I-alumina ceramicii-manipulators zidlala indima ebalulekileyo kwishishini le-semiconductor, ikakhulu esetyenziselwa ukuhambisa ama-wafers kwindawo ecocekileyo ephezulu. Imathiriyeli ye-alumina ye-ceramic inomsebenzi ogqwesileyo kwaye ifaneleke kakhulu ukwenza iirobhothi, kodwa i-alumina ceramic ayisiyonto nje ye-ceramic enobunzima obuphezulu kakhulu, ikwanzima kakhulu ukwenza imathiriyeli ye-ceramic. I-Semicera Energy Technology Co., Ltd. ngumboneleli ohamba phambili okhethekileyo kwi-wafer kunye ne-semiconductor consumables ephezulu., Phakathi kwazo, i-alumina ceramics yenye yeemveliso ezibalulekileyo ze-Semicera Energy. Sele sisebenza kule ntsimi iminyaka emininzi, kwaye siphuhlise ngokukhethekileyo itekhnoloji entsha yokulungisa iingxaki zokwenziwa kweeseramikhi zealumina. Ikwazile ukubonelela abathengi ngeemveliso zengalo ze-ceramic zoomatshini abafanelekileyo. Ezi njineli zilandelayo ezivela kwiSemicera Energy ziya kwazisa ukuba zeziphi iingxaki ekuchanekeni komatshini we-alumina ceramic manipulators.

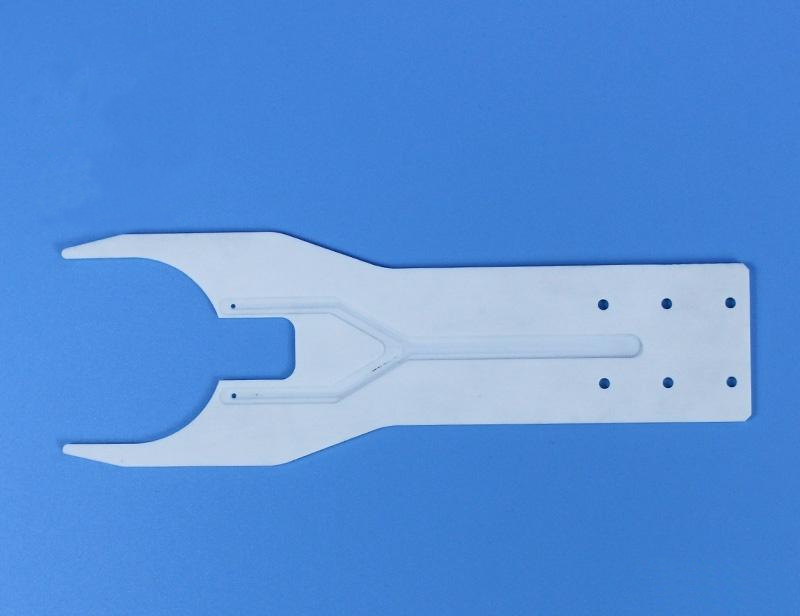

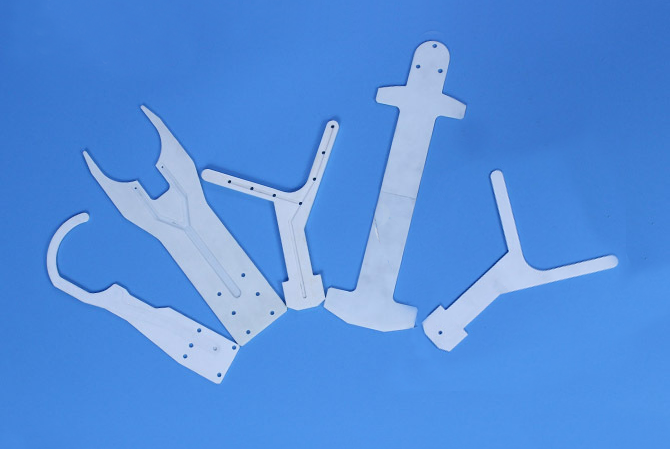

Ingalo yerobhothi ye-alumina ceramic

1. Ngenxa yobunzima obuphezulu be-alumina ceramics, ubunzima besixhobo esiqhelekileyo buncinci kakhulu kunobumba be-alumina, ngeli xesha siya kukhetha isixhobo sedayimane esinobunzima obungcono, nangona kunjalo kuya kukhawulezisa ukunxiba kwesixhobo kunye. ukwandisa iindleko zesixhobo; Ke ngoko, ixabiso lokuchaneka kokulungiswa kweeseramikhi ze-alumina liphezulu.

2. Iiseramikhi zealuminaube nokuzinza okuhle kwe-thermal, kodwa ukuchasana kwempembelelo kubi, ukunyanzeliswa kukhulu, kwaye isiganeko sokuwa komphetho kulula ukwenzeka kwinkqubo yokucubungula i-alumina ceramics; Kwishishini lokulungisa, kufuneka senze izinto ezahlukeneyo zokuphucula, kodwa itekhnoloji yokucubungula ayinakuphucula kakhulu inqanaba lesiqinisekiso semveliso ye-alumina ceramic manipulator.

3. Iiseramikhi zealuminangokwayo ineemfuno eziphezulu zokuchaneka kokugaya, ngoko ke ekusebenzeni komphezulu, ukunxitywa kwesixhobo kukhokelela ekuchanekeni komgangatho kunye nokunciphisa umphezulu wokugqiba, ukuba i-ceramic workpiece ineemfuno eziphezulu zokugqitywa komphezulu, ifuna ukuqhutyelwa phambili kokupholisha, okuye kwandisa iindleko zokusetyenzwa.

4. I-alumina ceramicukusetyenzwa kokusila, kulula ukuvelisa inani elikhulu lomgubo onzima we-ceramic, umgubo kulula ukuhlasela i-spindle kunye nezinye izincedisi zesixhobo somatshini, okubangela ukusilela kwemveliso yomatshini, umonakalo omkhulu kwisixhobo somatshini. Ukuze kulungiswe le ngxaki, i-Semicera Energy yazisa ngokukodwa umatshini wokukrola we-ceramic okhethekileyo kunye nomatshini wokusila, oye wasombulula le ngxaki ngokusisiseko, kwaye ukuchaneka kokulungiswa kwe-workpiece kuye kwaphuculwa kakhulu. I-Semicera Energy ineengenelo ezicacileyo kumatshini ochanekileyo we-alumina ceramic manipulator, ayinayo kuphela iqela labasebenzi bobugcisa, Kukho iiseti ezikhethekileyo ezipheleleyo zezixhobo zokusebenza.

Ixesha lokuposa: Sep-04-2023