Intshayelelo enye

I-Etching kwinkqubo yokwenziwa kwesekethe edibeneyo yahlulwe ibe:

-Ukuhlamba okumanzi;

-Ukukrola okomileyo.

Kwiintsuku zangaphambili, ukujongwa okumanzi kwakusetyenziswa ngokubanzi, kodwa ngenxa yokulinganiselwa kwayo kulawulo lobubanzi bomgca kunye nolwalathiso lwe-etching, iinkqubo ezininzi emva kwe-3μm zisebenzisa i-etching eyomileyo. Ukufakwa okumanzi kusetyenziswa kuphela ukususa iileya ezithile zezinto ezikhethekileyo kunye neentsalela ezicocekileyo.

I-etching eyomileyo ibhekiselele kwinkqubo yokusebenzisa i-etchants ye-gaseous chemical etchants ukusabela ngemathiriyeli ekwi-wafer ukuze ikhuphe indawo yemathiriyeli eza kususwa kwaye yenze iimveliso zokusabela eziguquguqukayo, ezithi ke zikhutshwe kwigumbi lokusabela. I-Etchant idla ngokuveliswa ngokuthe ngqo okanye ngokungathanga ngqo kwi-plasma yegesi yokufaka, ngoko ke ukufakwa okomileyo kukwabizwa ngokuba yi-plasma etching.

1.1 I-Plasma

I-Plasma yirhasi ekwimeko ene-ionized ebuthathaka eyenziwe kukuphuma okukhazimlayo kwerhasi ye-etching phantsi kwesenzo sommandla wombane we-electromagnetic wangaphandle (onjengokuveliswa ngumbane wamaza kanomathotholo). Ibandakanya ii-electron, ii-ion kunye nee-particle ezisebenzayo ezingathathi hlangothi. Phakathi kwabo, amasuntswana asebenzayo anokusabela ngokuthe ngqo kwimichiza kunye nezinto ezichongiweyo ukuze kuphunyezwe i-etching, kodwa le mpendulo yekhemikhali ecocekileyo idla ngokubakho kwinani elincinci kakhulu lezinto kwaye alikho icala; Xa iiyoni zinamandla athile, zinokuqatywa ngokutshiza okuthe ngqo ngokwasemzimbeni, kodwa izinga lokurhawuzelela lo mzimba usulungekileyo liphantsi kakhulu kwaye ukukhetha kumbi kakhulu.

Uninzi lwe-plasma etching lugqityiwe ngokuthatha inxaxheba kwamasuntswana asebenzayo kunye ne-ion ngexesha elinye. Kule nkqubo, i-ion bombardment inemisebenzi emibini. Enye kukutshabalalisa iibhondi ze-athomu kumphezulu wezinto ezigciniweyo, ngaloo ndlela ukwandisa izinga apho amasuntswana angathathi hlangothi asabela ngayo; enye kukunkqonkqoza kwiimveliso zokusabela ezifakwe kwi-reaction interface ukuze kube lula ukuba i-etchant iqhagamshelane ngokupheleleyo nomphezulu wezinto ezigciniweyo, ukuze ugcino luqhubeke.

Iimveliso zokusabela ezifakwe emacaleni esakhiwo esimisiweyo azikwazi ukususwa ngokufanelekileyo ngebhombu ye-ion eyalathayo, ngaloo ndlela ivalela ukukrolwa kweendonga zecala kunye nokwenza i-anisotropic etching.

Inkqubo yesibini etching

2.1 Ukuchetywa okumanzi kunye nokuCoca

I-Wet etching yenye yetekhnoloji yokuqala esetyenziswa kwimveliso yesekethe edibeneyo. Nangona uninzi lweenkqubo zokubamba ezimanzi zithathelwe indawo yi-anisotropic dry etching ngenxa ye-isotropic etching, isadlala indima ebalulekileyo ekucoceni iileya ezingabalulekanga zobukhulu obukhulu. Ngokukodwa kwi-etching ye-oxide yokususa iintsalela kunye ne-epidermal stripping, iyasebenza ngakumbi kwaye inoqoqosho kunokomisa okomileyo.

Izinto ze-etching ezimanzi ikakhulu ziquka isilicon oxide, isilicon nitride, isilicon enye yecrystal kunye nesilicon yepolycrystalline. Ukufakwa okumanzi kwesilicon oxide ngokuqhelekileyo kusebenzisa i-hydrofluoric acid (HF) njengeyona nto ithwala iikhemikhali. Ukuze kuphuculwe ukukhetha, i-dilute i-hydrofluoric acid ekhuselwe yi-ammonium fluoride isetyenziswa kwinkqubo. Ukuze kugcinwe ukuzinza kwexabiso le-pH, inani elincinci le-asidi eqinile okanye ezinye izinto zingongezwa. I-silicon oxide edotshiweyo idla ngokutya ngakumbi kune-silicon oxide ecocekileyo. Ukuhluthwa kweekhemikhali ezimanzi kusetyenziswa ikakhulu ukususa i-photoresist kunye nemaski enzima (i-silicon nitride). I-asidi ye-phosphoric eshushu (i-H3PO4) yeyona khemikhali iyilwelo ingundoqo esetyenziselwa ukuhluthwa kweekhemikhali ezimanzi ukususa i-silicon nitride, kwaye inokukhethwa okulungileyo kwe-silicon oxide.

Ukucoca okumanzi kufana ne-etching emanzi, kwaye ngokuyinhloko kususa izinto ezingcolileyo kumphezulu we-silicon wafers ngokuphendula kweekhemikhali, kubandakanywa amasuntswana, izinto eziphilayo, isinyithi kunye ne-oxides. Ukucoca okuqhelekileyo okumanzi yindlela yekhemikhali emanzi. Nangona ukucoca okomileyo kunokutshintsha iindlela ezininzi zokucoca okumanzi, akukho ndlela inokutshintsha ngokupheleleyo ukucoceka okumanzi.

Iikhemikhali eziqhelekileyo ezisetyenziselwa ukucoca okumanzi ziquka i-asidi ye-sulfuric, i-hydrochloric acid, i-hydrofluoric acid, i-phosphoric acid, i-hydrogen peroxide, i-ammonium hydroxide, i-ammonium fluoride, njl. Kwizicelo eziphathekayo, ikhemikhali enye okanye ngaphezulu ixutywe ngamanzi adiyiweyo ngokomlinganiselo othile njengoko kufuneka. yenza isisombululo sokucoca, njenge-SC1, i-SC2, i-DHF, i-BHF, njl.

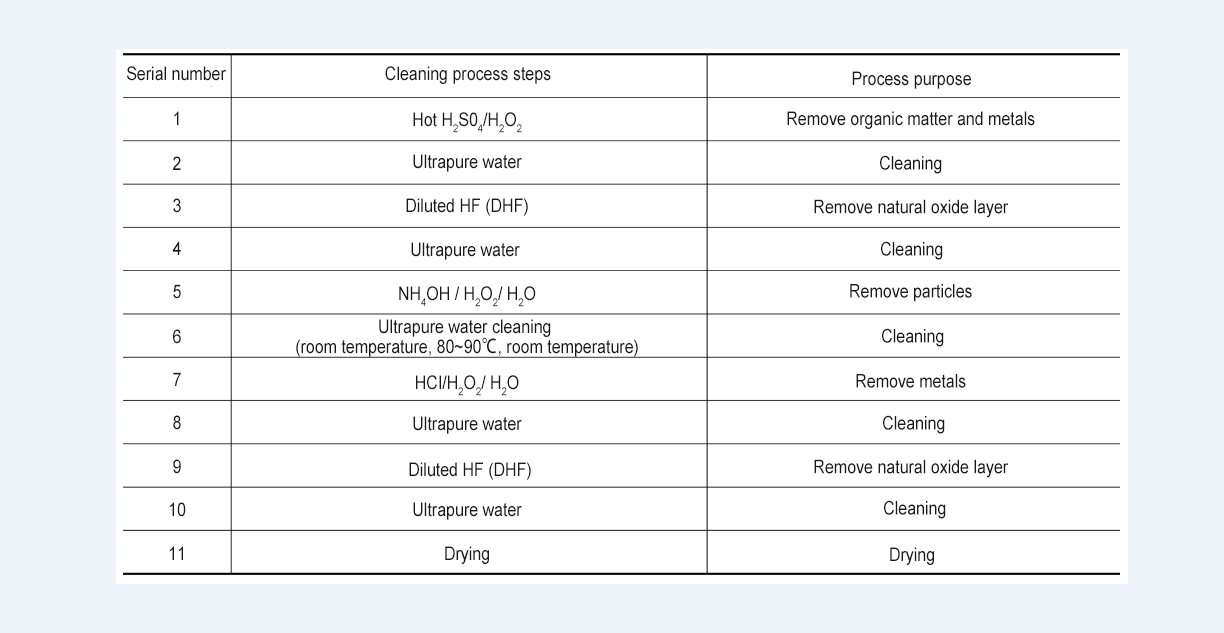

Ukucoca kudla ngokusetyenziswa kwinkqubo ngaphambi kokubekwa kwefilimu ye-oxide, kuba ukulungiswa kwefilimu ye-oxide kufuneka kuqhutywe kwindawo ecocekileyo ye-silicon. Inkqubo eqhelekileyo yokucoca i-silicon wafer yile ilandelayo:

2.2 Ukucheba okomileyo kunye nokuCoca

2.2.1 Ukukrola okomileyo

I-etching eyomileyo kwishishini ibhekisa ikakhulu kwi-plasma etching, esebenzisa iplasma enomsebenzi ophuculweyo ukukrola izinto ezithile. Inkqubo yezixhobo kwiinkqubo ezinkulu zokuvelisa isebenzisa i-plasma ephantsi yobushushu obungalinganiyo.

Ukufakwa kwePlasma ikakhulu kusebenzisa iindlela ezimbini zokukhupha: ukukhupha okudityanisiweyo okunamandla kunye nokukhutshwa okudibeneyo okudibeneyo.

Kwimo edityanisiweyo yokukhupha i-capacitively: i-plasma yenziwa kwaye igcinwe kwi-parallel plate capacitors nge-radio frequency yangaphandle (RF) unikezelo lwamandla. Uxinzelelo lwegesi ngokuqhelekileyo luyi-millitorr ukuya kumashumi e-millitorr, kwaye izinga le-ionization lingaphantsi kwe-10-5. Kwimo edityanisiweyo yokukhutshwa kwe-inductively: ngokuqhelekileyo kuxinzelelo lwegesi oluphantsi (amashumi e-millitorr), i-plasma yenziwa kwaye igcinwe ngamandla okufakwayo adibeneyo. Izinga le-ionization lidla ngokuba likhulu kune-10-5, ngoko likwabizwa ngokuba yi-plasma ephezulu. Imithombo ye-plasma yoxinaniso oluphezulu inokufumaneka kwakhona nge-electron cyclotron resonance kunye ne-cyclotron wave discharge. I-Plasma yoxinaniso oluphezulu lunokwandisa isantya sokutsala kunye nokukhetha kwenkqubo yokurhweba ngelixa kuncitshiswa umonakalo we-etching ngokulawula ngokuzimeleyo ukuhamba kwe-ion kunye ne-ion bombardment energy nge-RF yangaphandle okanye unikezelo lwamandla lwe-microwave kunye nonikezelo lwamandla olucala lwe-RF kwi-substrate.

Inkqubo eyomileyo ye-etching yile ilandelayo: i-gas etching ifakwe kwi-vacuum reaction room, kwaye emva kokuba uxinzelelo lwegumbi lokuphendula luzinzile, i-plasma iveliswa yi-radio frequency glow discharge; emva kokuchatshazelwa yi-electron-speed-speed electrons, iyabola ukuvelisa i-radicals yamahhala, esasazeka kumphezulu we-substrate kwaye i-adsorbed. Ngaphantsi kwesenzo se-ion bombardment, i-adsorbed free radicals isabela kunye ne-athomu okanye iimolekyuli kumphezulu we-substrate ukwenza i-gaseous byproducts, ekhutshwa kwigumbi lokusabela. Inkqubo iboniswa kulo mfanekiso ulandelayo:

Iinkqubo zokukrola okomileyo zinokwahlulwa ngokwezi ndidi ezine zilandelayo:

(1)Physical sputtering etching: Ixhomekeke ikakhulu kwii-ion ezinamandla kwiplasma ukuze ibhobhoze umphezulu wezinto ezigciniweyo. Inani leathom ezisasazekileyo lixhomekeke kumandla kunye ne-engile yamasuntswana esiganeko. Xa amandla kunye ne-angle zihlala zingatshintshi, isantya se-sputtering sezinto ezahlukeneyo ngokuqhelekileyo sihluke ngamaxesha angama-2 ukuya kwe-3 kuphela, ngoko akukho ukukhetha. Inkqubo yokusabela ikakhulu i-anisotropic.

(2)Ukufakwa kweekhemikhali: I-Plasma ibonelela nge-athomu ye-gas-phase etching athom kunye ne-athomu, ezithatha iikhemikhali kunye nomphezulu wezinto eziphathekayo ukuvelisa iigesi eziguqukayo. Le mpendulo yeekhemikhali inokukhetha okulungileyo kwaye ibonisa iimpawu ze-isotropic ngaphandle kokuqwalasela isakhiwo se-lattice.

Umzekelo: Si (oluqilima) + 4F → SiF4 (gaseous), photoresist + O (gaseous) → CO2 (gaseous) + H2O (gaseous)

(3)Ion amandla aqhutywa etching: I-Ions zombini ngamasuntswana abangela ukuba i-etching kunye namasuntswana aphethe amandla. Ukusebenza kakuhle kwe-etching yaloo masuntswana aphethe amandla angaphezulu komyalelo omnye wobukhulu obuphezulu kunolo lwe-etching elula yomzimba okanye yeekhemikhali. Phakathi kwabo, ukulungiswa kweeparameters zomzimba kunye neekhemikhali zenkqubo ngundoqo wokulawula inkqubo ye-etching.

(4)Ion-barrier composite etching: Ngokukodwa ibhekisela kwisizukulwana somqobo wokukhusela we-polymer ngamaqhekeza adibeneyo ngexesha lenkqubo yokubhala. I-Plasma idinga umaleko onjalo okhuselayo ukukhusela ukusabela kwe-etching of the sidewalls ngexesha lenkqubo yokubhala. Umzekelo, ukongeza i-C kwi-Cl kunye ne-Cl2 etching inokuvelisa umaleko we-chlorocarbon ekhompawundi ngexesha lokuthunga ukukhusela iindonga ezisecaleni ukuba zingabhalwa.

2.2.1 Ukucoca okomileyo

Ukucoca okomileyo kubhekiselele ekucoceni iplasma. Iiyoni kwiplasma zisetyenziselwa ukubhobhoza umphezulu ukuba zicocwe, kwaye iiathom kunye neeathomu ezikwimo esebenzayo zisebenzisana nomphezulu ukuze zicocwe, ukuze kususwe kwaye kuthuthukiswe ifotoresist. Ngokungafaniyo ne-etching eyomileyo, iiparameters zenkqubo yokucoca okomileyo ngokuqhelekileyo ayibandakanyi ukhetho lwesikhokelo, ngoko ke uyilo lwenkqubo lulula. Kwiinkqubo ezinkulu zokuvelisa, iigesi ezisekelwe kwi-fluorine, i-oksijini okanye i-hydrogen zisetyenziswa kakhulu njengomzimba oyintloko we-plasma yokusabela. Ukongeza, ukongeza inani elithile le-argon plasma inokuphucula i-ion bombardment effect, ngaloo ndlela iphucula ukusebenza kakuhle kokucoca.

Kwinkqubo yokucoca i-plasma eyomileyo, indlela ye-plasma ekude idla ngokusetyenziswa. Oku kungenxa yokuba kwinkqubo yokucoca, kunethemba lokunciphisa i-bombardment effect ye-ion kwi-plasma ukulawula umonakalo obangelwa yi-ion bombardment; kunye nokusabela okongeziweyo kweekhemikhali zasimahla zeradicals kunokuphucula ukusebenza kakuhle kokucoca. I-plasma ekude inokusebenzisa ii-microwaves ukuvelisa iplasma ezinzile kunye noxinaniso oluphezulu ngaphandle kwegumbi lokuphendula, ivelise inani elikhulu leeradicals zamahhala ezingena kwigumbi lokuphendula ukufezekisa ukusabela okufunekayo ekucoceni. Uninzi lwemithombo yegesi yokucoca eyomileyo kwishishini isebenzisa iigesi ezisekelwe kwi-fluorine, njenge-NF3, kwaye ngaphezu kwe-99% ye-NF3 ichithwa kwi-plasma ye-microwave. Phantse akukho siphumo se-ion bombardment kwinkqubo yokucoca okomileyo, ngoko ke kuyanceda ukukhusela i-silicon wafer kumonakalo kunye nokwandisa ubomi begumbi lokuphendula.

Izixhobo ezithathu zokucoca ezimanzi kunye nokucoca

3.1 Umatshini wokucoca iwafa yohlobo lwetanki

Umatshini wokucoca i-wafer-type wafer ikakhulu uqulunqwe yimodyuli yokuhambisa ibhokisi yokudlulisa i-wafer, imodyuli yokuhambisa i-wafer / ukukhulula, imodyuli yokukhupha umoya, imodyuli yetanki yekhemikhali, imodyuli yetanki yamanzi ediyiweyo, itanki yokumisa. imodyuli kunye nemodyuli yolawulo. Iyakwazi ukucoca iibhokisi ezininzi zeewafers ngaxeshanye kwaye inokufezekisa ezomileyo kwaye zome ngaphandle kweewafers.

3.2 Umsele weWafer Etcher

3.3 IsiXhobo esiNye seWafer esiManzi esinye

Ngokweenjongo zenkqubo ezahlukeneyo, isixhobo esinye se-wafer esimanzi sinokwahlulwa ngokweendidi ezintathu. Udidi lokuqala luyisixhobo sokucoca i-wafer enye, iithagethi zayo zokucoca ziquka iincinci, izinto eziphilayo, i-oxide yendalo, ukungcola kwesinyithi kunye nezinye izinto ezingcolileyo; udidi lwesibini sisixhobo sokukhuhla se-wafer enye, eyona njongo yayo kukususa amasuntswana kumphezulu we-wafer; udidi lwesithathu sisixhobo sokukrola iwafer enye, esetyenziswa ikakhulu ukususa iifilim ezibhityileyo. Ngokweenjongo zenkqubo ezahlukeneyo, isixhobo esinye se-wafer etching sinokwahlulwa zibe ziintlobo ezimbini. Uhlobo lokuqala sisixhobo sokukrola esithambileyo, esisetyenziswa ikakhulu ukususa iileya zomonakalo wefilimu ezingaphezulu ezibangelwa kukufakelwa kwe-ion enamandla kakhulu; uhlobo lwesibini sisixhobo sokususa umaleko wombingelelo, esisetyenziswa ikakhulu ukususa iileya zomqobo emva kokucolwa kwe-wafer okanye ukupolisha ngomatshini.

Ukusuka kwimbono yolwakhiwo lomatshini olubanzi, ulwakhiwo olusisiseko lwazo zonke iintlobo zezixhobo zenkqubo emanzi ye-wafer enye iyafana, ngokubanzi iqulethwe ngamacandelo amathandathu: isakhelo esiphambili, inkqubo yokuhanjiswa kwewafer, imodyuli yegumbi, unikezelo lwemichiza yolwelo kunye nemodyuli yokudlulisa, inkqubo yesoftware. kunye nemodyuli yolawulo lombane.

3.4 Isixhobo sokuCoca iWafer enye

Isixhobo sokucoca i-wafer esisodwa senziwe ngokusekelwe kwindlela yokucoca i-RCA yendabuko, kwaye injongo yayo yenkqubo kukucoca amaqhekeza, izinto eziphilayo, i-oxide yendalo, ukungcola kwesinyithi kunye nezinye izinto ezingcolileyo. Ngokubhekiselele kwisicelo senkqubo, izixhobo zokucoca i-wafer enye ngoku zisetyenziswa ngokubanzi kwiinkqubo zangaphambili kunye ne-back-end yokwenziwa kwesekethe edibeneyo, kubandakanywa ukucoca ngaphambi nangemva kokubunjwa kwefilimu, ukucoca emva kwe-plasma etching, ukucoca emva kokufakelwa kwe-ion, ukucoca emva kweekhemikhali. ukupolisha koomatshini, kunye nokucoca emva kokubekwa kwesinyithi. Ngaphandle kwenkqubo ye-asidi ye-phosphoric ephezulu yobushushu, izixhobo zokucoca i-wafer enye zihambelana ngokusisiseko nazo zonke iinkqubo zokucoca.

3.5 IsiXhobo sokuFakela iWafer esinye

Injongo yenkqubo yesixhobo sokukrolwa kwe-wafer enye kukukrolwa kwefilimu ebhityileyo. Ngokwenjongo yenkqubo, inokwahlulwa ibe ziindidi ezimbini, ezizezi, izixhobo zokukhanyisa ukukhanya (ezisetyenziselwa ukususa umaleko womonakalo wefilimu ongaphezulu obangelwa kukufakelwa kwe-ion ene-energy) kunye nezixhobo zokususwa kwedini (ezisetyenziselwa ukususa umaleko wesithintelo emva kwe-wafer). ukucheba okanye ukupolisha ngomatshini wekhemikhali). Izinto ezifuna ukususwa kwinkqubo ngokubanzi ziquka i-silicon, i-silicon oxide, i-silicon nitride kunye neengqimba zefilimu yesinyithi.

Izixhobo ezine zokuhombisa ezomileyo nezokucoca

4.1 Ukuhlelwa kwezixhobo ze-plasma etching

Ukongeza kwisixhobo sokutshiza se-ion esikufutshane nesenzo somzimba esisulungekileyo kunye nezixhobo zokucoca ezikufutshane nempendulo yekhemikhali esulungekileyo, ukufakwa kweplasma kunokwahlulwa ngokweendidi ezimbini ngokwendlela yokuvelisa iplasma kunye nolawulo lobuchwepheshe:

-I-Capacitively Coupled Plasma (CCP) etching;

-I-Inductively Coupled Plasma (ICP) etching.

4.1.1 I-CCP

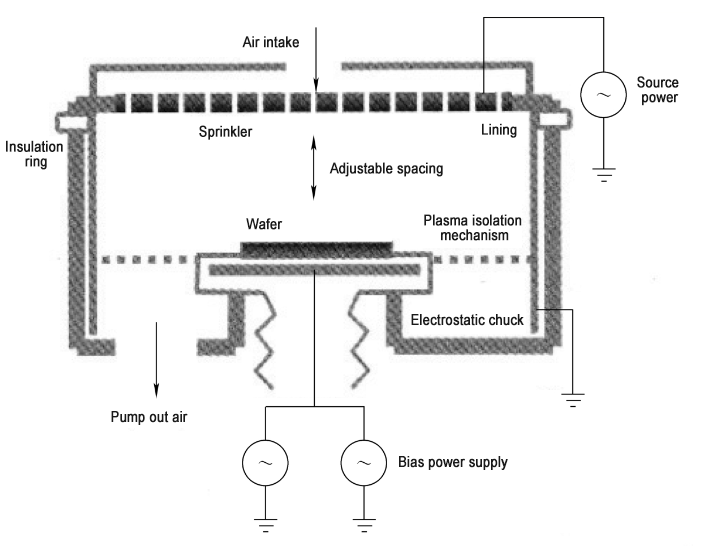

I-Capacitively edityaniswe kwi-plasma etching kukudibanisa unikezelo lwamandla kanomathotholo kwenye okanye zombini kwi-electrode ephezulu nasezantsi kwigumbi lokusabela, kwaye iplasma phakathi kweepleyiti ezimbini zenza i-capacitor kwisekethe elinganayo efanayo.

Zimbini zokuqala ezo teknoloji:

Enye yeyokuqala i-plasma etching, edibanisa umbane weRF kwi-electrode ephezulu kunye ne-electrode esezantsi apho i-wafer ibekwe khona. Ngenxa yokuba iplasma eveliswe ngale ndlela ayizukwenza i-ion sheath etyebileyo ngokwaneleyo kumphezulu we-wafer, amandla e-ion bombardment aphantsi, kwaye aqhele ukusetyenziswa kwiinkqubo ezinje ngesilicon etching esebenzisa amasuntswana asebenzayo njengeyona nto iphambili.

Enye yi-etching ion etching (RIE), edibanisa umbane we-RF kwi-electrode esezantsi apho i-wafer ikhoyo, kwaye imisa i-electrode ephezulu enendawo enkulu. Le teknoloji inokwenza i-ion sheath engqindilili, efanelekileyo kwiinkqubo ze-dielectric etching ezifuna amandla e-ion aphezulu ukuba athathe inxaxheba ekuphenduleni. Ngokwesiseko se-ion etching esebenzayo kwangethuba, i-DC magnetic field perpendicular kumhlaba wombane weRF yongezwa ukwenza i-ExB drift, enokwandisa ithuba lokungqubana kwee-electron kunye namasuntswana egesi, ngaloo ndlela iphucula ngokufanelekileyo ukugxininiswa kweplasma kunye nesantya sokutshona. Oku kujongwa kubizwa ngokuba yimagnethi ephuculweyo ye-ion etching (MERIE).

Ubuchwephesha obuthathu obungentla bunobugwenxa obuqhelekileyo, oko kukuthi, i-plasma concentration kunye namandla ayo ayinakulawulwa ngokwahlukileyo. Umzekelo, ukuze kunyuswe isantya sokutsala amandla, indlela yokunyusa amandla eRF ingasetyenziselwa ukonyusa uxinaniso lweplasma, kodwa ukonyuka kwamandla eRF kuya kukhokelela ekonyukeni kwamandla e-ion, okuya kubangela umonakalo kwizixhobo ezisetyenziswayo. iqhekezana. Kwiminyaka elishumi edlulileyo, itekhnoloji yokudibanisa i-capacitive yamkele uyilo lwemithombo ye-RF emininzi, eqhagamshelwe kwi-electrode ephezulu nasezantsi ngokulandelelanayo okanye zombini kwi-electrode esezantsi.

Ngokukhetha kunye nokutshatisa iifrikhwensi ezahlukeneyo zeRF, indawo ye-electrode, isithuba, imathiriyeli kunye nezinye iiparamitha eziphambili zilungelelaniswa enye kwenye, ukuxinana kweplasma kunye namandla e-ion kunokudityaniswa kangangoko kunokwenzeka.

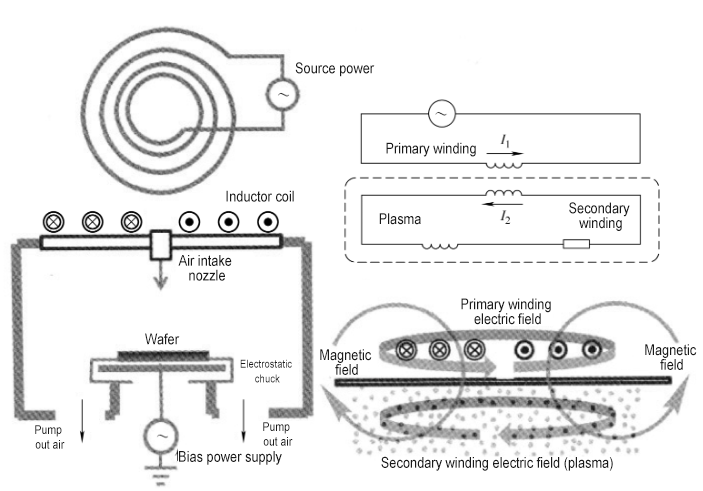

4.1.2 I-ICP

Ukufakwa kweplasma okudityanisiweyo kukubeka iseti enye okanye ezingaphezulu zeekhoyili eziqhagamshelwe kubonelelo lwamandla kanomathotholo kwindawo yokusabela okanye ejikeleze igumbi lokusabela. Intsimi yemagnethi etshintshanayo eveliswa yi-radio frequency yangoku kwikhoyili ingena kwigumbi lokusabela ngefestile ye-dielectric ukukhawulezisa ii-electron, ngaloo ndlela ivelisa iplasma. Kwisekethe elinganayo elinganayo (i-transformer), i-coil yi-inductance ephambili yomoya, kwaye i-plasma yi-inductance yomoya wesibini.

Le ndlela yokudibanisa inokufezekisa i-concentration ye-plasma engaphezu komyalelo omnye wobukhulu obuphezulu kunokudibanisa i-capacitive kwixinzelelo eliphantsi. Ukongeza, unikezelo lwamandla lwe-RF lwesibini luqhagamshelwe kwindawo yewafer njengobonelelo lwamandla olunomkhethe ukunika amandla e-ion bombardment. Ke ngoko, ugxininiso lwe-ion luxhomekeke kumthombo wamandla wekhoyili kunye namandla e-ion axhomekeke kunikezelo lwamandla olucalanye, ngaloo ndlela kuphunyezwa ukudityaniswa ngokucokisekileyo ngakumbi koxinzelelo kunye namandla.

4.2 Izixhobo zokudibanisa iPlasma

Phantse zonke ii-etchants kwi-etching eyomileyo zenziwe ngokuthe ngqo okanye ngokungathanga ngqo kwi-plasma, ngoko ke ukuchongwa okomileyo kuhlala kubizwa ngokuba yi-plasma etching. I-Plasma etching luhlobo lwe-plasma etching ngengqiqo ebanzi. Kuyilo lwangaphambili lwe-flat-plate reactor, enye kukwenza ipleyiti apho i-wafer ikhoyo kwaye enye ipleyiti iqhagamshelwe kumthombo weRF; enye ichasene. Kuyilo lwangaphambili, indawo yepleyiti ephantsi idla ngokuba nkulu kunendawo yepleyiti eqhagamshelwe kumthombo weRF, kwaye uxinzelelo lwegesi kwireactor luphezulu. I-ion sheath eyenziwe kumphezulu we-wafer ibhityile kakhulu, kwaye i-wafer ibonakala "intywiliselwe" kwiplasma. I-Etching igqitywe ngokugqithiseleyo yi-chemical reaction phakathi kweengqungquthela ezisebenzayo kwi-plasma kunye nomphezulu wezinto ezigciniweyo. Amandla e-ion bombardment mancinci kakhulu, kwaye ukuthatha kwayo inxaxheba kwi-etching kuphantsi kakhulu. Olu yilo lubizwa ngokuba yi-plasma etching mode. Kolunye uyilo, ngenxa yokuba iqondo lokuthatha inxaxheba kwibhombu ye-ion likhulu ngokwentelekiso, ibizwa ngokuba yimowudi esebenzayo ye-ion etching.

4.3 Isixhobo sokuFakela i-Ion esisebenzayo

I-Reactive ion etching (RIE) ibhekisela kwinkqubo yokubhala apho amasuntswana asebenzayo kunye neeoni ezihlawuliswayo zithatha inxaxheba kwinkqubo ngexesha elinye. Phakathi kwazo, iinqununu ezisebenzayo ziyi-particles engathathi hlangothi (eyaziwa nangokuthi i-radicals yamahhala), ene-concentration ephezulu (malunga ne-1% ukuya kwi-10% ye-concentration yegesi), ezona zixhobo eziphambili ze-etchant. Iimveliso eziveliswa yindlela yokusabela kweekhemikhali phakathi kwazo kunye nezinto ezicwangcisiweyo zinokuthi ziguquguquke kwaye zikhutshwe ngokuthe ngqo kwigumbi lokuphendula, okanye ziqokelelwe kumphezulu oqingqiweyo; ngelixa i-ion ehlawulisiweyo iphantsi koxinaniso (10-4 ukuya kwi-10-3 yoxinaniso lwegesi), kwaye zikhawuleza yintsimi yombane ye-ion sheath eyenziwe kumphezulu we-wafer ukuze ibhobhoze indawo edibeneyo. Mibini imisebenzi ephambili yamasuntswana ahlawuliweyo. Enye kukutshabalalisa isakhiwo se-athomu sezinto ezigciniweyo, ngaloo ndlela ukukhawuleza izinga apho amasuntswana asebenzayo asabela ngayo; enye ibhombu kwaye isuse iimveliso zokusabela eziqokelelweyo ukwenzela ukuba izinto ezichongiweyo zinxibelelane ngokupheleleyo namasuntswana asebenzayo, ukuze ugcino luqhubeke.

Ngenxa yokuba ii-ion zingathabathi nxaxheba ngokuthe ngqo kwi-etching reaction (okanye i-akhawunti yesahlulo esincinci kakhulu, esifana nokususwa kwebhombu emzimbeni kunye ne-chemical etching ye-ion esebenzayo), ngokungqongqo, le nkqubo yokubhala ingentla kufuneka ibizwe ngokuba yi-ion-assisted etching. Igama elithi reactive ion etching alichanekanga, kodwa lisasetyenziswa nanamhlanje. Esona sixhobo sokuqala se-RIE sasetyenziswa ngeminyaka yoo-1980. Ngenxa yokusetyenziswa kombane we-RF enye kunye noyilo olulula lwegumbi lokusabela, inomlinganiselo ngokubhekiselele kumyinge wokulinganisa, ukufana kunye nokukhetha.

4.4 Isixhobo soMbane weMagnetic eyongezelelweyo

I-MERIE (i-Magnetically Enhanced Reactive Ion Etching) isixhobo sisixhobo sokuqhafaza esakhiwe ngokudibanisa i-DC magnetic field kwi-flat-panel ye-RIE isixhobo kwaye ijolise ekunyuseni izinga lokunciphisa.

Isixhobo se-MERIE sasetyenziswa ngomlinganiselo omkhulu ngeminyaka yoo-1990, xa isixhobo sokukrola esisicaba esinye saba sesona sixhobo siphambili kushishino. Eyona nto ingeloncedo inkulu yesixhobo se-MERIE kukuba ukusasazeka kwendawo yoxinaniso lweplasma olubangelwa yimagnethi iya kukhokelela kumahluko wangoku okanye wombane kwisixhobo sesekethe esidibeneyo, ngaloo ndlela kubangele umonakalo wesixhobo. Ekubeni lo monakalo ubangelwa yi-inhomogeneity ngokukhawuleza, ukujikeleza kwendawo yamagnetic ayikwazi ukuyiphelisa. Njengoko ubungakanani beesekethe ezidityanisiweyo ziqhubeka nokucutheka, ukonakala kwesixhobo sabo kuya kusiba buthathaka ngakumbi kwi-plasma inhomogeneity, kwaye itekhnoloji yokunyusa izinga le-etching ngokuphucula indawo yamagnetic ithe chu yathatyathelw' indawo bubuchwephesha be-RF yombane osebenzayo we-ion etching, leyo kukuba, itekhnoloji edityaniswe ngokufanelekileyo iplasma etching.

4.5 Izixhobo ezidityaniswa ngokufanelekileyo zeplasma etching

Isixhobo sokudibanisa iplasma (CCP) sisixhobo esenza iplasma kwigumbi lokusabela ngokusebenzisa i-capacitive coupling ngokufaka unikezelo lwamandla kanomathotholo (okanye i-DC) kwipleyiti ye-electrode kwaye isetyenziselwa ukubetha. Umgaqo wayo wokujongisa uyafana naleyo yesixhobo sokusebenza se-ion etching.

Umzobo owenziwe lula wenkqubo yeCCP uboniswe ngezantsi. Ngokuqhelekileyo isebenzisa imithombo yeRF emibini okanye emithathu yeefrikhwensi ezahlukeneyo, kwaye abanye basebenzisa izixhobo zombane zeDC. Ubuninzi bonikezelo lwamandla eRF yi-800kHz ~ 162MHz, kwaye ezo zisetyenziswa ngokuqhelekileyo yi-2MHz, 4MHz, 13MHz, 27MHz, 40MHz kunye ne-60MHz. Ubonelelo lwamandla e-RF olune-2MHz okanye i-4MHz ludla ngokubizwa ngokuba yimithombo ye-RF ephantsi. Ngokuqhelekileyo zixhunywe kwi-electrode ephantsi apho i-wafer ikhona. Zisebenza ngakumbi ekulawuleni amandla e-ion, ngoko ke zikwabizwa ngokuba yi-bias power supply; Ubonelelo lwamandla e-RF olunomthamo ongaphezulu kwe-27MHz kuthiwa yimithombo ye-RF ephezulu. Ziyakwazi ukudityaniswa nokuba i-electrode ephezulu okanye i-electrode ephantsi. Zisebenza ngakumbi ekulawuleni ukugxilwa kweplasma, ngoko ke zikwabizwa ngokuba ngumthombo wamandla. Ubonelelo lwamandla lwe-13MHz RF luphakathi kwaye lujongwa njengendawo yomibini le misebenzi ingasentla kodwa lubuthathaka. Qaphela ukuba nangona ugxininiso lweplasma kunye namandla anokulungiswa kuluhlu oluthile ngamandla emithombo ye-RF yeefrikhwensi ezahlukeneyo (into ebizwa ngokuba yi-decoupling effect), ngenxa yeempawu ze-capacitive coupling, azinakulungelelaniswa kwaye zilawulwe ngokuzimeleyo ngokupheleleyo.

Ukuhanjiswa kwamandla e-ion kunempembelelo enkulu ekusebenzeni okuneenkcukacha kunye nomonakalo wesixhobo, ngoko ke uphuhliso lwetekhnoloji yokwandisa ukuhanjiswa kwamandla e-ion kuye kwaba lelinye lamanqaku aphambili ezixhobo zokujongisisa eziphambili. Okwangoku, iitekhnoloji ezisetyenziswe ngempumelelo kwimveliso ziquka i-multi-RF hybrid drive, i-DC superposition, i-RF idityaniswe ne-DC pulse bias, kunye ne-synchronous pulsed RF imveliso yobonelelo lombane olucalanye kunye nonikezelo lwamandla omthombo.

Isixhobo se-CCP se-etching sesinye sezona ntlobo zisetyenziswa kakhulu kwi-plasma etching izixhobo. Isetyenziswa ikakhulu kwinkqubo yokufakwa kwezixhobo zedielectric, ezinje ngesango elisecaleni kunye nokufakwa kwemaski enzima kwinqanaba elingaphambili lenkqubo ye-logic chip, ukukrolwa komngxuma wokuqhafaza kwinqanaba eliphakathi, i-mosaic kunye ne-aluminium etching pad kwinqanaba elingasemva, ngokunjalo ukufakwa kwemingxuma enzulu, imingxuma enzulu kunye nemingxuma yokunxibelelana kweengcingo kwi-3D flash memory chip process (ukuthatha isilicon nitride / isilicon oxide isakhiwo njengomzekelo).

Kukho imingeni emibini ephambili kunye nezalathiso zophuculo ezijongene nezixhobo ze-CCP etching. Okokuqala, ekusetyenzisweni kwamandla e-ion aphezulu ngokugqithisileyo, ukukwazi ukujongwa komgangatho ophezulu wezakhiwo (ezifana nomngxuma kunye ne-groove etching ye-3D flash memory ifuna umlinganiselo ophezulu kuno-50:1). Indlela yangoku yokwandisa amandla e-bias ukwandisa amandla e-ion isebenzise unikezelo lwamandla eRF ukuya kuthi ga kwi-10,000 watts. Ngenxa yobuninzi bobushushu obuveliswayo, iteknoloji yokupholisa kunye nokulawula ubushushu begumbi lokuphendula kufuneka iphuculwe ngokuqhubekayo. Okwesibini, kufuneka kubekho impumelelo ekuphuhlisweni kweegesi ezintsha zokuvala ukuze kusonjululwe ingxaki yesakhono sokudibanisa.

4.6 Isixhobo sokudibanisa i-Plasma esiDityanisiweyo

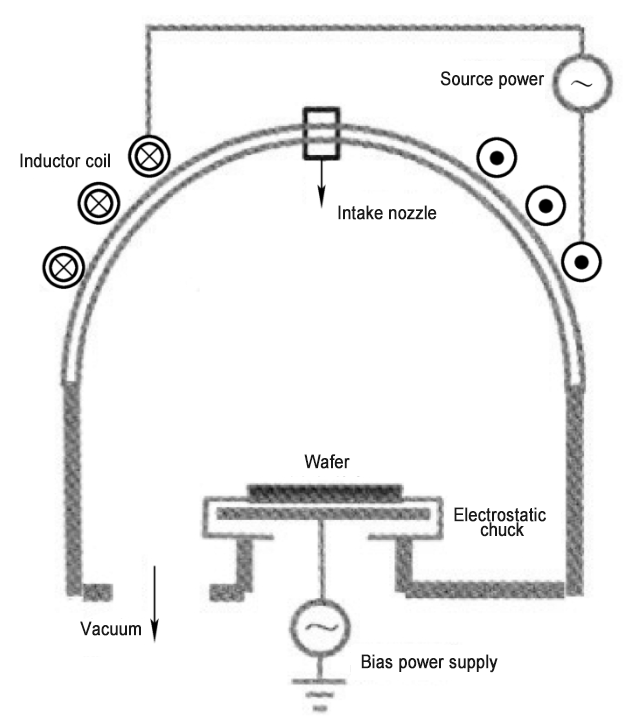

Isixhobo sokudibanisa iplasma (ICP) sisixhobo esidibanisa amandla omthombo wamandla kanomathotholo ukuya kwigumbi lokusabela ngendlela yemagnethi ngokusebenzisa ikhoyili ye-inductor, ngaloo ndlela kuvelisa iplasma yokukrola. Umgaqo wayo wokujongisisa ukwangowoluphawu lwe-ion olusebenzayo ngokubanzi.

Zimbini iindidi eziphambili zoyilo lomthombo weplasma wezixhobo zokuhombisa ze-ICP. Enye iteknoloji ye-plasma edibeneyo ye-transformer (TCP) ephuhliswe kwaye iveliswa nguLam Research. Ikhoyili yayo ye-inductor ifakwe kwindiza yefestile ye-dielectric ngaphezu kwegumbi lokuphendula. Isignali ye-13.56MHz ye-RF ivelisa indawo yemagnethi etshintshanayo kwikhoyili ethe gqolo kwifestile ye-dielectric kwaye iyahlukana ngokwerediyo nge-coil axis njengendawo esembindini.

Indawo yamagnetic ingena kwigumbi lokusabela ngefestile ye-dielectric, kwaye indawo enemagnethi etshintshanayo ivelisa indawo yombane etshintshanayo enxusene nefestile ye-dielectric kwigumbi lokusabela, ngaloo ndlela kufezekiswa ukuqhekeka kwerhasi ye-etching kunye nokuvelisa iplasma. Ekubeni lo mgaqo unokuqondwa njenge-transformer ene-coil ye-inductor njengeyona ndlela iphambili yokujika kunye neplasma kwigumbi lokuphendula njenge-winding yesibini, i-ICP etching ithiywe emva koku.

Inzuzo ephambili yeteknoloji ye-TCP kukuba isakhiwo silula ukunyusa. Ngokomzekelo, ukusuka kwi-wafer ye-200mm ukuya kwi-wafer ye-300mm, i-TCP inokugcina i-etching effect efanayo ngokunyusa ubungakanani bekhoyili.

Olunye uyilo lomthombo weplasma bubuchwephesha obudityanisiweyo beplasma (DPS) obuphuhliswe baza baveliswa yiApplied Materials, Inc. yaseUnited States. Ikhoyili yayo ye-inductor inamanxeba amathathu-dimensionally kwi-hemispherical dielectric window. Umgaqo wokuvelisa i-plasma ufana neteknoloji ye-TCP ekhankanywe ngasentla, kodwa ukusebenza kakuhle kwe-gas dissociation kuphezulu kakhulu, okwenza kube lula ukufumana i-concentration ye-plasma ephezulu.

Ekubeni ukusebenza kakuhle kwe-inductive coupling ukuvelisa i-plasma iphezulu kune-capacitive coupling, kwaye i-plasma yenziwa ikakhulu kwindawo ekufutshane nefestile ye-dielectric, ukugxilwa kwayo kwi-plasma kugqitywa ngamandla ombane womthombo oxhunywe kwi-inductor. Ikhoyili, kunye namandla e-ion kwi-sheath ye-ion kumphezulu we-wafer ngokusisiseko imiselwa ngamandla obonelelo lwamandla olucalanye, ngoko ke ugxininiso kunye namandla eeyoni. inokulawulwa ngokuzimeleyo, ngaloo ndlela ifezekisa ukuqhawula.

Isixhobo sokufaka i-ICP sesinye sezona ntlobo zisetyenziswa kakhulu zezixhobo ze-plasma etching. Isetyenziselwa ikakhulu ukufakwa kwesilicon emiseleni enganzulwanga, igermanium (Ge), izakhiwo zesango lepolysilicon, izakhiwo zesango lentsimbi, isilicon ehluziweyo (Strained-Si), iingcingo zentsimbi, iipads zetsimbi (Pads), imosaic etching metal imaski kunye neenkqubo ezininzi kwi. itekhnoloji yemifanekiso emininzi.

Ukongeza, ngokunyuka kweesekethe ezihlangeneyo ezinamacala amathathu, i-CMOS sensors yemifanekiso kunye ne-micro-electro-mechanical systems (MEMS), kunye nokunyuka ngokukhawuleza kokusetyenziswa kwe-silicon vias (TSV), imingxuma enkulu kunye ne-oblique. etching isilicon enzulu kunye morphologies ezahlukeneyo, abavelisi abaninzi baye baqalisa izixhobo etching eziphuhliswe ngokukodwa ezi zicelo. Iimpawu zayo zibunzulu obukhulu be-etching (amashumi okanye amakhulu eemicrons), ngoko ke isebenza kakhulu phantsi kokuhamba kwegesi ephezulu, uxinzelelo oluphezulu kunye neemeko zamandla aphezulu.

————————————————————————————————————————————————— ————————————-

I-Semicera inokubonelelaiindawo zegraphite, uthambile/uqinile, iinxalenye ze-silicon carbide, CVD iinxalenye zesilicon carbide, kwayeIindawo ezigqunywe yiSiC/TaCnge 30 iintsuku.

Ukuba unomdla kwezi mveliso zesemiconductor zingasentla,nceda ungathandabuzi ukuqhagamshelana nathi okokuqala.

Umnxeba: +86-13373889683

Whatsapp: +86-15957878134

Email: sales01@semi-cera.com

Ixesha lokuposa: Aug-31-2024