I-Epitaxial layer yifilimu ethile ye-crystal eyodwa ekhulile kwi-wafer nge-ep·itaxial process, kunye ne-substrate wafer kunye nefilimu ye-epitaxial ibizwa ngokuba yi-epitaxial wafer. Ngokukhulisa i-silicon carbide epitaxial layer kwi-conductive silicon carbide substrate, i-silicon carbide homogeneous epitaxial wafer inokulungiswa ngakumbi kwi-Schottky diodes, MOSFETs, IGBTs kunye nezinye izixhobo zamandla, phakathi kwazo i-4H-SiC substrate isetyenziswa kakhulu.

Ngenxa yenkqubo eyahlukileyo yokwenziwa kwesixhobo samandla se-silicon carbide kunye nesixhobo samandla se-silicon yemveli, ayinakwenziwa ngokuthe ngqo kwi-silicon carbide imathiriyeli yekristale enye. Izinto ezongezelelweyo ezikumgangatho ophezulu we-epitaxial kufuneka zikhuliswe kwi-conductive single crystal substrate, kunye nezixhobo ezahlukeneyo kufuneka zenziwe kwi-epitaxial layer. Ngoko ke, umgangatho we-epitaxial layer unempembelelo enkulu ekusebenzeni kwesixhobo. Ukuphuculwa kokusebenza kwezixhobo zamandla ezahlukeneyo kukwabeka phambili iimfuno eziphezulu zobunzima bomaleko we-epitaxial, ugxininiso lwe-doping kunye neziphene.

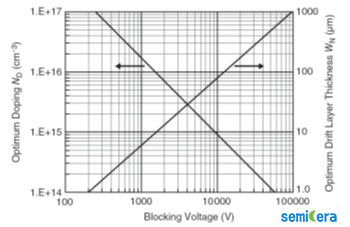

IKHIWANE. 1. Ubudlelwane phakathi koxinzelelo lwe-doping kunye nobukhulu bomaleko we-epitaxial wesixhobo se-unipolar kunye nokuvalwa kombane.

Iindlela zokulungiselela ze-SIC epitaxial layer ikakhulu zibandakanya indlela yokukhula komphunga, ukukhula kwesigaba solwelo epitaxial (LPE), ukukhula kwe-molecular beam epitaxial (MBE) kunye ne-chemical vapor deposition (CVD). Okwangoku, i-chemical vapor deposition (CVD) yeyona ndlela iphambili esetyenziselwa imveliso enkulu kwiifektri.

| Indlela yokulungiselela | Izinto eziluncedo kwinkqubo | Ukungalungi kwenkqubo |

|

Isigaba soLiquid Ukukhula kwe-Epitaxial

(LPE)

|

Iimfuno zezixhobo ezilula kunye neendlela zokukhula eziphantsi. |

Kunzima ukulawula i-morphology yomhlaba we-epitaxial layer. Isixhobo asikwazi ukwenza ii-wafers ezininzi ngaxeshanye, sinciphisa imveliso yobuninzi. |

|

Ukukhula kwe-Molecular Beam Epitaxial (MBE)

|

Izahlulo ezahlukeneyo ze-SiC crystal epitaxial layers zinokukhuliswa kumaqondo obushushu obuphantsi |

Iimfuno zokufunxa izixhobo ziphezulu kwaye zibiza. Isantya sokukhula esicothayo somaleko we-epitaxial |

|

Ukubekwa kweMichiza yoMphunga (CVD) |

Eyona ndlela ibalulekileyo yokuvelisa ngobuninzi kwiifektri. Izinga lokukhula linokulawulwa ngokuchanekileyo xa kukhula i-epitaxial layers. |

I-SiC epitaxial layers iseneziphene ezahlukahlukeneyo ezichaphazela iimpawu zesixhobo, ngoko ke inkqubo yokukhula kwe-epitaxial ye-SiC idinga ukuphuculwa ngokuqhubekayo.I-TaCkufuneka, bona iSemiceraImveliso ye-TaC) |

|

Indlela yokukhula engumphunga

|

Ukusebenzisa izixhobo ezifanayo njenge-SiC crystal yokutsalwa, inkqubo yahluke kancinane ekutsaleni ikristale. Izixhobo ezivuthiweyo, ixabiso eliphantsi |

Ukuguquka komphunga okungalinganiyo kwe-SiC kwenza kube nzima ukusebenzisa ukuphuphuma kwayo ukuze kukhule umgangatho ophezulu we-epitaxial layers. |

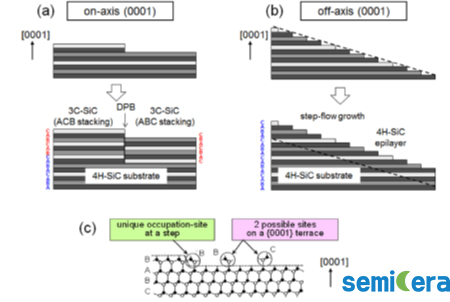

IKHIWANE. 2. Ukuthelekiswa kweendlela eziphambili zokulungiselela i-epitaxial layer

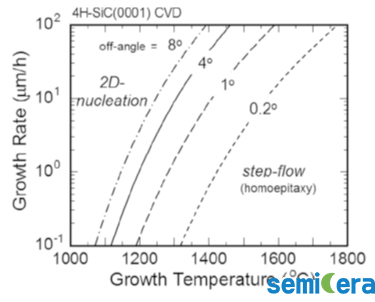

Kwi-off-axis {0001} substrate ene-engile ethambekileyo, njengoko kubonisiwe kuMfanekiso 2(b), ukuxinana komphezulu wenyathelo mkhulu, kwaye ubungakanani bomgangatho wenyathelo mncinci, kwaye icrystal nucleation akulula ukuyenza. yenzeka kumphezulu wenyathelo, kodwa kaninzi kwenzeka kwindawo yokudityaniswa kwenyathelo. Kule meko, kukho iqhosha elinye kuphela le-nucleating. Ngoko ke, i-epitaxial layer inokuphinda iphindaphinde ngokugqibeleleyo i-stacking order ye-substrate, ngaloo ndlela isusa ingxaki yokuhlalisana kweentlobo ezininzi.

IKHIWANE. 3. Umzobo wenkqubo ye-Physical process ye-4H-SiC inyathelo lokulawula indlela ye-epitaxy

IKHIWANE. 4. Iimeko ezibalulekileyo zokukhula kwe-CVD nge-4H-SiC indlela ye-epitaxy elawulwa ngamanyathelo

IKHIWANE. 5. Ukuthelekiswa kwamazinga okukhula phantsi kwemithombo eyahlukeneyo ye-silicon kwi-4H-SiC epitaxy

Okwangoku, iteknoloji ye-silicon carbide epitaxy ikhulile ngokufanelekileyo kwizicelo zombane ophantsi kunye nophakathi (njengezixhobo ze-1200 volt). Ubukhulu obufanayo, ukufana kwe-doping kunye nokusabalalisa isiphene kwi-epitaxial layer inokufikelela kwinqanaba elilungileyo, elinokuthi lihlangabezane neemfuno ze-SBD (Schottky diode), i-MOS (i-metal oxide semiconductor field effect transistor), i-JBS ( diode yokuhlangana) kunye nezinye izixhobo.

Nangona kunjalo, kwintsimi yoxinzelelo oluphezulu, i-epitaxial wafers isafuna ukoyisa imiceli mngeni emininzi. Ngokomzekelo, kwizixhobo ezifuna ukumelana ne-10,000 volts, ubukhulu be-epitaxial layer kufuneka bube malunga ne-100μm. Xa kuthelekiswa nezixhobo eziphantsi kwe-voltage, ubukhulu be-epitaxial layer kunye nokufana koxinaniso lwe-doping luhluke kakhulu, ngakumbi ukufana kwe-doping concentration. Ngexesha elifanayo, i-triangle defect kwi-epitaxial layer iya kutshabalalisa ukusebenza ngokubanzi kwesixhobo. Kwizicelo ze-voltage ephezulu, iintlobo zezixhobo zivame ukusebenzisa izixhobo ze-bipolar, ezifuna ixesha lokuphila elincinci elincinci kwi-epitaxial layer, ngoko ke inkqubo kufuneka iphuculwe ukuphucula ubomi obuncinci.

Okwangoku, i-epitaxy yasekhaya ubukhulu becala yi-intshi ezi-4 kunye nee-intshi ezi-6, kwaye ubungakanani be-silicon carbide epitaxy enkulu buyanda unyaka nonyaka. Ubungakanani bephepha le-silicon carbide epitaxial sheet lilinganiselwe ubukhulu becala le-silicon carbide substrate. Okwangoku, i-6-intshi ye-silicon carbide substrate iye yathengiswa, ngoko ke i-silicon carbide epitaxial ihamba ngokuthe ngcembe ukusuka kwi-intshi ezi-4 ukuya kwi-intshi ezi-6. Ngokuphuculwa okuqhubekayo kweteknoloji yokulungiselela i-silicon carbide substrate kunye nokwandiswa komthamo, ixabiso le-silicon carbide substrate liyehla ngokuthe ngcembe. Ekubunjweni kwexabiso le-epitaxial sheet, i-akhawunti ye-substrate ngaphezu kwe-50% yeendleko, ngoko ke ngokuhla kwexabiso le-substrate, ixabiso le-silicon carbide epitaxial sheet nalo lilindeleke ukuba lihle.

Ixesha lokuposa: Jun-03-2024