Ukwenziwa kweMEMS-Ukudibanisa: Ukusetyenziswa kunye nokuSebenza kuShishino lweSemiconductor, iSemicera Customized Service

Kwi-microelectronics kunye ne-semiconductor industries, i-MEMS (i-micro-electromechanical systems) iteknoloji iye yaba enye yezobuchwepheshe obuphambili obuqhuba izinto ezintsha kunye nezixhobo zokusebenza eziphezulu. Ngokuhambela phambili kwenzululwazi kunye nobuchwepheshe, itekhnoloji ye-MEMS isetyenziswe ngokubanzi kwizinzwa, ii-activators, izixhobo zokukhanya, izixhobo zonyango, i-elektroniki yemoto kunye nezinye iindawo, kwaye ngokuthe ngcembe iye yaba yinxalenye ebalulekileyo yetekhnoloji yale mihla. Kule mimandla, inkqubo yokubambisana (i-Bonding), njengenyathelo eliphambili kwi-MEMS processing, idlala indima ebalulekileyo ekusebenzeni kunye nokuthembeka kwesixhobo.

I-Bonding yitekhnoloji edibanisa ngokuqinileyo izinto ezimbini okanye ngaphezulu ngeendlela zomzimba okanye zekhemikhali. Ngokuqhelekileyo, iileya zezinto ezahlukeneyo kufuneka zidityaniswe ngokudibanisa kwizixhobo ze-MEMS ukufezekisa imfezeko yesakhiwo kunye nokuqonda ukusebenza. Kwinkqubo yokuvelisa izixhobo ze-MEMS, ukudibanisa akukona nje inkqubo yokudibanisa, kodwa kuchaphazela ngokuthe ngqo ukuzinza kwe-thermal, amandla omatshini, ukusebenza kombane kunye nezinye iinkalo zesixhobo.

Kwi-high-precision MEMS processing, iteknoloji yokudibanisa kufuneka iqinisekise ukudibanisa okusondeleyo phakathi kwezixhobo ngelixa uphepha naziphi na iziphene ezichaphazela ukusebenza kwesixhobo. Ke ngoko, ulawulo oluchanekileyo lwenkqubo yokudibanisa kunye nezinto ezikumgangatho ophezulu zokudibanisa zizinto eziphambili zokuqinisekisa ukuba imveliso yokugqibela idibana nemigangatho yoshishino.

Izicelo zokudibanisa i-MEMS kwishishini le-semiconductor

Kwishishini le-semiconductor, itekhnoloji ye-MEMS isetyenziswa kakhulu ekuveliseni izixhobo ezincinci ezifana ne-sensor, i-accelerometers, i-pressure sensors, kunye ne-gyroscopes. Ngokunyuka kwemfuno yeemveliso ezincinci, ezihlanganisiweyo kunye nezikrelekrele, ukuchaneka kunye neemfuno zokusebenza kwezixhobo ze-MEMS nazo ziyanda. Kwezi zicelo, itekhnoloji yokudibanisa isetyenziselwa ukudibanisa izinto ezahlukeneyo ezifana ne-silicon wafers, iglasi, isinyithi, kunye neepolymers ukufezekisa imisebenzi esebenzayo kunye nezinzile.

1. Iinzwa zoxinzelelo kunye ne-accelerometers

Kwimimandla yeemoto, i-aerospace, i-electronics yabathengi, njl., i-MEMS i-sensor ye-pressure sensors kunye ne-accelerometers zisetyenziswa ngokubanzi kwiinkqubo zokulinganisa kunye nokulawula. Inkqubo yokudibanisa isetyenziselwa ukudibanisa i-silicon chips kunye ne-sensor element ukuqinisekisa uvakalelo oluphezulu kunye nokuchaneka. Ezi zinzwa kufuneka zikwazi ukujamelana neemeko ezinzulu zokusingqongileyo, kunye neenkqubo zokubambisana ezikumgangatho ophezulu zinokuthintela ngokufanelekileyo izinto eziphathekayo okanye ukungasebenzi kakuhle ngenxa yokutshintsha kweqondo lokushisa.

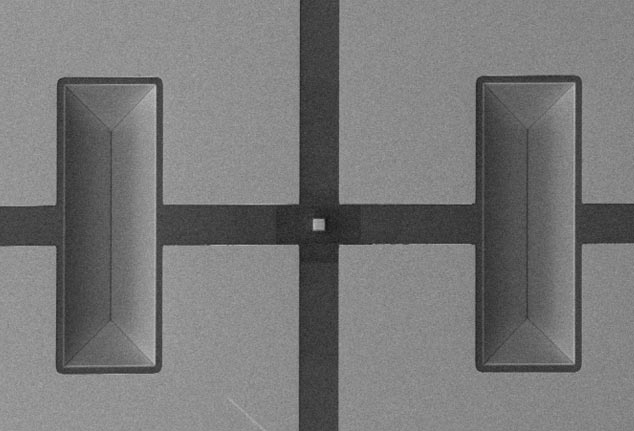

2. Izixhobo zeMicro-optical kunye neeswitshi zamehlo ze-MEMS

Kwintsimi yonxibelelwano lwe-optical kunye nezixhobo ze-laser, izixhobo ze-MEMS ze-optical kunye nee-switch switches zidlala indima ebalulekileyo. Itekhnoloji ye-Bonding isetyenziselwa ukufezekisa uxhulumaniso oluchanekileyo phakathi kwezixhobo ze-MEMS ezisekelwe kwi-silicon kunye nezixhobo ezifana nemicu ye-optical kunye nezibuko zokuqinisekisa ukusebenza kakuhle kunye nokuzinza kokuhanjiswa kwesignali ye-optical. Ngokukodwa kwizicelo ezine-frequency ephezulu, i-bandwidth ebanzi kunye nokuhanjiswa komgama omde, itekhnoloji ye-bonding ephezulu ibalulekile.

3. I-MEMS gyroscopes kunye ne-inertial sensors

I-MEMS gyroscopes kunye ne-inertial sensors zisetyenziswa ngokubanzi ukuhamba okuchanekileyo kunye nokubeka indawo kumashishini aphakamileyo afana nokuqhuba ukuzimela, iirobhothi kunye ne-aerospace. Iinkqubo ezichanekileyo zokubambisana zinokuqinisekisa ukuthembeka kwezixhobo kwaye ugweme ukuthotywa kokusebenza okanye ukungaphumeleli ngexesha lokusebenza kwexesha elide okanye ukusebenza okuphezulu.

Iimfuno eziphambili zokusebenza kweteknoloji yokudibanisa kwi-MEMS processing

Kwinkqubo ye-MEMS, umgangatho wenkqubo yokubambisana inquma ngokuthe ngqo ukusebenza, ubomi kunye nokuzinza kwesixhobo. Ukuqinisekisa ukuba izixhobo ze-MEMS zinokusebenza ngokuthembekileyo ixesha elide kwiimeko ezahlukeneyo zesicelo, itekhnoloji yokudibanisa kufuneka ibe nale ntsebenzo iphambili ilandelayo:

1. Ukuzinza okuphezulu kwe-thermal

Iimeko ezininzi zesicelo kwishishini le-semiconductor zineemeko eziphezulu zokushisa, ngokukodwa kwimimandla yeemoto, i-aerospace, njl.

2. Ukumelana nokunxiba okuphezulu

Izixhobo ze-MEMS zihlala zibandakanya izakhiwo ezincinci ze-micro-mechanical, kwaye ukungqubuzana kwexesha elide kunye nokunyakaza kunokubangela ukuguga kweendawo zokudibanisa. Izinto zokudibanisa kufuneka zibe nokuchasana okugqwesileyo kokugqoka ukuqinisekisa ukuzinza kunye nokusebenza kakuhle kwesixhobo ekusebenziseni ixesha elide.

3. Ubunyulu obuphezulu

Ishishini le-semiconductor lineemfuno ezingqongqo kakhulu kubunyulu bezinto eziphathekayo. Nasiphi na isingcolisi esincinci sinokubangela ukusilela kwesixhobo okanye ukuthotywa kokusebenza. Ngoko ke, izinto ezisetyenziselwa inkqubo yokudibanisa kufuneka zibe nobunyulu obuphezulu kakhulu ukuqinisekisa ukuba isixhobo asichatshazelwa kukungcoliswa kwangaphandle ngexesha lokusebenza.

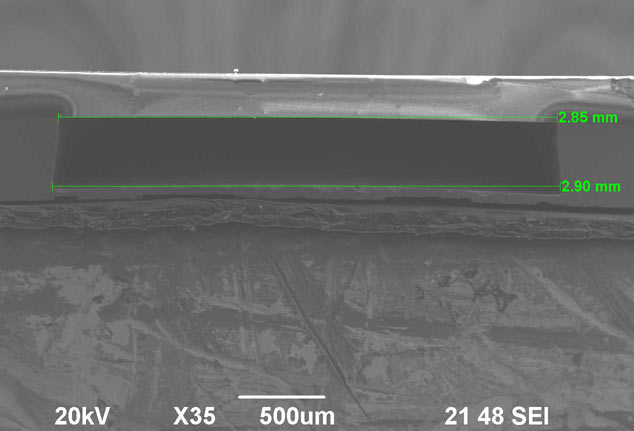

4. Ukuchaneka kokudibanisa okuchanekileyo

Izixhobo ze-MEMS zihlala zifuna i-micron-level okanye nakwi-nanometer-level processing echanekileyo. Inkqubo yokudibanisa kufuneka iqinisekise i-docking echanekileyo yoluhlu ngalunye lwezinto zokuqinisekisa ukuba umsebenzi kunye nokusebenza kwesixhobo akuthinteki.

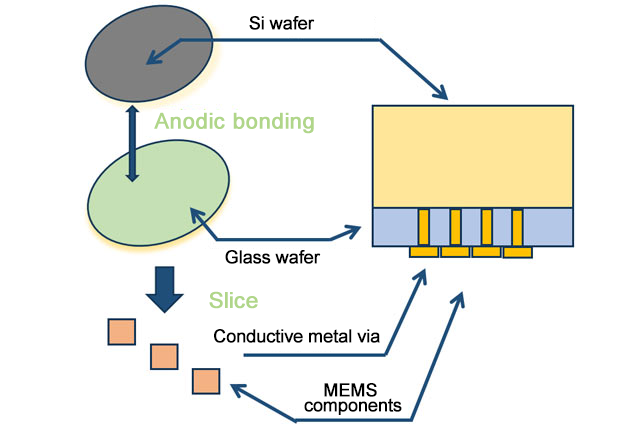

Ukudibanisa i-Anodic

Ukudibanisa i-Anodic:

● Isebenza kwikhonkco phakathi kwee-silicone wafers kunye neglasi, isinyithi neglasi, isemiconductor kunye nealloyi, kunye nesemiconductor kunye neglasi.

Ukudibanisa kwe-Eutectoid:

● Isebenza kwizinto ezifana ne-PbSn, i-AuSn, i-CuSn, kunye ne-AuSi

Ukudityaniswa kweglue:

● Sebenzisa i-glue ekhethekileyo yokudibanisa, efanelekileyo kwi-glues ekhethekileyo yokudibanisa njenge-AZ4620 kunye ne-SU8

● Isebenza kwi-intshi ye-4 kunye ne-6-intshi

Inkonzo yeSemicera Custom Bonding

Njengomboneleli ohamba phambili kwishishini le-MEMS processing solutions, i-Semicera izimisele ukubonelela abathengi ngeenkonzo ezichanekileyo ezichanekileyo, ezizinzile ezizinzile. Ithekhnoloji yethu yokubambisana ingasetyenziselwa ngokubanzi ukudibanisa izinto ezahlukeneyo, kubandakanywa i-silicon, iglasi, isinyithi, i-ceramics, njl., Ukubonelela ngezisombululo ezitsha zokusetyenziswa kwezicelo eziphezulu kwi-semiconductor kunye ne-MEMS fields.

I-Semicera inezixhobo zokuvelisa eziphambili kunye namaqela obugcisa, kwaye inokubonelela ngezisombululo ezidibeneyo ngokweemfuno ezithile zabathengi. Ingaba uxhulumaniso oluthembekileyo phantsi kobushushu obuphezulu kunye noxinzelelo oluphezulu, okanye i-micro-device bonding echanekileyo, i-Semicera inokuhlangabezana neemfuno ezahlukeneyo zenkqubo enzima ukuqinisekisa ukuba imveliso nganye inokuhlangabezana nemigangatho ephezulu.

Inkonzo yethu yokudibanisa isiko ayikhawulelwanga kwiinkqubo eziqhelekileyo zokubambisana, kodwa ibandakanya ukuxhamla kwetsimbi, i-thermal compression bonding, i-adhesive bonding kunye nezinye iinkqubo, ezinokubonelela ngenkxaso yobuchwephesha obuchwephesha kwizinto ezahlukeneyo, izakhiwo kunye neemfuno zesicelo. Ukongeza, i-Semicera inokubonelela abathengi ngenkonzo epheleleyo ukusuka kuphuhliso lweprototype ukuya kwimveliso yobuninzi ukuqinisekisa ukuba zonke iimfuno zobugcisa zabathengi zinokufezekiswa ngokuchanekileyo.