Silicon carbide eziko ityhubhuineengenelo zamandla aphezulu, ubunzima obuphezulu, ukumelana nokunxiba kakuhle, ukumelana nobushushu obuphezulu, ukumelana nokugqwala, ukuxhathisa ukothuka kwe-thermal, ukuguquguquka okuphezulu kwe-thermal, ukumelana ne-oxidation elungileyo njalo njalo. Isetyenziswa ikakhulu kwi-medium frequency casting, iziko lonyango lobushushu eyahlukeneyo, isinyithi, imboni yeekhemikhali, isinyithi esingeyoron kunye neminye imisebenzi.Silicon carbide eziko ityhubhuisetyenziswa ngokubanzi kwiziko lokutshisa i-metallurgical kunye ne-medium frequency frequency casting furnace, kwaye ubude bayo bunokwenziwa ngokweemfuno zokwenyani zesiza.

Iimpawu zeiityhubhu ze-silicon carbide eziko

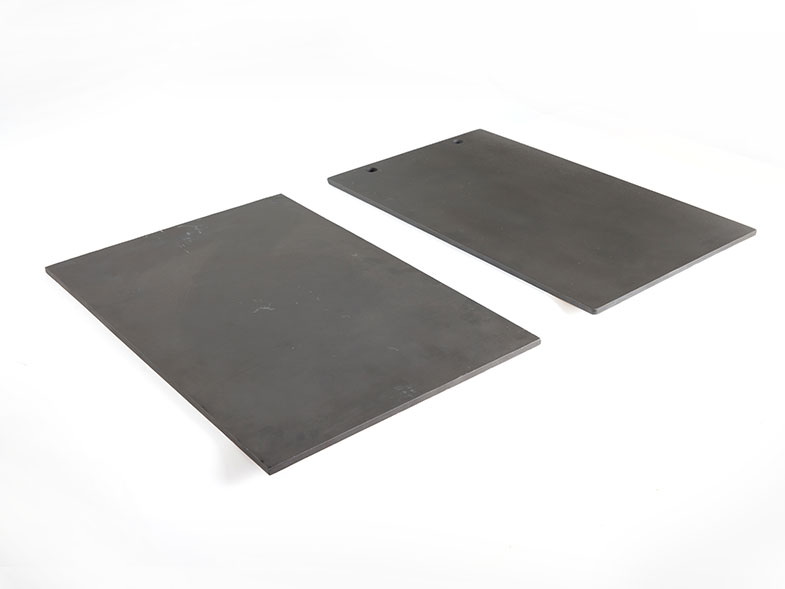

I-Silicon carbide furnace ityhubhu yimveliso egqwesileyo yesilicon carbide sintered kubushushu obuphezulu kunye nesilicon carbide njengeyona nto iphambili ekrwada. Ineenzuzo zokuxhathisa ubushushu obuphezulu, ukumelana nokugqwala, ukuguquguquka kwe-thermal okukhawulezayo, ukomelela okuphezulu, ukuqina okuphezulu, ukumelana nokunxiba kakuhle, ukuxhathisa ukothuka kwe-thermal, ukuguquguquka okukhulu kwe-thermal, ukumelana ne-oxidation elungileyo njalo njalo. Zombini iziphelo zixhotyiswe ngamahlahla akhethekileyo obushushu obuphezulu, ukubola kwesisombululo setsimbi kwizinto zokufudumeza zombane (kubandakanya intonga ye-silicon carbide, ucingo lwesithando sombane, njl. njl.) zinokuphetshwa ngokufanelekileyo, kwaye izikhombisi zingcono kunezo zonke iintlobo zeemveliso zegraphite. . I-silicon carbide furnace tube ine-thermal conductivity, ukumelana ne-oxidation, ukuxhathisa ukothuka kwe-thermal, ukumelana nobushushu obuphezulu, ukuzinza okuhle kweekhemikhali, ukuxhathisa okuqinileyo kwe-asidi, akukho mpendulo kwi-asidi eyomeleleyo kunye ne-alkali.

Silicon carbide eziko ityhubhuitekhnoloji yokuvelisa: imveliso egqityiweyo ithatha i-silicon carbide njengeyona nto iphambili ekrwada, kwaye yeyona mveliso igqwesileyo ye-silicon carbide egqitywe bubuchwephesha obukhethekileyo kubushushu obuphezulu. Umgangatho wobude unokwenziwa ngokwezifiso ngokweemfuno zabathengi. Olona setyenziso luphambili lwe-silicon carbide furnace tube: lusetyenziswa ngokubanzi kuqeqesho lwesinyithi olungeyontsimbi, inkqubo ye-aluminiyam yeemveliso ze-degasing, ukuprinta kunye nomatshini wokudaya, ukuqeqeshwa kwe-zinc kunye ne-aluminium kunye nokugqitywa kwemveliso.

Uphuhliso lwamashishini e-silicon carbide

I-Silicon carbide ineempawu ze-impedance ephezulu, ingxolo ephantsi, ukulandelelana okulungileyo, njl., yenye yezinto ezikhula ngokukhawuleza ze-silicon carbide, kunye neyokuqala ukufezekisa ukuthengisa. Xa kuthelekiswa ne-MOSFETs, akukho zingxaki zokuthembeka ezibangelwa ziziphene ze-oxide yesango kunye nokunciphisa ukuhamba kwe-carrier carrier, kunye neempawu zayo zokusebenza ze-unipolar zigcina amandla okusebenza okuhamba rhoqo. Ukongeza, i-silicon carbide junction structure inozinzo olungcono kunye nokuthembeka kumaqondo obushushu aphezulu ukuze i-voltage ye-threshold ihlale ingalunganga, oko kukuthi, isixhobo esiqhele ukuvuleka, esingathandekiyo kakhulu kwizicelo zamandla ombane, kwaye ayihambelani nesiqhelo sangoku. qhuba isiphaluka. Ngokuzisa itekhnoloji yesixhobo sokutofa igroove, isixhobo esomeleziweyo phantsi komgangatho wesiqhelo siyaphuhliswa. Nangona kunjalo, izixhobo eziphuculweyo zihlala ziyilwa ngeendleko zeempawu ezithile ezichanekileyo zokuxhathisa, ngoko ke ngokuqhelekileyo ukuvulwa (uhlobo lokunciphisa) kulula ukufikelela uxinano lwamandla aphezulu kunye nomthamo wangoku, kunye nohlobo lokunciphisa lunokufezekiswa ngokukhupha ngokuqhelekileyo kwimeko yokusebenza. Indlela ye-cascade iphunyezwa ngoluhlu lwee-MOSFET ezisekelwe kwi-silicon ephantsi-voltage. Isekethe ye-cascaded drive iyahambelana ngokwemvelo nenjongo eqhelekileyo ye-silicon yesixhobo sokuqhuba isekethe. Esi sakhiwo se-cascade sifanelekile kakhulu ekutshintsheni i-silicon yasekuqaleni kwi-high-voltage kunye nezihlandlo zamandla aphezulu, kwaye ithintela ngokuthe ngqo ingxaki yokuhambelana kwesekethe yokuqhuba.

Ixesha lokuposa: Sep-25-2023