Kuzo zonke iinkqubo ezibandakanyekayo ekudaleni i-chip, ikamva lokugqibela leiqhekezana lesonkaIza kusikwa kwiidies zomntu ngamnye kwaye zipakishwe kwiibhokisi ezincinci, ezivaliweyo kunye nezikhonkwane ezimbalwa eziveziweyo. I-chip iya kuvavanywa ngokusekwe kumda wayo, ukumelana, okwangoku, kunye namaxabiso ombane, kodwa akukho mntu uya kujonga inkangeleko yayo. Ngexesha lenkqubo yokuvelisa, siphindaphinda i-wafer ukuze sifezekise i-planarization efunekayo, ngakumbi kwisinyathelo ngasinye se-photolithography. Iiqhekezana lesonkaumphezulu kufuneka ube mcaba ngokugqithisileyo kuba, njengoko inkqubo yokwenziwa kwetshiphu icutheka, ilensi yomatshini wokufotokopa kufuneka ifikelele kwisisombululo sesikali se-nanometer ngokwandisa umngxuma wamanani (NA) welensi. Nangona kunjalo, oku ngaxeshanye kunciphisa ubunzulu bengqwalasela (DoF). Ubunzulu bengqwalasela bubhekiselele kubunzulu apho inkqubo ye-optical system inokugcina ukugxila. Ukuqinisekisa ukuba umfanekiso we-photolithography uhlala ucacile kwaye ugxininise, ukuhluka komphezulu we-iqhekezana lesonkakufuneka iwele ngaphakathi kubunzulu bengqwalasela.

Ngamagama alula, umatshini we-photolithography uncama amandla okugxila ekuphuculeni ukuchaneka kwemifanekiso. Umzekelo, isizukulwana esitsha soomatshini befotolithography be-EUV bane-aperture yamanani eyi-0.55, kodwa ubunzulu bogqaliselo bungama-45 ee-nanometers kuphela, kunye nolona luhlu luncinci lokujonga umfanekiso ngexesha lokufota. Ukuba iiqhekezana lesonkaayisicaba, inobunzima obungalinganiyo, okanye ukunyuswa komhlaba, kuya kubangela imiba ngexesha le-photolithography kwiindawo eziphakamileyo neziphantsi.

I-Photolithography ayisiyiyo kuphela inkqubo efuna ukugudiswaiqhekezana lesonkaumphezulu. Ezinye iinkqubo ezininzi zokwenziwa kweetshiphu zikwafuna ukupoliswa kwewafer. Umzekelo, emva kokufakwa okumanzi, ukupolisha kuyafuneka ukuze kugudiswe indawo erhabaxa ukuze kugqunywe nokubekwa. Emva kokwahlukaniswa komsele onzulu (STI), ukupolisha kuyafuneka ukuze kugudiswe isilicon dioxide engaphezulu kwaye kugqibezele ukuzaliswa komsele. Emva kokubekwa kwesinyithi, ukupolisha kuyafuneka ukususa iileya zetsimbi ezigqithisileyo kunye nokuthintela iisekethe ezimfutshane zesixhobo.

Ke ngoko, ukuzalwa kwetshiphu kubandakanya amanyathelo amaninzi okupholisha ukunciphisa uburhabaxa bewafer kunye nokwahluka komphezulu kunye nokususa imathiriyeli engaphezulu kumphezulu. Ukongeza, iziphene ezingaphezulu ezibangelwa yimiba eyahlukeneyo yenkqubo kwi-wafer zihlala zibonakala kuphela emva kwenyathelo ngalinye lokupolisha. Ke, iinjineli ezinoxanduva lokupholisha zinoxanduva olubalulekileyo. Bangamanani aphambili kwinkqubo yokwenziwa kwetshiphu kwaye bahlala bebekek' ityala kwiintlanganiso zemveliso. Kufuneka babe nobuchule kuyo yomibini i-etching emanzi kunye nesiphumo somzimba, njengezona ndlela ziphambili zokupholisa ekwenzeni iitshiphu.

Zeziphi iindlela zokupholisha iwafer?

Iinkqubo zokumenyeza zinokwahlulwa zibe ziindidi ezintathu eziphambili ezisekwe kwimigaqo yentsebenziswano phakathi kolwelo lokupolishwa kunye nomphezulu we-silicon wafer:

1. Indlela yokuNgcwelisa ngoomatshini:

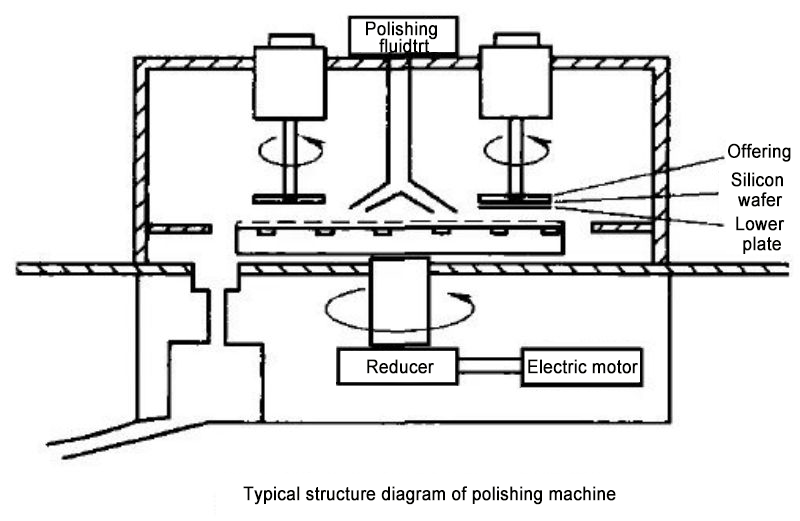

Ukupholisha koomatshini kususa iiprotrusions zomphezulu opolishiweyo ngokusikwa kunye nokuguqulwa kweplastiki ukufikelela kwindawo egudileyo. Izixhobo eziqhelekileyo ziquka amatye e-oyile, amavili oboya, kunye nephepha lesanti, elisebenza ngokuyintloko ngesandla. Amalungu akhethekileyo, afana nomphezulu wemizimba ejikelezayo, angasebenzisa ii-turntables kunye nezinye izixhobo ezincedisayo. Kwimigangatho eneemfuno ezikumgangatho ophezulu, iindlela zokupolisha ezigqwesileyo zingasetyenziswa. I-Super-fine polishing isebenzisa izixhobo ezinqabileyo ezenziwe ngokukodwa, ezithi, kwi-abrasive-containing polishing liquid, zixinzelelwe ngokuqinileyo kumphezulu wendawo yokusebenza kwaye zijikelezwe ngesantya esiphezulu. Obu buchule bunokufezekisa uburhabaxa bomphezulu be-Ra0.008μm, eyona iphakamileyo kuzo zonke iindlela zokupholisha. Le ndlela isetyenziswa ngokuqhelekileyo kwi-optical lens molds.

2. Indlela yokuNgcolisa ngemichiza:

I-Chemical polishing ibandakanya ukuchithwa okukhethiweyo kwe-micro-protrusions kumphezulu wezinto eziphathekayo kwimichiza yekhemikhali, okukhokelela kwindawo egudileyo. Iingenelo eziphambili zale ndlela kukunqongophala kwesidingo sezixhobo ezintsonkothileyo, ukukwazi ukupolisha izixhobo zokusebenza ezimilise okwemilo entsonkothileyo, kunye nokukwazi ukupolisha izinto ezininzi zokusebenza ngaxeshanye ngobuchule obuphezulu. Umba ongundoqo wokupholisa imichiza kukuqulunqwa kolwelo lokupholisha. Uburhabaxa bomphezulu obuphunyezwa ngokugudiswa kweekhemikhali ngokuqhelekileyo kumashumi aliqela eemicrometers.

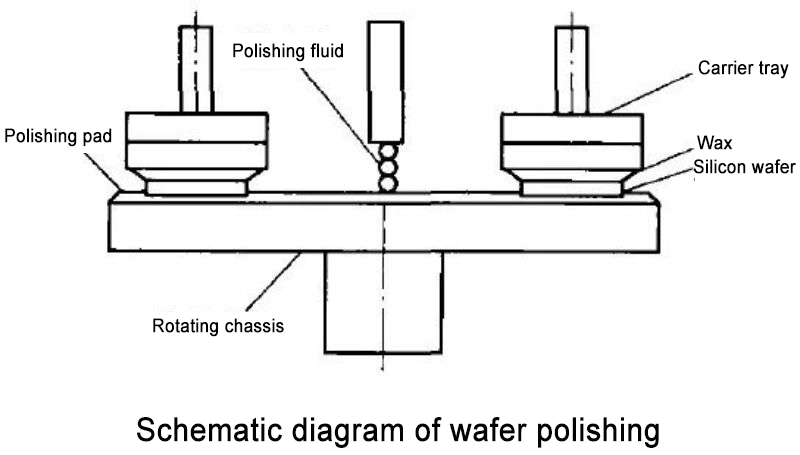

3. Indlela yokuNgcolisa kwiMichiza (CMP):

Nganye kwiindlela ezimbini zokuqala zokupolisha zineenzuzo zayo ezizodwa. Ukudibanisa ezi ndlela zimbini kunokufezekisa imiphumo ehambelanayo kwinkqubo. I-Chemical mechanical polishing idibanisa i-friction yomatshini kunye neenkqubo zokubola kweekhemikhali. Ngexesha le-CMP, ii-reagents zeekhemikhali kulwelo olupholisiweyo zikhupha i-substrate epholisiweyo, yenze umaleko othambileyo we-oxide. Lo maleko weoksidi emva koko uyasuswa ngokukhuhlana koomatshini. Ukuphindaphinda le oxidation kunye nenkqubo yokususwa ngoomatshini ifezekisa ukupolisha okusebenzayo.

Imingeni yangoku kunye neMiba yokuNgcolisa ngoomatshini beMichiza (CMP):

I-CMP ijongene nemingeni emininzi kunye nemiba kwiinkalo zobugcisa, uqoqosho, kunye nokuzinza kokusingqongileyo:

I-1) Ukuhambelana kweNkqubo: Ukufezekisa ukuhambelana okuphezulu kwinkqubo ye-CMP kuhlala kungumngeni. Nangaphakathi komgca wemveliso ofanayo, iinguqu ezincinci kwiiparamitha zenkqubo phakathi kweebhetshi ezahlukeneyo okanye izixhobo zinokuchaphazela ukuhambelana kwemveliso yokugqibela.

I-2) Ukulungelelaniswa kwezinto eziNtsha: Njengoko izinto ezintsha ziqhubeka zivela, iteknoloji ye-CMP kufuneka ihambelane neempawu zabo. Ezinye izixhobo eziphambili zisenokungahambelani neenkqubo ze-CMP zemveli, ezifuna uphuhliso lolwelo oluguquguqukayo lokupholisha kunye ne-abrasives.

3) Iimpembelelo zobungakanani: Njengoko imilinganiselo yesixhobo se-semiconductor iqhubeka nokuncipha, imiba ebangelwa yimiphumo yobungakanani ibaluleke ngakumbi. Imilinganiselo emincinci ifuna ukuthambeka okuphezulu komphezulu, kufuna iinkqubo ezichanekileyo zeCMP.

I-4) Ukulawulwa kwexabiso lokususwa kwezinto eziphathekayo: Kwezinye izicelo, ulawulo oluchanekileyo lwezinga lokususa izinto ezahlukeneyo lubalulekile. Ukuqinisekisa amazinga okususwa angaguquguqukiyo kwiileyibhile ezahlukeneyo ngexesha le-CMP kubalulekile ekwenzeni izixhobo zokusebenza okuphezulu.

5) Ubuhlobo beNdalo: Ulwelo lokupholisha kunye ne-abrasives ezisetyenziswe kwi-CMP zinokuba nezinto ezinobungozi bokusingqongileyo. Uphando kunye nophuhliso lweenkqubo ze-CMP ezinobuhlobo kunye nezizinzileyo kunye nemathiriyeli yimingeni ebalulekileyo.

I-6) Ubukrelekrele kunye ne-Automation: Ngelixa inqanaba lobukrelekrele kunye ne-automation yeenkqubo ze-CMP ziphucula ngokuthe ngcembe, kufuneka ziqhubeke nokujamelana nemeko enzima kunye neyohlukileyo yokuvelisa. Ukufikelela kumanqanaba aphezulu okuzisebenzela kunye nokubeka iliso olukrelekrele ukuphucula impumelelo yemveliso ngumngeni ekufuneka ujongwe.

7) Ukulawulwa kweendleko: I-CMP ibandakanya izixhobo eziphezulu kunye neendleko zempahla. Abavelisi kufuneka baphucule ukusebenza kwenkqubo ngelixa bezama ukunciphisa iindleko zemveliso ukugcina ukukhuphisana kwemarike.

Ixesha lokuposa: Jun-05-2024