I-Silicon nitride yi-ceramic engwevu enokuqina okuphezulu kokuqhekeka, ukuxhathisa ukothuka kobushushu, kunye neempawu ezingenakungeneka kwiintsimbi ezinyibilikisiweyo.

Usebenzisa ezi mpawu, isetyenziswa kumalungu enjini yokutsha yangaphakathi anje ngeendawo zenjini yemoto, imibhobho ye-welding machine welding, njl.

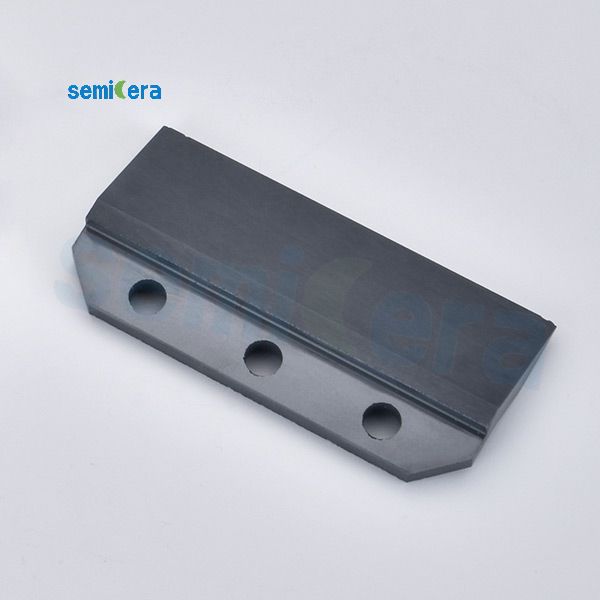

Ngokumelana kwayo okuphezulu kunye namandla aphezulu omatshini, izicelo zayo ekuthwaleni iinxalenye ze-roller, iibheringi ze-shaft ezijikelezayo kunye nezixhobo zokuvelisa izixhobo ze-semiconductor ezisecaleni zihlala zisanda.

Iipropati ze-silicon nitride ceramics

I-1, inamandla aphezulu kuluhlu olukhulu lobushushu;

2, ukomelela okuphezulu kokuqhekeka;

3, ukomelela okuhle kokugoba;

I-4, ukuchasana nokudinwa koomatshini kunye nokuhamba;

5, ukukhanya - ukuxinana okuphantsi;

6, ubunzima obuphezulu kunye nokumelana nokunxiba;

I-7, ukuxhathisa ukothuka kwe-thermal;

8, ukwanda kwe-thermal ephantsi;

9, i-insulator yombane;

I-10, ukuxhathisa okulungileyo kwe-oxidation;

I-11, ukuxhathisa okulungileyo kokubola kweekhemikhali.

I-Silicon nitride ceramics ine-coefficient ephantsi yokwandiswa kwe-thermal kunye ne-conductivity ephezulu ye-thermal, ngoko ke inokumelana nokutshatyalaliswa kobushushu. Isilicon nitride ecinezelekileyo eshushu ayisayi kwaphuka emva kokuba ifudunyezwe ukuya kutsho kwi-1000℃ kwaye ifakwe emanzini abandayo. Kwiqondo lobushushu elingekho phezulu kakhulu, i-silicon nitride inamandla amakhulu kunye nokumelana nempembelelo, kodwa ngaphezulu kwe-1200 ℃ iya konakaliswa ngokukhula kwexesha lokusetyenziswa, ukuze amandla ayo ancitshiswe, athandeke ngakumbi kumonakalo wokudinwa ngaphezulu kwe-1450 ℃, ngoko ke ukusetyenziswa. yeSi3N4 iqondo lobushushu jikelele alidluli kwi-1300℃.

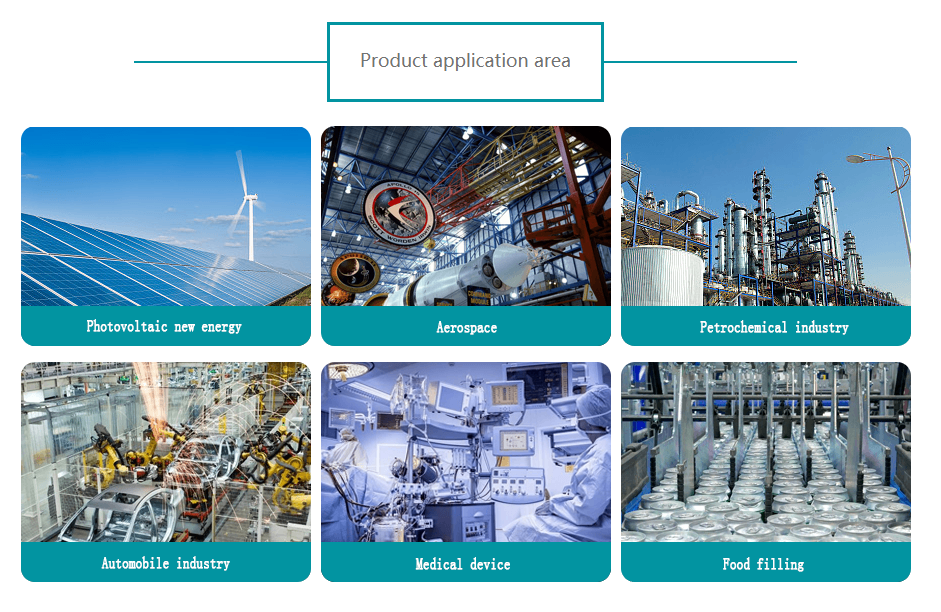

Ke ngoko, i-silicon nitride isetyenziswa ngokubanzi kwi:

1. Ibhola ejikelezayo kunye neebheringi ze-roller;

2. Amacandelo e-injini: ivalve, i-rocker arm pad, indawo yokutywina;

3. Isibiyeli sekhoyili yokufudumeza induction;

4. Iibhleyidi zomoya, iincakuba, iibhakethi;

5. Izinto zokuwelda kunye nebrazing;

6. Indibano yezinto zokufudumeza;

7. Indawo yokuwelda;

8. I-shafts echanekileyo kunye nemikhono kwiindawo eziphezulu zokunxiba;

9. I-Thermocouple sheath kunye ne-tube;

10. Izixhobo zenkqubo ye-semiconductor.

-

Isiko lobushushu obuphezulu obuxhathisa iSiC...

-

Izincedisi zeGraphite zentsimi eshushu ye-cr enye...

-

Uxinzelelo lweSintered SiC Lining

-

Izahlulo zeGrafite ezenziwe ngoBunjineli obuchanekileyo yiSemicera...

-

UmGangatho oPhezulu weGraphite eViwe nzima yiSemicera ye...

-

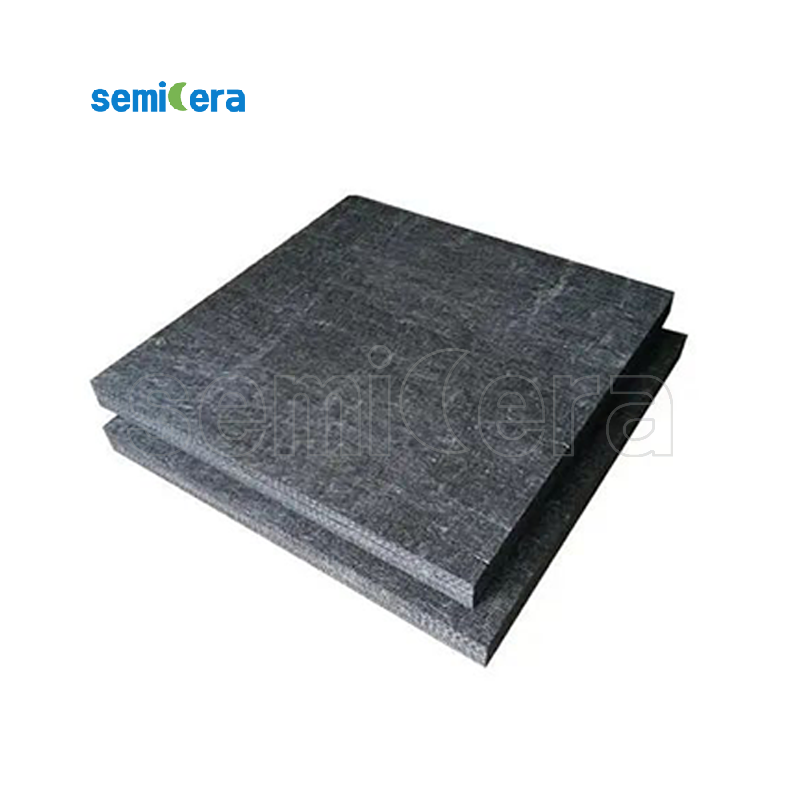

Imathiriyeli yegraphite eqinileyo evakala kakhulu