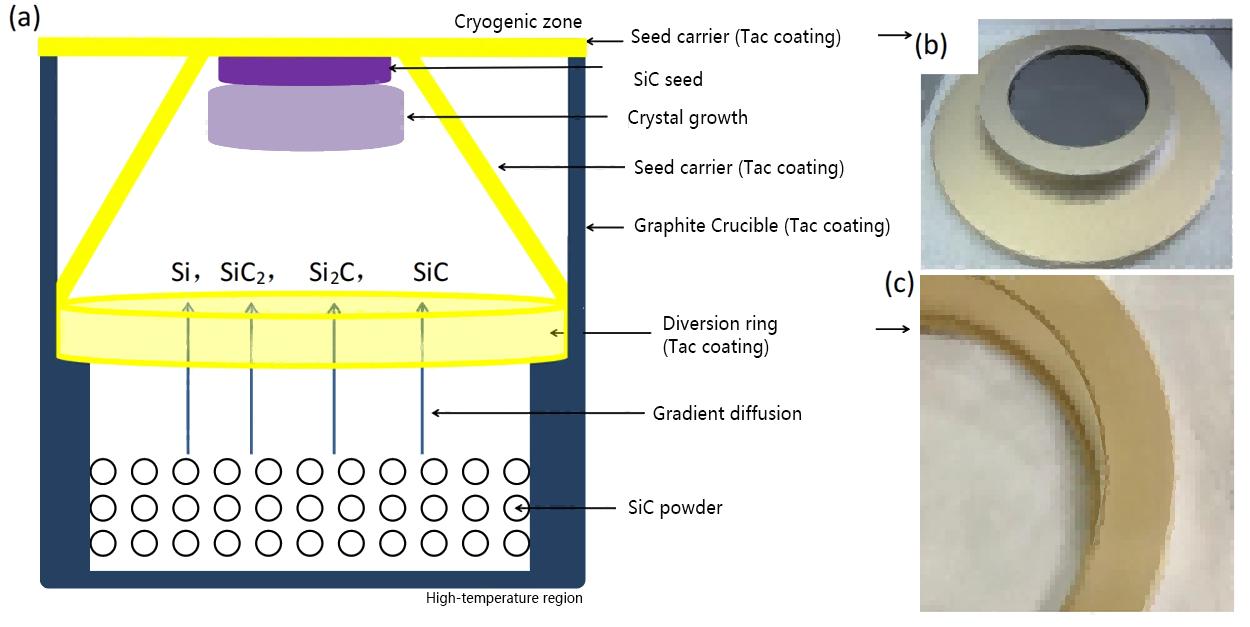

I-Semicera ibonelela ngeengubo ezikhethekileyo ze-tantalum carbide (TaC) kumacandelo ahlukeneyo kunye nabathwali.Inkqubo ehamba phambili yokugqoka i-Semicera yenza iingubo ze-tantalum carbide (TaC) zifezekise ukucoceka okuphezulu, ukuzinza kweqondo lokushisa eliphezulu kunye nokunyamezela kweekhemikhali eziphezulu, ukuphucula umgangatho wemveliso ye-crystals ye-SIC / GAN kunye neengqimba ze-EPI (Isixhasi seTaC esigqunywe ngegraphite), kunye nokwandisa ubomi bamacandelo angundoqo we-reactor. Ukusetyenziswa kwetantalum carbide TaC coating kukusombulula ingxaki edge kunye nokuphucula umgangatho wokukhula kwekristale, kwaye iSemicera iye yasombulula itekhnoloji ye-tantalum carbide coating (CVD), ifikelele kwinqanaba eliphezulu lamazwe ngamazwe.

I-graphite yinto ebalaseleyo yobushushu obuphezulu, kodwa i-oxidizes ngokulula kumaqondo aphezulu. Nakwiziko zokufunxa ezinerhasi engasebenziyo, isenokungena kwi-oxidation ecothayo. Ukusebenzisa i-CVD tantalum carbide (TaC) yokugqoka inokukhusela ngokufanelekileyo i-graphite substrate, inikeze ukuxhathisa okufanayo kobushushu obuphezulu njengegraphite. I-TaC ikwayinto engasebenziyo, okuthetha ukuba ayisayi kusabela ngeegesi ezifana ne-argon okanye i-hydrogen kumaqondo obushushu aphezulu.UkubuzaTantalum Carbide CVD Coating Crucible ngoku!

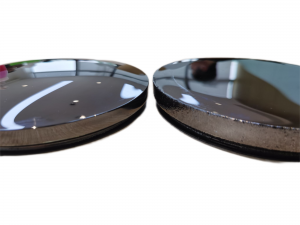

Emva kweminyaka yophuhliso, iSemicera yoyisile iteknoloji yeCVD TaCngeenzame ezidibeneyo zesebe leR&D. Iziphene kulula ukwenzeka kwinkqubo yokukhula kwee-wafers ze-SiC, kodwa emva kokusetyenziswaI-TaC, umahluko ubalulekile. Apha ngezantsi luthelekiso lweewafers ezine-TaC nangaphandle kwayo, kunye neendawo zeSimicera zokukhula kwekristale enye.

kunye nangaphandle kwe-TaC

Emva kokusebenzisa i-TaC (ekunene)

Ngaphezu koko, iSemicera'sIimveliso ezigqunywe yi-TaCbonisa ubomi benkonzo obude kunye nokumelana nobushushu obuphezulu xa kuthelekiswaIingubo zeSiC.Imilinganiselo yeLabhoratri ibonise ukuba yethuIingubo ze-TaCiyakwazi ukusebenza rhoqo kumaqondo obushushu ukuya kuma 2300 degrees Celsius ixesha elide. Ngezantsi yimizekelo yeesampulu zethu: