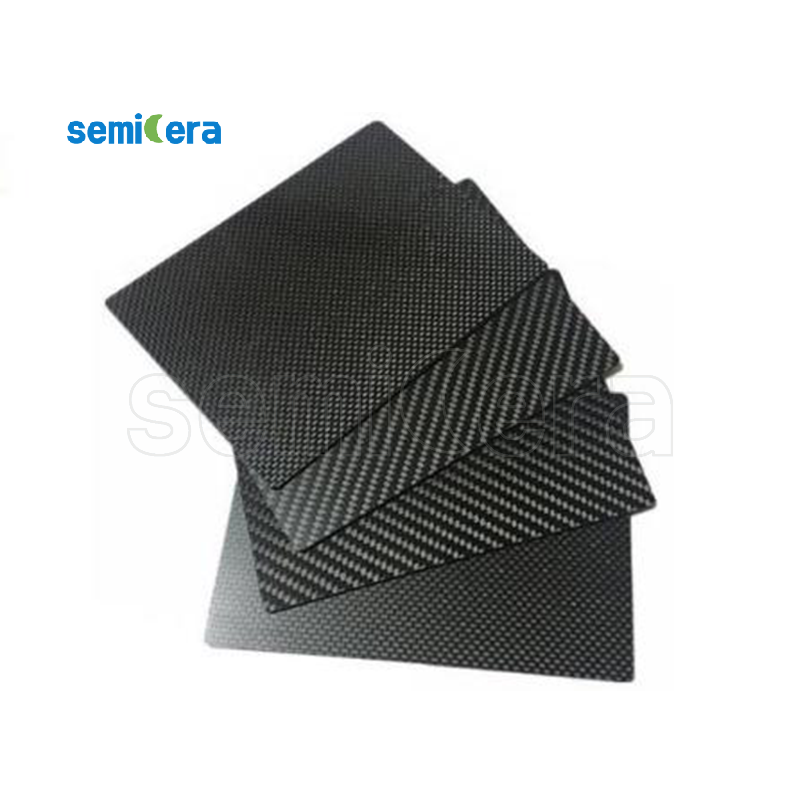

Product Overview

II-Silicon-Impregnated Silicon Carbide (SiC) Paddle kunye ne-Wafer Carrieryenzelwe ukukhawulelana neemfuno ezibangwayo ze-semiconductor yokusetyenziswa kwe-thermal processing applications. Iyilwe ukusuka kwi-SiC yococeko oluphezulu kwaye iphuculwe ngokumiliselwa kwe-silicon, le mveliso ibonelela ngokudityaniswa okukhethekileyo kokusebenza kobushushu obuphezulu, i-thermal conductivity egqwesileyo, ukumelana nokubola, kunye namandla abalaseleyo omatshini.

Ngokudibanisa isayensi yezinto eziphambili kunye nokuveliswa ngokuchanekileyo, esi sisombululo siqinisekisa ukusebenza okuphezulu, ukuthembeka, kunye nokuqina kwabavelisi be-semiconductor.

Ezona mpawu

1.Ukumelana nobushushu obubalaseleyo

Ngenqanaba lokunyibilika elidlula i-2700 ° C, izinto ze-SiC zizinzile ngokwendalo phantsi kobushushu obukhulu. Ukufakwa kwe-silicon kukhulisa ngakumbi ukuzinza kwabo kwe-thermal, okubavumela ukuba bamelane nokuvezwa ixesha elide kumaqondo obushushu aphezulu ngaphandle kokuncipha kwesakhiwo okanye ukuthotywa kokusebenza.

2.I-Superior Thermal Conductivity

I-conductivity ekhethekileyo ye-thermal ye-silicon-impregnated SiC iqinisekisa ukuhanjiswa kobushushu obufanayo, ukunciphisa uxinzelelo lwe-thermal ngexesha lokucubungula okubalulekileyo. Le propati yandisa ubomi besixhobo kwaye inciphisa ixesha lokunciphisa imveliso, iyenze ilungele ukulungiswa kobushushu obuphezulu.

3.I-Oxidation kunye noKunyangwa kokuNgxwala

Umaleko owomeleleyo wesilicon oxide wenza ngokwendalo kumphezulu, ubonelela ukuxhathisa okubalaseleyo kwi-oxidation kunye nokubola. Oku kuqinisekisa ukuthembeka kwexesha elide kwiindawo zokusebenza ezinzima, ukukhusela zombini izinto eziphathekayo kunye namacandelo ajikelezayo.

4.Amandla oMtshini aPhezulu kunye nokuNxitywa kokuNxitywa

I-Silicon-impregnated SiC ibonakalisa amandla abalaseleyo oxinzelelo kunye nokumelana nokunxiba, ukugcina ingqibelelo yayo yesakhiwo phantsi komthwalo ophezulu, iimeko zobushushu obuphezulu. Oku kunciphisa umngcipheko womonakalo onxulumene nokunxitywa, ukuqinisekisa ukusebenza okungaguqukiyo kwimijikelo yokusetyenziswa eyandisiweyo.

Iinkcukacha

| Igama lemveliso | SC-RSiC-Si |

| Izinto eziphathekayo | ISilicon Impregnation yeSilicon Carbide Compact (ucoceko oluphezulu) |

| Usetyenziso | Amacandelo oNyango loBubushushu beSemiconductor, aMacandelo eZixhobo zokuVelisa iSemiconductor |

| Ifomu yokuhanjiswa | Umzimba obunjiweyo |

| Ukuqamba | IPropati yoomatshini | I-Modulus eselula (GPA) | Ukugoba Amandla (MPa) | ||

| Ukwakhiwa (vol%) | α-SiC | α-SiC | RT | 370 | 250 |

| 82 | 18 | 800°C | 360 | 220 | |

| Ubuninzi Bobuninzi (kg/m³) | 3.02 x 103 | 1200°C | 340 | 220 | |

| Ubushushu obungangenwa bubushushu°C | 1350 | Umlinganiselo wePoisson | 0.18(RT) | ||

| Ipropati yoThermal | I-Thermal Conductivity (W/(m· K)) | Umthamo wobushushu obuthe ngqo (kJ/(kg·K)) | I-Coefficient yoKwandiswa kweThermal (1/K) | ||

| RT | 220 | 0.7 | RT~700°C | 3.4 x 10-6 | |

| 700°C | 60 | 1.23 | 700~1200°C | 4.3 x10-6 | |

| Isiqulatho sokungcola ((ppm) | |||||||||||||

| Isiqalelo | Fe | Ni | Na | K | Mg | Ca | Cr | Mn | Zn | Cu | Ti | Va | Ai |

| Izinga loMxholo | 3 | <2 | <0.5 | <0.1 | <1 | 5 | 0.3 | <0.1 | <0.1 | <0.1 | <0.3 | <0.3 | 25 |

Usetyenziso

▪ISemiconductor Thermal Processing:Ilungele iinkqubo ezifana ne-chemical vapor deposition (CVD), ukukhula kwe-epitaxial, kunye ne-annealing, apho ulawulo oluchanekileyo lweqondo lokushisa kunye nokuqina kwezinto kubalulekile.

▪Abathwali beWafer & Paddles:Yenzelwe ukubamba ngokukhuselekileyo kwaye ithuthe ii-wafers ngexesha lonyango lobushushu obuphezulu.

▪Imekobume yokuSebenza ngokugqithisileyo: Ifanelekile kwiisetingi ezifuna ukumelana nobushushu, ukuvezwa kweekhemikhali, kunye noxinzelelo lomatshini.

Izinto eziluncedo zeSilicon-iMpregnated SiC

Ukudityaniswa kwe-silicon carbide ephezulu yococeko kunye netekhnoloji yokufakelwa kwe-silicon ephucukileyo inika izibonelelo zokusebenza ezingenakulinganiswa:

▪Ukuchaneka:Ukwandisa ukuchaneka kunye nolawulo lwe-semiconductor processing.

▪Uzinzo:Imelana nemekobume erhabaxa ngaphandle kokubeka esichengeni ukusebenza.

▪Ubomi obude:Yandisa ubomi benkonzo yezixhobo zokwenziwa kwe-semiconductor.

▪Ukusebenza kakuhle:Ukuphucula imveliso ngokuqinisekisa iziphumo ezithembekileyo nezihambelanayo.

Kutheni le nto ukhethe izisombululo zethu zeSilicon-iMpregnated SiC?

At Semicera, Sisebenza ngokukhethekileyo ekuboneleleni ngezisombululo eziphezulu ezihambelana neemfuno zabavelisi be-semiconductor. I-Silicon-Impregnated Silicon Carbide Paddle yethu kunye ne-Wafer Carrier zivavanywa ngokuqatha kunye nokuqinisekiswa komgangatho ukuhlangabezana nemigangatho yoshishino. Ngokukhetha iSemicera, ufumana ukufikelela kwiimathiriyeli zokusika ezenzelwe ukukhulisa iinkqubo zakho zokuvelisa kunye nokuphucula amandla akho emveliso.

IiNgcaciso zobuGcisa

▪Ukuqulunqwa kwezinto:Ucoceko oluphezulu lwe-silicon carbide ene-silicon impregnation.

▪Uluhlu lobushushu obusebenzayo:Ukuya kuthi ga kuma-2700°C.

▪ I-Thermal Conductivity:Iphezulu kakhulu ngokusasazwa kobushushu obufanayo.

▪Iinkcazelo Ngeempawu Zokuchasa:I-oxidation, i-corrosion, kunye ne-resistant-resistant.

▪Usetyenziso:Iyahambelana neenkqubo ezahlukeneyo ze-semiconductor thermal processing.

Qhagamshelana nathi

Ngaba ukulungele ukuphakamisa inkqubo yakho yokuvelisa i-semiconductor? QhagamshelanaSemiceranamhlanje ukufunda ngakumbi malunga neSilicon-Impregnated Silicon Carbide Paddle yethu kunye neWafer Carrier.

▪I-imeyile: sales01@semi-cera.com/sales05@semi-cera.com

▪Ifowuni: +86-0574-8650 3783

▪Indawo:No.1958 Jiangnan Road, Ningbo High tech, Zone, Zhejiang Province, 315201, China