Okokuqala, isakhiwo kunye neempawu ze-crystal ye-SiC.

I-SiC yi-binary compound eyenziwe yi-Si element kunye ne-C element kumlinganiselo we-1: 1, oko kukuthi, i-50% ye-silicon (Si) kunye ne-50% ye-carbon (C), kunye neyunithi yayo yesakhiwo esisisiseko yi-SI-C tetrahedron.

Umzobo weSchematic we-silicon carbide tetrahedron structure

Umzekelo, iiathom ze-Si zinkulu ngobubanzi, zilingana ne-apile, kwaye ii-athomu ze-C zincinci ububanzi, zilingana ne-orenji, kunye nenani elilinganayo le-orenji kunye nama-apile ahlanganiswe ndawonye ukuze enze i-crystal ye-SiC.

I-SiC yiKhompawundi yokubini, apho isithuba se-athom ye-Si-Si yi-3.89 A, siqonda njani esi sithuba? Okwangoku, umatshini we-lithography ogqwesileyo kwimarike unokuchaneka kwe-lithography ye-3nm, engumgama we-30A, kunye nokuchaneka kwe-lithography ngamaxesha angama-8 kumgama we-athomu.

Amandla ebhondi ye-Si-Si yi-310 kJ/mol, ngoko unokuqonda ukuba amandla ebhondi ngamandla atsala ezi athom zimbini, kwaye amandla amakhulu ebhondi, kokukhona amandla okufuna ukutsala.

Umzekelo, iiathom ze-Si zinkulu ngobubanzi, zilingana ne-apile, kwaye ii-athomu ze-C zincinci ububanzi, zilingana ne-orenji, kunye nenani elilinganayo le-orenji kunye nama-apile ahlanganiswe ndawonye ukuze enze i-crystal ye-SiC.

I-SiC yiKhompawundi yokubini, apho isithuba se-athom ye-Si-Si yi-3.89 A, siqonda njani esi sithuba? Okwangoku, umatshini we-lithography ogqwesileyo kwimarike unokuchaneka kwe-lithography ye-3nm, engumgama we-30A, kunye nokuchaneka kwe-lithography ngamaxesha angama-8 kumgama we-athomu.

Amandla ebhondi ye-Si-Si yi-310 kJ/mol, ngoko unokuqonda ukuba amandla ebhondi ngamandla atsala ezi athom zimbini, kwaye amandla amakhulu ebhondi, kokukhona amandla okufuna ukutsala.

Umzobo weSchematic we-silicon carbide tetrahedron structure

Umzekelo, iiathom ze-Si zinkulu ngobubanzi, zilingana ne-apile, kwaye ii-athomu ze-C zincinci ububanzi, zilingana ne-orenji, kunye nenani elilinganayo le-orenji kunye nama-apile ahlanganiswe ndawonye ukuze enze i-crystal ye-SiC.

I-SiC yiKhompawundi yokubini, apho isithuba se-athom ye-Si-Si yi-3.89 A, siqonda njani esi sithuba? Okwangoku, umatshini we-lithography ogqwesileyo kwimarike unokuchaneka kwe-lithography ye-3nm, engumgama we-30A, kunye nokuchaneka kwe-lithography ngamaxesha angama-8 kumgama we-athomu.

Amandla ebhondi ye-Si-Si yi-310 kJ/mol, ngoko unokuqonda ukuba amandla ebhondi ngamandla atsala ezi athom zimbini, kwaye amandla amakhulu ebhondi, kokukhona amandla okufuna ukutsala.

Umzekelo, iiathom ze-Si zinkulu ngobubanzi, zilingana ne-apile, kwaye ii-athomu ze-C zincinci ububanzi, zilingana ne-orenji, kunye nenani elilinganayo le-orenji kunye nama-apile ahlanganiswe ndawonye ukuze enze i-crystal ye-SiC.

I-SiC yiKhompawundi yokubini, apho isithuba se-athom ye-Si-Si yi-3.89 A, siqonda njani esi sithuba? Okwangoku, umatshini we-lithography ogqwesileyo kwimarike unokuchaneka kwe-lithography ye-3nm, engumgama we-30A, kunye nokuchaneka kwe-lithography ngamaxesha angama-8 kumgama we-athomu.

Amandla ebhondi ye-Si-Si yi-310 kJ/mol, ngoko unokuqonda ukuba amandla ebhondi ngamandla atsala ezi athom zimbini, kwaye amandla amakhulu ebhondi, kokukhona amandla okufuna ukutsala.

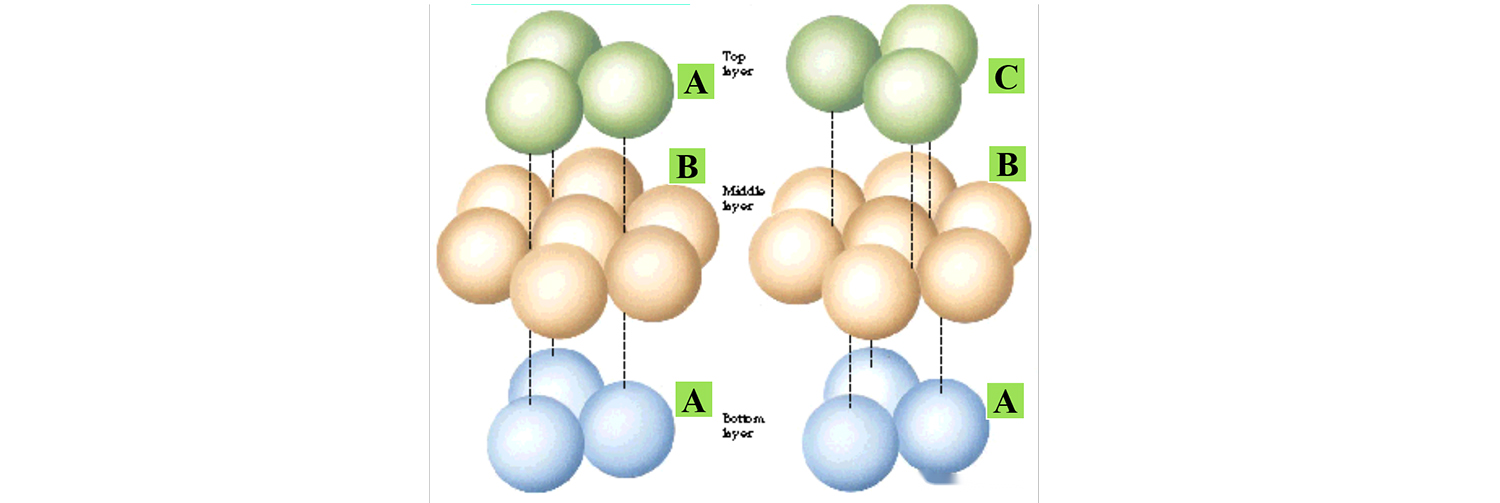

Siyazi ukuba yonke into yenziwe ngama-athomu, kwaye isakhiwo sekristale lulungiselelo oluqhelekileyo lwee-athomu, olubizwa ngokuba luluhlu olude, olufana nolu lulandelayo. Iyunithi encinci yekristale ibizwa ngokuba yiseli, ukuba iseli iyisakhiwo se-cubic, ibizwa ngokuba yi-cubic evaliweyo, kwaye iseli iyisakhiwo esine-hexagonal, ibizwa ngokuba yi-hexagonal esondeleyo.

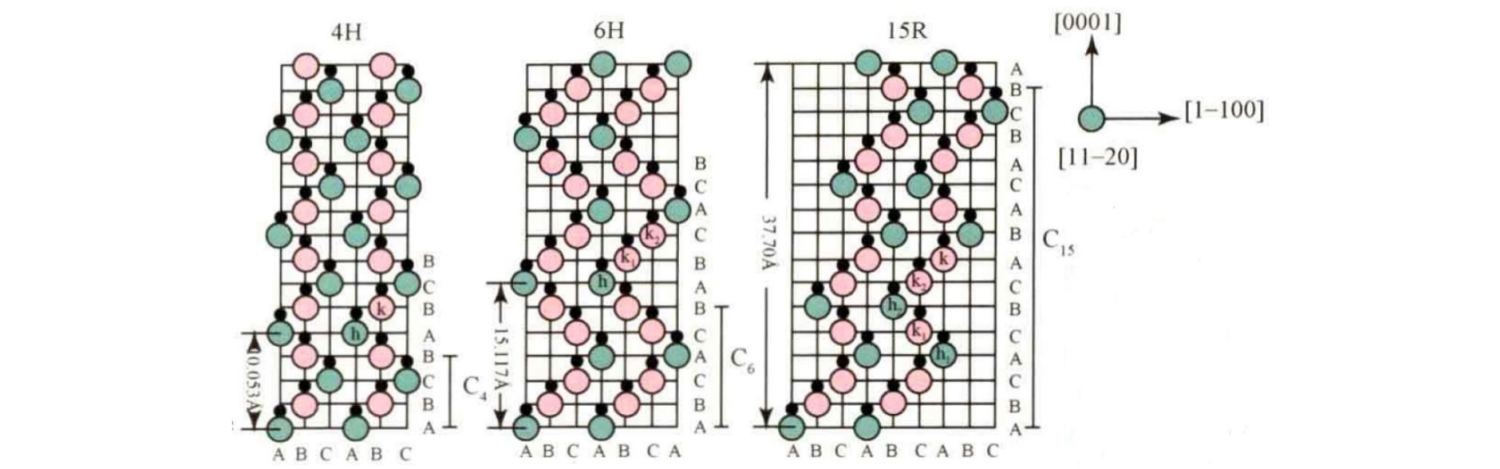

Iintlobo zekristale zeSiC eziqhelekileyo ziquka i-3C-SiC, i-4H-SiC, i-6H-SiC, i-15R-SiC, njl njl. Ulandelelwano lwabo lokupakisha kwi-c axis direction iboniswe kumfanekiso.

Phakathi kwabo, ulandelelwano olusisiseko lwe-stacking ye-4H-SiC yi-ABCB...; Ulandelelwano olusisiseko lwe-stacking ye-6H-SiC yi-ABCACB...; Ulandelelwano olusisiseko lwe-stacking ye-15R-SiC yi-ABCACBCABACABCB... .

Oku kunokubonwa njengesitena sokwakha indlu, ezinye izitena zendlu zineendlela ezintathu zokubeka, ezinye zineendlela ezine zokubeka, ezinye zineendlela ezintandathu.

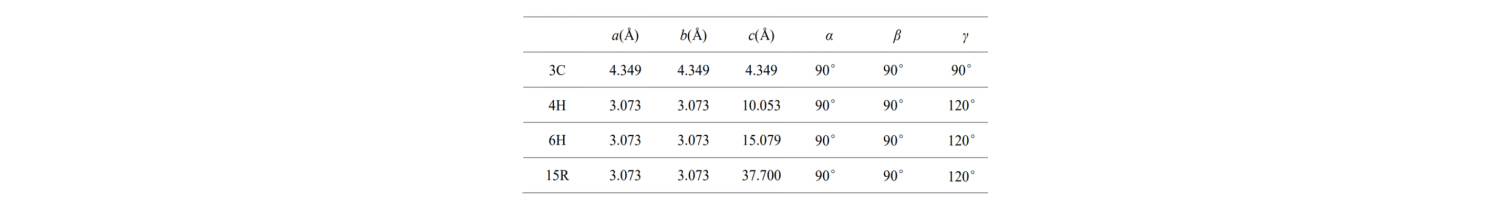

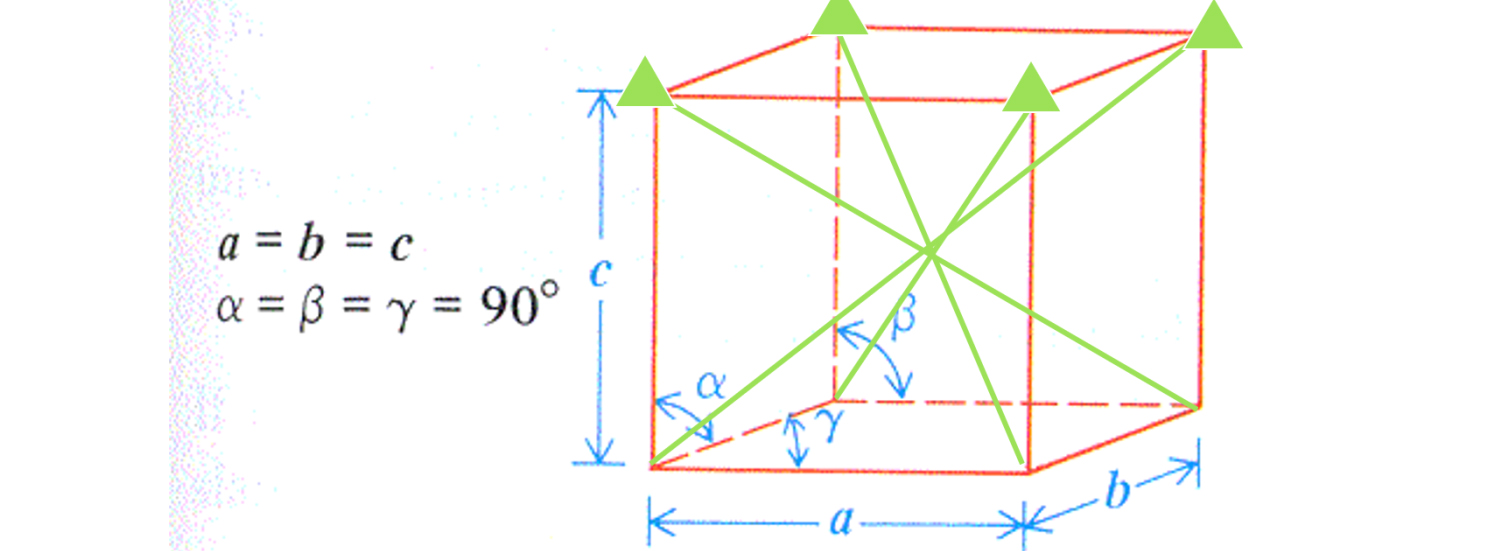

Iiparamitha zeeseli ezisisiseko zezi ntlobo zekristale ze-SiC zibonisiwe kwitheyibhile:

Uthetha ukuthini u-a, b, c kunye nee-engile? Ubume beyona yunithi incinci yeseli kwi-SiC semiconductor ichazwa ngolu hlobo lulandelayo:

Kwimeko yeseli enye, ukwakheka kwekristale kuya kwahluka, oku kufana nokuba sithenga ilotho, inani eliphumeleleyo ngu-1, 2, 3, uthenge 1, 2, 3 amanani amathathu, kodwa ukuba inani lihleliwe. ngokwahlukileyo, inani eliphumeleleyo lihlukile, ngoko ke inani kunye nomyalelo wekristale efanayo, inokubizwa ngokuba yikristale efanayo.

Lo mfanekiso ulandelayo ubonisa iindlela ezimbini eziqhelekileyo zokupakisha, kuphela umahluko kwindlela yokubeka i-athomu ephezulu, i-crystal structure ihluke.

Isakhiwo sekristale esakhiwe yi-SiC sinxulumene kakhulu nobushushu. Ngaphantsi kwesenzo sobushushu obuphezulu be-1900 ~ 2000 ℃, i-3C-SiC iya kuguqula ngokukhawuleza ibe yi-polyform ye-SiC ene-hexagonal efana ne-6H-SiC ngenxa yokuzinza kwayo kwesakhiwo. Kuchanekileyo ngenxa yokulungelelaniswa okuqinileyo phakathi kwamathuba okubunjwa kwe-polymorphs ye-SiC kunye nobushushu, kunye nokungazinzi kwe-3C-SiC ngokwayo, izinga lokukhula kwe-3C-SiC kunzima ukuphucula, kwaye ukulungiswa kunzima. Inkqubo ye-hexagonal ye-4H-SiC kunye ne-6H-SiC iyona nto ixhaphakileyo kwaye kulula ukuyilungisa, kwaye ifundwe ngokubanzi ngenxa yeempawu zabo.

Ubude bobhondi be-SI-C bond kwi-crystal ye-SiC yi-1.89A kuphela, kodwa amandla okubopha aphakamileyo njenge-4.53eV. Ngoko ke, i-gap yenqanaba lamandla phakathi kwelizwe elidibeneyo kunye nelizwe elichasene ne-anti-bonding likhulu kakhulu, kwaye i-gap yebhendi ebanzi inokwakheka, ephindwe kaninzi ye-Si kunye ne-GaAs. Ububanzi be-gap band ephezulu kuthetha ukuba isakhiwo sekristale esiphezulu sobushushu sizinzileyo. Amandla ombane ahambelanayo anokuqonda iimpawu zokusebenza okuzinzileyo kumaqondo obushushu aphezulu kunye nesakhiwo esilula sokulahla ubushushu.

Ukubophelela okuqinileyo kwebhondi ye-Si-C kwenza i-lattice ibe ne-vibration frequency frequency, oko kukuthi, i-phonon yamandla aphezulu, okuthetha ukuba i-crystal ye-SiC inokunyakaza okuphezulu kwe-electron kunye ne-thermal conductivity, kunye nezixhobo zombane ezinxulumene nazo isantya esiphezulu sokutshintsha kunye nokuthembeka, okunciphisa umngcipheko wokusilela kobushushu obugqithisileyo besixhobo. Ukongeza, amandla aphezulu okuqhekeka kwe-SiC ayivumela ukuba ifezekise ukugxininiswa okuphezulu kwe-doping kwaye ibe nokumelana okuphantsi.

Okwesibini, imbali yophuhliso lwekristale yeSiC

Ngomnyaka ka 1905, uGqr. Henri Moissan wafumanisa ikristale yeSiC yendalo kwi crater, awayifumanisa ifana nedayimane wayibiza ngokuba yidayimani ye-Mosan.

Enyanisweni, ekuqaleni kwe-1885, u-Acheson wafumana i-SiC ngokuxuba i-coke kunye ne-silica kunye nokufudumeza kwisithando somlilo sombane. Ngelo xesha, abantu babecinga ukuba ngumxube wedayimani kwaye bayibiza ngokuba imery.

Ngo-1892, u-Acheson waphucula inkqubo yokudibanisa, waxuba isanti ye-quartz, i-coke, inani elincinci leenkuni kunye ne-NaCl, kwaye wayitshisa kwisithando sombane se-arc ukuya kwi-2700 ℃, kwaye wafumana ngempumelelo iikristale ze-scaly SiC. Le ndlela yokudibanisa i-crystals ye-SiC yaziwa ngokuba yindlela ye-Acheson kwaye iseyona ndlela eqhelekileyo yokuvelisa i-SiC abrasives kumashishini. Ngenxa yokucoceka okuphantsi kwezinto zokwenziwa kwezinto eziluhlaza kunye nenkqubo ye-rough synthesis, indlela ye-Acheson ivelisa ukungcola okungaphezulu kwe-SiC, ingqibelelo yekristale embi kunye nobukhulu obuncinane bekristale, okunzima ukuhlangabezana neemfuno zeshishini le-semiconductor ngobukhulu obukhulu, obuphezulu kunye nokuphakama okuphezulu. -iikristale ezisemgangathweni, kwaye azinakusetyenziselwa ukwenza izixhobo zombane.

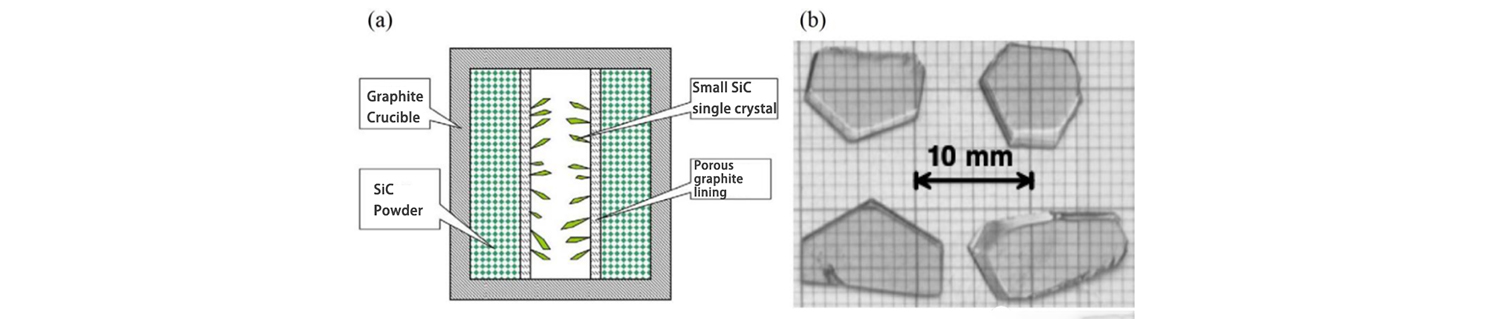

I-Lely ye-Philips Laboratory iphakamise indlela entsha yokukhulisa i-crystals ye-SiC eyodwa kwi-1955. Kule ndlela, i-graphite crucible isetyenziswe njengesitya sokukhula, i-crystal ye-SiC powder isetyenziselwa ukukhulisa i-crystal ye-SiC, kunye ne-graphite e-porous isetyenziselwa ukuhlukanisa. indawo engumngxuma ukusuka kumbindi wemathiriyeli ekrwada ekhulayo. Xa ikhula, i-graphite crucible ifudunyezwa kwi-2500 ℃ phantsi kwe-atmosphere ye-Ar okanye i-H2, kwaye i-peripheral SiC powder ithotywa kwaye iboliswe kwizinto zesigaba somphunga we-Si kunye ne-C, kwaye i-crystal ye-SiC ikhuliswe kwindawo ephakathi emngxuma emva kwegesi. Ukuhamba kudluliselwa kwi-graphite ene-porous.

Okwesithathu, itekhnoloji yokukhula kwekristale yeSiC

Ukukhula kwekristale enye yeSiC kunzima ngenxa yeempawu zayo. Oku kungenxa yokuba akukho nqanaba lolwelo kunye nomlinganiselo we-stoichiometric we-Si: C = 1: 1 kuxinzelelo lwe-atmospheric, kwaye ayinakukhuliswa ngeendlela zokukhula ezikhulile ezisetyenziswa yinkqubo yangoku yokukhula ye-semiconductor. ishishini - cZ indlela, falling crucible method kunye nezinye iindlela. Ngokobalo lwethiyori, kuphela xa uxinzelelo lungaphezu kwe-10E5atm kwaye izinga lokushisa liphezulu kune-3200 ℃, umlinganiselo we-stoichiometric weSi: C = 1: 1 isisombululo sinokufumaneka. Ukoyisa le ngxaki, izazinzulu zenze iinzame ezingagungqiyo zokucebisa iindlela ezahlukeneyo zokufumana umgangatho wekristale ephezulu, ubungakanani obukhulu kunye neekristale zeSiC ezincinci. Okwangoku, iindlela eziphambili zePVT indlela, indlela yesigaba solwelo kunye nendlela yokubeka imichiza yobushushu obuphezulu.

Ixesha lokuposa: Jan-24-2024