Ukugaya i-disc sisixhobo esibalulekileyo senkqubo yokuvelisa ama-silicone wafers kwi-ultra-large scale integrated circuits kwishishini le-semiconductor. Ngokuqhelekileyo isetyenziselwa i-iron cast okanye i-carbon steel grinding disc inobomi obuphantsi benkonzo kunye ne-coefficient enkulu yokwandisa i-thermal. Kwinkqubo yokucutshungulwa kwe-silicon wafers, ngokukodwa kwinkqubo yokugaya okanye ukupholisa ngokukhawuleza, ukunyanzeliswa kwe-flatness kunye ne-parallelism ye-silicon wafers kunzima ukuqinisekisa ngenxa yokugqoka kunye ne-thermal deformation yediski yokusila.

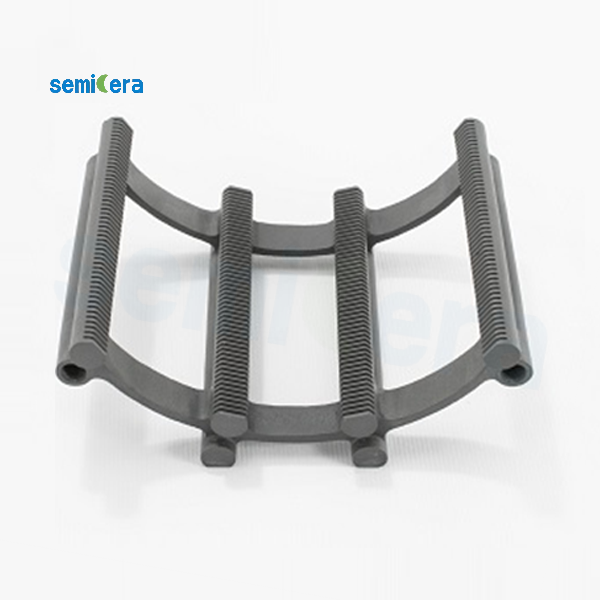

Idiski yokusila ye-silicon carbide ceramic inokusilwa kwaye ipolishwe ngesantya esiphezulu ngenxa yokuqina okuphezulu kunye nokunxiba okuncinci kwediski yokusila, kunye nokwandiswa kwe-thermal coefficient ngokusisiseko kuyafana naleyo ye-silicon wafer. Ingakumbi kule minyaka yamva nje, ubungakanani besilicon wafer buba bukhulu kwaye bukhudlwana, nto leyo ibeka phambili iimfuno eziphezulu zomgangatho kunye nokusebenza kakuhle kwe-silicon wafer yokusila.

Ukusetyenziswa kwe-silicon carbide ceramic grinding disc kuya kuphucula kakhulu umgangatho kunye nokusebenza kakuhle kwe-silicon wafer wafer. Kwangaxeshanye, i-silicon carbide ceramic grinding disk ingasetyenziselwa ukugaya kunye nokupolisha inqwelomoya yezinye izinto ezifana neflake okanye izinto ezibhloko. Ngophuhliso loshishino, ngakumbi ukuphunyezwa komgangatho we-ISO14000 wamazwe ngamazwe, iimfuno eziphezulu ziye zabekwa phambili zokuthutha ulwelo olungekho luncedo kukhuseleko lokusingqongileyo.

Enye yezona mpawu zibalulekileyo ze-silicon carbide ceramics ngamandla ayo aphezulu obushushu, oko kukuthi, amandla awancitshiswanga kwii-degrees ze-1600, kwaye ukuxhathisa kwe-oxidation kuhle kakhulu, ngoko kunokusetyenziswa kwiindawo zesakhiwo sokushisa okuphezulu. Okufana nepleyiti ephezulu yeziko lobushushu obuphezulu, inkxaso, kunye nezixhobo zokulinga lobushushu obuphezulu.

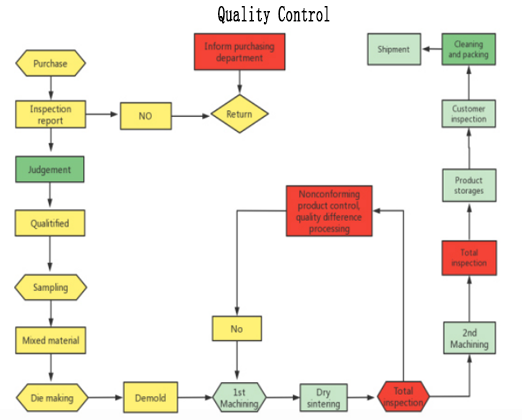

SemiceraI-Energy Technology Co., Ltd luphando lobungcali, uphuhliso, imveliso kunye nokuthengiswa kweemveliso ze-silicon carbide ceramic.Ukususela ekusekweni kwayo ngo-2016,SemiceraAmandla ayazi kakuhle inkqubo yokubumba i-isostatic, inkqubo yokubumba iwaka, inkqubo yokubumba i-grouting kunye nenkqubo yokubumba i-vacuum extrusion. Inkampani yethu isebenzisa iilayini ezi-6 ze-silicon carbide ceramic sintering sintering, zine-8 CNC, ii-6 ezichanekileyo zoomatshini bokusila, zinokukubonelela ngesilicon carbide ceramic sintered products, kodwa inokubonelela ngesilicon carbide ceramics, alumina ceramics, aluminiyam nitride ceramics, zirconia ceramics processing service. .

-

IiNkampani zokuVelisa iGraphite Soft Felt ...

-

Isaphulelo esikhulu sePolyacrylonitrile Thermal Insul...

-

2019 Umgangatho ophezulu weSilicon Carbide Liner Sisic T...

-

Isaphulelo esiQhelekileyo soMbane soMbane seSpiral Cerami...

-

Ubuchwephesha be-China Silicon Carbide Graphite Cru...

-

Isampulu yasimahla yeeMveliso eziKhethekileyo zeSic eziDoubl...