I-Silicon nitride (Si₃N₄) iiseramics, njengeeseramics eziphucukileyo zolwakhiwo, zineempawu ezibalaseleyo ezifana nokumelana nobushushu obuphezulu, ukomelela okuphezulu, ukuqina okuphezulu, ubulukhuni obuphezulu, ukuxhathisa kokuhamba, ukumelana ne-oxidation, kunye nokumelana nokunxiba. Ukongeza, banikezela ukuxhathisa ukothuka kwe-thermal, iipropathi ze-dielectric, ukuhanjiswa kwe-thermal ephezulu, kunye nokusebenza okugqwesileyo kokuhanjiswa kwe-electromagnetic wave. Ezi mpawu zibalaseleyo ezibanzi zenza ukuba zisetyenziswe ngokubanzi kumacandelo ezakhiwo ezintsonkothileyo, ngakumbi kwi-aerospace kunye nezinye iindawo zobugcisa obuphezulu.

Nangona kunjalo, i-Si₃N₄, iyikhompawundi enezibophelelo eziqinileyo ezidibeneyo, inesakhiwo esizinzile esenza ukuba ukuxinana kuxinaniso oluphezulu kube nzima ngokusasazwa kwemeko eqinileyo yodwa. Ukukhuthaza i-sintering, i-sintering aids, njenge-oxides yensimbi (i-MgO, i-CaO, i-Al₂O₃) kunye nee-oksidi zomhlaba ezinqabileyo (Yb₂O₃, Y₂O₃, Lu₂O₃, CeO₂), zongezwa ukuququzelela ukuxinana nge-liquid-phase sintering mechanism.

Okwangoku, itekhnoloji yesixhobo se-semiconductor yehlabathi iqhubela phambili isiya kumandla ombane aphezulu, imisinga emikhulu, kunye nokuxinana kwamandla amakhulu. Uphando kwiindlela zokwenza iiseramics zeSi₃N₄ lubanzi. Eli nqaku lizisa iinkqubo ze-sintering eziphucula ngokufanelekileyo ukuxinana kunye neempawu ezibanzi zoomatshini be-silicon nitride ceramics.

Iindlela eziqhelekileyo zeSintering zeSi₃N₄ Ceramics

Ukuthelekiswa kokuSebenza kweSi₃N₄ Ceramics elungiselelwe ziindlela ezahlukeneyo zeSintering

1. I-Reactive Sintering (RS):I-reactive sintering yayiyeyona ndlela yokuqala eyayisetyenziswa ekulungiseleleni i-Si₃N₄ iiseramikhi. Ilula, ingabizi kakhulu, kwaye iyakwazi ukwenza iimilo ezintsonkothileyo. Nangona kunjalo, inomjikelo wemveliso omde, ongekho luncedo kwimveliso yomgangatho weshishini.

2. I-Pressureless Sintering (PLS):Le yeyona nkqubo isisiseko kwaye elula sintering. Nangona kunjalo, ifuna umgangatho ophezulu we-Si₃N₄ imathiriyeli eluhlaza kwaye ihlala ikhokelela kwiiseramikhi ezinoxinano olusezantsi, ukucutheka okubalulekileyo, kunye notyekelo lokuqhekeka okanye ukonakala.

3. I-Hot-Press Sintering (HP):Ukusetyenziswa koxinzelelo lwe-uniaxial mechanical kwandisa amandla okuqhubela phambili kwi-sintering, ukuvumela ukuba ii-ceramics ezixineneyo ziveliswe kumaqondo okushisa angama-100-200 ° C angaphantsi kunezo zisetyenziselwa ukuhlambalaza okungenaxinzelelo. Le ndlela iqhele ukusetyenziselwa ukwenza iiseramikhi ezimile okwebhloko kodwa kunzima ukuhlangabezana nobukhulu kunye neemfuno zokumila kwemathiriyeli engaphantsi.

4. I-Spark Plasma Sintering (SPS):I-SPS iphawulwa ngokuntywila ngokukhawuleza, ukucokiswa kweenkozo, kunye nokunciphisa amaqondo obushushu e-sintering. Nangona kunjalo, i-SPS ifuna utyalo-mali olubalulekileyo kwizixhobo, kwaye ukulungiswa kwe-thermal conductivity ephezulu ye-Si₃N₄ iiseramics nge-SPS isekwinqanaba lovavanyo kwaye ayikabikho kwimizi-mveliso.

5. I-Gas-Pressure Sintering (GPS):Ngokusebenzisa uxinzelelo lwegesi, le ndlela inqanda ukubola kwe-ceramic kunye nokulahlekelwa kwesisindo kumaqondo aphezulu. Kulula ukuvelisa ii-ceramics ezinoxinano oluphezulu kwaye kwenza ukuba ibhetshi ivelise. Nangona kunjalo, inyathelo elinye le-gas-pressure sintering process liyasokola ukuvelisa amacandelo ezakhiwo ezinombala ofanayo wangaphakathi nangaphandle kunye nesakhiwo. Ukusebenzisa amanqanaba amabini okanye inkqubo ye-sintering ye-multi-step inokunciphisa kakhulu umxholo we-oksijini ye-intergranular, ukuphucula ukuhanjiswa kwe-thermal, kunye nokuphucula iipropati ezipheleleyo.

Nangona kunjalo, ubushushu obuphezulu be-sintering enamanyathelo amabini oxinzelelo lwegesi lukhokelele uphando lwangaphambili ukuba lugxile ikakhulu ekulungiseleleni i-Si₃N₄ ii-substrates ze-ceramic ezinomgangatho ophezulu we-thermal conductivity kunye namandla okugoba kwegumbi. Uphando malunga neeseramics ze-Si₃N₄ ezineempawu ezibanzi zoomatshini kunye neempawu zoomatshini bobushushu obuphezulu bulinganiselwe.

I-Gas-Pressure ye-Sintering Method ye-Sintering ye-Si₃N₄

U-Yang Zhou kunye noogxa baseChongqing University of Technology basebenzise inkqubo yokuncedisa i-sintering ye-5 wt.% Yb₂O₃ + 5 wt.% Al₂O₃ ukulungiselela ii-ceramics ze-Si₃N₄ zisebenzisa zombini inyathelo elinye kunye nezinyathelo ezimbini ze-gas-pressure sintering process kwi-1800 ° C. I-Si₃N₄ iiseramics eziveliswe yinkqubo ye-sintering enamanyathelo amabini ayenoxinano oluphezulu kunye neempawu ezingcono zoomatshini. Oku kulandelayo kushwankathela iziphumo zenyathelo elinye kunye namanyathelo amabini e-gas-pressure sintering process kwi-microstructure kunye ne-mechanical properties ze-Si₃N₄ ze-ceramic components.

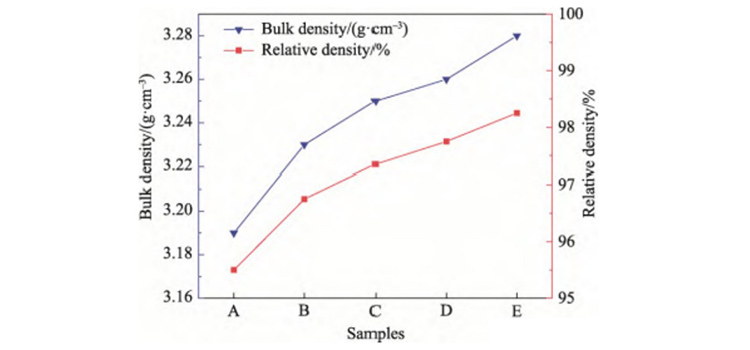

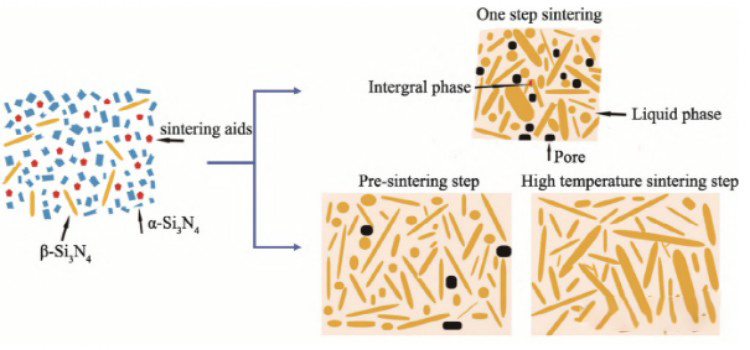

Uxinaniso Inkqubo yoxinaniso ye-Si₃N₄ ibandakanya amanqanaba amathathu, kunye nokudibana phakathi kwezigaba. Inqanaba lokuqala, ukuhlengahlengiswa kwamasuntswana, kunye nenqanaba lesibini, ukunyibilika kwemvula, zezona zigaba zibalulekileyo zokuxinana. Ixesha elaneleyo lokuphendula kwezi zigaba liphucula kakhulu uxinaniso lwesampulu. Xa iqondo lokushisa langaphambili le-sintering yenkqubo ye-sintering yamanyathelo amabini ibekwe kwi-1600 ° C, i-β-Si₃N₄ iinkozo zenza isakhelo kwaye zenze ii-pores ezivaliweyo. Emva kwe-sintering yangaphambili, ukufudumeza okuqhubekayo phantsi kobushushu obuphezulu kunye noxinzelelo lwe-nitrogen kukhuthaza ukuhamba kwesigaba se-liquid kunye nokuzaliswa, okunceda ukuphelisa ii-pores ezivaliweyo, ukuphucula ngakumbi ukuxinwa kwee-ceramics ze-Si₃N₄. Ke ngoko, iisampulu eziveliswe yinkqubo ye-sintering enamanyathelo amabini abonisa ukuxinana okuphezulu kunye noxinzelelo olunxulumeneyo kunezo ziveliswa ngenyathelo elinye.

Isigaba kunye neMicrostructure Ngexesha le-sintering yenyathelo elinye, ixesha elikhoyo lokuhlengahlengiswa kwamasuntswana kunye nokusabalalisa komda wengqolowa lilinganiselwe. Kwinkqubo ye-sintering yamanyathelo amabini, inyathelo lokuqala liqhutyelwa kwiqondo lokushisa eliphantsi kunye noxinzelelo oluphantsi lwegesi, okwandisa ixesha lokuhlengahlengiswa kwe-particle kwaye kubangele iinkozo ezinkulu. Iqondo lokushisa liye landa ukuya kwinqanaba eliphezulu lobushushu, apho iinkozo ziqhubeka zikhula ngenkqubo yokuvuthwa kwe-Ostwald, inika i-ceramics ye-Si₃N₄ ephezulu.

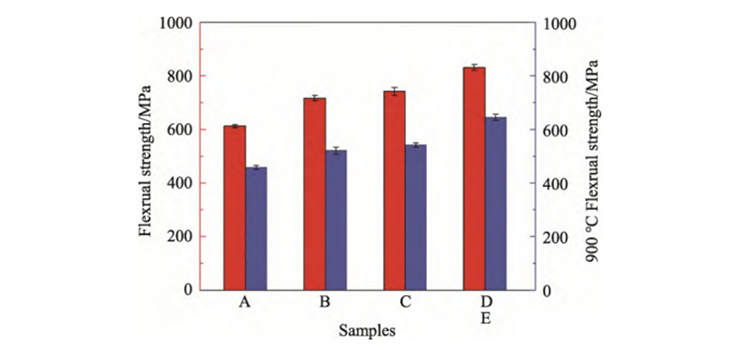

IiPropati zoomatshini Ukuthambisa kwesigaba se-intergranular kumaqondo obushushu aphezulu sesona sizathu siphambili sokunciphisa amandla. Kwi-sintering yenyathelo elinye, ukukhula okungaqhelekanga okuziinkozo kudala ama-pores amancinci phakathi kweenkozo, ezithintela ukuphuculwa okubalulekileyo kumandla aphezulu obushushu. Nangona kunjalo, kwinkqubo ye-sintering enamanyathelo amabini, isigaba seglasi, sisasazwe ngokulinganayo kwimida yeenkozo, kunye neenkozo ezinobungakanani obulinganayo zonyusa amandla e-intergranular, okukhokelela kumandla aphezulu wokugoba wobushushu obuphezulu.

Ukuqukumbela, ukubamba ixesha elide ngexesha le-sintering yenyathelo elinye kunokunciphisa ngokufanelekileyo i-porosity yangaphakathi kunye nokufezekisa umbala wangaphakathi ofanayo kunye nokwakheka kodwa kunokukhokelela ekukhuleni okungaqhelekanga okuziinkozo, okuthoba iipropati ezithile zoomatshini. Ngokusebenzisa inkqubo ye-sintering enamanyathelo amabini-ukusebenzisa iqondo lobushushu eliphantsi langaphambi kwe-sintering ukwandisa ixesha lokuhlengahlengiswa kwamasuntswana kunye nobushushu obuphezulu ukukhuthaza ukukhula okuziinkozo okufanayo-i-ceramic ye-Si₃N₄ enoxinano lwe-98.25%, i-microstructure efanayo, kunye neempawu ezigqwesileyo zomatshini ezigqwesileyo. inokulungiswa ngempumelelo.

| Igama | ISubstrate | Ukuqulunqwa kwe-epitaxial layer | Inkqubo ye-Epitaxial | Epitaxial medium |

| I-silicon homoepitaxial | Si | Si | I-Vapor Phase Epitaxy (VPE) | SiCl4+H2 |

| I-silicon heteroepitaxial | Isafire okanye i-spinel | Si | I-Vapor Phase Epitaxy (VPE) | SiH₄+H₂ |

| I-GaAs i-homoepitaxial | IiGaAs | IiGaAs IiGaAs | I-Vapor Phase Epitaxy (VPE) | I-AsCl₃+Ga+H₂ (Ar) |

| IiGaAs | IiGaAs IiGaAs | I-Molecular Beam Epitaxy (MBE) | Ga+Njenge | |

| GaAs heteroepitaxial | IiGaAs IiGaAs | GaAlAs/GaAs/GaAlAs | I-Liquid Phase Epitaxy (LPE) Isigaba soMphunga (VPE) | I-Ga+Al+CaAs+ H2 Ga+AsH3+PH3+CHl+H2 |

| I-GaP ye-homoepitaxial | I-GaP | I-GaP(GaP;N) | I-Liquid Phase Epitaxy (LPE) I-Liquid Phase Epitaxy (LPE) | IGa+GaP+H2+(NH3) IGa+GaAs+GaP+NH3 |

| Superlattice | IiGaAs | GaAlAs/GaAs (umjikelo) | I-Molecular Beam Epitaxy (MBE) MOCVD | Ca, Njengoko, Al I-GaR₃+AlR3+AsH3+H2 |

| InP homoepitaxial | InP | InP | I-Vapor Phase Epitaxy (VPE) I-Liquid Phase Epitaxy (LPE) | PCl3+Ku+H2 Kwi+InAs+GaAs+InP+H₂ |

| Si/GaAs Epitaxy | Si | IiGaAs | I-Molecular Beam Epitaxy (MBE) MOGVD | Ga, njengoko I-GaR₃+AsH₃+H₂ |

Ixesha lokuposa: Dec-24-2024