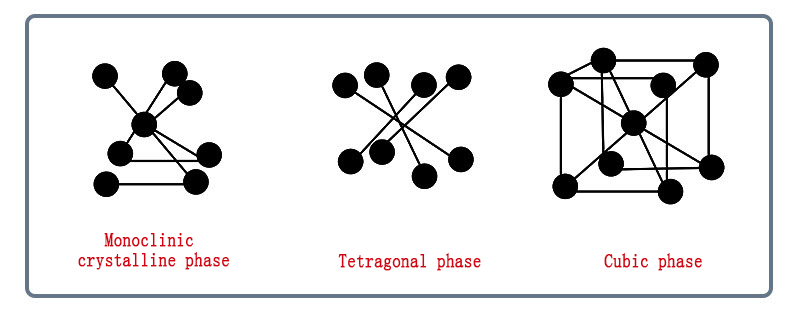

I-zirconia ceramicszimhlophe, tyheli okanye zingwevu xa ziqulathe ukungcola, kwaye ziqulathe ngokubanzi i-HfO2, ekungekho lula ukwahlula. Kukho i-crystal states ezintathu ze-ZrO2 ecocekileyo phantsi koxinzelelo oluqhelekileyo.

■Ubushushu obuphantsi be-monoclinic (m-ZrO2)■Ubushushu obuphakathi be-tetragonal (t-ZrO2)■Ubushushu obuphezulu cubic (c-ZrO2)

Ezi ntlobo zintathu zingentla zekristale zikhona kumanqanaba obushushu ahlukeneyo, kwaye kukho olu budlelwane bulandelayo benguqu:

Iimpawu zeeramics ze-zirconia

Hindawo yokunyibilika

Indawo yokunyibilika kweZirconia yile: 2715 ℃, ingasetyenziswa njengesixhobo sokumelana nobushushu obuphezulu.

Ubunzima obuphezulu, ukumelana nokunxiba kakuhle

Ngokobulukhuni bukaMohs: isafire >I-zirconia ceramics> Iglasi yeCorning > iAluminiyam ingxubevange yemagnesium > Iglasi epholileyo > i-polycarbonate

Amandla aphezulu kunye nokuqina

Amandla e-zirconia anokufikelela: 1500MPa

I-conductivity ephantsi ye-thermal kunye ne-coefficient yokwandisa

Phakathi kwezinto eziqhelekileyo ze-ceramic, i-thermal conductivity yayo iphantsi (1.6-2.03W / (mk)), kwaye i-coefficient yokwandiswa kwe-thermal isondele kwintsimbi.

Ukusebenza kakuhle kombane

I-dielectric constant ye-zirconia ngamaxesha e-3 yesafire, kwaye umqondiso unzima ngakumbi.

Ukusetyenziswa kweekeramics ze-zirconia

I-zirconia ceramicszisetyenziswa ngokubanzi kwi-elektroniki ye-3C, unxibelelwano lwamehlo, ukunxitywa kwe-smart, i-biomedical, ubucwebe, ubomi bemihla ngemihla, izinto eziphikisayo kunye nezinye iinkalo.

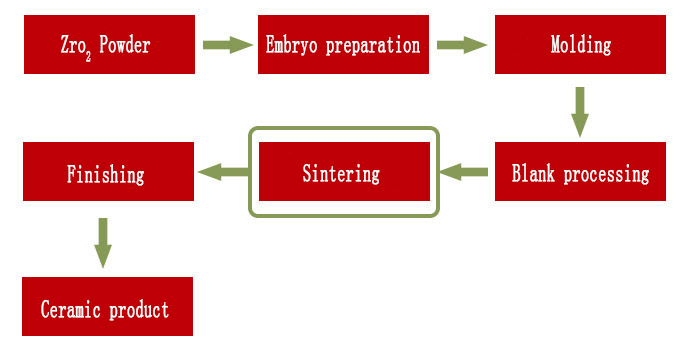

Iteknoloji yokulungiselela imveliso ye-zirconia ceramic

Sintering yinkqubo ebaluleke kakhulu ekulungiseleleniiiceramics ze-zirconia, umgangatho we-sintering uya kuchaphazela ngokuthe ngqo ukulungiswa kwe-ceramic, kuphela ukushisa kwe-sintering kulungelelaniswa ngokufanelekileyo, umzimba wayo we-embryo uya kufezeka. Uxinzelelo lwe-sintering yeyona ndlela isetyenziswa kakhulu.

Ngenxa yokuba izinto ze-ceramic ezicocekileyo ngamanye amaxesha zinzima ukucwina, phantsi kweemeko zokusebenza, ezinye izongezo ze-sintering zivame ukwaziswa ukuba zenze indawo ephantsi yokunyibilika kwesisombululo esiqinileyo, isigaba seglasi okanye esinye isigaba solwelo, ukukhuthaza ukulungiswa kwakhona kwamasuntswana kunye nokuhamba kwe-viscous. , ukuze ufumane imveliso eshinyeneyo, kodwa nokunciphisa ubushushu be-sintering.

Ukunciphisa ubungakanani bepowder kangangoko kunokwenzeka kwakhona enye yemilinganiselo ebalulekileyo yokukhuthaza i-sintering. Kuba okukhona umgubo ucotha kakhulu, kokukhona uphezulu amandla angaphezulu, kokukhona ukuthambisa kulula. Kwizinto ze-ceramic kunye neemveliso ezineemfuno eziqhelekileyo zokusebenza, i-non-pressure sintering yeyona ndlela ifanelekileyo kunye neyoqoqosho ye-sintering.

Ixesha lokuposa: Jul-24-2023