Intshayelelo kwi-CVD TaC Coating:

I-CVD TaC Coating bubugcisa obusebenzisa i-chemical vapor deposition ukufaka i-tantalum carbide (TaC) umaleko kumphezulu wesubstrate. I-Tantalum carbide yimathiriyeli ye-ceramic esebenza kakhulu eneempawu ezibalaseleyo zoomatshini kunye neekhemikhali. Inkqubo ye-CVD yenza ifilimu ye-TaC efanayo kumphezulu we-substrate ngokusabela kwegesi.

Iimpawu eziphambili:

Ubulukhuni obugqwesileyo kunye nokumelana nokunxiba: I-Tantalum carbide inobunzima obuphezulu kakhulu, kwaye i-CVD TaC Coating inokuphucula kakhulu ukuxhathisa ukunxiba kwe-substrate. Oku kwenza i-coating ifaneleke kwizicelo kwiindawo eziphezulu zokunxiba, ezifana nezixhobo zokusika kunye nokubumba.

Uzinzo lobushushu obuphezulu: Iingubo ze-TaC zikhusela isithando somlilo esibalulekileyo kunye namalungu e-reactor kumaqondo obushushu ukuya kuma-2200 ° C, ebonisa ukuzinza okulungileyo. Igcina ukuzinza kweekhemikhali kunye nomatshini phantsi kweemeko ezinzulu zokushisa, okwenza kube yinto efanelekileyo yokulungiswa kobushushu obuphezulu kunye nokusetyenziswa kwiindawo eziphezulu zokushisa.

Ukuzinza kweekhemikhali okugqwesileyo: I-Tantalum carbide inokumelana ne-corrosion eqinile kwii-acids ezininzi kunye ne-alkali, kunye ne-CVD TaC Coating inokuthintela ngokufanelekileyo umonakalo kwi-substrate kwiindawo ezinobungozi.

Indawo yokunyibilika ephezulu: I-Tantalum carbide inendawo ephezulu yokunyibilika (malunga ne-3880 ° C), evumela i-CVD TaC Coating ukuba isetyenziswe kwiimeko ezigqithisileyo zokushisa ngaphandle kokunyibilika okanye ukuthotywa.

Ukuqhuba kakuhle kwe-thermal: I-TaC yokugqoka ine-conductivity ephezulu ye-thermal, enceda ukutshabalalisa ngokufanelekileyo ubushushu kwiinkqubo eziphezulu zokushisa kunye nokukhusela ukushisa kwendawo.

Usetyenziso olunokwenzeka:

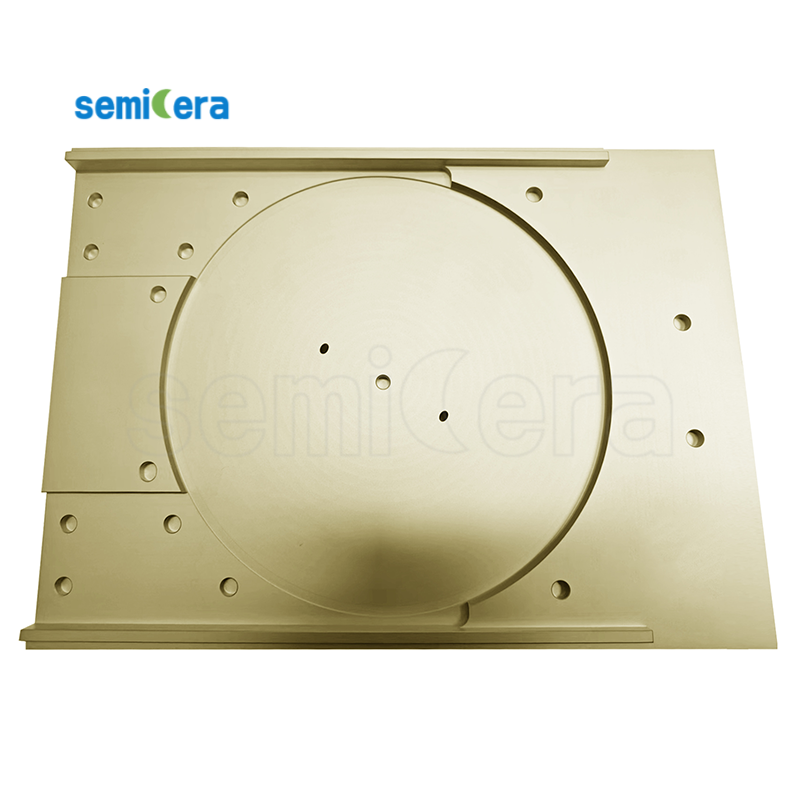

• I-Gallium Nitride (GaN) kunye ne-Silicon Carbide epitaxial CVD reactor components kuquka izithwali zewafer, izitya zesathelayithi, iishawara, iisilingi, kunye neesusceptors.

• I-Silicon carbide, i-gallium nitride kunye ne-aluminiyam nitride (i-AlN) iikhomponenti zokukhula kwekristale eziquka iicrucibles, izibambi zembewu, iiringi zesikhokelo kunye nezihluzo

• Amacandelo emizi-mveliso aquka izinto zokufudumeza ezinganyangekiyo, imilomo yokutofa, iiringi zokugquma kunye neejigi zokubrawuza

Iimpawu zesicelo:

• Iqondo lobushushu lizinzile ngaphezu kwe-2000°C, livumela ukusebenza kumaqondo obushushu agqithisileyo

•Ukumelana ne-hydrogen (Hz), i-ammonia (NH3), i-monosilane (i-SiH4) kunye ne-silicon (Si), inika ukhuseleko kwiindawo ezinobungozi beekhemikhali

• Ukumelana nokothuka kwe-thermal kwenza imijikelo yokusebenza ngokukhawuleza

• Igraphite inoncamathelo olomeleleyo, iqinisekisa ubomi obude benkonzo kwaye akukho delamination yokwaleka.

• Ukucoceka okuphezulu kakhulu ukuphelisa ukungcola okungeyomfuneko okanye ukungcola

• Ukugqunywa ngokusesikweni kokwaleka ukunyamezelwa komgangatho

Iinkcukacha zobugcisa:

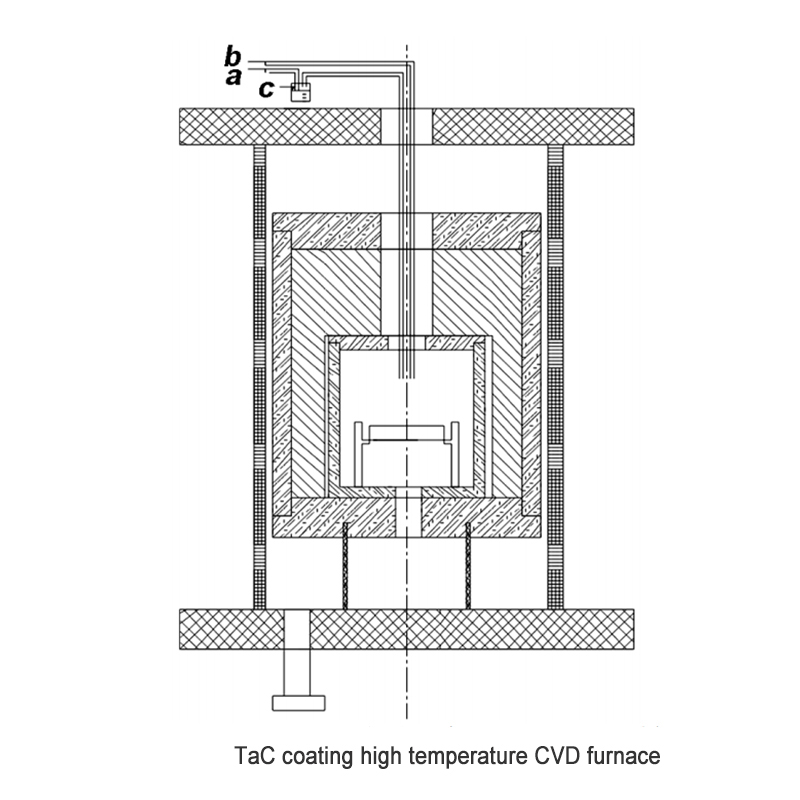

Ukulungiswa kweengubo ezixineneyo ze-tantalum carbide ngeCVD:

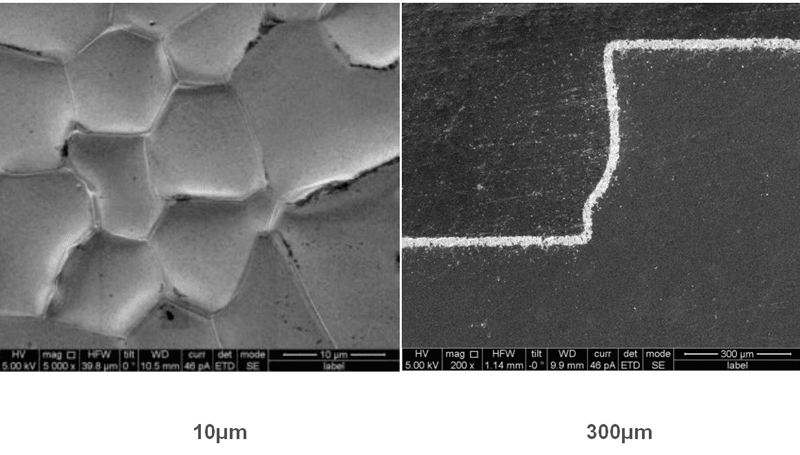

Ukugquma kwe-TAC ngokukhanya okuphezulu kunye nokufana okugqwesileyo:

I-CVD TAC COATING I-Technical Parameters_Semicera:

| Iimpawu ezibonakalayo zokwaleka kwe-TaC | |

| Ukuxinana | 14.3 (g/cm³) |

| Uxinaniso ngobuninzi | 8 x 1015/i-cm |

| Ukukhupha izinto ezithile | 0.3 |

| I-coefficient yokwandisa i-Thermal | 6.3 10-6/K |

| Ukuqina(HK) | 2000 HK |

| Ukuxhathisa ngobuninzi | 4.5 ohm-cm |

| Ukuchasa | 1x10-5Ohm*cm |

| Ukuzinza kwe-Thermal | <2500℃ |

| Ukushukuma | 237cm2/Vs |

| Ubungakanani begraphite utshintsho | -10 ~ -20um |

| Ubunzima bokugquma | ≥20um ixabiso eliqhelekileyo (35um+10um) |

Oku kungasentla ngamaxabiso aqhelekileyo.