1. Intshayelelo

Ukufakelwa kwe-Ion yenye yeenkqubo eziphambili kwimveliso yesekethe edibeneyo. Ibhekisela kwinkqubo yokukhawulezisa i-ion beam kumandla athile (ngokubanzi kuluhlu lwe-keV ukuya kwi-MeV) kwaye emva koko uyifake kumphezulu wezinto eziqinileyo ukuze utshintshe iimpawu ezibonakalayo zomphezulu wezinto eziphathekayo. Kwinkqubo yesekethe edibeneyo, izinto eziqinileyo zihlala zi-silicon, kwaye ii-ion zokungcola ezifakelweyo zidla ngokuba yi-boron ion, i-phosphorus ions, i-arsenic ions, i-indium ion, i-germanium ions, njl. izinto okanye wenze isiphambuka sePN. Xa ubukhulu beempawu zeesekethe ezidibeneyo zancitshiswa kwixesha le-sub-micron, inkqubo yokufakelwa kwe-ion yayisetyenziswa ngokubanzi.

Kwinkqubo yokwenziwa kwesekethe edibeneyo, ukufakelwa kwe-ion ngokuqhelekileyo kusetyenziselwa iileyile ezingcwatyiweyo ezinzulu, i-reverse doped sources, ukulungiswa kwe-voltage ye-threshold, umthombo kunye nokufakelwa kwe-drain extension implantation, umthombo kunye nokufakelwa kwe-drain, i-polysilicon gate doping, ukwenza i-PN junctions kunye ne-resistors / capacitors, njl. Kwinkqubo yokulungisa imathiriyeli ye-silicon kwi-insulators, umaleko we-oxide ongcwatyiweyo wenziwa ikakhulu kukufakelwa kwe-ion yeoksijini ephezulu, okanye ngobukrelekrele. ukusika kufezekiswa ngokugxunyekwa okuphezulu kwe-hydrogen ion implantation.

Ukufakelwa kwe-ion kwenziwa yi-ion implanter, kwaye eyona nto ibaluleke kakhulu iiparameters zenkqubo yi-dose kunye namandla: idosi inquma ukugxininiswa kokugqibela, kwaye amandla anquma uluhlu (oko kukuthi, ubunzulu) be-ion. Ngokweemfuno zoyilo lwesixhobo ezahlukeneyo, iimeko zokufakelwa zahlulwe kwidosi ephezulu yamandla, idosi ephakathi-eneji, idosi ephakathi-eneji eliphantsi, okanye idosi ephezulu yamandla aphantsi. Ukuze ufumane isiphumo esifanelekileyo sofakelo, izifakeli ezahlukeneyo kufuneka zixhotyiselwe iimfuno zenkqubo ezahlukeneyo.

Emva kokufakelwa kwe-ion, kuyafuneka ngokubanzi ukuba kuqhutywe inkqubo ye-annealing yobushushu obuphezulu ukulungisa umonakalo we-lattice obangelwa kukufakelwa kwe-ion kunye nokuvula ii-ion zokungcola. Kwiinkqubo zesekethe ezidityanisiweyo zemveli, nangona ukushisa kwe-annealing kunempembelelo enkulu kwi-doping, ubushushu benkqubo yokufakelwa kwe-ion ngokwayo ayibalulekanga. Kwiindawo zeteknoloji ezingaphantsi kwe-14nm, iinkqubo ezithile zokufakelwa kwe-ion kufuneka zenziwe kwiindawo eziphantsi okanye eziphezulu zokushisa ukuze zitshintshe imiphumo yomonakalo we-lattice, njl.

2. inkqubo yokufakelwa kwe-ion

2.1 Imigaqo-siseko

Ukufakelwa kwe-Ion yinkqubo yedoping eyaphuhliswa ngeminyaka yoo-1960 egqwesileyo kubuchule bokusasaza bemveli kwimiba emininzi.

Umahluko ophambili phakathi kwedoping yokufakelwa kwe-ion kunye ne-doping yendabuko yokusasazwa kolu hlobo lulandelayo:

(1) Ukusasazwa kokugxininiswa kokungcola kummandla we-doped kuyahluka. Incopho yoxinaniso lokungcola kwe-ion implantation ifumaneka ngaphakathi kwekristale, ngelixa incopho yoxinaniso yokungcola kokusasazwa ibekwe phezu komphezulu wekristale. (2) Ukufakelwa kwe-ion yinkqubo eqhutyelwa kwiqondo lokushisa okanye kwiqondo lokushisa eliphantsi, kwaye ixesha lokuvelisa lifutshane. Ukusasazwa kwedoping kufuna unyango olude lobushushu obuphezulu. (3) Ukufakelwa kwe-ion kuvumela ukhetho oluguquguqukayo kunye noluchanekileyo lwezinto ezifakelweyo. (4) Ekubeni ukungcola kuchaphazeleka kukusasazwa kwe-thermal, i-waveform eyenziwe yi-ion implantation kwi-crystal ingcono kune-waveform eyenziwe ngokusasazwa kwi-crystal. (5) Ukufakelwa kwe-iyoni ngokuqhelekileyo kusebenzisa kuphela i-photoresist njengesixhobo semaski, kodwa i-diffusion doping ifuna ukukhula okanye ukubekwa kwefilimu yobunzima obuthile njengemaski. (6) Ukufakelwa kwe-ion ngokusisiseko kuthathe indawo yokusasazwa kwaye ibe yeyona nkqubo iphambili yedoping ekwenzeni iisekethe ezidibeneyo namhlanje.

Xa isiganeko se-ion beam esinamandla athile sibhobhoza into ekujoliswe kuyo eyomeleleyo (idla ngokuba yi-wafer), ii-ion kunye nee-athom ezikumphezulu ekujoliswe kuwo ziya kudibana ngeendlela ezahlukeneyo zokusebenzisana, kwaye zidlulisele amandla kwii-athom ekujoliswe kuzo ngendlela ethile ukuze zivuyise okanye zibe ne-ionize. bona. I-ion inokulahlekelwa ngumlinganiselo othile wamandla ngokugqithiselwa ngokukhawuleza, kwaye ekugqibeleni isasazwe ngama-athomu ekujoliswe kuwo okanye ukuyeka kwizinto ezijoliswe kuzo. Ukuba iiyoni ezitofwayo zinzima, uninzi lweeyoni ziya kugalelwa kwithagethi eqinileyo. Ngokuchasene noko, ukuba ii-ion ezitofwayo zikhaphukhaphu, uninzi lwee-ion ezitofiweyo ziya kugxumeka kumphezulu ojoliswe kuwo. Ngokusisiseko, ezi ion zamandla aphezulu zitofelwe kwithagethi ziya kungqubana ne-athomu ye-lattice kunye nee-electron kwithagethi eqinileyo ukuya kumaqondo ahlukeneyo. Phakathi kwazo, ungquzulwano phakathi kwee-ion kunye nee-athom ekujoliswe kuzo eziqinileyo zinokuthathwa njengongquzulwano olulastiki kuba zisondele ngobunzima.

2.2 Iiparamitha eziphambili zokufakelwa kwe-ion

Ukufakelwa kwe-ion yinkqubo ebhetyebhetye ekufuneka ihlangabezane noyilo olungqongqo lwetshiphu kunye neemfuno zemveliso. Iiparamitha zokufakelwa kwe-ion ezibalulekileyo zezi: idosi, uluhlu.

Idosi (D) ibhekisa kwinani leeyoni ezitofwayo ngeyunithi yendawo nganye yomphezulu wesilicon wafer, kwii-atom nge-square centimeter (okanye iiyoni nge-square centimeter). D ingabalwa ngale fomula ilandelayo:

Apho D idosi yokufakelwa (inani leeyoni/iyunithi yendawo); t lixesha lokufakelwa; Ndim umsinga; q yintlawulo eyenziwa yi-ion (intlawulo enye yi-1.6 × 1019C [1]); kwaye i-S yindawo yokufakelwa.

Esinye sezizathu eziphambili zokuba kutheni ukufakelwa kwe-ion kube yitekhnoloji ebalulekileyo ekwenzeni i-silicon wafer kukuba inokuphinda ifake idosi efanayo yokungcola kwii-silicon wafers. I-implanter ifezekisa le njongo ngoncedo lwentlawulo emihle ye-ion. Xa i-ion yokungcola i-positive yenze i-ion beam, izinga lokuhamba kwayo libizwa ngokuba yi-ion beam current, elinganiselwa kwi-mA. Uluhlu lwemijelo ephakathi kunye nephantsi luyi-0.1 ukuya kwi-10 mA, kunye noluhlu oluphezulu lwamanzi luyi-10 ukuya kwi-25 mA.

Ubungakanani be-ion beam yangoku yinguqu ephambili ekuchazeni umthamo. Ukuba ukwanda kwangoku, inani le-athomu zokungcola ezifakwe ngexesha leyunithi liyanda. Umgangatho ophezulu wangoku ulungele ukunyusa isivuno se-silicon wafer (ukutofa ii-ion ezininzi ngexesha lokuvelisa iyunithi), kodwa kwakhona kubangela iingxaki ezifanayo.

3. izixhobo zokufakelwa kwe-ion

3.1 Ulwakhiwo olusisiseko

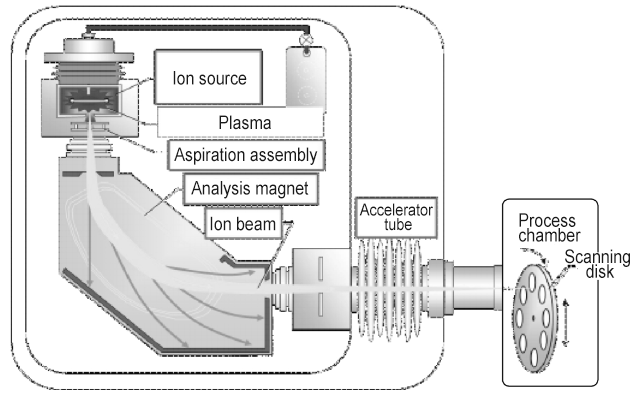

Izixhobo zokufakelwa kwe-ion ziquka iimodyuli ezisisiseko ezi-7:

① umthombo we-ion kunye ne-absorber;

② isihlalutyi sobunzima (oko kukuthi imagnethi yohlalutyo);

③ ityhubhu ye-accelerator;

④ idiski yokuskena;

⑤ inkqubo ye-electrostatic neutralization;

⑥ igumbi lenkqubo;

⑦ inkqubo yokulawula umthamo.

AZonke iimodyuli zikwimeko-bume yesingxobo esekwe sisixokelelwano sevacuum. Umzobo osisiseko wesakhiwo sofakelo lwe-ion uboniswe kumzobo ongezantsi.

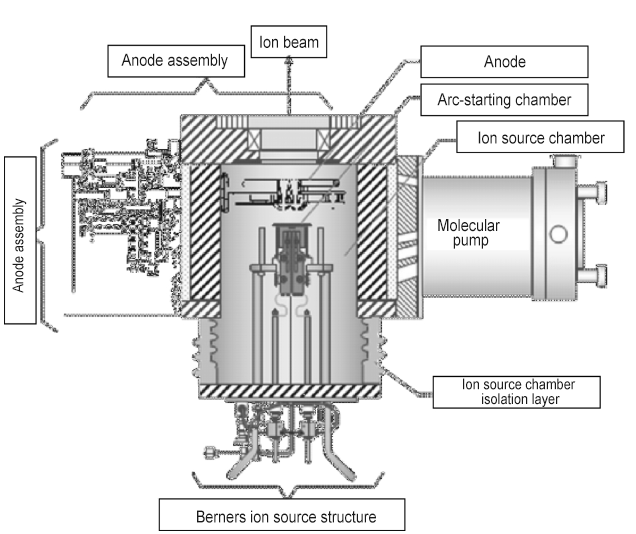

(1)Ion umthombo:

Ngokuqhelekileyo kwigumbi elinye le-vacuum njenge-electrode yokufunxa. Ukungcola okulinde ukutofwa kufuneka kubekho kwindawo ye-ion ukwenzela ukuba ilawulwe kwaye ikhawuleziswe ngumbane wombane. Ezona zisetyenziswa ngokuqhelekileyo iB +, P +, As +, njl.

Imithombo yokungcola esetyenzisiweyo yi-BF3, PH3 kunye ne-ASH3, njl., kwaye izakhiwo zabo ziboniswe kumzobo ongezantsi. Ii-electron ezikhutshwe yi-filament zingqubana ne-athomu yegesi ukuvelisa ii-ion. Ii-electron ngokuqhelekileyo ziveliswa ngumthombo oshushu we-tungsten filament. Ngokomzekelo, umthombo we-ion Berners, i-cathode filament ifakwe kwigumbi le-arc kunye ne-gas inlet. Udonga lwangaphakathi lwegumbi le-arc yi-anode.

Xa umthombo wegesi ungeniswa, i-current enkulu idlula kwi-filament, kwaye i-voltage ye-100 V isetyenziswe phakathi kwee-electrodes ezintle kunye nezibi, eziza kuvelisa ii-electron zamandla aphezulu malunga ne-filament. Ii-ion ezintle ziveliswa emva kokuba ii-electron zamandla aphezulu zingqubane nemolekyuli yegesi engumthombo.

Imagnethi yangaphandle isebenzisa intsimi yamagnetic ehambelana nefilament ukunyusa i-ionization kunye nokuzinzisa iplasma. Kwigumbi le-arc, kwelinye icala elimalunga ne-filament, kukho i-reflector ehlawuliswa kakubi ebonisa i-electrons emva kokuphucula isizukulwana kunye nokusebenza kakuhle kwee-electron.

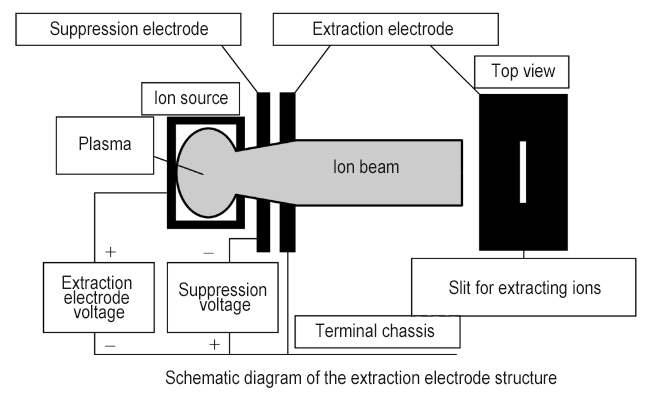

(2)Ukufunxa:

Isetyenziselwa ukuqokelela iiyoni ezilungileyo ezenziwe kwigumbi le-arc lomthombo we-ion kwaye zenze i-ion beam. Ekubeni igumbi le-arc liyi-anode kwaye i-cathode icinezeleke kakubi kwi-electrode yokufunxa, indawo yombane eyenziwe ilawula ii-ion ezilungileyo, zibangele ukuba zihambele kwi-electrode yokufunxa kwaye zikhutshwe kwi-ion slit, njengoko kubonisiwe kumfanekiso ongezantsi. . Okukhona amandla ebala lombane emandla, kokukhona amandla e-kinetic ezuza ii-ion emva kokukhawuleza. Kukwakho noxinzelelo lombane kwi-electrode yokufunxa ukuthintela ukuphazamiseka kwii-electron ezikwiplasma. Ngelo xesha, i-electrode yokunciphisa inokwenza i-ion ibe yi-ion beam kwaye igxininise kwi-ion beam stream ehambelanayo ukuze idlule kwi-implanter.

(3)Isihlalutyi sobuninzi:

Kusenokubakho iintlobo ezininzi zeeyoni ezenziwe kumthombo we-ion. Ngaphantsi kokukhawuleza kombane we-anode, ii-ion zihamba ngesantya esiphezulu. Ii-ion ezahlukeneyo zineeyunithi zobunzima beathom ezahlukeneyo kunye nereyishini ezahlukeneyo zobunzima ukuya kutshaji.

(4)Umbhobho we-Accelerator:

Ukuze ufumane isantya esiphezulu, amandla aphezulu ayafuneka. Ukongeza kwintsimi yombane enikezelwa yi-anode kunye ne-mass analyzer, intsimi yombane ebonelelwe kwi-tube ye-accelerator nayo iyadingeka ukukhawuleza. Ityhubhu ye-accelerator iqulethe uchungechunge lwee-electrode ezihlukaniswe yi-dielectric, kwaye i-voltage engafanelekanga kwi-electrodes iyanda ngokulandelelana ngoqhagamshelwano lwechungechunge. Ukuphakama kombane opheleleyo, sikhulu isantya esifunyenwe yi-ion, oko kukuthi, amandla amakhulu aqhutywe. Amandla aphezulu anokuvumela iiyoni zokungcola ukuba zitofwe nzulu kwi-silicon wafer ukwenza ijunction enzulu, ngelixa amandla aphantsi anokusetyenziswa ukwenza ijunction engekho nzulu.

(5)Iskena idiski

I-ion beam ekugxilwe kuyo idla ngokuba yincinci kakhulu ububanzi. Idayamitha yendawo yomqadi ye-implants yangoku ephakathi imalunga ne-1 cm, kwaye i-beam enkulu yangoku ifakela malunga ne-3 cm. I-wafer ye-silicon yonke kufuneka igqunywe ngokuskena. Ukuphinda-phinda kofakelo lwedosi kumiselwa ngokuskena. Ngesiqhelo, kukho iintlobo ezine zeenkqubo zokuskena zokufakelwa:

① ukuskena kwe-electrostatic;

② ukuskena koomatshini;

③ ukuskena okuxutyiweyo;

④ ukuskena okufanayo.

(6)Inkqubo yokungathathi hlangothi kombane omileyo:

Ngexesha lenkqubo yokufakelwa, i-ion beam ibetha i-silicon wafer kwaye ibangela ukuba intlawulo iqokelele kumphezulu wemaski. Isiphumo sokuqokelelwa kwentlawulo sitshintsha ibhalansi yentlawulo kumqadi we-ion, yenze indawo yomqadi ibe nkulu kwaye ulwabiwo lwethamo lungalingani. Isenokugqobhoza umaleko weoksidi yomphezulu kwaye ibangele ukusilela kwesixhobo. Ngoku, i-silicon wafer kunye ne-ion beam zihlala zibekwe kwindawo ezinzileyo yeplasma ephezulu ebizwa ngokuba yi-plasma electron shower system, enokulawula ukutshaja kwe-silicon wafer. Le ndlela ikhupha ii-electron kwi-plasma (ngokuqhelekileyo i-argon okanye i-xenon) kwigumbi le-arc elikwi-ion beam path kunye kufuphi ne-silicon wafer. I-plasma iyahluzwa kwaye kuphela ii-electron zesibini ezinokufikelela kumphezulu we-silicon wafer ukuze zinciphise intlawulo efanelekileyo.

(7)Inkqubo yomgodi:

Ukutofwa kwemiqadi ye-ion kwi-silicon wafers kwenzeka kwigumbi lenkqubo. Igumbi lenkqubo liyinxalenye ebalulekileyo yesifakeli, kubandakanywa inkqubo yokuskena, isikhululo se-terminal esinesitshixo sokuvala ukulayisha kunye nokukhulula ii-silicone wafers, inkqubo yokudlulisa i-silicon wafer, kunye nenkqubo yokulawula ikhompyutha. Ukongeza, kukho ezinye izixhobo zokubeka iliso kwiidosi kunye nokulawula iziphumo zetshaneli. Ukuba ukuskena ngoomatshini kusetyenziswa, isikhululo se-terminal siya kuba sikhulu noko. I-vacuum yegumbi lenkqubo iphonswe kuxinzelelo oluphantsi olufunwa yinkqubo yempompo ye-multi-stage mechanical, ipompo ye-turbomolecular, kunye nepompo ye-condensation, ngokuqhelekileyo malunga ne-1 × 10-6Torr okanye ngaphantsi.

(8)Inkqubo yokulawula umthamo:

Ukujongwa kwedosi yexesha lokwenyani kwisifakeli se-ion kufezekiswa ngokulinganisa umqa we-ion ofikelela kwi-silicon wafer. I-ion beam current ilinganiswa kusetyenziswa inzwa ebizwa ngokuba yiFaraday cup. Kwinkqubo yeFaraday elula, kukho inzwa yangoku kwindlela ye-ion beam elinganisa okwangoku. Nangona kunjalo, oku kunika ingxaki, njengoko i-ion beam iphendula kunye nenzwa kwaye ivelise ii-electron zesibini eziza kubangela ukufundwa okuphosakeleyo kwangoku. Inkqubo yeFaraday inokucinezela ii-electron zesibini zisebenzisa amandla ombane okanye imagnethi ukuze ifumane umqadi wokufunda ngoku. Umlinganiselo wangoku ulinganiswe yinkqubo yeFaraday yondliwa kwisilawuli sedosi ye-elektroniki, esebenza njenge-accumulator yangoku (eqhubeka ngokuqhubekayo iqokelela i-beam current current). Umlawuli usetyenziselwa ukunxulumanisa inani langoku kwixesha elihambelanayo lokufakelwa kunye nokubala ixesha elifunekayo kwidosi ethile.

3.2 Ukulungiswa komonakalo

Ukufakelwa kwe-iyoni kuya kunkqonkqoza iiathom kwisakhiwo selathisi kwaye konakalise ilitye le-silicon wafer. Ukuba idosi efakiweyo inkulu, umaleko ofakiweyo uya kuba yi-amorphous. Ukongeza, ii-ion ezifakelwe ngokusisiseko azihlali kwindawo ye-lattice ye-silicon, kodwa zihlale kwizithuba ze-lattice gap. Oku kungcola kwangaphakathi kunokwenziwa kusebenze kuphela emva kwenkqubo yobushushu obuphezulu.

I-anealing inokufudumeza i-silicon wafer emiliselweyo ukulungisa iziphene zelathisi; inokuhambisa iiathom zokungacoceki kwiindawo ze-lattice kwaye zisebenze. Ubushushu obufunekayo ukulungisa iziphene zeeletisi malunga nama-500°C, kwaye ubushushu obufunekayo ukuze kusebenze iiathom zokungcola bumalunga nama-950°C. Ukusebenza kokungcola kuhambelana nexesha kunye neqondo lokushisa: ixesha elide kwaye liphezulu izinga lokushisa, ngakumbi ukungcola kusebenze ngokupheleleyo. Kukho iindlela ezimbini ezisisiseko zokuthambisa ii-silicone wafers:

① ukuvalelwa kweziko lobushushu obuphezulu;

② ukukhutshwa ngokukhawuleza kwe-thermal (RTA).

Ubushushu obuphezulu be-annealing kwiziko lobushushu obuphezulu: Ubushushu obuphezulu be-annealing yesithando somlilo yindlela yemveli yokufunxa, esebenzisa iziko lobushushu obuphezulu ukufudumeza i-silicon wafer ukuya kuma-800-1000℃ kwaye uyigcine imizuzu engama-30. Kweli qondo lobushushu, iiathom zesilicon zibuyela umva kwindawo yelattice, kwaye iiathom zokungcola zinokuthatha indawo yeeathom zesilicon kwaye zingene kwilathisi. Nangona kunjalo, unyango lobushushu kwiqondo lokushisa elinjalo kunye nexesha liya kukhokelela ekusasazweni kokungcola, into leyo imboni yemveliso ye-IC yanamhlanje ayifuni ukuyibona.

Rapid Thermal Annealing: Rapid thermal annealing (RTA) iphatha ii-silicon wafers ngokunyuka kweqondo lobushushu ngokukhawuleza kakhulu kunye nobude bexesha elifutshane kwiqondo lobushushu ekujoliswe kulo (lidla ngokuba yi-1000°C). Ukufakelwa kwee-wafers ze-silicon ezifakelweyo ngokuqhelekileyo kwenziwa kwiprosesa ekhawulezayo ye-thermal nge-Ar okanye i-N2. Inkqubo yokunyuka kweqondo lokushisa ngokukhawuleza kunye nobude obufutshane bunokuphucula ukulungiswa kwe-lattice defects, ukusebenza kokungcola kunye nokuvinjelwa kokusasazwa kokungcola. I-RTA isenokunciphisa usasazo olongezelelekileyo okwethutyana kwaye yeyona ndlela ilungileyo yokulawula ubunzulu besiphambuka kwizifakelo ezinzulu zesiphambuka.

————————————————————————————————————————————————— ————————————-

I-Semicera inokubonelelaiindawo zegraphite, uthambile/uqinile, iinxalenye ze-silicon carbide, CVD iinxalenye zesilicon carbide, kwayeIindawo ezigqunywe yiSiC/TaCnge 30 iintsuku.

Ukuba unomdla kwezi mveliso zesemiconductor zingasentla,nceda ungathandabuzi ukuqhagamshelana nathi okokuqala.

Umnxeba: +86-13373889683

Whatsapp: +86-15957878134

Email: sales01@semi-cera.com

Ixesha lokuposa: Aug-31-2024