I-Silicon carbide luhlobo olutsha lweekeramics ezinexabiso eliphezulu lokusebenza kunye neempawu ezintle zezinto eziphathekayo. Ngenxa yeempawu ezinje ngokuqina okuphezulu kunye nokuqina, ukumelana nobushushu obuphezulu, ukuguquguquka okukhulu kwe-thermal kunye nokuxhathisa ukubola kweekhemikhali, iSilicon Carbide inokumelana nayo yonke imichiza ephakathi. Ke ngoko, i-SiC isetyenziswa kakhulu kwimigodi yeoli, kwimichiza, koomatshini kunye ne-airspace, nkqu amandla enyukliya kunye nomkhosi banemfuno zabo ezikhethekileyo kwi-SIC. Esinye isicelo esiqhelekileyo esinokusinika amakhonkco okutywina epompo, i-valve kunye nezixhobo zokukhusela njl.

Siyakwazi ukuyila kunye nokwenza ngokwemilinganiselo yakho ethile ngomgangatho olungileyo kunye nexesha lokuhambisa elifanelekileyo.

Aizinto eziluncedo:

Ukumelana ne-oxidation yobushushu obuphezulu

Uxhathiso olugqwesileyo lweCorrosion

Ukuxhathisa okulungileyo kweAbrasion

I-coefficient ephezulu yokushisa ukushisa

Ukuzithambisa, ukuxinana okuphantsi

Ukuqina okuphezulu

Uyilo olulungiselelweyo.

Usetyenziso:

-Indawo ekwaziyo ukumelana nokunxiba: ibhulorho, ipleyiti, umbhobho wesanti, umgca wenkanyamba, umphanda wokusila, njl.

-Umgangatho wobushushu obuphezulu: i-siC Slab, iTube yokuCima iFurnace, iTube eRadiant, i-crucible, i-Heating Element, i-Roller, i-Beam, i-Heat Exchanger, i-Cold Air Pipe, i-Burner Nozzle, i-Thermocouple Protection Tube, isikhephe se-SiC, i-Kiln car Structure, i-Setter, njl.

-Ibala leBulletproof yoMkhosi

-I-Silicon Carbide Semiconductor: Isikhephe se-SiC wafer, i-sic chuck, i-sic paddle, i-sic cassette, i-sic diffusion ityhubhu, i-wafer fork, ipleyiti yokufunxa, isikhokelo, njl.

-I-Silicon Carbide Seal Field: zonke iintlobo zeringi yokutywina, ukuthwala, i-bushing, njl.

-I-Photovoltaic Field: I-Cantilever Paddle, i-Barrel yokugaya, i-Silicon Carbide Roller, njl.

-Indawo yebhetri yeLithium

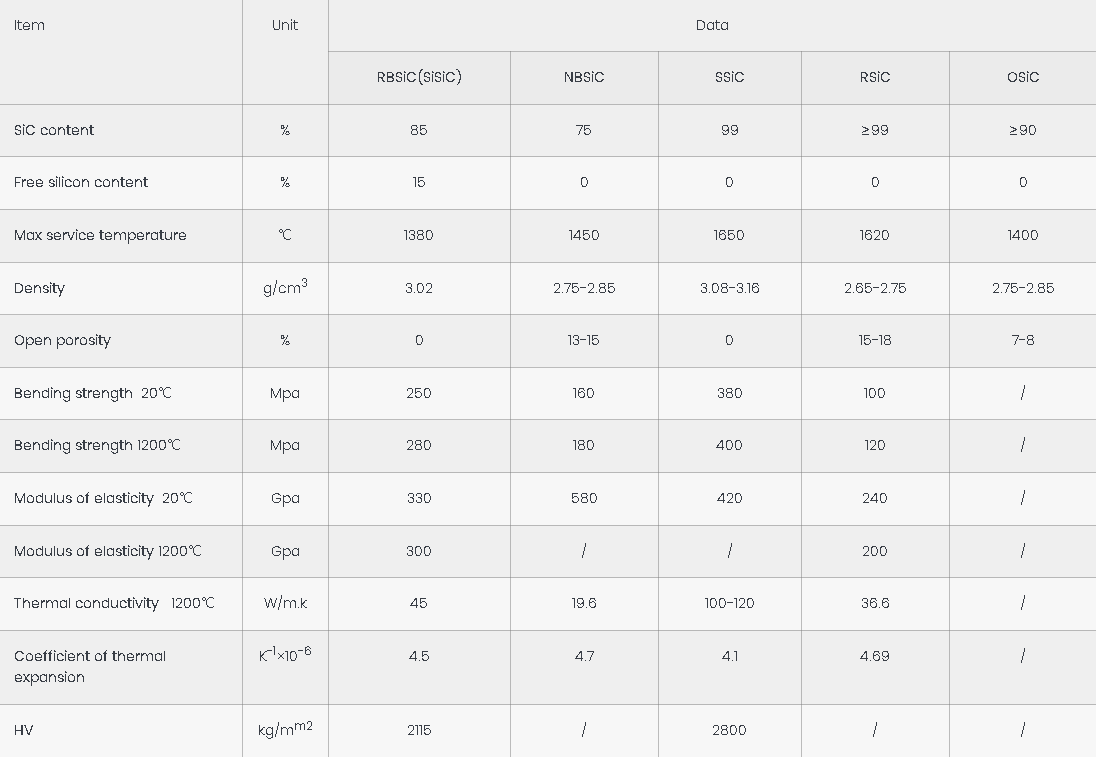

Iiparamitha zobuGcisa:

Idatha yeMathiriyeli

| 材料Izinto eziphathekayo | R-SiC |

| 使用温度Ubushushu bokusebenza (°C) | 1600°C (ILogo Simahla Akukho mlinganiselo Ipapashwe ngu- 氧化气氛Ubume beOxidizing) 1700°C (还原气氛Ukunciphisa okusingqongileyo) |

| SiC含量Umxholo weSiC (%) | > 99 |

| 自由Si含量Umxholo wesi Si samahala (%) | < 0.1 |

| 体积密度Ubuninzi bobuninzi (g/cm3) | 2.60-2.70 |

| 气孔率I-porosity ebonakalayo (%) | <16 |

| 抗压强度Amandla okutyumza (MPa) | > 600 |

| 常温抗弯强度Amandla okugoba abandayo (MPa) | 80-90 (20°C) |

| 高温抗弯强度Amandla okugoba ashushu (MPa) | 90-100 (1400°C) |

| 热膨胀系数 Ukwandiswa komlinganiso wobushushu @1500°C (10-6/°C) | 4.70 |

| 导热系数Thermal conductivity @1200°C (W/m•K) | 23 |

| 杨氏模量Imodyuli yeelastiki (GPa) | 240 |

| 抗热震性Ukuxhathisa ukothuka kwe-Thermal | 很好Ulunge kakhulu |