Ii-Wafers zezona zinto ziphambili zokwenziwa kweesekethe ezidibeneyo, izixhobo ezidityanisiweyo ze-semiconductor kunye nezixhobo zamandla. Ngaphezulu kwe-90% yeesekethe ezidibeneyo zenziwa kwi-high-purity, i-wafers ephezulu.

Isixhobo sokulungiselela i-wafer sibhekisa kwinkqubo yokwenza izinto ezisulungekileyo ze-polycrystalline silicon zibe yi-silicon enye intonga yekristale yobukhulu obuthile kunye nobude, kwaye emva koko ibeke izinto ze-silicon enye yekristale kuthotho lokusetyenzwa koomatshini, unyango lwekhemikhali kunye nezinye iinkqubo.

Izixhobo ezenza iiwafers zesilicon okanye ii-epitaxial silicon wafers ezihlangabezana nokuchaneka kwejometri kunye neemfuno zomgangatho womphezulu kwaye zibonelela nge-silicon substrate efunekayo yokwenziwa kwetshiphu.

Ukuhamba kwenkqubo eqhelekileyo yokulungiselela ii-wafers ze-silicon ezinobubanzi obungaphantsi kwe-200 mm yile:

Ukukhula kwekristale enye → ukunqunqa → ukuqengqeleka kwedayamitha yangaphandle → ukunqunqa → ukurhabula → ukucola → ukucolisisa → ukupolisha → ukucoca → i-epitaxy → ukupakishwa, njl.

Eyona nkqubo iphambili yokuqukuqela ilungiselela iiwafers zesilicon ezinobubanzi obuyi-300 mm zilandelayo:

Ukukhula kwekristale enye → ukunqunqa → ukuqengqeleka kwedayamitha yangaphandle → ukunqunqa → ukuthandela → ukucola umphezulu → ukucolwa → ukupolisha komphetho → ukupolisha okumacala amabini → ukupolisha kwicala elinye → ukucocwa kokugqibela → i-epitaxy/annealing → ukupakishwa, njl.

1.Izinto zeSilicon

I-silicon yimathiriyeli ye-semiconductor kuba inee-electron ezi-4 ze-valence kwaye ikwiqela le-IVA letafile yeperiodic kunye nezinye izinto.

Inani leelektroni ze-valence kwisilicon liyibeka kanye phakathi komqhubi olungileyo (i-electron e-1 ye-valence) kunye ne-insulator (ii-electron ezi-8 ze-valence).

I-silicon ecocekileyo ayifumaneki kwindalo kwaye kufuneka ikhutshwe kwaye ihlanjululwe ukuze icoceke ngokwaneleyo ukuvelisa. Ngokuqhelekileyo ifumaneka kwi-silica (i-silicon oxide okanye i-SiO2) kunye nezinye i-silicates.

Ezinye iindlela zeSiO2 ziquka iglasi, ikristale engenambala, iquartz, iagate kunye neliso lekati.

Izinto zokuqala ezisetyenziswe njenge-semiconductor yayiyi-germanium kwi-1940 kunye ne-1950 yokuqala, kodwa yatshintshwa ngokukhawuleza yi-silicon.

I-silicon yakhethwa njengeyona nto iphambili ye-semiconductor ngenxa yezizathu ezine eziphambili:

Ubuninzi bezinto zeSilicon: I-silicon yinto yesibini eyona nto ininzi emhlabeni, ibalwa kwi-25% ye-crust Earth.

Indawo ephezulu yokunyibilika kwezinto zesilicon ivumela ukunyamezela inkqubo ebanzi: indawo yokunyibilika kwe-silicon kwi-1412 ° C iphezulu kakhulu kunendawo yokunyibilika kwegermanium kwi-937 ° C. Indawo ephezulu yokunyibilika ivumela i-silicon ukuba imelane neenkqubo zobushushu obuphezulu.

Izinto ze-silicon zinezinga elibanzi lobushushu bokusebenza;

Ukukhula ngokwendalo kwesilicon oxide (SiO2): I-SiO2 yinto ephezulu, ezinzileyo yokufakelwa kombane kwaye isebenza njengomqobo obalaseleyo weekhemikhali ukukhusela i-silicon ekungcoleni kwangaphandle. Ukuzinza kombane kubalulekile ukuphepha ukuvuza phakathi kwabaqhubi abasondeleyo kwiisekethe ezidibeneyo. Ukukwazi ukukhulisa iileya ezizinzileyo ezibhityileyo zezinto ze-SiO2 zibalulekile ekwenziweni kwezixhobo eziphezulu ze-metal-oxide semiconductor (MOS-FET). I-SiO2 ineepropathi zoomatshini ezifanayo kwisilicon, ivumela ukusetyenzwa kobushushu obuphezulu ngaphandle kokugqithiswa kwe-silicon wafer warping.

2.Ukulungiselela iWafer

Ii-wafers ze-semiconductor zisikwa kwizinto ezininzi ze-semiconductor. Le mpahla ye-semiconductor ibizwa ngokuba yi-crystal rod, ekhuliswe kwibhloko enkulu ye-polycrystalline kunye ne-intrinsic material engafakwanga.

Ukuguqula ibhloko ye-polycrystalline ibe yikristale enye enkulu kwaye inike i-crystal orientation echanekileyo kunye nomlinganiselo ofanelekileyo we-N-type okanye i-P-type doping ibizwa ngokuba yi-crystal ukukhula.

Iitekhnoloji eziqhelekileyo zokuvelisa i-ingots ye-crystal ye-silicon enye yokulungiselela i-silicon wafer yindlela ye-Czochralski kunye nendlela yokunyibilika kwendawo.

2.1 Indlela yeCzochralski kunye neCzochralski enye icrystal furnace

Indlela yeCzochralski (CZ), ekwabizwa ngokuba yiCzochralski (CZ) indlela, ibhekisa kwinkqubo yokuguqula ulwelo lwesilicon enyibilikisiweyo lwesemiconductor-grade lube ziingots zesilicon eziqinileyo ezinekristale echanekileyo kwaye ifakwe kuhlobo lweN okanye iP- uhlobo.

Okwangoku, ngaphezu kwe-85% ye-silicon eyodwa ye-crystal ikhulile kusetyenziswa indlela yeCzochralski.

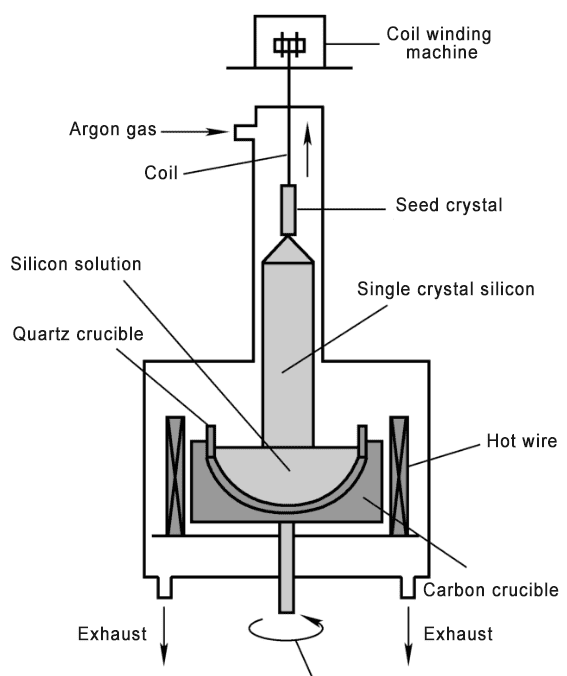

Isithando somlilo sekristale esisodwa seCzochralski sibhekisa kwisixhobo senkqubo esinyibilikisa izinto zepolysilicon ezicoceke kakhulu zibe lulwelo ngokufudumeza kwindawo evaliweyo okanye irhasi enqabileyo (okanye igesi engasebenziyo) yokukhusela indawo yokhuseleko, emva koko iphinde iphinde iphinde ibenze ikristale enye imathiriyeli yesilicon ngezinto ezithile zangaphandle. imilinganiselo.

Umgaqo-siseko wokusebenza wesithando somlilo sekristale yinkqubo ebonakalayo ye-polycrystalline silicon imathiriyeli ephinda iphinda iphinde ibe yinto enye ye-crystal silicon kwimeko yolwelo.

Iziko lekristale elilodwa le-CZ linokwahlulwa libe ngamacandelo amane: umzimba wesithando somlilo, inkqubo yokuhambisa ngoomatshini, inkqubo yokufudumala kunye nobushushu, kunye nenkqubo yokuhanjiswa kwegesi.

Umzimba wesithando somlilo ubandakanya indawo yomlilo, i-axis ye-crystal yembewu, i-quartz crucible, i-spoon ye-doping, i-seed crystal cover, kunye nefestile yokujonga.

Isithando somlilo kukuqinisekisa ukuba iqondo lokushisa kwisithando somlilo lihanjiswa ngokulinganayo kwaye liyakwazi ukukhupha ukushisa kakuhle; i-seed crystal shaft isetyenziselwa ukuqhuba ikristale yembewu ukuya phezulu naphantsi kwaye ijikeleze; ukungcola okufuneka kufakwe kwi-doping spoon;

Isigqubuthelo sekristale sembewu kukukhusela ikristale yembewu ekungcolisekeni. Inkqubo yokuhanjiswa komatshini isetyenziselwa ikakhulu ukulawula ukuhamba kwekristale yembewu kunye ne-crucible.

Ukuze kuqinisekiswe ukuba isisombululo se-silicon asiyi-oxidized, idigri ye-vacuum kwisithando somlilo kufuneka ibe phezulu kakhulu, ngokubanzi ngaphantsi kwe-5 Torr, kwaye ukucoceka kwegesi eyongeziweyo ye-inert kufuneka ibe ngaphezu kwe-99.9999%.

Iqhekeza le-silicon enye yekristale ene-crystal orientation efunekayo isetyenziswa njengekristale yembewu ukukhulisa i-silicon ingot, kwaye i-silicon ingot ekhulileyo ifana nekopi yekristale yembewu.

Iimeko kwi-interface phakathi kwe-silicon etyhidiweyo kunye ne-crystal ye-silicon yembewu yekristale kufuneka ilawulwe ngokuchanekileyo. Ezi meko ziqinisekisa ukuba umaleko obhityileyo we-silicon unokuphinda ngokuchanekileyo ukwakheka kwekristale yembewu kwaye ekugqibeleni ukhule ube yi-ingot enkulu ye-crystal silicon.

2.2 Indlela yokuNyibilikisa iZowuni kunye neZowuni yokuNyibilikisa iZiko leCrystal elinye

Indlela ye-float zone (FZ) ivelisa i-ingots ye-crystal ye-silicon enye kunye nomxholo we-oxygen ophantsi kakhulu. Indlela yezowuni yokudada yaphuhliswa ngeminyaka yoo-1950 kwaye inokuvelisa eyona silicon icwengileyo yecrystal enye ukuza kuthi ga ngoku.

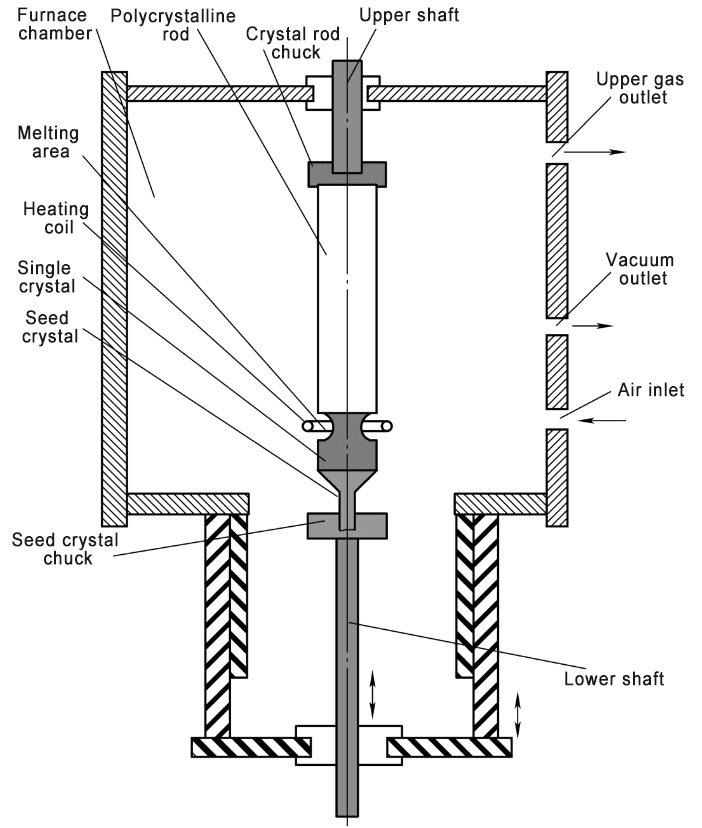

Indawo yokunyibilikisa isithando somlilo esinye sekristale sibhekisa kwiziko elisebenzisa umgaqo wokunyibilika kwendawo ukuvelisa indawo emxinwa yokunyibilika kwintonga yepolycrystalline ngendawo enobushushu obuphezulu obumxinwa obuvaliweyo bomzimba we-polycrystalline intonga yesithando somlilo kwi-vacuum ephezulu okanye irhasi ye-quartz enqabileyo. indawo yokhuseleko.

Isixhobo senkqubo esihambisa intonga ye-polycrystalline okanye umzimba wokufudumeza iziko ukuhambisa indawo yokunyibilika kwaye ngokuthe ngcembe uyikristale ibe yintonga enye yekristale.

Uphawu lokulungiselela iintonga zekristale enye ngendlela yokunyibilika kwendawo kukuba ukucoceka kweentonga ze-polycrystalline kunokuphuculwa kwinkqubo ye-crystallization kwiintonga ze-crystal enye, kunye nokukhula kwe-doping yezinto zokhuni kufana ngakumbi.

Iindidi zezowuni zokunyibilikisa iziko lekristale enye zinokwahlulwa zibe ziindidi ezimbini: indawo edadayo enyibilikisa iziko elinye lekristale elixhomekeke kuxinzelelo lomphezulu kunye nendawo ethe tye yokunyibilika kwiziko elinye lekristale. Kwizicelo ezisebenzayo, indawo yokunyibilika iziko elinye lekristale ngokubanzi lithatha ukunyibilika kwendawo edadayo.

Indawo enyibilikisa isithando somlilo sekristale enye inokulungiselela ukucoceka okuphezulu kwe-oksijini ephantsi ye-silicon yekristale ngaphandle kwesidingo se-crucible. Isetyenziswa ikakhulu ukulungiselela ukuxhathisa okuphezulu (> 20kΩ · cm) isilicon eyodwa yekristale kunye nokucoca isilicon enyibilikayo yendawo. Ezi mveliso zisetyenziswa ikakhulu ekwenzeni izixhobo zombane ezidityanisiweyo.

Indawo yokunyibilikisa isithando somlilo esinye sekristale sinegumbi lesithando somlilo, ishafti ephezulu kunye neshaft esezantsi (inxalenye yothumelo lomatshini), ikristale rod chuck, imbewu yekristale chuck, icoil yokufudumeza (ijeneretha ephezulu), izibuko zegesi (izibuko lokucoca, indawo yokungena igesi, indawo yokukhutshwa kwegesi ephezulu), njl.

Kwisakhiwo segumbi lesithando somlilo, ukujikeleza kwamanzi okupholisa kulungiselelwe. Isiphelo esisezantsi se-shaft ephezulu yesithando somlilo se-crystal yi-crystal rod chuck, esetyenziselwa ukunyanzelisa intonga ye-polycrystalline; isiphelo esiphezulu se-shaft esezantsi yi-seed crystal chuck, esetyenziselwa ukucinezela ikristale yembewu.

Unikezelo lwamandla ombane oluphezulu lunikezelwa kwi-coil yokufudumala, kwaye indawo encinci yokuncibilika iqulunqwe kwintonga ye-polycrystalline eqala ukusuka ekupheleni kwezantsi. Ngelo xesha, ii-axes eziphezulu kunye nezantsi zijikeleza kwaye zehla, ukwenzela ukuba indawo yokunyibilika ifakwe kwikristale enye.

Iinzuzo zommandla wokunyibilika kwesithando somlilo esisodwa sekristale kukuba ayinakuphucula kuphela ukucoceka kwekristale enye elungiselelwe, kodwa yenza ukuba i-doping ikhule ngokufana ngakumbi, kwaye intonga enye yekristale inokuhlanjululwa ngeenkqubo ezininzi.

Ukungalungi kwendawo yokunyibilika kwesithando somlilo esisodwa sekristale ziindleko eziphezulu zenkqubo kunye nobubanzi obuncinci bekristale enye elungiselelwe. Okwangoku, ubukhulu becala lekristale enye enokulungiswa yi-200mm.

Ubude bubonke bendawo yokunyibilika kwesixhobo somlilo sekristale esinye siphezulu, kwaye i-axes ephezulu kunye nesezantsi ide kakhulu, ngoko ke iinduku ezinde zekristale zinokukhuliswa.

3. Ukulungiswa kwe-wafer kunye nezixhobo

Intonga yekristale kufuneka ihambe ngoluhlu lweenkqubo zokwenza i-silicon substrate ehlangabezana neemfuno zokwenza i-semiconductor, oko kukuthi i-wafer. Inkqubo esisiseko yokuqhubekeka yile:

Ukuwa, ukusika, ukusika, i-wafer annealing, i-chamfering, ukucola, ukupolisha, ukucocwa kunye nokupakishwa, njl.

3.1 Ukufakwa kweWafer

Kwinkqubo yokuvelisa i-polycrystalline silicon kunye ne-Czochralski silicon, i-silicon eyodwa ye-crystal iqulethe i-oksijini. Kwiqondo lobushushu elithile, ioksijini kwi-silicon enye yekristale iya kunikela ngee-electron, kwaye ioksijini iya kuguqulwa ibe ngabanikeli be-oksijini. Ezi electron ziya kudibanisa kunye nokungcola kwi-silicon wafer kwaye zichaphazele ukuxhathisa kwe-silicon wafer.

Isithando somlilo: sibhekisela kwisithando somlilo esiphakamisa ubushushu kwisithando somlilo ukuya kwi-1000-1200 ° C kwindawo ye-hydrogen okanye i-argon. Ngokugcina ubushushu kunye nokupholisa, ioksijini ekufutshane nomphezulu we-silicon wafer epholishiweyo iyaguquguquka kwaye isuswe kumphezulu wayo, ibangela ukuba ioksijini igxame kunye nomaleko.

Izixhobo zenkqubo ezinyibilikisa iziphene ezincinci kumphezulu wee-silicon wafers, zinciphisa ubungakanani bokungcola kufutshane nomphezulu we-silicon wafers, zinciphisa iziphene, kwaye zenze indawo ecocekileyo kumphezulu wee-silicon wafers.

Isithando somlilo sikwabizwa ngokuba sisithando sobushushu obuphezulu ngenxa yobushushu baso obuphezulu. Ishishini likwabiza inkqubo yokufakwa kwe-silicon wafer annealing.

Isithando somlilo seSilicon sahlulwe saba:

-Iziko elithe tye;

Isithando somlilo esithe nkqo;

-Iziko lokutshisa ngokukhawuleza.

Umahluko ophambili phakathi kwesithando somlilo esithe tye kunye nesithando somlilo esithe nkqo yindlela yoyilo lwegumbi lokusabela.

Igumbi lokusabela lesithando somlilo esithe tye lakhiwe ngokuthe tye, kwaye ibhetshi yeziphalufa zesilicon inokulayishwa kwigumbi lokusabela lesithando somlilo ukuze sifakwe ngaxeshanye. Ixesha lokufunxa lidla ngokuba yimizuzu engama-20 ukuya kwengama-30, kodwa igumbi lokusabela lifuna ixesha elide lokufudumeza ukufikelela kubushushu obufunwa yinkqubo yokufunxa.

Inkqubo yesithando somlilo esithe nkqo yamkela indlela yokulayisha ngaxeshanye ibhetshi yee-silicone wafers kwigumbi lokusabela le-annealing to anneal treatment. Igumbi lokusabela linoyilo lwesakhiwo esithe nkqo, esivumela ii-wafers ze-silicon ukuba zibekwe kwisikhephe se-quartz kwindawo ethe tye.

Kwangaxeshanye, kuba isikhephe sequartz sinokujikeleza sisonke kwigumbi lokusabela, iqondo lobushushu le-annealing legumbi lokusabela lifana, ukuhanjiswa kwamaqondo obushushu kwi-silicon wafer kufana, kwaye ineempawu ezibalaseleyo zokufana kwe-annealing. Nangona kunjalo, iindleko zenkqubo yesithando somlilo esithe nkqo ziphezulu kunelo leziko elithe tye.

Isithando somlilo esikhawulezayo sisebenzisa isibane se-halogen tungsten ukutshisa ngokuthe ngqo i-silicon wafer, enokufikelela ukufudumeza ngokukhawuleza okanye ukupholisa kuluhlu olubanzi lwe-1 ukuya kwi-250 ° C / s. Izinga lokufudumeza okanye lokupholisa likhawuleza ngakumbi kunelo lomlilo wemveli. Kuthatha nje imizuzwana embalwa ukufudumeza iqondo lobushushu legumbi lokusabela libe ngaphezulu kwe-1100°C.

————————————————————————————————————————————————— —-

I-Semicera inokubonelelaiindawo zegraphite,uthambile/uqinile,iinxalenye ze-silicon carbide, CVD iinxalenye zesilicon carbide, kwayeIindawo ezigqunywe yiSiC/TaCngenkqubo epheleleyo ye-semiconductor kwiintsuku ezingama-30.

Ukuba unomdla kwezi mveliso zesemiconductor zingasentla, nceda ungathandabuzi ukuqhagamshelana nathi okokuqala.

Umnxeba: +86-13373889683

Whatsapp: +86-15957878134

Email: sales01@semi-cera.com

Ixesha lokuposa: Aug-26-2024