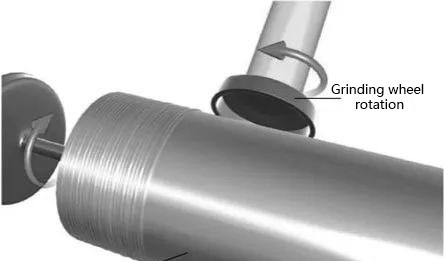

Ukuqengqeleka kubhekisa kwinkqubo yokusila idayamitha yangaphandle yesilicon intonga enye yekristale ibe yintonga enye yekristale yobukhulu obufunekayo kusetyenziswa ivili lokusila idayimani, kunye nokusila umphezulu osicaba wesalathiso okanye indawo yokubeka intonga yekristale enye.

Umphandle wedayamitha yangaphandle yentonga enye yekristale elungiselelwe sisithando somlilo sekristale ayigudi kwaye ithe tyaba, kwaye ububanzi bayo bukhulu kunobubanzi be-silicon wafer esetyenziswe kwisicelo sokugqibela. Ububanzi bentonga efunekayo bunokufumaneka ngokuqengqeleka kobubanzi obungaphandle.

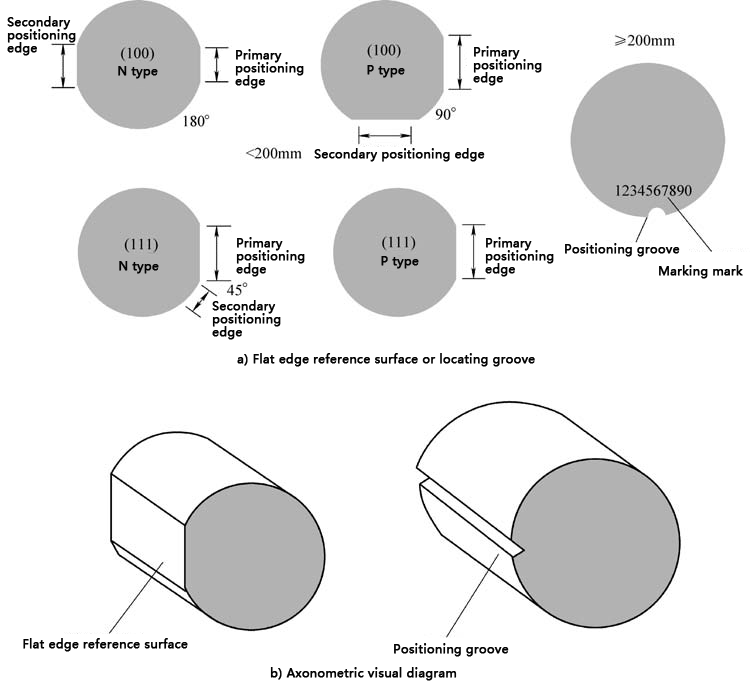

Ilitye lokusila linomsebenzi wokusila umphezulu wesalathiso somphetho osicaba okanye igroove yokubeka i-silicon enye intonga yekristale, oko kukuthi, ukwenza uvavanyo olubhekiselele kwintonga enye yekristale enobubanzi obufunekayo. Kwakwesi sixhobo sokungqusha esinye, umphezulu osicaba wesalathiso somphezulu okanye indawo yokubeka intonga yekristale enye iyaphantsi. Ngokubanzi, iintonga zekristale enye enobubanzi obungaphantsi kwe-200mm zisebenzisa umphezulu wesalathiso osicaba, kunye neentonga zekristale enye enobubanzi obuyi-200mm nangaphezulu zisebenzisa iigrooves. Iintonga zekristale enye enobubanzi obuyi-200mm nazo zinokwenziwa ngemiphezulu yesalathiso esisicaba njengoko kufuneka. Injongo yendawo yesalathiso ye-crystal rod enye kukuhlangabezana neemfuno ze-automated positioning operation yenkqubo yokwenziwa kwesekethe; ukubonisa ukuqhelaniswa nekristale kunye nohlobo lwe-conductivity ye-silicon wafer, njl., ukuququzelela ulawulo lwemveliso; indawo ephambili yokumisa okanye i-groove yokumisa i-perpendicular ukuya <110> isalathiso. Ngexesha lenkqubo yokupakisha i-chip, inkqubo yokudayela inokubangela ukucandeka kwendalo kwe-wafer, kwaye ukubeka indawo kunokuthintela ukuveliswa kwamaqhekeza.

Iinjongo eziphambili zenkqubo yokujikeleza zibandakanya: Ukuphucula umgangatho womphezulu: Ukujikeleza kunokususa i-burrs kunye nokungalingani kumphezulu wee-silicone wafers kunye nokuphucula ukugudiseka komphezulu we-silicon wafers, ebaluleke kakhulu kwi-photolithography elandelayo kunye ne-etching systems. Ukunciphisa uxinzelelo: Uxinzelelo lunokuveliswa ngexesha lokusikwa kunye nokusetyenzwa kwee-wafers ze-silicon. Ukujikeleza kunokunceda ukukhulula olu xinzelelo kwaye kuthintele amaqhekeza e-silicon ekwaphukeni kwiinkqubo ezilandelayo. Ukuphucula amandla oomatshini be-silicon wafers: Ngexesha lenkqubo yokujikeleza, imiphetho ye-silicon wafers iya kuba mde, enceda ekuphuculeni amandla omatshini we-silicon wafers kunye nokunciphisa umonakalo ngexesha lokuthuthwa kunye nokusetyenziswa. Ukuqinisekisa ukuchaneka komgangatho: Ngokurhangqwa, ukuchaneka komda wee-silicon wafers kunokuqinisekiswa, okubalulekileyo kukwenziwa kwezixhobo ze-semiconductor. Ukuphucula iipropathi zombane ze-silicon wafers: Ukusetyenzwa komphetho wee-silicon wafers kunempembelelo ebalulekileyo kwiipropathi zabo zombane. Ukujikeleza kunokuphucula iimpawu zombane ze-silicon wafers, ezifana nokunciphisa ukuvuza kwangoku. I-Aesthetics: Imida yee-silicone wafers zigudile kwaye zintle ngakumbi emva kokujikeleza, nto leyo eyimfuneko kwiimeko ezithile zokusetyenziswa.

Ixesha lokuposa: Jul-30-2024