Iirola ze-ceramic ze-SiC zinokuxhathisa okugqwesileyo kwaye ziyakwazi ukumelana noxinzelelo oluphezulu kunye nokukhuhlana ngaphandle kokuphulukana nomgangatho womphezulu. Ubunzima bayo busondele kwidayimane, eyenza ukuba ikwazi ukunciphisa ngokufanelekileyo ukudibanisa kunye nezinto zetsimbi kunye nokwandisa ubomi benkonzo ye-roller. I-coefficient ephantsi ye-friction ye-SiC ye-ceramic rollers nayo iyanciphisa ukulahleka kwamandla kunye nokuveliswa kobushushu, ukuphucula ukusebenza kakuhle kwemveliso.

Ukongeza, iirola ze-ceramic ze-SiC zinokumelana nobushushu obuphezulu. Iyakwazi ukusebenza ngokuzinzileyo kwiindawo eziphakamileyo zobushushu ngaphandle kokuthambisa okanye ukuguqulwa. Oku kwenza iiroli ze-ceramic ze-SiC zifaneleke kakhulu kwiinkqubo zokulungisa ubushushu obuphezulu ezifana nokuqengqeleka kwentsimbi kunye nokuphosa okuqhubekayo, ukuqinisekisa ukuba ii-roller zigcina ukusebenza okugqwesileyo kunye nokuzinza kwe-dimensional phantsi kobushushu obugqithisileyo.

Iirola ze-ceramic ze-SiC zikwanokumelana nokugqwesa okugqwesileyo. Iyakwazi ukumelana nokukhukuliseka kweekhemikhali ezifana ne-acids, i-alkalis, i-solvents kunye ne-corrosive gases, ukugcina ukugqitywa komphezulu kunye nokusebenza kwee-rollers. Oku kwenza iirola ze-ceramic ze-SiC ziqhube kakuhle kwizicelo ezifana nokulungiswa kweekhemikhali kunye ne-electroplating, ukwandisa ubomi benkonzo yezixhobo kunye nokuphucula umgangatho wokuvelisa.

Iimpawu ezikhaphukhaphu ze-SiC ze-ceramic rollers zibanika iimpawu ezintle ze-inertial kunye nokukwazi ukunciphisa ukungcangcazela, ngaloo ndlela kuncitshiswe ukungcangcazela kunye nengxolo, ukuphucula ukuzinza kwezixhobo kunye nokuthuthuzela ukusebenza. Imilinganiselo yayo echanekileyo kunye nomphezulu osicaba iqinisekisa ukuzinza kunye nokugudiswa kwe-roller, inika iziphumo ezigqwesileyo zesinyithi kunye neenkqubo zoshicilelo.

I-non-pressure sintered silicon carbide roller, i-atmospheric pressure sintered silicon carbide iimveliso zeceramic, ukusetyenziswa kobunyulu obuphezulu be-silicon carbide powder, i-sintered ku-2450℃ ubushushu obuphezulu, umxholo we-silicon carbide ongaphezulu kwe-99.1%, ubuninzi bemveliso ≥3.10g/ cm3, akukho ukungcola kwesinyithi njengesilicon yesinyithi.

► Umxholo weSilicon carbide --≥99%;

► Ukumelana nokushisa okuphezulu - ukusetyenziswa okuqhelekileyo kwi-1800 ℃;

► High thermal conductivity - xa kuthelekiswa ne-thermal conductivity yezinto zegraphite;

► Ubulukhuni obuphezulu - ukuqina okwesibini kuphela kwidayimane, i-cubic boron nitride;

► Ukuxhatshazwa kwe-Corrosion - i-asidi eyomeleleyo kunye ne-alkali ayinayo nayiphi na i-corrosion, ukumelana ne-corrosion kungcono kune-tungsten carbide kunye ne-alumina;

► Ubunzima bokukhanya - ubuninzi be-3.10g / cm3, kufuphi ne-aluminium;

► Akukho deformation - i-coefficient encinci kakhulu yokwandiswa kwe-thermal;

► Ukuxhatshazwa kwe-thermal shock - izinto eziphathekayo zinokumelana nokutshintsha kweqondo lokushisa ngokukhawuleza, ukuxhathisa ukutshatyalaliswa kwe-thermal, ukuchasana nokubanda kunye nokushisa, ukusebenza okuzinzileyo.

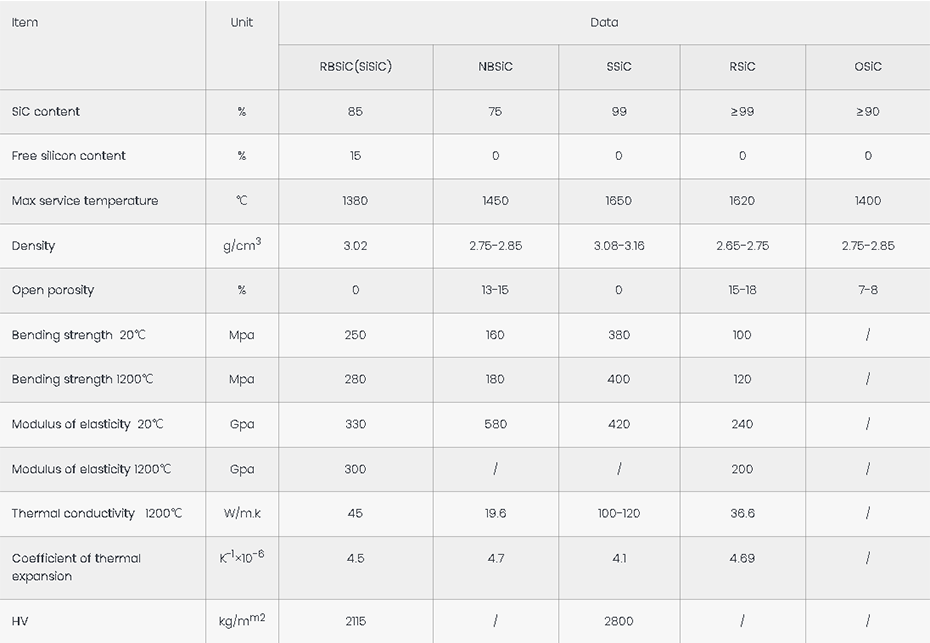

Iiparamitha zobuGcisa: