Izihlandlo ezininzi zemveliso yemizi-mveliso ziya kusetyenziswa kwialumina ceramiciinxalenye, ezibonisa ngokupheleleyo ukuba iinxalenye ze-ceramic xa kuthelekiswa nezinye izinto ezinomsebenzi ophezulu kakhulu, ziya kuthandwa kwishishini. Zinokwenziwa njani iziqwenga zeceramic ezilungileyo kangaka?

Okwangoku, iiseramikhi ze-alumina zingasetyenziselwa ubukhulu becala isixhobo sokulinganisa ubushushu thermocouple thermometer ityhubhu ekhuselayo, ityhubhu yokugquma; Kwangaxeshanye, inokusetyenziswa kwakhona kwityhubhu yomlilo yesithando somlilo sokuxhathisa, isithando somlilo sokulinga kunye nesithando somlilo sokushisa. Ukongeza, uhlalutyo lweekhemikhali zensimbi zetyhubhu yekhabhoni kunye netyhubhu yesulfure, kunye nokunye ukumelana nobushushu obuphezulu, iasidi kunye nealkali kunye nealkali yokumelana nokumelana nezixhobo zesixhobo sokusebenzisa izixhobo ze-ceramic porcelain njengesiseko.

I-alumina ceramicumkhono wokufudumeza

Kubonakala ngathi iiseramics ze-alumina zisebenzisa amandla ayo omatshini anamandla, ukuxhathisa impembelelo ye-thermal; Ukuqhuba kakuhle kwe-thermal kunye nokugquma; Kunye neenzuzo eziphezulu zokuthambisa ubushushu, kumashishini amaninzi asetyenziswa ngendlela eluncedo, ebalulekileyo.

Inkqubo yemveliso yeiiseramikhi zealuminangokuqhelekileyo yahlulahlulwe ngamanyathelo amathathu aphambili, ukuze kuqinisekiswe ukuba umgangatho wayo kufuneka wenziwe kwikhonkco ngalinye, eyokuqala kukulungiselela umgubo weceramic njengento ekrwada. Ukuba ukuveliswa kweendawo zeporcelain ze-ceramic zendalo yonke, zilungele ukutshiza umgubo omisiweyo wegranulation kwimarike; Ukuba ufuna ukulawula izithako ngokwakho, kuya kufuneka uthenge ilitye lokusila kunye nebhola kunye nesomisi sokutshiza.

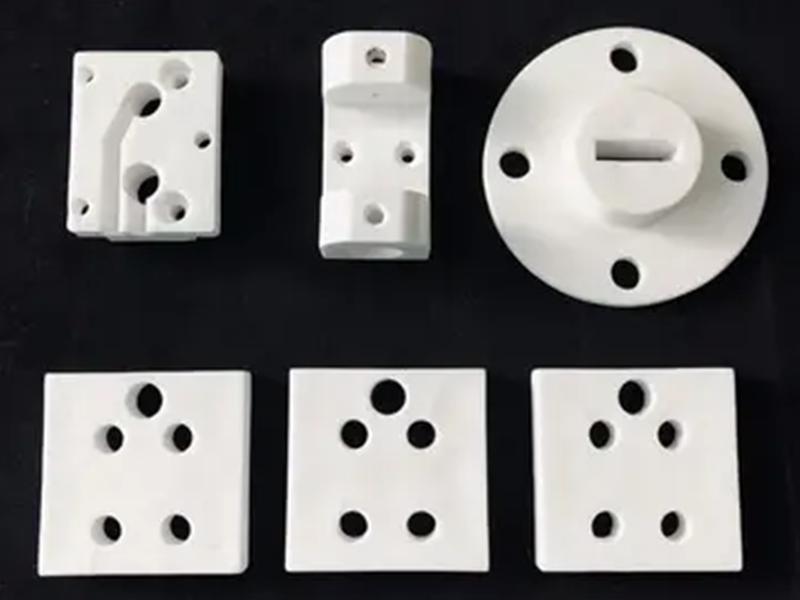

Emva kokuba unemathiriyeli ekrwada, unokuqalisa ukucofa ukubumba. Kwiimveliso ze-flake ezingaphantsi kwe-2 mm, unokuqwalasela ukusebenzisa indlela ye-gelatinized; Kwaye ngaphezu kwe-2 mm yeengxenye ze-ceramic porcelain zingaqwalaselwa ukuba zisebenzise indlela yokucofa ukubumba.

Kulandelwa sintering kunye nokusetyenzwa, ukuba izixa ezikhulu sintered alumina iiseramikhi zingasetyenziselwa ukuveliswa okuqhubekayo kwi tonela; Ukucutshungulwa kugqitywa ngokuxhomekeke kubunzima bemveliso. Ezinye ii-ceramics azidingeki ukuba ziqhutywe kwaye zingathengiswa ngokuthe ngqo ngokuvula ukubumba.

Ixesha lokuposa: Jun-05-2023