Yintoni iSilicon Carbide SiC Coating?

I-Silicon Carbide (i-SiC) i-coating yi-teknoloji eguqukayo enika ukhuseleko olukhethekileyo kunye nokusebenza kwiindawo eziphezulu zokushisa kunye neekhemikhali ezisebenzayo. Olu tyalo luphucukileyo lusetyenziswa kwizinto ezahlukeneyo, kubandakanya igraphite, iiseramics, kunye neentsimbi, ukomeleza iipropathi zazo, zibonelela ngokhuseleko oluphezulu ngokuchasene nomhlwa, i-oxidation kunye nokunxiba. Iipropathi ezikhethekileyo zeengubo ze-SiC, kubandakanya ukucoceka kwazo okuphezulu, ukuhanjiswa kwe-thermal okugqwesileyo, kunye nokuthembeka kwesakhiwo, kubenza balungele ukusetyenziswa kumashishini afana ne-semiconductor yokuvelisa, i-aerospace, kunye ne-high-performance technologies yokufudumeza.

Izinto eziluncedo zokugquma i-silicon carbide

Ukwaleka kwe-SiC kubonelela ngeengenelo ezininzi eziphambili eziyahlulahlula kwiingubo zokhuselo zemveli:

- -Uxinano oluphezulu kunye noKuxhathisa ukuMhlwa

- Ulwakhiwo lwe-cubic SiC luqinisekisa ukuxinana okuphezulu koxinaniso, luphucula kakhulu ukuxhathisa umhlwa kunye nokwandisa ixesha lokuphila lecandelo.

- -Ugutyulo oluKhethekileyo lweMilo entsonkothileyo

- I-SiC coating idume ngokugquma kwayo kakuhle, nakwimingxuma emincinci eyimfama enobunzulu ukuya kuthi ga kwi-5 mm, inika ubukhulu obufanayo ukuya kuthi ga kwi-30% kweyona ndawo inzulu.

- -Customizable Surface Uburhabaxa

- Inkqubo yokwaleka iyaguquguquka, ivumela ukurhabaxa komhlaba okwahlukileyo ukuze ihambelane neemfuno ezithile zesicelo.

- -High Purity Coating

- Iphunyezwe ngokusetyenziswa kweegesi ezicocekileyo, i-SiC coating ihlala inyulu, kunye namanqanaba okungcola angaphantsi kwe-5 ppm. Olu coceko lubalulekile kumashishini aphezulu afuna ukuchaneka kunye nokungcoliseka okuncinci.

- -Ukuzinza kweThermal

- I-silicon carbide i-ceramic coating inokumelana nokushisa okukhulu, kunye nokushisa okuphezulu okusebenzayo ukuya kwi-1600 ° C, iqinisekisa ukuthembeka kwiindawo eziphezulu zokushisa.

Usetyenziso lweSiC Coating

Iingubo ze-SiC zisetyenziswa ngokubanzi kuwo wonke amashishini ahlukeneyo ngenxa yokusebenza kwawo okungenakulinganiswa kwiindawo ezicela umngeni. Izicelo eziphambili ziquka:

- -I-LED kunye noShishino lweSolar

- Ukwaleka kukwasetyenziselwa amacandelo e-LED kunye nokuveliswa kweeseli zelanga, apho ukucoceka okuphezulu kunye nokumelana nobushushu kubalulekile.

- -Ubuchwephesha bokufudumeza obuphezulu

- I-graphite ene-SiC-coated kunye nezinye izinto ziqeshwe kwizinto zokufudumeza kwiziko kunye ne-reactors ezisetyenziselwa iinkqubo ezahlukeneyo zoshishino.

- -Semiconductor Ukukhula kweCrystal

- Ekukhuleni kwekristale ye-semiconductor, iingubo ze-SiC zisetyenziselwa ukukhusela amacandelo abandakanyekayo ekukhuleni kwe-silicon kunye nezinye iikristale ze-semiconductor, ezinikezela ukuxhathisa okuphezulu kwe-corrosion kunye nokuzinza kwe-thermal.

- -Silicon kunye ne-SiC Epitaxy

- Iingubo ze-SiC zisetyenziselwa amacandelo kwinkqubo yokukhula kwe-epitaxial ye-silicon kunye ne-silicon carbide (SiC). Ezi zogquma zithintela i-oxidation, ukungcoliseka, kunye nokuqinisekisa umgangatho we-epitaxial layers, obaluleke kakhulu kwimveliso yezixhobo eziphezulu ze-semiconductor.

- -IiNkqubo ze-Oxidation kunye ne-Diffusion

- Amacandelo e-SiC-coated asetyenziswa kwiinkqubo ze-oxidation kunye nokusabalalisa, apho zibonelela ngomqobo osebenzayo ngokuchasene nokungcola okungafunekiyo kunye nokuphucula ukunyaniseka kwemveliso yokugqibela. Iingubo ziphucula ixesha elide kunye nokuthembeka kwamacandelo abonakaliswe kwi-high-temperature oxidation okanye amanyathelo okusabalalisa.

Iimpawu eziphambili zeSiC Coating

Iingubo ze-SiC zibonelela ngoluhlu lweepropathi eziphucula ukusebenza kunye nokuqina kwezinto ezigqunywe sic:

- -Isakhiwo seCrystal

- Ukwaleka kuvame ukwenziwa ngeβ 3C (cubic) ikristaleUlwakhiwo, oluyi-isotropic kwaye lubonelela ngokhuseleko olululo lwe-corrosion.

- -Ukuxinana kunye nePorosity

- Iingubo ze-SiC zinobuninzi be3200 kg/m³kunye nomboniso0% porosity, ukuqinisekisa ukusebenza okuvuzayo kwe-helium kunye nokumelana nokuthotywa okusebenzayo.

- -IiPropati zeThermal kunye nezoMbane

- I-coating ye-SiC ine-conductivity ephezulu ye-thermal(200 W/m·K)kunye nokumelana nombane okugqwesileyo(1MΩ·m), okwenza kube yinto efanelekileyo kwizicelo ezifuna ukulawulwa kobushushu kunye nokufakelwa kombane.

- -Amandla oomatshini

- Ngemodyuli elastiki ye450 GPA, Iingubo ze-SiC zibonelela ngamandla omatshini aphezulu, ukuphucula ukunyaniseka kwesakhiwo samacandelo.

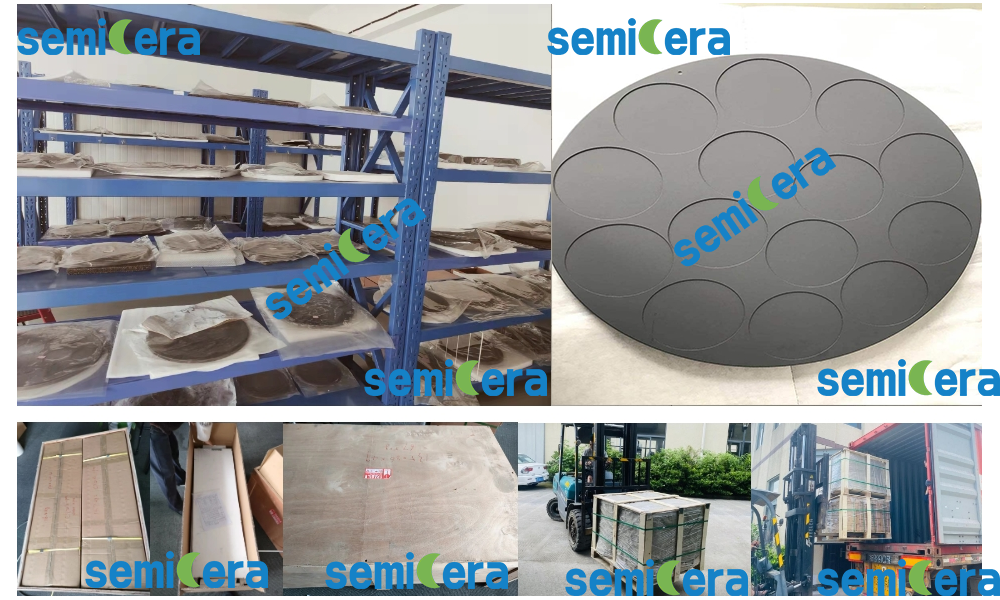

SiC silicon carbide Coating Inkqubo

I-coating ye-SiC isetyenziswa nge-Chemical Vapor Deposition (CVD), inkqubo ebandakanya ukubola kwe-thermal ye-gases ukufaka i-SiC layers kwi-substrate. Le ndlela yokubeka ivumela amazinga aphezulu okukhula kunye nolawulo oluchanekileyo phezu kobunzima bomaleko, onokuqala ukusuka10µm ukuya kuma-500µm, kuxhomekeke kwisicelo. Inkqubo yokugquma ikwaqinisekisa ukugqunywa okufanayo, nakwijiyometri entsonkothileyo njengemingxuma emincinci okanye enzulu, edla ngokuba ngumngeni kwiindlela zokwaleka zesintu.

Izixhobo ezifanelekileyo kwiSiC Coating

Iingubo ze-SiC zinokufakwa kuluhlu olubanzi lwezixhobo, kubandakanya:

- -IGraphite kunye neCarbon Composites

- Igraphite yindawo edumileyo yokugquma iSiC ngenxa yeempawu zayo ezibalaseleyo zobushushu kunye nombane. Ukwaleka kwe-SiC kungena kwi-graphite kwi-porous structure, idala ibhondi eyomeleziweyo kunye nokubonelela ngokhuseleko oluphezulu.

- -IiCeramics

- Iiseramics ezisekelwe kwi-silicon ezifana ne-SiC, i-SiSiC, kunye ne-RSiC zixhamla kwiingubo ze-SiC, eziphucula ukuxhathisa kwazo kunye nokuthintela ukusasazwa kokungcola.

Kutheni ukhetha i-SiC Coating?

Iingubo zomphezulu zibonelela ngesisombululo esiguquguqukayo kunye neendleko ezifanelekileyo kumashishini afuna ukucoceka okuphezulu, ukumelana nokubola, kunye nokuzinza kwe-thermal. Nokuba usebenza kwi-semiconductor, i-aerospace, okanye icandelo lokufudumeza elisebenza kakhulu, iingubo ze-SiC zihambisa ukhuseleko kunye nokusebenza okufunayo ukugcina ukugqwesa kokusebenza. Udibaniso lwesakhiwo se-cubic esinoxinaniso oluphezulu, iipropathi zomphezulu onokwenziwa ngokwezifiso, kunye nokukwazi ukugquma iijiyometri ezintsonkothileyo ziqinisekisa ukuba izinto ezigqunywe nge-sic zinokumelana nezona ndawo zinzima.

Ngolwazi oluthe kratya okanye ukuxoxa ngendlela isilicon carbide yokwambathisa ngeceramic enokuthi ixhamle ngayo isicelo sakho esithile, ncedaQhagamshelana nathi.

Ixesha lokuposa: Aug-12-2024