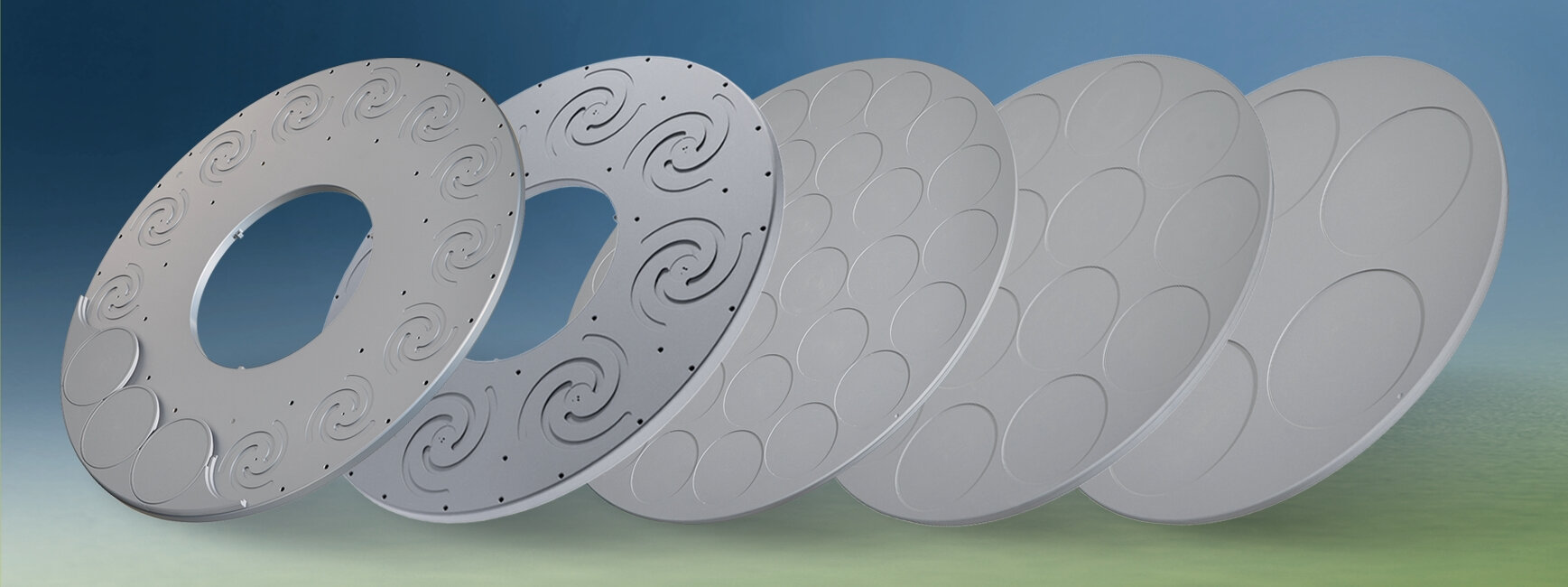

Iitreyi ze-silicon ze-carbide, ekwaziwa ngokuba ziitreyi zeSiC, zizinto ezibalulekileyo ezisetyenziselwa ukuthwala ii-silicone wafers kwinkqubo yokwenziwa kwesemiconductor. I-Silicon carbide ineepropathi ezigqwesileyo ezinjengokuqina okuphezulu, ukumelana nobushushu obuphezulu, kunye nokuxhathisa umhlwa, ke ngokuthe ngcembe ithatha indawo yezixhobo zemveli ezifana ne-quartz kunye neetreyi ze-ceramic kwishishini le-semiconductor. Ngophuhliso lweshishini le-semiconductor, ngakumbi kwimimandla ye-5G, izixhobo ze-optoelectronic, ii-elektroniki zamandla, njl., imfuno yeetreyi ze-silicon carbide nayo iyanda.

Semiceraiitreyi ze-silicon carbidesebenzisa iinkqubo ze-sintering eziphambili ngexesha lenkqubo yokuvelisa ukuqinisekisa ubuninzi obuphezulu kunye namandla eetreyi, ezibenza bakwazi ukugcina ukusebenza okuzinzileyo phantsi kweemeko ezinzima ezifana nokushisa okuphezulu kunye noxinzelelo oluphezulu. Kwangaxeshanye, i-coefficient ephantsi yokwandiswa kwe-thermal yeetreyi ze-silicon carbide inokunciphisa impembelelo yokutshintsha kobushushu ekusetyenzweni kokuchaneka.amaqhekeza e-silicon, ngaloo ndlela kuphuculwe izinga lemveliso yeemveliso.

Iiitreyi ze-silicon carbideephuhliswe yi Semicera ayilunganga kuphela ukusetyenzwa kwemveliamaqhekeza e-silicon, kodwa ingasetyenziswa ekwenzeni ii-silicon carbide wafers, ezibaluleke kakhulu kuphuhliso lwexesha elizayo loshishino lwesemiconductor. I-silicon carbide wafers inokuhamba okuphezulu kwe-electron kunye nokuhamba okungcono kwe-thermal, enokuphucula kakhulu ukusebenza kakuhle kunye nokusebenza kwezixhobo. Ke ngoko, imfuno yeetreyi ze-silicon carbide ezifanelekileyo kwimveliso yazo iyanda.

Ngokuqhubela phambili okuqhubekayo kobugcisa bokuvelisa i-semiconductor, uyilo kunye nenkqubo yokwenziwa kweetreyi ze-silicon carbide nazo ziyalungiswa. Kwixesha elizayo, i-Semicera iya kuqhubeka nokusebenza ekuphuculeni ukusebenza kwe-silicon carbide pallets ukuhlangabezana nemfuno yemarike yokuchaneka okuphezulu, ukuthembeka okuphezulu. Ukusetyenziswa ngokubanzi kwe-silicon carbide pallets akukhuthazi nje kuphela ukuphuhliswa kweenkqubo zokuvelisa i-semiconductor, kodwa kwakhona kunika inkxaso eqinile yokuzaliseka kweemveliso ze-elektroniki ezisebenzayo nezizinzileyo.

Ixesha lokuposa: Aug-30-2024