumina | Zirconia | I-silicon carbide | IsiliconNhamba | AluminiyamNhamba | I-ceramic ephathwayo |

| Umbala | mhlophe | Mthubi okhanyayo | mhlophe | mnyama | mnyama | ngwevu | mhlophe |

| Ubuninzi (g/cm3) | 3.7g/cm3 | 3.9g/cm3 | 6.02g/cm3 | 3.2g/cm3 | 3.25g/cm3 | 3.2g/cm3 | 2.48g/cm3 |

| Ukufunxwa kwamanzi | 0% | 0% | 0% | 0% | 0% | 0% | 0% |

| Ukuqina(HV) | 23.7 | 23.7 | 16.5 | 33 | 20 | - | - |

| Amandla eFlexural(MPa) | 300MPa | 400MPa | 1100MPa | 450MPa | 800MPa | 310MPa | 91MPa |

| Amandla acinezelayo(MPa) | 2500MPa | 2800MPa | 3600MPa | 2000MPa | 2600MPa | - | 340MPa |

| Imodyuli eNcinci ye-Elasticity | 300GPa | 300GPa | 320GPa | 450GPa | 290GPa | 310 ~ 350GPa | 65GPa |

| Umlinganiselo wePoisson | 0.23 | 0.23 | 0.25 | 0.14 | 0.24 | 0.24 | 0.29 |

| I-Thermal Conductivity | 20W/m°C | 32W/m°C | 3W/m°C | 50W/m°C | 25W/m°C | 150W/m°C | 1.46W/m°C |

| Amandla eDielectric | 14KV/mm | 14KV/mm | 14KV/mm | 14KV/mm | 14KV/mm | 14KV/mm | 14KV/mm |

| Ukuxhathisa uMqulu (25℃) | >1014Ω·cm | >1014Ω·cm | >1014Ω·cm | >105Ω·cm | >1014Ω·cm | >1014Ω·cm | >1014Ω·cm |

I-Zirconia (ZrO2) Ndiyisebenzisa kakhulu

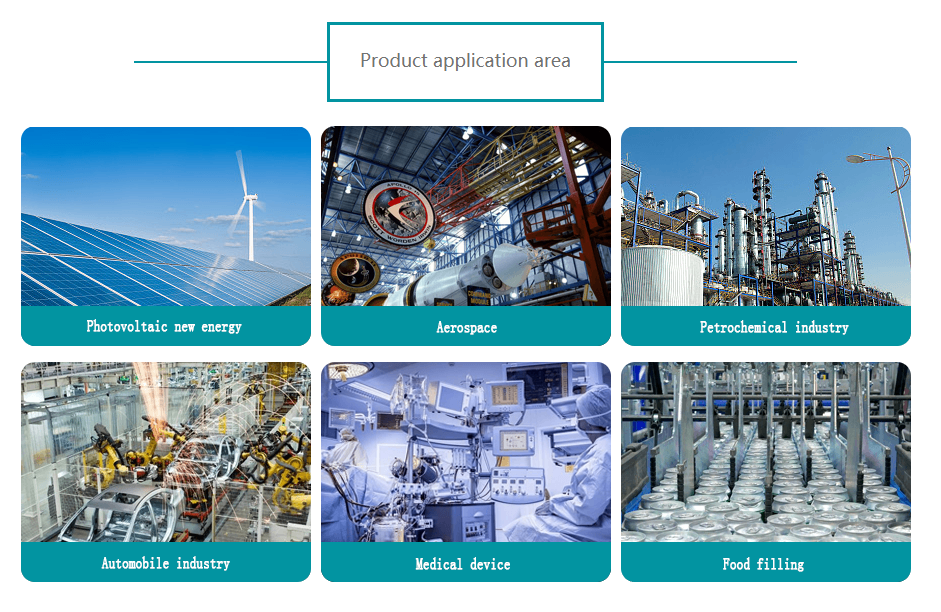

Izixhobo zokubumba kunye ne-mold (iintlobo ezahlukeneyo zokubumba, ukulungiswa kokumisa ngokuchanekileyo, ukulungiswa kwe-insulation); Amalungu okusila (umdidiyeli, ilitye lokusila lokuhamba komoya, ilitye lokusila); Isixhobo semizi-mveliso (i-industrial cutter, i-slitter machine, i-flat press roll); Amacandelo okudibanisa okubonakalayo (umsesane wokutywina, umkhono, i-V-groove fixture); Intwasahlobo ekhethekileyo (i-coil spring, i-plate spring); Iimveliso zabathengi (i-screwdriver encinci ye-insulated, imela ye-ceramic, i-slicer).