Isishwankathelo esinye

Kwinkqubo yokuvelisa isekethe edibeneyo, i-photolithography yinkqubo ephambili emisela inqanaba lokuhlanganiswa kweesekethe ezidibeneyo. Umsebenzi wale nkqubo kukudlulisa ngokuthembekileyo kwaye udlulisele ulwazi lomzobo wesiphaluka kwimaski (ekwabizwa ngokuba yi-mask) kwi-substrate yezinto ze-semiconductor.

Umgaqo osisiseko wenkqubo ye-photolithography kukusebenzisa i-photochemical reaction ye-photoresist egqunywe kumphezulu we-substrate ukurekhoda ipateni yesekethe kwimaski, ngaloo ndlela kufezekiswa injongo yokudlulisa iphethini yesekethe edibeneyo ukusuka kuyilo ukuya kwi-substrate.

Inkqubo esisiseko ye-photolithography

Okokuqala, i-photoresist isetyenziswe kwi-substrate surface usebenzisa umatshini wokugubungela;

Emva koko, umatshini we-photolithography usetyenziselwa ukuveza i-substrate ehlanganiswe ne-photoresist, kwaye i-photochemical reaction mechanism isetyenziselwa ukurekhoda ulwazi lwepatheni yemaski ehanjiswa ngumatshini we-photolithography, ukugqiba ukuhanjiswa kokunyaniseka, ukudluliselwa kunye nokuphindaphinda iphethini yemaski kwi-substrate;

Ekugqibeleni, umphuhlisi usetyenziselwa ukuphuhlisa i-substrate eveziweyo yokususa (okanye ukugcina) i-photoresist eyenziwa yi-photochemical reaction emva kokuvezwa.

Inkqubo yesibini ye-photolithography

Ukuze kudluliselwe ipateni yesekethe eyiliweyo kwimaski ukuya kwi-silicon wafer, ukudluliselwa kufuneka kuqala kuphunyezwe ngenkqubo yokuvezwa, kwaye ke ipatheni yesilicon kufuneka ifunyanwe ngenkqubo yokufaka.

Ekubeni ukukhanya kwendawo yenkqubo ye-photolithography isebenzisa umthombo wokukhanya ophuzi apho izinto ze-photosensitive zingenaluvelwano, ikwabizwa ngokuba yindawo yokukhanya ephuzi.

I-Photolithography yaqala ukusetyenziswa kushishino loshicilelo kwaye yayiyeyona teknoloji iphambili yokwenza i-PCB yokuqala. Ukususela kwi-1950s, i-photolithography iye ngokuthe ngcembe ibe yithekhnoloji eqhelekileyo yokudluliselwa kwephethini kwi-IC yokuvelisa.

Iimpawu eziphambili zenkqubo ye-lithography zibandakanya isisombululo, uvakalelo, ukuchaneka kokugqithisa, izinga lesiphako, njl.

Izinto ezibaluleke kakhulu kwinkqubo ye-photolithography yi-photoresist, eyona nto i-photosensitive material. Ekubeni uvakalelo lwe-photoresist luxhomekeke kubude be-wavelength yomthombo wokukhanya, izinto ezahlukeneyo ze-photoresist ziyafuneka kwiinkqubo ze-photolithography ezifana ne-g / i line, i-248nm KrF, kunye ne-193nm ArF.

Inkqubo ephambili yenkqubo ye-photolithography eqhelekileyo iquka amanyathelo amahlanu

:

-Ukulungiswa kwefilimu esisiseko;

-Faka i-photoresist kunye ne-soft bake;

-Ukulungelelaniswa, ukuvezwa kunye nokubhaka emva kokuvezwa;

-Phuhlisa ifilimu enzima;

-Ukufunyanwa kophuhliso.

(1)Ukulungiswa kwefilimu esisiseko: ikakhulu ukucoca kunye nokuphelelwa ngamanzi emzimbeni. Ngenxa yokuba naluphi na ungcoliseko luya kwenza buthathaka ukunamathela phakathi kwe-photoresist kunye ne-wafer, ukucocwa ngokucokisekileyo kunokuphucula ukunamathela phakathi kwe-wafer kunye ne-photoresist.

(2)Photoresist ukutyabeka: Oku kuphunyezwa ngokujikelezisa iwafer yesilicon. Iifotoresist ezahlukeneyo zifuna iiparamitha zenkqubo yokwambathisa, kubandakanya isantya sokujikeleza, ubukhulu befotoresist, kunye nobushushu.

Ukubhaka okuthambileyo: Ukubhaka kunokuphucula ukunamathela phakathi kwe-photoresist kunye ne-silicon wafer, kunye nokufana kobukhulu be-photoresist, okuyingenelo kulawulo oluchanekileyo lwemilinganiselo yejometri yenkqubo yokubhala elandelayo.

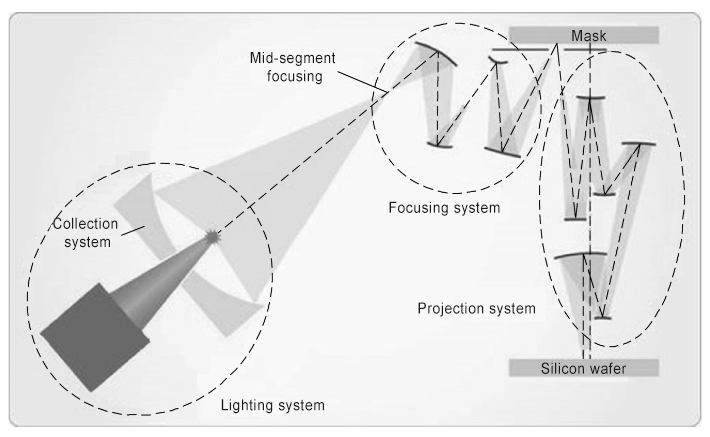

(3)Ulungelelwaniso kunye nokuvezwa: Ukulungelelaniswa kunye nokuvezwa ngamanyathelo abaluleke kakhulu kwinkqubo ye-photolithography. Babhekisa ekulungelelaniseni ipateni yemaski kunye nepateni ekhoyo kwi-wafer (okanye ipateni yomaleko wangaphambili), kwaye emva koko ilayite ngokukhanya okuthe ngqo. Amandla okukhanya avula amacandelo e-photosensitive kwi-photoresist, ngaloo ndlela idlulisela ipateni yemaski kwi-photoresist.

Izixhobo ezisetyenziselwa ukulungelelaniswa kunye nokuvezwa ngumatshini we-photolithography, eyona nto ibiza kakhulu enye yezixhobo zenkqubo kuyo yonke inkqubo yokuvelisa isekethe edibeneyo. Inqanaba lobugcisa lomatshini we-photolithography limele inqanaba lokuqhubela phambili komgca wokuvelisa wonke.

I-Post-exposure baking: ibhekisela kwinkqubo yokubhaka emfutshane emva kokuvezwa, enempembelelo eyahlukileyo kune-photoresists enzulu ye-ultraviolet kunye ne-photoresists ye-i-line yesiqhelo.

Kwi-photoresist ye-ultraviolet enzulu, i-post-exposure baking isusa amacandelo akhuselayo kwi-photoresist, evumela ukuba i-photoresist ichithe kumthuthukisi, ngoko ke ukubhaka kwe-post-exposure kuyimfuneko;

Kwi-photoresists ye-i-line yesiqhelo, ukubhaka emva kwe-post-exposure kunokuphucula ukunamathela kwe-photoresist kunye nokunciphisa amaza amileyo (amaza amileyo aya kuba nefuthe elibi kwi-edge morphology ye-photoresist).

(4)Ukuphuhlisa ifilimu enzima: usebenzisa umphuhlisi ukunyibilikisa inxalenye enyibilikayo ye-photoresist (i-photoresist enhle) emva kokuvezwa, kwaye ubonise ngokuchanekileyo ipateni yemaski kunye nephethini ye-photoresist.

Iiparamitha eziphambili zenkqubo yophuhliso ziquka ubushushu bophuhliso kunye nexesha, umthamo womphuhlisi kunye nokugxininiswa, ukucocwa, njl. Ngokuhlengahlengisa iiparameters ezifanelekileyo kuphuhliso, umahluko kwizinga lokuchithwa phakathi kweendawo eziveziweyo nezingabonakaliyo zefotoresist zinokunyuswa, ngaloo ndlela. ukufumana isiphumo esifunekayo sophuhliso.

Ukuqina kwakhona kwaziwa njengokuqina kokubhaka, okuyinkqubo yokususa i-solvent eseleyo, umphuhlisi, amanzi kunye nezinye izinto ezingafunekiyo ezishiyekileyo kwi-photoresist ephuhlisiwe ngokufudumeza kunye nokuwafaka umphunga, ukuze kuphuculwe ukunamathela kwe-photoresist kwi-silicon substrate kwaye ukuxhathisa etching of photoresist.

Ukushisa kwenkqubo yokuqina kuyahluka ngokuxhomekeke kwiifotoresist ezahlukeneyo kunye neendlela zokuqina. Isiseko kukuba ipateni ye-photoresist ayiguquki kwaye i-photoresist kufuneka yenziwe nzima ngokwaneleyo.

(5)Ukuhlolwa kophuhliso: Oku kukukhangela iziphene kwipatheni yefotoresist emva kophuhliso. Ngokwesiqhelo, itekhnoloji yokuqonda umfanekiso isetyenziselwa ukuskena ngokuzenzekelayo ipateni yetshiphu emva kophuhliso kwaye uyithelekise nepateni esemgangathweni engenasiphako egcinwe ngaphambili. Ukuba kukho nawuphi na umahluko ofunyenweyo, uthathwa njengonesiphene.

Ukuba inani leziphene lidlula ixabiso elithile, i-silicon wafer ithathwa njengengaphumelelanga kuvavanyo lophuhliso kwaye inokuchithwa okanye iphinde isetyenziswe ngokufanelekileyo.

Kwinkqubo yokwenziwa kwesekethe edibeneyo, uninzi lweenkqubo azinakuguqulwa, kwaye i-photolithography yenye yeenkqubo ezimbalwa ezinokuthi ziphinde zenziwe kwakhona.

Iifotomaski ezintathu kunye nezixhobo zefotoresist

3.1 I-Photomask

I-photomask, ekwabizwa ngokuba yi-photolithography imaski, yinkosi esetyenziswa kwinkqubo ye-photolithography yokwenziwa kwe-wafer yesekethe edibeneyo.

Inkqubo yokwenza ifotomask kukuguqula idatha yoyilo lwantlandlolo olufunekayo kwimveliso ye-wafer eyilwe ziinjineli zoyilo oludityanisiweyo lwesekethe kwifomathi yedatha enokwamkelwa ngabavelisi bepateni yelaser okanye izixhobo zokuvezwa kwe-electron beam ngokusetyenzwa kwedatha yemaski, ukuze ibe nokuvezwa izixhobo ezingasentla kwi-photomask substrate imathiriyeli egqunywe nge-photosensitive material; emva koko icutshungulwa ngoluhlu lweenkqubo ezifana nophuhliso kunye ne-etching ukulungisa iphethini kwi-substrate material; ekugqibeleni, ihlolwe, ilungiswe, ihlanjululwe, kwaye ifilimu-laminated ukwenza imveliso yemaski kwaye ihanjiswe kumenzi wesekethe edibeneyo ukuze isetyenziswe.

3.2 Ingcali yokufota

Ifotoresist, ekwabizwa ngokuba yifotoresist, yimathiriyeli ye-photosensitive. Amacandelo e-photosensitive kuwo aya kutshintsha iikhemikhali phantsi kwe-irradiation of light, ngaloo ndlela ebangela utshintsho kwizinga lokuchithwa. Umsebenzi wayo oyintloko kukudlulisa iphethini kwimaski kwi-substrate efana ne-wafer.

Umgaqo osebenzayo we-photoresist: Okokuqala, i-photoresist ifakwe kwi-substrate kwaye i-pre-baked ukuze isuse i-solvent;

Okwesibini, i-mask ibonakaliswe ekukhanyeni, ibangela ukuba amacandelo e-photosensitive kwindawo evezwe ukuba ayenze i-chemical reaction;

Emva koko, i-post-exposure bake yenziwa;

Ekugqibeleni, i-photoresist inyibilika ngokuyinxenye ngophuhliso (kwi-photoresist elungileyo, indawo evezwayo iyachithwa; kwi-photoresist engathandekiyo, indawo engabonakaliyo iyachithwa), ngaloo ndlela iqonda ukuhanjiswa kwepateni yesekethe edibeneyo ukusuka kwimaski ukuya kwi-substrate.

Amacandelo e-photoresist ikakhulu abandakanya i-resin yokwenza ifilimu, i-photosensitive component, i-trace additives kunye ne-solvent.

Phakathi kwabo, i-resin-forming resin isetyenziselwa ukubonelela ngeempawu zomatshini kunye nokuchasana kwe-etching; icandelo le-photosensitive lifumana utshintsho lweekhemikhali phantsi kokukhanya, okubangela utshintsho kwizinga lokuchithwa;

Izongezo zokulandelela ziquka idayi, i-viscosity enhancers, njl., ezisetyenziselwa ukuphucula ukusebenza kwe-photoresist; izinyibilikisi zisetyenziselwa ukunyibilikisa amacandelo kwaye zixutywe ngokulinganayo.

Iifotoresists ezisetyenziswa ngoku ngokubanzi zinokwahlulwa zibe ziifotoresist zemveli kunye ne-photoresist eyandisiweyo ngokwekhemikhali ngokwendlela yokusabela kwefotochemical, kwaye inokwahlulwa ibe yi-ultraviolet, i-ultraviolet enzulu, i-ultraviolet egqithisileyo, i-electron beam, i-ion beam kunye ne-X-ray photoresists ngokutsho. Ubude be-photosensitivity.

Izixhobo ezine zokufota

Itekhnoloji ye-Photolithography iye yadlula kwinkqubo yophuhliso yoqhagamshelwano / i-proximity lithography, i-optical projection lithography, i-step-and-repeat lithography, i-lithography yokuskena, i-immersion lithography, kunye ne-EUV lithography.

4.1 UQhagamshelwano/Ukusondela kweLithography Machine

I-teknoloji ye-lithography yoqhagamshelwano yavela kwi-1960 kwaye yayisetyenziswa ngokubanzi kwi-1970s. Yayiyeyona ndlela iphambili yelithography ngexesha leesekethe ezincinci ezihlanganisiweyo kwaye yayisetyenziswa ikakhulu ukuvelisa iisekethe ezidibeneyo ezinobukhulu beempawu ezinkulu kune-5μm.

Kumatshini wokudibanisa / okufutshane we-lithography, i-wafer idla ngokubekwa kwindawo ephantsi elawulwa ngesandla kunye netafile yokusebenza ejikelezayo. Umsebenzisi usebenzisa i-microscope yendawo ecacileyo ukujonga ngaxeshanye indawo yemaski kunye ne-wafer, kwaye ulawula ngesandla indawo yetafile yokusebenza ukulungelelanisa imaski kunye ne-wafer. Emva kokuba i-wafer kunye nemaski zilungelelaniswe, zombini ziya kucinezelwa kunye ukuze imaski idibane ngqo ne-photoresist kumphezulu we-wafer.

Emva kokususa injongo ye-microscope, i-wafer ecinezelweyo kunye nemaski zihanjiswa kwitafile yokuvezwa ukuze ibe sesichengeni. Ukukhanya okukhutshwe sisibane semercury kuhlanganiswe kwaye kuhambelana nemaski ngelensi. Ekubeni imaski idibene ngokuthe ngqo kunye ne-photoresist layer kwi-wafer, ipateni yemaski idluliselwa kwi-photoresist layer kwi-relation ye-1: 1 emva kokuvezwa.

Izixhobo zoqhagamshelwano zelithography sesona sixhobo silula kwaye sinoqoqosho lwelithography, kwaye sinokufikelela ekuvezweni kobukhulu bemizobo ye-sub-micron, ke sisasetyenziswa kwimveliso yeebhetshi ezincinci kunye nophando lwebhubhoratri. Kwimveliso yesekethe ehlanganisiweyo enkulu, itekhnoloji ye-lithography ekufutshane yaziswa ukuphepha ukunyuka kweendleko ze-lithography ezibangelwa kukudibana ngokuthe ngqo phakathi kwemaski kunye ne-wafer.

I-proximity lithography yayisetyenziswa ngokubanzi kwiminyaka yee-1970 ngexesha leesekethe ezidibeneyo ezincinci kunye nexesha lokuqala leesekethe ezidibeneyo ezidibeneyo. Ngokungafaniyo ne-lithography yoqhagamshelwano, imaski kwi-lithography ekufutshane ayidibanisi ngokuthe ngqo ne-photoresist kwi-wafer, kodwa i-gap egcwele i-nitrogen ishiywe. Imaski idada kwi-nitrogen, kwaye ubungakanani besithuba phakathi kwe-mask kunye ne-wafer bunqunywe nguxinzelelo lwe-nitrogen.

Kuba akukho nxibelelwano luthe ngqo phakathi kwe-wafer kunye nemaski kwi-lithography ekufutshane, iziphene eziveliswe ngexesha lenkqubo ye-lithography ziyancitshiswa, ngaloo ndlela zinciphisa ilahleko yemaski kunye nokuphucula isivuno se-wafer. Kubume be-lithography, umsantsa phakathi kwewafer kunye nemaski ibeka iwafer kwindawo yeFresnel diffraction. Ubukho bomda we-diffraction bunciphisa ukuphuculwa ngakumbi kwesisombululo sezixhobo ze-lithography ezikufutshane, ngoko ke obu bugcisa bufaneleka ngokukodwa ukuveliswa kweesekethe ezidibeneyo ezinobukhulu beempawu ezingaphezu kwe-3μm.

4.2 I-Stepper kunye ne-Repeater

I-stepper sesinye sezixhobo ezibaluleke kakhulu kwimbali ye-wafer lithography, eye yakhuthaza inkqubo ye-sub-micron lithography kwimveliso yobuninzi. I-stepper isebenzisa i-static exposure field ye-22mm × 22mm kunye ne-lens ye-optical projection kunye nomlinganiselo wokunciphisa we-5: 1 okanye 4: 1 ukudlulisa iphethini kwimaski kwi-wafer.

Umatshini we-lithography wokunyathela kunye nokuphinda udityaniswe ngokubanzi ngenkqubo esezantsi yokuvezwa, isixokelelwano senqanaba lendawo yokusebenza, inkqubo esezantsi yeqonga lemaski, inkqubo esezantsi yogqaliselo/yomgangatho, inkqubo engaphantsi yolungelelwaniso, inkqubo esezantsi yesakhelo, inkqubo esezantsi yodluliselo lwewafer, inkqubo esezantsi yokudlulisa imaski. , isistim esezantsi yombane, kunye nesistim esezantsi yesoftware.

Inkqubo eqhelekileyo yokusebenza yomatshini we-lithography wesinyathelo-kunye-uphinda ngolu hlobo lulandelayo:

Okokuqala, i-wafer efakwe kwi-photoresist idluliselwa kwitafile ye-workpiece ngokusebenzisa i-wafer transfer subsystem, kwaye imaski ukuba ibonakaliswe idluliselwe kwitafile yemaski ngokusebenzisa isistim sokudlulisa imaski;

Emva koko, inkqubo isebenzisa indlela esezantsi yogxininiso/yenqanaba ukwenza umlinganiselo wokuphakama kwamanqaku amaninzi kwiwafer ekwiqonga lesixhobo sokusebenza ukufumana ulwazi olunjengobude kunye ne-angle yokuthambeka komphezulu wewafer ukuba ivele, ukuze indawo yokuvezwa I-wafer inokuhlala ilawulwa ngaphakathi kubunzulu benjongo yeprojekthi ngexesha lenkqubo yokuvezwa;Emva koko, inkqubo isebenzisa isistim yokulungelelanisa ukulungelelanisa imaski kunye ne-wafer ukwenzela ukuba ngexesha lenkqubo yokuvezwa ukuchaneka kwendawo yomfanekiso wemaski kunye nokuhanjiswa kwepatheni ye-wafer ihlala ingaphakathi kweemfuno ezingaphezulu.

Ekugqibeleni, isenzo sokunyathela kunye nokuvezwa kwendawo yonke ye-wafer igqitywe ngokwendlela emiselweyo yokufezekisa umsebenzi wokudlulisa ipateni.

Umatshini olandelayo wokunyathela kunye nomatshini wokuskena welithography usekelwe kwinkqubo yokusebenza esisiseko engasentla, ukuphucula ukunyathela → ukutyhileka kwiskena → utyhileko, nokujolisa/umgangatho → ulungelelwaniso → ukuvezwa kwimodeli enamanqanaba amabini kumlinganiselo (ujoliso/umgangatho → ulungelelwaniso) kunye nokuskena. ukuvezwa ngokuhambelanayo.

Xa kuthelekiswa nomatshini we-lithography wesinyathelo kunye ne-scan, umatshini we-lithography wokunyathela kunye nokuphindaphinda akufuneki ukuba ufezekise ukuskena kwe-synchronous reverse ye-mask kunye ne-wafer, kwaye ayifuni itafile yemaski yokuskena kunye nenkqubo yokulawula ukuskena okuhambelanayo. Ngoko ke, isakhiwo silula, ixabiso liphantsi, kwaye umsebenzi unokuthenjwa.

Emva kokuba iteknoloji ye-IC ingene kwi-0.25μm, ukusetyenziswa kwe-lithography ye-step-and-repeat lithography yaqala ukuhla ngenxa yeenzuzo ze-step-and-scan lithography kwi-scan exposure field and exposure uniformity. Okwangoku, inyathelo lokuphinda-phinda-phinda-phinda i-lithography ebonelelwe ngu-Nikon inommandla wokuvezwa omileyo omkhulu njengaleyo ye-lithography ye-step-and-scan, kwaye inokuqhuba ngaphezulu kwe-200 wafers ngeyure, ngokusebenza okuphezulu kakhulu kwemveliso. Olu hlobo lomatshini we-lithography okwangoku lusetyenziswa ikakhulu ekwenzeni iileya ze-IC ezingabalulekanga.

4.3 I-Stepper Scanner

Ukusetyenziswa kwe-lithography ye-step-and-scan kwaqala ngo-1990. Ngokuqwalasela imithombo yokukhanya eyahlukeneyo, itekhnoloji yenyathelo kunye ne-scan inokuxhasa itekhnoloji yenkqubo eyahlukileyo, ukusuka kwi-365nm, 248nm, 193nm ukuntywiliselwa ukuya kwi-EUV lithography. Ngokungafaniyo ne-step-and-repeat lithography, i-single-field exposure ye-step-and-scan lithography ithatha ukuskena okuguquguqukayo, oko kukuthi, ipleyiti yemaski igqibezela intshukumo yokuskena ngokuhambelana ne-wafer; emva kokuba ukuvezwa kwentsimi yangoku kugqityiwe, i-wafer ithwalwa yinqanaba lomsebenzi kwaye inyuswe kwindawo elandelayo yokuskena indawo, kwaye ukubonakaliswa okuphindaphindiweyo kuyaqhubeka; phinda inyathelo-kunye-scan ukuvezwa izihlandlo ezininzi de onke amabala e-wafer abonakaliswe.

Ngokuqwalasela iintlobo ezahlukeneyo zemithombo yokukhanya (njenge-i-line, i-KrF, i-ArF), i-stepper-scanner inokuxhasa phantse zonke iinode zeteknoloji zenkqubo ye-semiconductor front-end. Iinkqubo ze-CMOS ezisekelwe kwi-silicon ziye zamkela i-stepper-scanners ngobuninzi ukususela kwi-0.18μm node; I-ultraviolet (EUV) koomatshini bokuthungatha ngokugqithisileyo abasetyenziswa ngoku kwiinkqubo zenkqubo ezingaphantsi kwe-7nm nabo basebenzisa i-stepper-scanning. Emva kohlengahlengiso oluyinxenye, iskena se-stepper sinokuxhasa uphando kunye nophuhliso kunye nokuveliswa kweenkqubo ezininzi ezingezizo-silicon ezifana ne-MEMS, izixhobo zamandla, kunye nezixhobo zeRF.

Abavelisi abakhulu benyathelo-kunye ne-scan projection lithography machines ziquka i-ASML (Netherlands), i-Nikon (eJapan), i-Canon (eJapan) kunye ne-SMEE (eChina). I-ASML iqalise uchungechunge lwe-TWINSCAN lwe-step-and-scan lithography machines kwi-2001. Yamkela inkqubo ye-architecture ye-double-stage, enokuthi iphucule ngokufanelekileyo izinga lokukhutshwa kwezixhobo kwaye ibe yinto esetyenziswa kakhulu kwi-lithography ephezulu.

4.4 ILithografi yokuntywiliselwa

Inokubonwa kwifomula yeRayleigh ukuba, xa i-exposure wavelength ihlala ingatshintshi, indlela esebenzayo yokuphucula ngakumbi isisombululo se-imaging kukunyusa ukuvuleka kwamanani kwenkqubo yokucinga. Kwizisombululo ze-imaging ezingaphantsi kwe-45nm nangaphezulu, indlela ye-ArF yokuvezwa okomileyo ayinakukwazi ukuhlangabezana neemfuno (kuba ixhasa isisombululo esiphezulu se-imaging ye-65nm), ngoko kuyimfuneko ukwazisa indlela yokuntywila ye-lithography. Kwiteknoloji ye-lithography yendabuko, i-medium phakathi kwe-lens kunye ne-photoresist ngumoya, ngelixa i-teknoloji ye-lithography yokuntywila ithatha indawo ye-air medium kunye ne-liquid (ngokuqhelekileyo amanzi e-ultrapure kunye ne-refractive index ye-1.44).

Ngapha koko, itekhnoloji yokuntywiliselwa i-lithography isebenzisa ukucutha kobude bomthombo wokukhanya emva kokuba ukukhanya kudlule kumbindi wolwelo ukuze kuphuculwe isisombululo, kwaye umlinganiselo wobufutshane yisalathiso sokuphinda sigqame kumbindi wolwelo. Nangona umatshini wokuntywiliselwa we-lithography luhlobo lomatshini we-lithography wenyathelo kunye ne-scan, kunye nesisombululo senkqubo yezixhobo zayo ayikatshintshi, luhlengahlengiso kunye nokwandiswa komatshini we-ArF wenyathelo kunye ne-scan ngenxa yokungeniswa kobuchwepheshe obuphambili obunxulumeneyo. ukuntywiliselwa.

Inzuzo yokucwiliswa kwe-lithography kukuba, ngenxa yokunyuka kwamanani okungena kwenkqubo, ukukwazi ukulinganiswa kwe-imaging ye-stepper-scanner lithography machine iphuculwe, enokuthi ihlangabezane neemfuno zenkqubo yesisombululo se-imaging ngaphantsi kwe-45nm.

Ekubeni umatshini wokuntywila we-lithography usasebenzisa umthombo wokukhanya we-ArF, ukuqhubeka kwenkqubo kuqinisekisiwe, ukugcina ixabiso le-R&D lomthombo wokukhanya, izixhobo kunye nenkqubo. Ngesi siseko, kudibaniswe nemizobo emininzi kunye neteknoloji ye-lithography, umatshini wokuntywila we-lithography ungasetyenziselwa kwiinkqubo ze-22nm nangaphantsi. Phambi kokuba umatshini we-EUV welithography ufakwe ngokusemthethweni kwimveliso yobuninzi, umatshini wokuntywilisela welithography wawusetyenzisiwe ngokubanzi kwaye unokuhlangabezana neemfuno zenkqubo ye-7nm node. Nangona kunjalo, ngenxa yokungeniswa kolwelo lokuntywiliselwa, ubunzima bobunjineli besixhobo ngokwawo buye banda kakhulu.

Ubuchwephesha bayo obuphambili bubandakanya unikezelo lolwelo lokuntywiliselwa kunye netekhnoloji yokubuyisela, itekhnoloji yokuntywiliselwa kolwelo lokugcinwa kwentsimi, ungcoliseko lwelithography yokuntywiliselwa kunye nolawulo lwesiphene, uphuhliso kunye nokugcinwa kweelensi zokuntywiliselwa kwamanani okuntywila kwamanani amakhulu, kunye nomfanekiso wobuchwephesha bokubona umgangatho phantsi kweemeko zokuntywiliselwa.

Okwangoku, oomatshini bokurhweba be-ArFi benyathelo kunye ne-scan lithography babonelelwa ikakhulu ziinkampani ezimbini, ezizezi, i-ASML yaseNetherlands kunye ne-Nikon yaseJapan. Phakathi kwabo, ixabiso le-ASML NXT1980 Di enye limalunga ne-80 yezigidi zee-euro.

4.5 Umatshini woLithography we-Ultraviolet ogqithisileyo

Ukuze kuphuculwe isisombululo se-photolithography, i-exposure wavelength iyancipha ngakumbi emva kokuba umthombo wokukhanya we-excimer wamkelwe, kwaye ukukhanya okugqithisileyo kwe-ultraviolet kunye nobude be-10 ukuya kwi-14 nm kwaziswa njengomthombo wokukhanya. Ubude bokukhanya okugqithisileyo kwe-ultraviolet bufutshane kakhulu, kwaye inkqubo ye-optical ebonakalisayo enokuthi isetyenziswe ngokuqhelekileyo iquka izibonisi zefilimu ezininzi ezifana ne-Mo/Si okanye i-Mo/Be.

Phakathi kwazo, olona phawu luphezulu lwethiyori yokubonakalisa ifilimu yeMo/Si kuluhlu lwamaza oluyi-13.0 ukuya kwi-13.5nm lumalunga ne-70%, kunye nethiyori ebonisa ubuninzi befilimu yeMo/Be kubude obufutshane be-11.1nm bumalunga nama-80%. Nangona umboniso weMo/Be izibonisi bhanyabhanya ezininzi ziphezulu, Yiba yityhefu kakhulu, ke uphando ngemathiriyeli enjalo yayekwa xa kusenziwa itekhnoloji yelithography ye-EUV.Itekhnoloji yangoku ye-EUV lithography isebenzisa ifilimu yeMo/Si ye-multilayer, kwaye i-exposure wavelength nayo imiselwe ukuba yi-13.5nm.

Umthombo wokukhanya ogqithiseleyo we-ultraviolet usebenzisa i-laser-produced plasma (LPP) iteknoloji, esebenzisa i-laser ephezulu kakhulu ukuze ivuse i-plasma ye-Sn eshushu enyibilikayo ukuze ikhuphe ukukhanya. Ixesha elide, amandla kunye nokufumaneka komthombo wokukhanya kuye kwaba yimiqobo ethintela ukusebenza kakuhle koomatshini be-EUV lithography. Ngokusebenzisa i-master oscillator amandla amplifier, iteknoloji yeplasma (PP) exela kwangaphambili kunye ne-in-situ yokuqokelela isipili sobuchwephesha bokucoca, amandla kunye nokuzinza kwemithombo yokukhanya ye-EUV kuphuculwe kakhulu.

Umatshini we-EUV welithography wenziwa ikakhulu ziinkqubo ezisezantsi ezifana nomthombo wokukhanya, ukukhanya, ilensi enenjongo, iqonga lesixhobo sokusebenza, inqanaba lemaski, ulungelelwaniso lwewafer, ujoliso/inqanaba, ukuhanjiswa kwemaski, ukuhanjiswa kwewafer, kunye nesakhelo sokufunxa. Emva kokudlula kwisixokelelwano sokukhanyisa esinezibonisi ezininzi ezigqunyiweyo, ukukhanya okugqithisileyo kwe-ultraviolet kukhanyiswa kwimaski ebonakalisayo. Ukukhanya okubonakaliswa sisigqubuthelo semaski kungena kwisixokelelwano somfanekiso we-optical total reflection eyenziwe luthotho lwezibonisi, kwaye ekugqibeleni umfanekiso obonakalisiweyo wemaski uqikelelwa kumphezulu we-wafer kwindawo yevacuum.

Ummandla wokuvezwa kwembonakalo kunye nebala lokujonga umfanekiso we-EUV umatshini welithography zombini i-arc-shaped, kwaye indlela yokuskena inyathelo ngenyathelo isetyenziselwa ukufikelela kwi-wafer exposure epheleleyo ukuphucula izinga lokuphuma. I-ASML ye-NXE ephezulu kakhulu yochungechunge lwe-EUV umatshini we-lithography usebenzisa umthombo wokukhanya okuvezwayo kunye nobude be-wavelength ye-13.5nm, imaski ekhanyayo (i-6 ° izehlo ze-oblique), inkqubo ye-4x yokunciphisa imbonakalo ebonisa imbonakalo ene-6-mirror structure (NA=0.33), a indawo yokuskena yembono ye-26mm × 33mm, kunye ne-vacuum exposure environment.

Xa kuthelekiswa noomatshini bokuntywiliselwa kwe-lithography, isisombululo esisodwa sokuvezwa koomatshini be-EUV be-lithography abasebenzisa imithombo yokukhanya okugqithisileyo kwe-ultraviolet iye yaphuculwa kakhulu, enokuthi iphephe ngokufanelekileyo inkqubo entsonkothileyo efunekayo kwi-photolithography emininzi ukwenza imizobo enesisombululo esiphezulu. Okwangoku, isisombululo esisodwa sokuvezwa komatshini we-lithography we-NXE 3400B kunye ne-aperture yamanani ye-0.33 ifikelela kwi-13nm, kwaye izinga lokuphuma lifikelela kwiinqununu ze-125 / h.

Ukuze kuhlangatyezwane neemfuno zokwandiswa okungaphezulu koMthetho kaMoore, kwixesha elizayo, oomatshini be-EUV bezinto zelithography abane-aperture yamanani engu-0.5 baya kwamkela inkqubo yenjongo yoqikelelo enokuthintela ukukhanya okusembindini, kusetyenziswa i-asymmetric magnification ka-0.25 amaxesha/0.125 amaxesha, kunye Indawo yokujonga imbonakalo yokuskena iya kuncitshiswa ukusuka kwi-26m × 33mm ukuya kwi-26mm × 16.5mm, kwaye isisombululo esisodwa sinokufikelela ngaphantsi kwe-8nm.

————————————————————————————————————————————————— ————————————

I-Semicera inokubonelelaiindawo zegraphite, uthambile/uqinile, iinxalenye ze-silicon carbide, CVD iinxalenye zesilicon carbide, kwayeIindawo ezigqunywe yiSiC/TaCngenkqubo epheleleyo ye-semiconductor kwiintsuku ezingama-30.

Ukuba unomdla kwezi mveliso zesemiconductor zingasentla,nceda ungathandabuzi ukuqhagamshelana nathi okokuqala.

Umnxeba: +86-13373889683

Whatsapp: +86-15957878134

Email: sales01@semi-cera.com

Ixesha lokuposa: Aug-31-2024