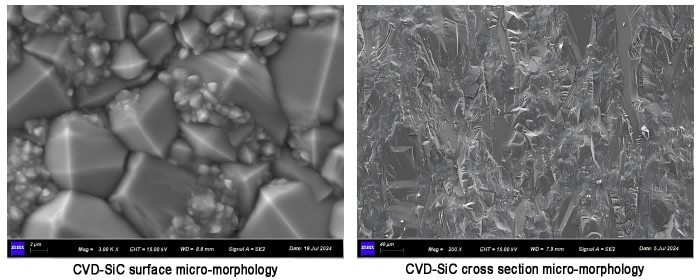

I-CVD Bulk Silicon Carbide (SiC)

Isishwankathelo:CVDisambuku sesilicon carbide (SiC)yinto efunwa kakhulu kwizixhobo ze-plasma etching, usetyenziso olukhawulezayo lwe-thermal processing (RTP), kunye nezinye iinkqubo zokuvelisa i-semiconductor. Iipropathi zayo ezikhethekileyo zoomatshini, iikhemikhali, kunye ne-thermal ziyenza ibe yeyona nto ifanelekileyo kusetyenziso lwetekhnoloji ephezulu efuna ukuchaneka okuphezulu kunye nokuqina.

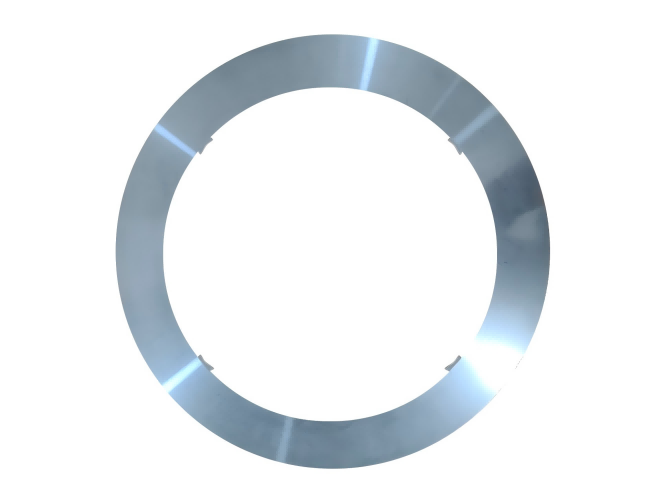

Usetyenziso lwe-CVD Bulk SiC:I-Bulk SiC ibalulekile kwishishini le-semiconductor, ngakumbi kwiinkqubo ze-plasma etching, apho amacandelo afana namakhonkco okugxila, iintloko zeeshawari zerhasi, iiringi zomphetho, kunye neeplatens zixhamla kwi-SiC's egqwesileyo yokuxhathisa umhlwa kunye ne-thermal conductivity. Ukusetyenziswa kwayo kufikelela kwiRTPiinkqubo ngenxa yesakhono seSiC sokumelana nokuguquguquka okukhawulezileyo kobushushu ngaphandle kokuthotywa okubalulekileyo.

Ukongeza kwi-etching izixhobo, i-CVDiSiC eninziithandwa kwiifurnaces zokusasaza kunye neenkqubo zokukhula kwekristale, apho uzinzo oluphezulu lwe-thermal kunye nokuchasana neendawo ezinobungozi bemichiza kufuneka. Ezi mpawu zenza i-SiC ibe yinto ekhethwayo kwizicelo eziphezulu ezibandakanya ukushisa okuphezulu kunye neegesi ezinobungozi, ezifana nezo ziqukethe i-chlorine kunye ne-fluorine.

Izinto eziluncedo kwi-CVD Bulk SiC Components:

•Ukuxinana okuphezulu:Ngoxinano lwe 3.2 g/cm³,CVD isambuku SiCamacandelo axhathisa kakhulu ukunxiba kunye nefuthe lomatshini.

•I-Superior Thermal Conductivity:Ukubonelela nge-thermal conductivity ye-300 W/m·K, isambuku se-SiC silawula ngokufanelekileyo ubushushu, siyenza ilungele izinto ezivezwe kwimijikelo yobushushu obugqithisileyo.

•Ukumelana neMichiza okuKhethekileyo:I-reactivity ephantsi ye-SiC ene-etching gases, kuquka i-chlorine kunye neekhemikhali ezisekelwe kwi-fluorine, iqinisekisa ubomi becandelo elide.

•Ukuxhathisa okunokulungiswa: CVD isambuku SiC'sukuxhathisa kunokwenziwa ngokwezifiso ngaphakathi koluhlu lwe-10⁻²–10⁴ Ω-cm, iyenze ikwazi ukuziqhelanisa neemfuno zokwenziwa kwe-etching kunye ne-semiconductor.

•I-Thermal Expansion Coefficient:Nge-coefficient yokwandisa i-thermal ye-4.8 x 10⁻⁶ / ° C (25-1000 ° C), i-CVD inqwaba ye-SiC ixhathisa ukutshatyalaliswa kwe-thermal, igcina ukuzinza kwe-dimensional nakwixesha lokufudumeza ngokukhawuleza kunye nokupholisa imijikelezo.

•Ukuqina kwiPlasma:Ukubonakaliswa kweplasma kunye neegesi ezisebenzayo akunakuphepheka kwiinkqubo ze-semiconductor, kodwaCVD isambuku SiCinikeza ukuxhathisa okuphezulu kwi-corrosion kunye nokuthotywa, ukunciphisa ukuphindaphinda okutshintshileyo kunye neendleko zokulondoloza jikelele.

IiNgcaciso zobuGcisa:

•Ububanzi:Ingaphezulu kwe-305 mm

•Ukuxhathisa:Ilungiselelwa ngaphakathi kwe-10⁻²–10⁴ Ω-cm

•Ubuninzi:3.2 g/cm³

•I-Thermal Conductivity:300 W/m·K

•I-Thermal Expansion Coefficient:4.8 x 10⁻⁶/°C (25–1000°C)

Ukwenziwa ngokwezifiso kunye nokuguquguquka:NgeISemicera Semiconductor, siyaqonda ukuba isicelo ngasinye se-semiconductor sinokufuna iinkcukacha ezahlukeneyo. Yiyo loo nto yethu i-CVD isambuku samacandelo e-SiC enziwe ngokwezifiso ngokupheleleyo, kunye nokumelana okuhlengahlengiswayo kunye nemilinganiselo eyenzelwe ukuba ihambelane neemfuno zesixhobo sakho. Nokuba uphucula iinkqubo zakho zokujongwa kweplasma okanye ujonge izinto ezomeleleyo kwi-RTP okanye iinkqubo zokusasaza, i-CVD yethu yesambuku ye-SiC inikezela ngentsebenzo engenakuthelekiswa nanto.