I-Quartz: ICandelo eliBalulekileyo kwii-Electronics zanamhlanje

Intshayelelo kwiiMathiriyeli zeQuartz

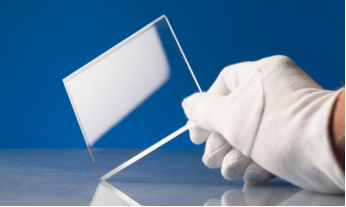

I-Quartz (SiO₂) inokufana neglasi ekuboneni kuqala, kodwa iipropati zayo ezizodwa ziyibeka yodwa. Ngokungafaniyo neglasi eqhelekileyo, equlathe amacandelo amaninzi (njengesanti yequartz, iborax, i-barium carbonate, i-limestone, i-feldspar, kunye nesoda), i-quartz yenziwe kuphela yi-SiO₂. Oku kunika ulwakhiwo olulula lwenethiwekhi eyenziwe ziiyunithi ze-tetrahedral zesilicon dioxide.

Ukubaluleka kweQuartz ecocekileyo

I-quartz ecocekileyo, edla ngokubizwa ngokuba "yintsimbi yesithsaba" yezixhobo zeglasi, ibonelela ngeempawu ezikhethekileyo ngenxa yobuncinci bentsimbi. Esi sixhobo simangalisayo siyimfuneko kwiinkqubo ezahlukeneyo ze-semiconductor, ukuqhayisa ngeenzuzo ezinje:

1. Ukumelana nobushushu obuphezulu: Ngendawo yokuthambisa emalunga ne-1730 ° C, i-quartz inokumelana nokusetyenziswa kwexesha elide kwi-1150 ° C kwaye ibambe ukuqhuma okufutshane ukuya kwi-1450 ° C.

2. I-Chemical Corrosion Resistance: I-quartz ye-high-purity ibonisa i-reactivity encinci kunye ne-acids ezininzi (ngaphandle kwe-hydrofluoric acid) kwaye ibonisa ukuzinza okuphezulu ngokuchasene nokuhlaselwa kweekhemikhali, ibe ngamaxesha angama-30 ngaphezulu kwe-acid-resistant kune-ceramics kunye namaxesha angama-150 ngaphezu kwensimbi engenasici.

3. Ukuzinza kwe-Thermal: I-quartz ye-high-purity ine-coefficient yokwandisa i-thermal ephantsi kakhulu, evumela ukuba inyamezele utshintsho olukhawulezayo lobushushu ngaphandle kokuphuka.

4. I-Optical Clarity: Esi sixhobo sigcina ukuhanjiswa okuphezulu kwi-spectrum ebanzi, kunye nokuhanjiswa kokukhanya okubonakalayo okudlula i-93% kunye ne-ultraviolet transmittance ifikelela ngaphezu kwe-80%.

5. I-Insulation yoMbane: I-quartz yococeko oluphezulu lunikeza ukuxhathisa kombane okungaqhelekanga, okwenza kube yi-insulator egqwesileyo nakwiqondo lokushisa eliphakamileyo.

Izicelo kuShishino lweSemiconductor

Ngenxa yezi zakhiwo zibalaseleyo zomzimba kunye neekhemikhali, i-quartz yococeko oluphezulu isetyenziswa kakhulu kwi-elektroniki yanamhlanje, unxibelelwano, kunye neshishini le-semiconductor. Imfuno ekhulayo yee-wafers ze-silicon inyuse kakhulu imfuno yamalungu e-quartz, ngakumbi kwimveliso ye-chip.

Usetyenziso oluPhambili lweQuartz kwiSemiconductor Manufacturing:

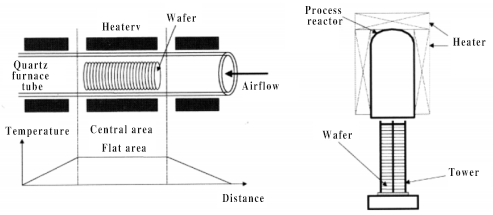

1. Izixhobo zoBubushushu obuphezulu:

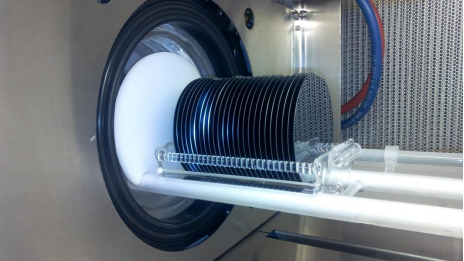

·Iityhubhu zeQuartz Furnace:Ibalulekile kwiinkqubo ezifana nokusasazwa, i-oxidation, kunye nokufakelwa, ezi ityhubhu ziqinisekisa uzinzo oluphezulu lobushushu kunye nokusebenza kakuhle ngexesha lokwenziwa kwe-semiconductor.

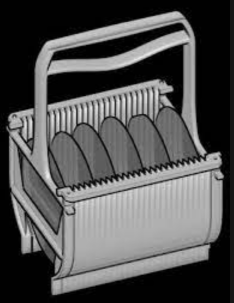

·Izikhitshane zeQuartz:Isetyenziselwa ukuthutha kunye nokusetyenzwa kwee-wafers ze-silicon, izikhephe ze-quartz ziququzelela ukuveliswa kwebhetshi kwiinkqubo zokusasazwa.

2. Izixhobo zoBubushushu obuphantsi:

Iringi zeQuartz:Ukudityaniswa kwenkqubo yokudibanisa, iindandatho ze-quartz zithintela ukungcola kunye nokuqinisekisa ukuveliswa okuchanekileyo ngexesha le-lithography kunye nepateni.

·Iibhaskithi zokucoca iiQuartz kunye neeTanki:Ezi zixhobo zibalulekile ekucoceni ii-silicone wafers. Kufuneka baxhathise i-asidi kunye ne-alkali ngelixa benciphisa indawo yoqhagamshelwano ukuze kuphuculwe ukusebenza kakuhle kokucoca.

Ukuqukumbela

Ngelixa amacandelo e-quartz anokubonakala njengezinto ezincinci zokusetyenziswa kwinkqubo yokwenziwa kwe-semiconductor, adlala indima ebalulekileyo ekuqinisekiseni umgangatho kunye nokuthembeka kwezixhobo ze-semiconductor. Ngokutsho kweTechcet, izixhobo zeglasi zequartz ezicocekileyo zithatha malunga ne-90% yemveliso yonyaka yehlabathi kushishino lolwazi lwe-elektroniki.

Kwi-Semicera, sizinikele ekuqhubeleni phambili ishishini le-semiconductor ngokubonelela ngezinto eziphezulu zokusebenza kwe-quartz. Kanye njengoko izikhonkwane ziyimfuneko kwimfezeko yolwakhiwo, ngokunjalo iquartz yokwenziwa kwesemiconductor.

2. Izixhobo zoBubushushu obuphantsi:

·Amakhonkco e-quartz: Ukudibanisa kwinkqubo yokubhala, i-quartz rings ikhusela ukungcoliswa kunye nokuqinisekisa ukuveliswa okuchanekileyo ngexesha le-lithography kunye nepateni.

·Iibhasikithi zokuCoca iiQuartz kunye neeTanki: La macandelo abalulekile ekucoceni ii-silicone wafers. Kufuneka baxhathise i-asidi kunye ne-alkali ngelixa benciphisa indawo yoqhagamshelwano ukuze kuphuculwe ukusebenza kakuhle kokucoca.

Ukuqukumbela

Ngelixa amacandelo e-quartz anokubonakala njengezinto ezincinci zokusetyenziswa kwinkqubo yokwenziwa kwe-semiconductor, adlala indima ebalulekileyo ekuqinisekiseni umgangatho kunye nokuthembeka kwezixhobo ze-semiconductor. Ngokutsho kweTechcet, izixhobo zeglasi zequartz ezicocekileyo zithatha malunga ne-90% yemveliso yonyaka yehlabathi kushishino lolwazi lwe-elektroniki.

Kwi-Semicera, sizinikele ekuqhubeleni phambili ishishini le-semiconductor ngokubonelela ngezinto eziphezulu zokusebenza kwe-quartz. Kanye njengoko izikhonkwane ziyimfuneko kwimfezeko yolwakhiwo, ngokunjalo iquartz yokwenziwa kwesemiconductor.