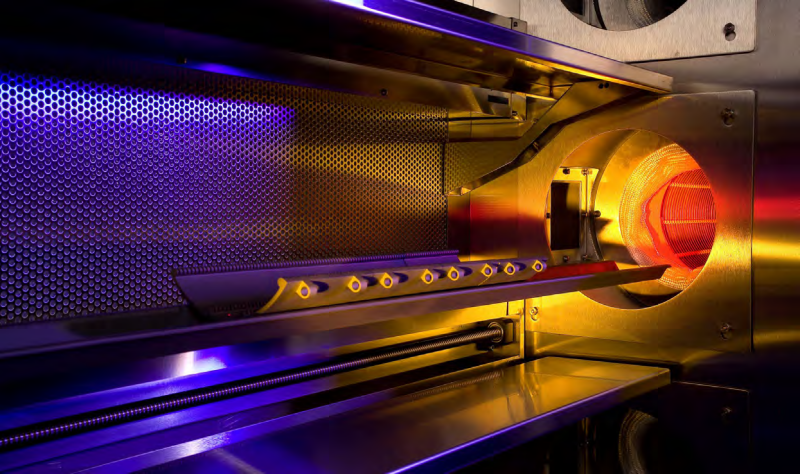

ISemiceraISiC Cantilever Wafer Paddleyenzelwe ukuhlangabezana neemfuno zokwenziwa kwesemiconductor yanamhlanje. Okuisikhephe esibheqayoinika amandla omatshini agqwesileyo kunye nokumelana nobushushu, okubaluleke kakhulu ekuphatheni ii-wafers kwindawo ezinobushushu obuphezulu.

Uyilo lwe-SiC cantilever luvumela ukubekwa kwe-wafer ngokuchanekileyo, ukunciphisa umngcipheko womonakalo ngexesha lokuphatha. I-conductivity yayo ephezulu ye-thermal iqinisekisa ukuba i-wafer ihlala izinzile naphantsi kweemeko ezinzima, ezibaluleke kakhulu ekugcineni ukusebenza kwemveliso.

Ukongeza kwiinzuzo zayo zesakhiwo, iSemicera'sISiC Cantilever Wafer Paddleikwabonelela ngeenzuzo kubunzima kunye nokuqina. Ukwakhiwa okulula kwenza kube lula ukuphatha kunye nokudibanisa kwiinkqubo ezikhoyo, ngelixa i-high-density SiC material iqinisekisa ukuhlala ixesha elide phantsi kweemeko ezinzima.

| Iimpawu ezibonakalayo zeRecrystallized Silicon Carbide | |

| Ipropati | Ixabiso eliqhelekileyo |

| Ubushushu bokusebenza (°C) | 1600°C (neoksijini), 1700°C (ukunciphisa okusingqongileyo) |

| Umxholo weSiC | > 99.96% |

| Isiqulatho sasimahla Si | < 0.1% |

| Unizi lolwapho kuyiwa khona | 2.60-2.70 g / cm3 |

| I-porosity ebonakalayo | < 16% |

| Amandla oxinzelelo | > 600 MPa |

| Amandla okugoba okubandayo | 80-90 MPa (20°C) |

| Amandla okugoba ashushu | 90-100 MPa (1400°C) |

| Ukwandiswa kweThermal @1500°C | 4.70 10-6/°C |

| I-Thermal conductivity @1200°C | 23 W/m•K |

| Imodyuli ye-elastic | 240 GPA |

| Ukuxhathisa ukothuka kwe-Thermal | Ulunge kakhulu |