1. Intshayelelo

Inkqubo yokuncamathisela izinto (izinto eziphathekayo) kumphezulu we-substrate ngeendlela zenyama okanye iikhemikhali kuthiwa ukukhula kwefilimu encinci.

Ngokwemigaqo yokusebenza eyahlukeneyo, isekethe edibeneyo yokubekwa kwefilimu encinci inokwahlulwa ibe:

-I-Physical Vapor Deposition (PVD);

-I-Chemical Vapor Deposition (CVD);

-Ukwandiswa.

2. Inkqubo yokuKhula kweFilimu encinci

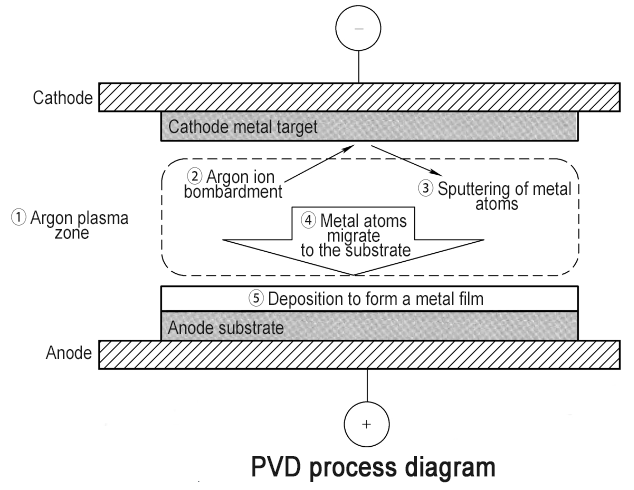

2.1 Ukufakwa komphunga obonakalayo kunye nenkqubo yokutshiza

Inkqubo ye-Physical vapor Deposition (PVD) ibhekiselele kusetyenziso lweendlela eziphathekayo ezifana nokuphuma komphunga, ukutshiza, ukugquma kweplasma kunye ne-molecular beam epitaxy ukwenza ifilimu ebhityileyo kumphezulu we-wafer.

Kwishishini le-VLSI, iteknoloji ye-PVD esetyenziswa kakhulu i-sputtering, esetyenziswa kakhulu kwi-electrodes kunye ne-metal interconnects yeesekethe ezidibeneyo. I-Sputtering yinkqubo apho iigesi ezinqabileyo [ezifana ne-argon (Ar)] zifakwe kwi-ion (ezifana ne-Ar +) phantsi kwesenzo sentsimi yombane yangaphandle phantsi kweemeko eziphezulu ze-vacuum, kunye nokubhobhoza umthombo ojoliswe kuyo phantsi kwendawo yombane ophezulu, ukunkqonkqoza iiathom okanye iimolekyuli zezinto ekujoliswe kuzo, kwaye emva koko zifike kumphezulu we-wafer ukwenza ifilimu ebhityileyo emva kwenkqubo yokubhabha engangqubaniyo. I-Ar ineempawu ezizinzileyo zeekhemikhali, kwaye i-ion zayo aziyi kusabela ngamachiza kunye nezinto ezijoliswe kuzo kunye nefilimu. Njengoko iitshiphusi zesekethe ezihlanganisiweyo zingena kwixesha le-0.13μm lonxibelelwano lobhedu, i-copper barrier material layer isebenzisa i-titanium nitride (TiN) okanye ifilimu ye-tantalum nitride (TaN). Imfuno yetekhnoloji yemizi-mveliso ikhuthaze uphando kunye nophuhliso lwetekhnoloji ye-chemical reaction sputtering, oko kukuthi, kwigumbi lokutshiza, ukongeza kwi-Ar, kukwakho i-nitrogen yegesi esebenzayo (N2), ukuze i-Ti okanye i-Ta iqhushumbise imathiriyeli ekujoliswe kuyo i-Ti okanye i-Ta idibana ne-N2 ukuvelisa ifilimu ye-TiN okanye i-TaN efunekayo.

Kukho iindlela ezintathu eziqhelekileyo ezisetyenziswayo zokutshiza, ezizezi, ukutshiza kwe-DC, ukutshiza kwe-RF kunye ne-magnetron sputtering. Njengoko ukuhlanganiswa kweesekethe ezidibeneyo kuqhubeka nokunyuka, inani leengqimba ze-multi-layer ze-wiring zetsimbi ziyanda, kwaye ukusetyenziswa kweteknoloji ye-PVD kuya kuba kuninzi. Izinto ze-PVD ziquka i-Al-Si, i-Al-Cu, i-Al-Si-Cu, i-Ti, i-Ta, i-Co, i-TiN, i-TaN, i-Ni, i-WSi2, njl.

I-PVD kunye neenkqubo ze-sputtering zidla ngokugqitywa kwigumbi lokuphendula elitywinwe kakhulu kunye neqondo le-vacuum ye-1 × 10-7 ukuya kwi-9 × 10-9 Torr, enokuqinisekisa ukucoceka kwegesi ngexesha lokuphendula; kwangaxeshanye, amandla ombane aphezulu angaphandle ayadingeka ukuze i-ionize igesi enqabileyo ukuvelisa amandla ombane aphezulu ngokwaneleyo ukubhobhoza ekujoliswe kuko. Iiparamitha eziphambili zokuvavanya i-PVD kunye neenkqubo ze-sputtering ziquka ubuninzi bothuli, kunye nexabiso lokuchasana, ukufana, ubukhulu obubonakalayo kunye noxinzelelo lwefilimu eyenziwe.

2.2 UkuBekwa koMphunga weMichiza kunye neNkqubo yokuFafaza

I-Chemical vapor deposition (CVD) ibhekisa kubuchwepheshe benkqubo apho iintlobo ngeentlobo zee-reactants zegesi ezinoxinzelelo oluyinxenye olwahlukeneyo zisabela ngokwekhemikhali kubushushu obuthile kunye noxinzelelo, kwaye izinto eziqinileyo ezenziweyo zifakwa kumphezulu we-substrate imathiriyeli ukuze kufumaneke obhityileyo olufunekayo. ifilimu. Kwinkqubo yokwenziwa kwesekethe edityanisiweyo, izixhobo zefilimu ezicekethekileyo ezifunyenweyo zihlala zikhompawundi ezinje ngeeoxides, nitrides, carbides, okanye izinto ezifana nesilicon yepolycrystalline kunye nesilicon amorphous. Ukukhula okukhethiweyo kwe-epitaxial, esetyenziswa ngokuqhelekileyo emva kwe-node ye-45nm, njengomthombo kunye ne-drain SiGe okanye i-Si selective epitaxial growth, ibuye ibe yi-CVD iteknoloji.

Ubuchwephesha bunokuqhubeka nokwenza izinto zekristale zohlobo olufanayo okanye ezifana neletisi yokuqala kwi-crystal substrate ye-silicon okanye ezinye izinto ezisecaleni kweleti yasekuqaleni. I-CVD isetyenziswa ngokubanzi ekukhuleni kweefilimu ze-dielectric ezikhuselayo (ezifana ne-SiO2, i-Si3N4 kunye ne-SiON, njl.) kunye neefilimu zetsimbi (ezifana ne-tungsten, njl.).

Ngokuqhelekileyo, ngokokuhlelwa koxinzelelo, i-CVD inokwahlulwa ibe yi-atmospheric pressure chemical vapor deposition (APCVD), i-sub-atmosphere pressure chemical vapor deposition (SAPCVD) kunye ne-low-atmosphere ye-chemical vapor deposition (LPCVD).

Ngokohlelo lobushushu, i-CVD inokohlulwa ibe ngubushushu obuphezulu/ubushushu obuphantsi befilimu ye-oxide yekhemikhali yokubeka umphunga (HTO/LTO CVD) kunye nokubeka umphunga wekhemikhali we-thermal (Rapid Thermal CVD, RTCVD);

Ngokomthombo wokusabela, i-CVD inokohlulwa ibe yi-CVD esekwe kwi-silane, i-polyester-based CVD (i-TEOS-based CVD) kunye ne-metal organic chemical vapor deposition (MOCVD);

Ngokohlelo lwamandla, i-CVD inokohlulwa ibe yi-thermal chemical vapor deposition (i-Thermal CVD), i-plasma ephuculweyo ye-chemical vapor deposition (i-Plasma Enhanced CVD, PECVD) kunye ne-high density plasma chemical vapor deposition (High Density Plasma CVD, HDPCVD). Kutshanje, i-flowable chemical vapor deposition (i-CVD ebalekayo, i-FCVD) enobuchule obugqwesileyo bokuzalisa umsantsa iye yaphuhliswa.

Iifilimu ezahlukeneyo ezikhuliswe kwi-CVD zineempawu ezahlukeneyo (ezifana nokubunjwa kweekhemikhali, i-dielectric constant, tension, stress and breakdown voltage) kwaye ingasetyenziselwa ngokwahlukileyo ngokweemfuno zenkqubo ezahlukeneyo (ezifana neqondo lokushisa, ukunyathela, iimfuno zokuzalisa, njl.).

2.3 Inkqubo yokubeka umaleko we-atom

I-atomic layer deposition (ALD) ibhekisa ekubekeni umaleko weathom ngokomaleko kwimathiriyeli engaphantsi ngokukhulisa ifilimu enye yeathom ngokomaleko. I-ALD eqhelekileyo yamkela indlela yokufaka i-precursors yegesi kwi-reactor ngendlela etshintshanayo ye-pulsed.

Ngokomzekelo, okokuqala, i-reaction precursor 1 ifakwe kwi-substrate surface, kwaye emva kwe-adsorption yeekhemikhali, i-athomu enye ye-athomu yenziwe kwi-substrate surface; ke i-precursor 1 esele kwi-substrate surface kunye ne-reaction room ikhutshwe yimpompo yomoya; emva koko i-reaction precursor 2 ifakwe kumphezulu we-substrate, kwaye i-chemically isabela kunye ne-precursor 1 i-adsorbed kwi-substrate surface ukuvelisa izinto ezihambelanayo zefilimu kunye neemveliso ezihambelanayo kumphezulu we-substrate; xa i-precursor ye-1 isabela ngokupheleleyo, ukusabela kuya kuphelisa ngokuzenzekelayo, okuyimpawu zokuzikhawulela ze-ALD, kwaye ke i-reactants eseleyo kunye neemveliso zikhutshwe ukuze zilungiselele isigaba esilandelayo sokukhula; ngokuphinda le nkqubo ingentla ngokuqhubekayo, ukubekwa kwezixhobo zefilim ezibhityileyo ezikhuliswe umaleko nge-athom enye zinokufezekiswa.

Zombini i-ALD kunye ne-CVD ziindlela zokwazisa umthombo we-gaseous chemical reaction source ukusabela ngokwekhemikhali kumphezulu we-substrate, kodwa umahluko kukuba umthombo we-gaseous reaction we-CVD awunalo uphawu lokukhula okuzikhawulelayo. Ingabonwa ukuba isitshixo ekuphuhliseni itekhnoloji ye-ALD kukufumana izandulela ezineempawu zokusabela ezizikhawulelayo.

2.4 Inkqubo ye-Epitaxial

Inkqubo ye-Epitaxial ibhekisela kwinkqubo yokukhulisa i-crystal layer eyalelwe ngokupheleleyo kwi-substrate. Ngokuqhelekileyo, inkqubo ye-epitaxial kukukhulisa i-crystal layer kunye ne-lattice orientation efanayo njenge-substrate yokuqala kwi-crystal substrate enye. Inkqubo ye-Epitaxial isetyenziswa ngokubanzi kwimveliso ye-semiconductor, efana ne-epitaxial silicon wafers kushishino lwesekethe edibeneyo, umthombo odibeneyo kunye nokukhupha ukukhula kwe-epitaxial ye-MOS transistors, ukukhula kwe-epitaxial kwii-substrates ze-LED, njl.

Ngokwezigaba ezahlukeneyo zomthombo wokukhula, iindlela zokukhula kwe-epitaxial zinokwahlulwa zibe yi-epitaxy yesigaba esiqinileyo, i-epitaxy yesigaba solwelo, kunye ne-epitaxy yesigaba somphunga. Kwimveliso yesekethe edibeneyo, iindlela ezisetyenziswa ngokuqhelekileyo ze-epitaxial ziyi-epitaxy yesigaba esiqinileyo kunye ne-vapor phase epitaxy.

I-epitaxy yesigaba esiqinileyo: ibhekisela ekukhuleni komgangatho wekristale enye kwi-substrate usebenzisa umthombo oqinileyo. Ngokomzekelo, ukufakwa kwe-thermal emva kokufakelwa kwe-ion ngokwenene yinkqubo yesigaba esiqinileyo se-epitaxy. Ngexesha lofakelo lwe-ion, iiathom ze-silicon ze-silicon wafer zibethelwa zii-ion ezifakelweyo ezinamandla aphezulu, zishiya izikhundla zazo zokuqala ze-lattice kwaye zibe yi-amorphous, zenza umaleko we-silicon ongaphezulu. Emva kobushushu obuphezulu bobushushu, iiathom ze-amorphous zibuyela kwiindawo zazo zelattice kwaye zihlala zihambelana nokuqhelaniswa nekristale yeathom ngaphakathi kwe-substrate.

Iindlela zokukhula ze-vapor phase epitaxy ziquka i-chemical vapor phase epitaxy, i-molecular beam epitaxy, i-atomic layer epitaxy, njl. Kwimveliso yesekethe edibeneyo, i-chemical vapor phase epitaxy yeyona isetyenziswa ngokuqhelekileyo. Umgaqo wesigaba somphunga wekhemikhali i-epitaxy ngokusisiseko iyafana naleyo yokubekwa komphunga wekhemikhali. Zombini ziinkqubo ezifaka iifilimu ezibhityileyo ngokusabela ngokwekhemikhali kumphezulu weewafa emva kokuxuba igesi.

Umahluko kukuba ngenxa yokuba i-epitaxy ye-chemical vapor phase ikhula i-crystal layer enye, ineemfuno eziphezulu zomxholo wokungcola kwisixhobo kunye nokucoceka komgangatho we-wafer. Inkqubo yokuqala ye-epitaxial silicon ye-chemical vapor phase kufuneka iqhutywe phantsi kweemeko eziphezulu zokushisa (ngaphezulu kwe-1000 ° C). Ngokuphuculwa kwezixhobo zenkqubo, ngakumbi ukwamkelwa kwetekhnoloji yegumbi lokutshintshiselana nge-vacuum, ukucoceka komgodi wesixhobo kunye nomphezulu we-silicon wafer kuphuculwe kakhulu, kwaye i-silicon epitaxy inokuqhutywa kwiqondo lobushushu elisezantsi (600-700 °). C). Inkqubo ye-epitaxial silicon wafer kukukhulisa umaleko we-silicon enye yekristale kumphezulu we-silicon wafer.

Xa kuthelekiswa ne-silicon substrate yokuqala, umaleko we-silicon ye-epitaxial unobunyulu obuphezulu kunye neziphene ezimbalwa ze-lattice, ngaloo ndlela ziphucula isivuno sokwenziwa kwe-semiconductor. Ukongeza, ubukhulu bokukhula kunye nokuxinana kwe-doping yomaleko we-silicon ye-epitaxial ekhule kwi-silicon wafer inokwakheka ngokuguquguqukayo, okuzisa ukuguquguquka kuyilo lwesixhobo, esifana nokunciphisa ukuxhathisa kwe-substrate kunye nokuphucula ukwahlukaniswa kwe-substrate. Inkqubo ye-epitaxial edibeneyo yomthombo yitekhnoloji esetyenziswa ngokubanzi kwiindawo eziphambili zetekhnoloji.

Ibhekisa kwinkqubo yokukhula kwe-epitaxially ye-doped germanium silicon okanye isilicon kwindawo yomthombo kunye neendawo zokukhupha ii-MOS transistors. Iinzuzo eziphambili zokuzisa inkqubo ye-epitaxial edibeneyo yomthombo-drain ibandakanya: ukukhulisa i-pseudocrystalline layer equlethe uxinzelelo ngenxa yokulungiswa kwe-lattice, ukuphucula ukuhamba kwe-charrier carrier; i-in-situ doping yomthombo kunye ne-drain inokunciphisa ukuxhathisa kwe-parasitic ye-junction ye-source-drain junction kunye nokunciphisa iziphene ze-high-energy ion implantation.

3. izixhobo zokukhulisa ifilimu ebhityileyo

3.1 Isixhobo sokufunxa umphunga

I-vacuum evaporation yindlela yokwaleka efudumeza izinto eziqinileyo kwigumbi lokufunxa ukuze zibe ngumphunga, zibe ngumphunga okanye zibe ngaphantsi kwe-sublimate, emva koko zijike zifake kumphezulu we-substrate kwiqondo lobushushu elithile.

Ngokuqhelekileyo iqulathe iinxalenye ezintathu, ezizezi, inkqubo vacuum, inkqubo evaporation kunye nenkqubo zokufudumeza. Inkqubo yokucoca iqulethe imibhobho yokucoca kunye neempompo ze-vacuum, kwaye umsebenzi wayo oyintloko kukubonelela ngeendawo ezifanelekileyo zokufunxa umoya. Inkqubo yokuphuphuma kwamanzi iquka itafile yokuphuphuma kwamanzi, icandelo lokufudumeza kunye necandelo lokulinganisa ubushushu.

Izinto ekujoliswe kuzo ukuba zibe ngumphunga (ezifana ne-Ag, Al, njl. njl.) zibekwe kwitafile yokuguquka; icandelo lokulinganisa ubushushu kunye neqondo lokushisa yinkqubo evaliweyo esetyenziselwa ukulawula ubushushu bokufudumala ukuqinisekisa ukukhuphuka kwamanzi. Inkqubo yokufudumala iquka isiteji se-wafer kunye necandelo lokufudumala. Inqanaba le-wafer lisetyenziselwa ukubeka i-substrate apho ifilimu ebhityileyo ifuna ukutshitshiswa, kwaye icandelo lokufudumeza lisetyenziselwa ukuqonda ukufudumeza kwe-substrate kunye nokulawula impendulo yokulinganisa ubushushu.

Ubume be-vacuum yimeko ebaluleke kakhulu kwinkqubo yokukhupha i-vacuum evaporation, ehambelana nesantya sokunyuka kunye nomgangatho wefilimu. Ukuba idigri ye-vacuum ayihlangabezani neemfuno, iiathom okanye iimolekyuli ezifakwe ngumphunga ziya kungqubana rhoqo kunye neemolekyuli zegesi ezishiyekileyo, zenze indlela yazo ekhululekileyo ibe ncinci, kwaye iiathomu okanye iiathomu ziya kusasazeka kakhulu, ngaloo ndlela zitshintsha indlela yokuhamba kunye nokunciphisa ifilimu. izinga lokuqulunqa.

Ukongeza, ngenxa yobukho beemolekyuli zegesi ezingcolileyo ezishiyekileyo, ifilimu efakiweyo ingcoliseke kakhulu kwaye ikumgangatho ophantsi, ngakumbi xa izinga lokunyuka koxinzelelo lwegumbi lingahambelani nomgangatho kwaye kukho ukuvuza, umoya uya kuvuza kwigumbi lokucoca. , eya kuba nefuthe elibi kumgangatho wefilimu.

Iimpawu zesakhiwo sezixhobo zokufunxa i-vacuum zigqiba ukuba ukufana kwengubo kwii-substrates ezinobungakanani obukhulu kubi. Ukuze kuphuculwe ukufana kwayo, indlela yokunyusa umgama we-source-substrate kunye nokujikeleza i-substrate ngokuqhelekileyo yamkelwa, kodwa ukwandisa umgama we-source-substrate uya kubingelela izinga lokukhula kunye nokucoceka kwefilimu. Ngexesha elifanayo, ngenxa yokunyuka kwendawo yokucoca, izinga lokusetyenziswa kwezinto ezikhukhulayo liyancipha.

3.2 Izixhobo zokubeka umphunga we-DC

Ukubekwa komphunga okuthe ngqo wangoku (DCPVD) ikwabizwa ngokuba yi-cathode sputtering okanye i-vacuum DC enamanqanaba amabini. Izinto ezijoliswe kuzo ze-vacuum ze-DC sputtering zisetyenziswa njenge-cathode kwaye i-substrate isetyenziswa njenge-anode. I-vacuum sputtering kukwenza iplasma ngokwenza i-ionizing inkqubo yegesi.

Iinqununu ezihlawulisiweyo kwi-plasma zikhawuleza kwintsimi yombane ukuze zifumane umlinganiselo othile wamandla. Amasuntswana anamandla aneleyo abhobhoza umphezulu wento ekujoliswe kuyo, ukuze iiathom ekujoliswe kuzo zisasazwe ngaphandle; iiathom ezisasaziweyo ezinamandla athile ekinetic zihamba zisiya kwisubstrate zenze ifilim ebhityileyo kumphezulu wesubstrate. Irhasi esetyenziselwa ukutshiza ngokuqhelekileyo yigesi enqabileyo, efana ne-argon (Ar), ngoko ifilimu eyenziwe ngokutshiza ayiyi kungcoliswa; Ukongeza, iradiyasi ye-atom ye-argon ifaneleke ngakumbi ukutshiza.

Ubungakanani bamasuntswana e-sputtering kufuneka busondele kubukhulu be-athomu ekujoliswe kuyo ukuba itshizwe. Ukuba iinqununu zikhulu kakhulu okanye zincinci kakhulu, i-sputtering esebenzayo ayinakwenziwa. Ukongeza kubungakanani beathom, ubunzima be-athomu iya kuchaphazela umgangatho wokutshiza. Ukuba i-particle sputtering source ilula kakhulu, i-athomu ekujoliswe kuyo ayiyi kuchithwa; ukuba iinqununu ze-sputtering zinzima kakhulu, injongo iya kuba "igobile" kwaye injongo ayiyi kuchithwa.

Izinto ekujoliswe kuzo ezisetyenziswe kwiDCPVD mazibe ngumqhubi. Oku kungenxa yokuba xa i-argon ion kwinkqubo yegesi ibhobhoza izinto ezijoliswe kuyo, ziya kuphinda zidibanise kunye nee-electron phezu kwezinto ezijoliswe kuzo. Xa into ekujoliswe kuyo yi-conductor efana nentsimbi, ii-electron ezisetyenzisiweyo ngolu hlanganiso ziphinda zizaliswe lula ngumbane kunye nee-electron ezikhululekile kwezinye iindawo zezinto ekujoliswe kuzo ngokuqhutywa kombane, ukuze umphezulu wezinto ekujoliswe kuzo njenge yonke ihlala ihlawulwe kakubi kwaye ukutshiza kuyagcinwa.

Ngokuchasene noko, ukuba into ekujoliswe kuyo sisigqubuthelo, emva kokuba ii-electron eziphezu kwendawo ekujoliswe kuyo ziphinde zadityaniswa, ii-electron zasimahla kwezinye iindawo zento ekujoliswe kuyo azinakuzaliswa ngokuqhutywa kombane, kwaye neentlawulo ezilungileyo ziya kuqokelelana phezu kombane. umphezulu wento ekujoliswe kuyo, ebangela ukuba izinto ekujoliswe kuzo ziphakame, kwaye intlawulo engalunganga yezinto ekujoliswe kuyo iyancipha ide iphele, ekugqibeleni ikhokelele ekuphelisweni kokutshiza.

Ngoko ke, ukuze wenze izinto zokukhusela zikwazi ukusetyenziselwa ukutshiza, kuyimfuneko ukufumana enye indlela yokutshiza. I-Radio frequency sputtering yindlela yokutshiza efanelekileyo kuzo zombini iithagethi eziqhubayo nezingaqhubiyo.

Enye into engalunganga ye-DCPVD kukuba i-voltage yokutshisa iphezulu kwaye i-electron bombardment kwi-substrate yomelele. Indlela esebenzayo yokusombulula le ngxaki kukusebenzisa i-magnetron sputtering, ngoko ke i-magnetron sputtering inexabiso elifanelekileyo kwintsimi yeesekethe ezidibeneyo.

3.3 IsiXhobo se-RF yokuFaka umphunga obonakalayo

Irediyo frequency physical vapor deposition (RFPVD) isebenzisa amandla erediyo yerediyo njengomthombo wovuselelo kwaye yindlela yePVD efanelekileyo kwiindidi zentsimbi nezingezozentsimbi.

Iifrikhwensi eziqhelekileyo zobonelelo lwamandla eRF olusetyenziswa kwi-RFPVD yi-13.56MHz, 20MHz, kunye ne-60MHz. Imijikelo eyakhayo nengalunganga yobonelelo lwamandla eRF ibonakala ngokutshintshanayo. Xa ithagethi ye-PVD ikumjikelo wesiqingatha esilungileyo, ngenxa yokuba indawo ekujoliswe kuyo ikwimeko entle, ii-electron kwi-atmosfera yenkqubo ziya kumpompoza kwindawo ekujoliswe kuyo ukuze zithintele intlawulo elungileyo eqokelelwe kumphezulu wayo, kwaye iqhubeke iqokelela ii-electron, ukwenza umphezulu wayo ube necala elibi; xa ithagethi yokutshiza ikumjikelo wesiqingatha esibi, ii-ion eziphozithivu ziyakubheka koko kujoliswe kuko kwaye zithintelwe ngokuyinxenye kumphezulu ekujoliswe kuwo.

Eyona nto ibaluleke kakhulu kukuba isantya sokuhamba kwee-elektroni kwibala lombane leRF sikhawuleza kakhulu kuneso seeyoni ezilungileyo, ngelixa ixesha lomjikelo wesiqingatha esilungileyo nesibi siyafana, ke emva komjikelo opheleleyo, indawo ekujoliswe kuyo iya kuba. "umnatha" ohlawuliswa kakubi. Ngoko ke, kwimijikelezo embalwa yokuqala, umrhumo ongalunganga wendawo ekujoliswe kuyo ubonisa ukunyuka okunyukayo; emva koko, indawo ekujoliswe kuyo ifikelela kwithuba elizinzileyo elibi; emva koko, ngenxa yokuba intlawulo engalunganga yethagethi inefuthe elichasayo kwii-electron, isixa seentlawulo ezilungileyo nezingalunganga ezifunyenwe yi-electrode ekujoliswe kuyo idla ngokulingana, kwaye ithagethi inika intlawulo ezinzileyo engalunganga.

Ukusuka kule nkqubo ingasentla, kunokubonwa ukuba inkqubo yokwakhiwa kwamandla ombane ongalunganga ayinanto yakwenza neempawu zezinto ekujoliswe kuzo ngokwazo, ngoko ke indlela ye-RFPVD ayinakusombulula kuphela ingxaki yokutshiza kweethagethi ze-insulating, kodwa ihambelana kakuhle. ngeethagethi zomqhubi wentsimbi eqhelekileyo.

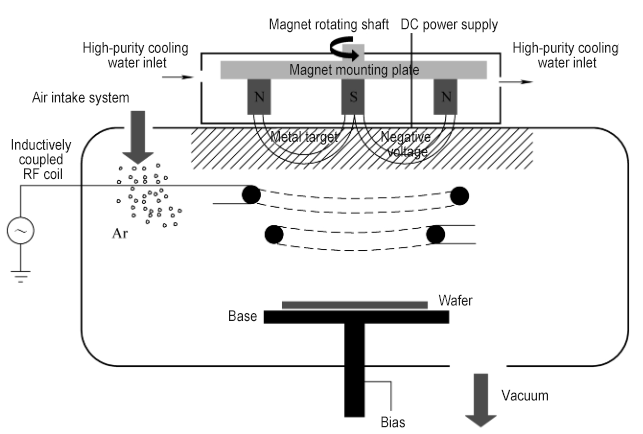

3.4 Isixhobo sokutshiza ngeMagnetron

I-Magnetron sputtering yindlela yePVD eyongeza iimagnethi ngasemva koko kujoliswe kuko. Iimagnethi ezongeziweyo kunye nonikezelo lwamandla lweDC (okanye unikezelo lwamandla e-AC) lwenza i-magnetron sputtering source. Umthombo we-sputtering usetyenziselwa ukwenza intsimi ye-electromagnetic esebenzayo kwigumbi, ukubamba kunye nokunciphisa umda wokuhamba kwee-electron kwiplasma ngaphakathi kwegumbi, ukwandisa indlela yokuhamba yee-electron, kwaye ngaloo ndlela ukwandisa ukuxinana kweplasma, kwaye ekugqibeleni uzuze ngakumbi. ukubekwa.

Ukongezelela, ngenxa yokuba ii-electron ezininzi ziboshwe kufuphi nomphezulu wenjongo, i-bombardment ye-substrate ngama-electron iyancitshiswa, kwaye ubushushu be-substrate buyancipha. Xa kuthelekiswa netekhnoloji ye-DCPVD yeplati ecaba, enye yezona zinto zicacileyo zetekhnoloji yokubeka umphunga wemagnetron kukuba i-voltage yokukhupha i-ignition isezantsi kwaye izinzile.

Ngenxa yoxinzelelo oluphezulu lweplasma kunye nesivuno esikhulu sokutshiza, inokufezekisa ukusebenza kakuhle kokubekwa, ukulawula ubukhulu bokubekwa kuluhlu lobungakanani obukhulu, ulawulo oluchanekileyo lokubumba kunye nombane ophantsi wokutshisa. Ke ngoko, i-magnetron sputtering ikwisikhundla esiphezulu kwifilimu yentsimbi yangoku yePVD. Eyona nto ilula uyilo lomthombo we-magnetron sputtering kukubeka iqela lemagnethi ngasemva kwithagethi ecaba (ngaphandle kwenkqubo yokufunxa) ukuvelisa intsimi yemagnethi engqamene nendawo ekujoliswe kuyo kwindawo yendawo ekujoliswe kuyo.

Ukuba imagnethi esisigxina ibekwe, intsimi yayo yamagnetic iqinisiwe, okukhokelela ekuhanjisweni kwemagnethi esisigxina kwindawo ekujoliswe kuyo kwigumbi. Izinto eziphathekayo kuphela kwiindawo ezithile ezijoliswe kuzo zichithwa, izinga lokusetyenziswa okujoliswe kuyo liphantsi, kwaye ukufana kwefilimu elungiselelwe kubi.

Kukho ithuba elithile lokuba isinyithi esputtered okanye ezinye izinto eziphathekayo ziya kuphinda zifakwe kwindawo ekujoliswe kuyo, ngaloo ndlela zidibanisa zibe ngamaqhekeza kwaye zenze ukungcola kwesiphene. Ke ngoko, imithombo yokuthengisa imagnetron sputtering ubukhulu becala isebenzisa uyilo lwemagnethi ejikelezayo ukuphucula ukufana kwefilimu, izinga lokusetyenziswa ekujoliswe kulo, kunye nokutshixa okujoliswe kuko okupheleleyo.

Kubalulekile ukulungelelanisa ezi zinto zintathu. Ukuba ibhalansi ayiphathwanga kakuhle, inokubangela ukufana kwefilimu enhle ngelixa inciphisa kakhulu izinga lokusetyenziswa okujoliswe kuyo (ukunciphisa ubomi obujoliswe kuyo), okanye ukusilela ukufezekisa ukutshatyalaliswa okujoliswe kuyo ngokupheleleyo okanye ukubola okujoliswe kuyo ngokupheleleyo, okuya kubangela iingxaki ze-particle ngexesha lokutshiza. inkqubo.

Kwitekhnoloji yePVD yemagnetron, kuyafuneka ukuba kuthathelwe ingqalelo umatshini wokushukuma umazibuthe ojikelezayo, imilo ekujoliswe kuyo, inkqubo yokupholisa ekujoliswe kuyo kunye nomthombo wokutshiza wemagnetron, kunye nokucwangciswa okusebenzayo kwesiseko esithwala iwafer, njenge-wafer adsorption kunye nolawulo lobushushu. Kwinkqubo ye-PVD, ubushushu be-wafer bulawulwa ukufumana isakhiwo se-crystal esifunekayo, ubungakanani bengqolowa kunye nokuqhelaniswa, kunye nokuzinza kokusebenza.

Ekubeni ukuqhutyelwa kobushushu phakathi komva we-wafer kunye nomphezulu wesiseko kufuna uxinzelelo oluthile, ngokuqhelekileyo ngokulandelelana kweTorr ezininzi, kunye noxinzelelo olusebenzayo lwegumbi ludla ngokulandelelana kweemTorr ezininzi, uxinzelelo ngasemva. I-wafer inkulu kakhulu kunoxinzelelo olukumphezulu we-wafer, ngoko ke i-chuck yomatshini okanye i-electrostatic chuck iyafuneka ukubeka kunye nokunciphisa i-wafer.

I-chuck yomatshini ixhomekeke kubunzima bayo kunye nomda we-wafer ukufezekisa lo msebenzi. Nangona ineenzuzo zesakhiwo esilula kunye nokungakhathali kwizinto eziphathekayo ze-wafer, umphumo we-edge we-wafer uyabonakala, ongenakuhambelana nokulawulwa okungqongqo kweengqungquthela. Ke ngoko, ithathelwe indawo ngokuthe ngcembe yi-electrostatic chuck kwinkqubo yokwenziwa kwe-IC.

Kwiinkqubo ezingakhathaleli kakhulu kwiqondo lobushushu, i-non-adsorption, i-non-edge contact shelving method (akukho ntlupheko yoxinzelelo phakathi kweendawo eziphezulu nezisezantsi ze-wafer) nazo zingasetyenziswa. Ngethuba lenkqubo ye-PVD, umgca wegumbi kunye nomphezulu weendawo ezidibene ne-plasma ziya kufakwa kwaye zigqunywe. Xa ubukhulu befilimu obugciniweyo budlula umda, ifilimu iya kuqhekeza kwaye ikhuphe, ibangele iingxaki ze-particle.

Ngoko ke, unyango olungaphezulu lweengxenye ezifana ne-lining luyisitshixo sokwandisa lo mda. I-sandblasting ye-surface kunye ne-aluminium yokutshiza zimbini iindlela ezisetyenziswa ngokuqhelekileyo, injongo yoko kukwandisa uburhabaxa bomphezulu ukuqinisa ukudibanisa phakathi kwefilimu kunye ne-lining surface.

3.5 I-ionization Physical Vapor Deposition Isixhobo

Ngophuhliso oluqhubekayo lwetekhnoloji ye-microelectronics, ubukhulu beempawu buya buncinci kwaye buncinci. Kuba itekhnoloji ye-PVD ayinako ukulawula indlela yokubekwa kwamasuntswana, ukukwazi kwe-PVD ukungena ngemingxunya kunye nemijelo emxinwa enomlinganiselo ophezulu wokulinganisa ulinganiselwe, okwenza ukusetyenziswa okwandisiweyo kobuchwepheshe be-PVD bendabuko kucela umngeni. Kwinkqubo ye-PVD, njengoko umyinge we-aspect ratio ye-pore groove isanda, i-coverage esezantsi iyancipha, yenza i-eaves-efana nesakhiwo sokuxhoma kwikona ephezulu, kwaye yenze i-coverage ebuthathaka kwikona esezantsi.

Itekhnoloji ye-ionized yokubeka umphunga womzimba yaphuhliswa ukusombulula le ngxaki. Iqala ngeplasmatize iiathom zentsimbi ezisasazeke ukusuka ekujoliswe kuko ngeendlela ezahlukeneyo, emva koko ilungelelanise amandla ombane ocalanye alayishwe kwi-wafer ukulawula isalathiso kunye namandla e-ion zetsimbi ukufumana i-ion yensimbi ezinzileyo yokuhamba ukuze kulungiswe ifilimu ebhityileyo, ngaloo ndlela iphucula. ukugutyungelwa kwezantsi kwamanyathelo omlinganiselo ophezulu wenkalo ngokusebenzisa imingxuma kunye nemijelo emxinwa.

Uphawu oluqhelekileyo lwetekhnoloji ye-ionized metal plasma kukongezwa kwekhoyili yamaza kanomathotholo kwigumbi. Ngethuba lenkqubo, uxinzelelo olusebenzayo lwegumbi lugcinwa kwindawo ephakamileyo (i-5 ukuya ku-10 amaxesha oxinzelelo oluqhelekileyo lokusebenza). Ngexesha le-PVD, i-coil yerediyo yerediyo isetyenziselwa ukuvelisa indawo yesibini yeplasma, apho i-argon plasma concentration inyuka ngokunyuka kwamandla kanomathotholo kunye noxinzelelo lwegesi. Xa ii-athom zesinyithi zigxobhoza ukusuka ekujoliswe kuzo zidlula kulo mmandla, zisebenzisana ne-argon plasma ephezulu yoxinaniso ukuze zenze i-ion zetsimbi.

Ukusebenzisa umthombo we-RF kwisiphathi se-wafer (efana ne-electrostatic chuck) kunokonyusa i-bias engalunganga kwi-wafer ukutsala ii-ion zentsimbi ezikhabayo ezantsi kwe pore groove. Oku kuhamba nge-ion yensimbi ejikelezayo kumphezulu we-wafer kuphucula ukugubungela inyathelo elisezantsi leepores zomlinganiselo ophezulu kunye nemijelo emxinwa.

Icala elibi elisetyenziswa kwiwafer likwabangela ukuba ii-ion zibhombuze umphezulu wewafer (reverse sputtering), ethi yenza buthathaka isakhiwo esijingayo somlomo we pore groove kwaye iphalaze ifilimu efakwe emazantsi emacaleni kwiikona zomzantsi we pore. i-groove, ngaloo ndlela iphucula ukugubungela inyathelo kwiikona.

3.6 Uxinzelelo lwe-Atmospheric Isixhobo se-Chemical Vapor Deposition Deposition

Isixhobo soxinzelelo lwe-atmospheric chemical vapor deposition (APCVD) sibhekisa kwisixhobo esitshiza umthombo wokusabela kwegesi ngesantya esingaguqukiyo kumphezulu wesubstrate eshushu eqinileyo phantsi kokusingqongileyo noxinzelelo olusondele kuxinzelelo lomoya, obangela ukuba umthombo wokusabela usabele ngokwekhemikhali i-substrate surface, kunye nemveliso yokusabela ifakwe kwi-substrate surface ukwenza ifilimu ebhityileyo.

Izixhobo ze-APCVD sesona sixhobo se-CVD sokuqala kwaye sisasetyenziswa ngokubanzi kwimveliso yamashishini kunye nophando lwezenzululwazi. Izixhobo ze-APCVD zingasetyenziselwa ukulungiselela iifilimu ezincinci ezifana ne-silicon eyodwa yekristale, i-silicon ye-polycrystalline, i-silicon dioxide, i-zinc oxide, i-titanium dioxide, iglasi ye-phosphosilicate, kunye neglasi ye-borophosphosilicate.

3.7 Uxinzelelo oluphantsi lweSixhobo sokuBeka uMphunga weMichiza

Isixhobo soxinzelelo olusezantsi lwekhemikhali yokufaka umphunga (LPCVD) sibhekisa kwisixhobo esisebenzisa izixhobo ezisetyenziswa yigesi ekrwada ukusabela ngokwekhemikhali kumphezulu wesubstrate eqinileyo phantsi kobushushu (350-1100°C) kunye noxinzelelo oluphantsi (10-100mTorr) okusingqongileyo, kunye i-reactants ifakwe kumphezulu we-substrate ukwenza ifilimu encinci. Izixhobo ze-LPCVD ziphuhliswa ngesiseko se-APCVD ukuphucula umgangatho weefilimu ezibhityileyo, ukuphucula ukufana kokusasazwa kweempawu zeempawu ezifana nobukhulu befilimu kunye nokumelana, kunye nokuphucula ukusebenza kakuhle kwemveliso.

Isici sayo esiphambili kukuba kwindawo ephantsi yoxinzelelo lwe-thermal field, inkqubo yegesi ithatha ikhemikhali kumphezulu we-wafer substrate, kwaye iimveliso zokusabela zifakwe kwi-substrate surface ukwenza ifilimu encinci. Izixhobo zeLPCVD zineengenelo ekulungiseleleni iifilimu ezibhityileyo ezikumgangatho ophezulu kwaye zingasetyenziselwa ukulungisa iifilim ezincinci ezifana nesilicon oxide, isilicon nitride, i-polysilicon, isilicon carbide, i-gallium nitride kunye negraphene.

Xa kuthelekiswa ne-APCVD, indawo yokusabela yoxinzelelo oluphantsi lwezixhobo ze-LPCVD yonyusa indlela yasimahla kunye ne-coefficient yokusasazwa kwegesi kwigumbi lokuphendula.

I-reaction gas kunye ne-carrier yegesi iimolekyuli kwigumbi lokuphendula zingasasazwa ngokulinganayo ngexesha elifutshane, ngaloo ndlela kuphuculwe kakhulu ukufana kobunzima befilimu, ukufana okufanayo kunye nokugubungela inyathelo lefilimu, kunye nokusetyenziswa kwegesi yokusabela kuncinci. Ukongeza, indawo yoxinzelelo oluphantsi nayo ikhawulezisa isantya sothumelo lwezinto zegesi. Ukungcola kunye ne-reaction by-products esasazwa kwi-substrate inokukhutshwa ngokukhawuleza kwindawo yokusabela ngokusebenzisa umda womda, kwaye igesi yokusabela idlula ngokukhawuleza kumaleko womda ukufikelela kumphezulu we-substrate ukuze iphendule, ngaloo ndlela icinezela ngokufanelekileyo i-self-doping, ukulungiselela. Iifilimu ezikumgangatho ophezulu ezinemimandla yotshintsho, kunye nokuphucula ukusebenza kakuhle kwemveliso.

3.8 Izixhobo zePlasma Ezongeziweyo zoMphunga weMichiza

I-Plasma iphuculwe i-chemical vapor deposition (PECVD) yinto esetyenziswa ngokubanziitekhnoloji yokubeka ifilimu ngehin. Ngethuba lenkqubo ye-plasma, i-precursor ye-gaseous i-ionized phantsi kwesenzo se-plasma ukwenza amaqela asebenzayo anomdla, asasazeke kwindawo ye-substrate kwaye emva koko enze ii-chemical reactions ukugqiba ukukhula kwefilimu.

Ngokwe-frequency ye-plasma generation, i-plasma esetyenziswe kwi-PECVD inokwahlulwa ibe ziindidi ezimbini: i-radio frequency plasma (RF plasma) kunye ne-microwave plasma (i-Microwave plasma). Okwangoku, amaza kanomathotholo asetyenziswa kushishino ngokubanzi yi-13.56MHz.

Ukuqaliswa kwe-plasma ye-radio frequency ngokuqhelekileyo kwahlulahlula kwiindidi ezimbini: i-capacitive coupling (CCP) kunye ne-inductive coupling (ICP). Indlela yokudibanisa i-capacitive ngokuqhelekileyo yindlela yokuphendula ngokuthe ngqo kwi-plasma; ngelixa indlela yokudibanisa i-inductive ingaba yindlela echanekileyo ye-plasma okanye indlela ye-plasma ekude.

Kwiinkqubo zokuvelisa i-semiconductor, i-PECVD isoloko isetyenziselwa ukukhulisa iifilimu ezincinci kwii-substrates ezinezinyithi okanye ezinye izakhiwo ezinobushushu bobushushu. Ngokomzekelo, kwintsimi ye-metal-end interconnection ye-circuits ezidibeneyo, ekubeni umthombo, isango kunye nezakhiwo ze-drain zesixhobo zenziwe kwinkqubo yangaphambili, ukukhula kweefilimu ezibhityileyo kwintsimi yokudibanisa isinyithi kuxhomekeke. kwimiqobo engqongqo kakhulu yohlahlo lwabiwo-mali lobushushu, ngoko ke idla ngokugqityezelwa ngoncedo lweplasma. Ngokulungelelanisa iiparamitha zenkqubo yeplasma, ubuninzi, ukubunjwa kweekhemikhali, umxholo wokungcola, ukuqina komatshini kunye neeparitha zoxinzelelo zefilimu encinci ekhuliswe yi-PECVD inokulungelelaniswa kwaye ilungiswe phakathi koluhlu oluthile.

3.9 Izixhobo zoMaleko we-Atomic

I-Atomic layer Deposition (ALD) bubuchwephesha bokubekwa kwefilim ecekethekileyo ekhula ngamaxesha athile ngokomaleko we-quasi-monoatomic. Uphawu lwayo kukuba ubukhulu befilimu egciniweyo bunokulungiswa ngokuchanekileyo ngokulawula inani lemijikelezo yokukhula. Ngokungafaniyo nenkqubo ye-chemical vapor deposition (CVD), ezimbini (okanye ngaphezulu) zandulela kwinkqubo ye-ALD zidlula ngokuhlukileyo kwi-substrate surface kwaye zihlulwe ngokufanelekileyo ngokucocwa kwegesi enqabileyo.

Izandulela ezimbini aziyi kudibanisa kwaye zihlangane kwisigaba segesi ukuze ziphendule ngamakhemikhali, kodwa zisabela kuphela nge-adsorption yeekhemikhali kwi-substrate surface. Kumjikelezo ngamnye we-ALD, isixa se-precursor adsorbed kwi-substrate surface inxulumene noxinaniso lwamaqela asebenzayo kwi-substrate surface. Xa amaqela asebenzayo kwi-substrate surface aphelile, nangona ukugqithisa kwe-precursor kungeniswa, i-adsorption yeekhemikhali ayiyi kwenzeka kwi-substrate surface.

Le nkqubo yokusabela ibizwa ngokuba yi-surface self-limiting reaction. Le nkqubo yenkqubo yenza ukuba ubukhulu befilimu bukhule kumjikelo ngamnye wenkqubo ye-ALD rhoqo, ngoko ke inkqubo ye-ALD ineenzuzo zolawulo oluchanekileyo kunye nenyathelo lefilimu elungileyo.

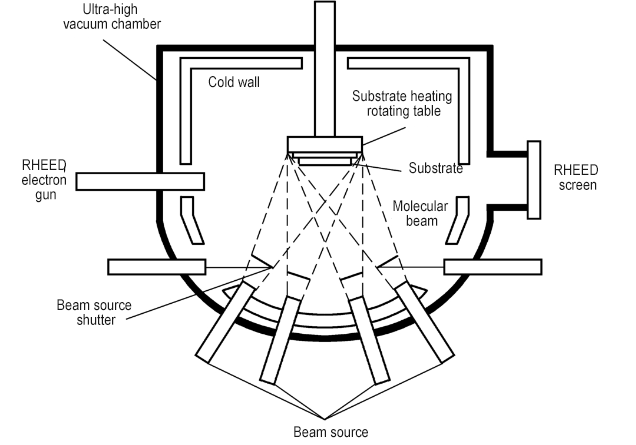

3.10 Isixhobo se-Molecular Beam Epitaxy

Inkqubo ye-Molecular Beam Epitaxy (MBE) ibhekiselele kwisixhobo se-epitaxial esisebenzisa enye okanye ngaphezulu imiqadi ye-athom yamandla e-thermal okanye imiqadi yemolekyuli ukutshiza kumphezulu we-substrate eshushu ngesantya esithile phantsi kweemeko ze-vacuum eziphezulu, kwaye i-adsorb kwaye ifudukele kumphezulu we-substrate. ukukhulisa i-epitaxially ifilimu enye yekristale encinci ecaleni kwendlela ye-crystal axis ye-substrate material. Ngokuqhelekileyo, phantsi kweemeko zokufudumeza ngesithando somlilo esinekhuselo lobushushu, umthombo we-athomu wenza umqadi we-athomu okanye i-molecular beam, kwaye ifilimu ikhula umaleko ngomgca ecaleni kolwalathiso lwe-crystal axis ye-substrate material.

Iimpawu zayo ziphantsi kobushushu bokukhula kwe-epitaxial, kwaye ubukhulu, i-interface, ukubunjwa kweekhemikhali kunye nokugxininiswa kokungcola kunokulawulwa ngokuchanekileyo kwinqanaba le-athomu. Nangona i-MBE ivela ekulungiseleleni iifilimu zekristale ze-semiconductor ultra-thin single crystal, ukusetyenziswa kwayo ngoku kuye kwanda kwiinkqubo zezinto eziphathekayo ezifana nesinyithi kunye ne-insulating dielectrics, kwaye inokulungiselela i-III-V, II-VI, i-silicon, i-silicon germanium (SiGe ), igraphene, iioksidi kunye neefilimu eziphilayo.

Inkqubo ye-molecular beam epitaxy (MBE) ikakhulu iqulunqwe yi-ultra-high vacuum system, umthombo we-molecular beam, i-substrate fixing kunye nenkqubo yokufudumeza, inkqubo yokudlulisa isampuli, inkqubo yokubeka iliso kwi-situ, inkqubo yokulawula, kunye novavanyo. inkqubo.

Inkqubo yokucoca ibandakanya iimpompo ze-vacuum (iimpompo zomatshini, iimpompo ze-molecular, iipompo ze-ion, kunye neepompo ze-condensation, njl.) kunye neevalve ezahlukeneyo, ezinokudala indawo yokukhula kwe-vacuum ephezulu. Iqondo elifikelelekayo levacuum ngokubanzi li-10-8 ukuya kwi-10-11 Torr. Inkqubo yokufunxa ubukhulu becala inamagumbi okufunxa amathathu, angala gumbi lokutofa isampuli, igumbi lonyango lwangaphambili kunye negumbi lokuhlalutya umphezulu, kunye negumbi lokukhula.

Igumbi lokutofa isampula lisetyenziselwa ukudlulisa iisampuli kwihlabathi langaphandle ukuze kuqinisekiswe iimeko eziphezulu ze-vacuum zamanye amagumbi; Igumbi lokuhlalutywa kwangaphambili kunye negumbi lokuhlalutya umphezulu lidibanisa igumbi lokutofa isampuli kunye negumbi lokukhula, kwaye umsebenzi walo ophambili kukucubungula kwangaphambili isampuli (i-high-temperature degassing ukuqinisekisa ukucoceka okupheleleyo komphezulu we-substrate) kunye nokwenza uhlalutyo lwangaphambili kumphezulu. isampuli ecocekileyo; Igumbi lokukhula liyinxalenye ephambili yenkqubo ye-MBE, ikakhulu iqulunqwe sisithando somlilo kunye nendibano yayo yesivalo esihambelanayo, isampula yokulawula i-console, inkqubo yokupholisa, i-reflection ye-electron high energy diffraction (RHEED), kunye ne-in-situ monitoring system. . Ezinye izixhobo zeMBE zokuvelisa zineendlela ezininzi zokukhula kwegumbi. Umzobo oqingqiweyo wesakhiwo sesixhobo se-MBE uboniswe ngezantsi:

I-MBE yezinto ze-silicon isebenzisa i-silicon ecocekileyo njengezinto eziluhlaza, ikhula phantsi kweemeko ze-vacuum ephezulu kakhulu (10-10~10-11Torr), kunye nobushushu bokukhula yi-600~900℃, kunye ne-Ga (P-uhlobo) kunye ne-Sb ( N-uhlobo) njengemithombo ye-doping. Imithombo ye-doping esetyenziswa ngokuqhelekileyo njenge-P, As no-B ayifane isetyenziswe njengemithombo ye-beam kuba kunzima ukuyikhupha.

I-reaction chamber ye-MBE ine-ultra-high vacuum bume, eyandisa intsingiselo yamahhala yeemolekyuli kwaye inciphisa ukungcoliseka kunye ne-oxidation kumphezulu wezinto ezikhulayo. Izinto ze-epitaxial ezilungiselelwe zine-morphology entle yomhlaba kunye nokufana, kwaye zingenziwa kwisakhiwo se-multilayer kunye ne-doping eyahlukeneyo okanye amacandelo ahlukeneyo.

Itekhnoloji ye-MBE ifezekisa ukukhula okuphindaphindiweyo kwe-ultra-thin epitaxial layers kunye nobukhulu bomaleko we-athomu enye, kwaye ujongano phakathi kwe-epitaxial layers ngumnqantsa. Ikhuthaza ukukhula kwee-semiconductors ze-III-V kunye nezinye izinto ezininzi ze-heterogeneous. Okwangoku, inkqubo ye-MBE iye yaba sisixhobo senkqubo ephuculweyo yokuvelisa isizukulwana esitsha sezixhobo ze-microwave kunye nezixhobo ze-optoelectronic. Izinto ezingeloncedo zobugcisa be-MBE zisantya sokukhula kwefilimu, iimfuno eziphezulu ze-vacuum, kunye neendleko eziphezulu zokusetyenziswa kwezixhobo kunye nezixhobo.

3.11 Inkqubo ye-Epitaxy yeSigaba soMphunga

Inkqubo ye-vapor phase epitaxy (VPE) ibhekisela kwisixhobo sokukhula kwe-epitaxial esihambisa i-gaseous compounds kwi-substrate kwaye ifumane i-crystal material layer kunye nelungiselelo elifanayo le-lattice njenge-substrate ngokusebenzisa iikhemikhali. I-epitaxial layer ingaba yi-homoepitaxial layer (Si/Si) okanye i-heteroepitaxial layer (SiGe/Si, SiC/Si, GaN/Al2O3, njl.). Okwangoku, iteknoloji ye-VPE isetyenziswe ngokubanzi kwiinkalo zokulungiswa kwe-nanomaterial, izixhobo zamandla, izixhobo ze-optoelectronic ze-semiconductor, i-photovoltaics yelanga, kunye neesekethe ezidibeneyo.

I-VPE eqhelekileyo iquka i-epitaxy yoxinzelelo lwe-atmospheric kunye nokunciphisa uxinzelelo lwe-epitaxy, i-ultra-high vacuum ye-chemical vapor deposition, i-metal organic chemical organic vapor deposition, njl. ulawulo loxinzelelo kunye nokuzinza, i-particle kunye ne-defect control, njl.

Okwangoku, umkhombandlela wophuhliso lweenkqubo ze-VPE zentengiso kumthwalo omkhulu we-wafer, ulawulo oluzenzekelayo ngokupheleleyo, kunye nokubeka iliso ngexesha lokwenyani lobushushu kunye nenkqubo yokukhula. Iinkqubo ze-VPE zinezakhiwo ezintathu: ezithe nkqo, ezithe tyaba kunye ne-cylindrical. Iindlela zokufudumeza ziquka ukufudumeza ukuxhathisa, ukufudumala kwe-high-frequency induction heat kunye ne-infrared radiation heat.

Okwangoku, iinkqubo ze-VPE ezininzi zisebenzisa izakhiwo zediski ezithe tye, ezineempawu zokufana okuhle kokukhula kwefilimu ye-epitaxial kunye nokulayisha okukhulu kwe-wafer. Iinkqubo ze-VPE zihlala zineendawo ezine: i-reactor, inkqubo yokufudumeza, inkqubo yegesi kunye nenkqubo yokulawula. Ngenxa yokuba ixesha lokukhula kweefilimu ze-GaAs kunye ne-GaN epitaxial lide kakhulu, ukufudumeza kwe-induction kunye nokufudumala kokumelana kusetyenziswa kakhulu. Kwi-silicon VPE, ukukhula kwefilimu eshinyeneyo ye-epitaxial ikakhulu isebenzisa ukufudumeza kwe-induction; ukukhula kwefilim ye-epitaxial encinci kakhulu isebenzisa ukufudumeza kwe-infrared ukufezekisa injongo yokunyuka kwamaqondo obushushu / ukuwa.

3.12 Inkqubo ye-Epitaxy yeSigaba soLiquid

Inkqubo ye-Liquid Phase Epitaxy (LPE) ibhekisela kwisixhobo sokukhula kwe-epitaxial esinyibilikisa izinto eziza kukhuliswa (ezifana ne-Si, Ga, As, Al, njl.) kunye needopants (ezifana neZn, Te, Sn, njl.) Isinyithi esinendawo esezantsi yokunyibilika (efana neGa, In, njl. njl.), ukuze i-solute ihluthe okanye ixutywe kakhulu kwi-solvent, kwaye ke i-crystal substrate enye udibene nesisombululo, kwaye i-solute iyancipha kwi-solvent ngokuthe ngcembe ipholisa phantsi, kunye noluhlu lwe-crystal material ene-crystal structure kunye ne-lattice eqhubekayo efana ne-substrate ikhuliswe phezu kwe-substrate.

Indlela ye-LPE yacetywa nguNelson et al. ngo 1963. Isetyenziselwa ukukhulisa iifilimu ezibhityileyo kunye nekristale enye, kunye nezixhobo zesemiconductor njengamaqela e-III-IV kunye ne-mercury cadmium telluride, kwaye ingasetyenziselwa ukwenza izixhobo ezahlukeneyo ze-optoelectronic, izixhobo ze-microwave, izixhobo ze-semiconductor kunye neeseli zelanga. .

————————————————————————————————————————————————— ————————————-

I-Semicera inokubonelelaiindawo zegraphite, uthambile/uqinile, iinxalenye ze-silicon carbide, CVD iinxalenye zesilicon carbide, kwayeIindawo ezigqunywe yiSiC/TaCnge 30 iintsuku.

Ukuba unomdla kwezi mveliso zesemiconductor zingasentla,nceda ungathandabuzi ukuqhagamshelana nathi okokuqala.

Umnxeba: +86-13373889683

Whatsapp: +86-15957878134

Email: sales01@semi-cera.com

Ixesha lokuposa: Aug-31-2024