1.Malunga neeSekethe eziDityanisiweyo

1.1 Ingcamango kunye nokuzalwa kweesekethe ezidibeneyo

ISekethe eDityanisiweyo (IC): ibhekisa kwisixhobo esidibanisa izixhobo ezisebenzayo ezifana ne-transistors kunye ne-diode kunye namalungu asebenzayo afana ne-resistors kunye ne-capacitors ngokusebenzisa uluhlu lweendlela ezithile zokucubungula.

Isekethe okanye inkqubo "edibeneyo" kwi-semiconductor (efana ne-silicon okanye iikhompawundi ezifana ne-gallium arsenide) i-wafer ngokuhambelana noqhagamshelwano lwesekethe ethile kwaye emva koko ipakishwe kwiqokobhe ukwenza imisebenzi ethile.

Ngo-1958, uJack Kilby, owayenoxanduva lokwenziwa kweminiaturization yezixhobo ze-elektroniki eTexas Instruments (TI), ucebise imbono yeesekethe ezidibeneyo:

"Ekubeni onke amacandelo anje ngee-capacitors, resistors, transistors, njl.njl. angenziwa kwizinto enye, bendicinga ukuba kuyakwenzeka ukuwenza kwisiqwenga semathiriyeli ye-semiconductor kwaye emva koko udibanise ukwenza isekethe epheleleyo."

NgoSeptemba 12 noSeptemba 19, 1958, uKilby wagqiba ukuveliswa kunye nokubonakaliswa kwe-oscillator ye-phase-shift oscillator kunye ne-trigger, ngokulandelanayo, ephawula ukuzalwa kwesiphaluka esidibeneyo.

Ngo-2000, uKilby wawongwa ngeBhaso leNobel kwiFiziksi. IKomiti yeBhaso likaNobel yakha yathi uKilby “wabeka isiseko seteknoloji yenkcazelo yanamhlanje.”

Lo mfanekiso ungezantsi ubonisa uKilby kunye ne-patent yakhe edibeneyo yesekethe:

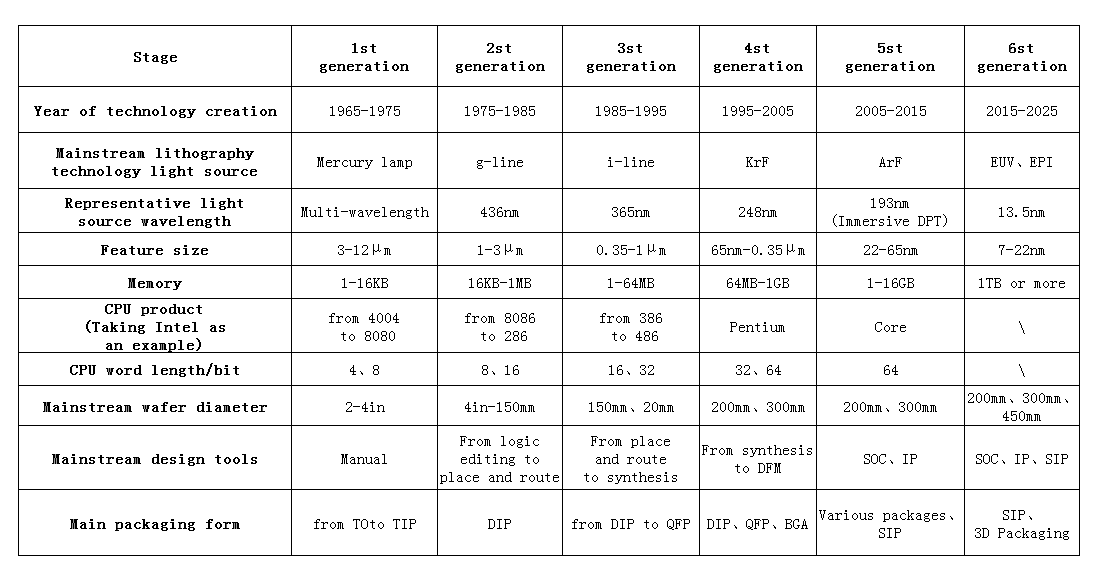

1.2 Uphuhliso lobugcisa bokuvelisa i-semiconductor

Lo mzobo ulandelayo ubonisa amanqanaba ophuhliso lwetekhnoloji yokwenziwa kwe-semiconductor:

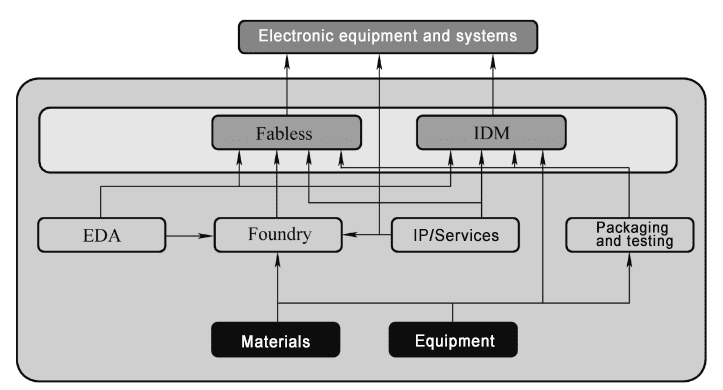

1.3 Ikhonkco loShishino lweSekethe eDityanisiweyo

Ukwakhiwa kwetsheyini yoshishino lwesemiconductor (ubukhulu becala iisekethe ezidityanisiweyo, kubandakanywa izixhobo ezidityanisiweyo) kubonisiwe kulo mfanekiso ungentla:

-Fabless: Inkampani eyila iimveliso ngaphandle komgca wemveliso.

- I-IDM: Umenzi weDivaysi oDityanisiweyo, umenzi wesixhobo esidibeneyo;

- IP: umenzi wemodyuli yeSekethe;

- I-EDA: I-Electronic Design Automatic, i-electronic design automation, inkampani ibonelela ngokukodwa ngezixhobo zokuyila;

- Foundry; Iwafer Foundry, ibonelela ngeenkonzo zokwenza itshiphu;

- Ukupakishwa kunye nokuvavanya iinkampani Foundry: ikakhulu ukukhonza Fabless kunye IDM;

- Izinto kunye neenkampani zezixhobo ezikhethekileyo: ubukhulu becala zibonelela ngezinto eziyimfuneko kunye nezixhobo kwiinkampani zokwenziwa kwetshiphu.

Iimveliso eziphambili eziveliswa kusetyenziswa itekhnoloji ye-semiconductor zizijikelezo ezidibeneyo kunye nezixhobo ze-semiconductor ezidityanisiweyo.

Iimveliso eziphambili zeesekethe ezidibeneyo ziquka:

- ISicelo seMigangatho eMiselweyo (ASSP);

- IYunithi yeMicroprocessor (MPU);

- Inkumbulo

- ISekethe eDityanisiweyo yeSicelo esiKhethekileyo (ASIC);

-ISekethe ye-Analog;

- Isekethe yengqiqo ngokubanzi (iSekethe eQongileyo).

Iimveliso eziphambili zezixhobo ze-semiconductor discrete ziquka:

-Diode;

- Transistor;

-Isixhobo saMandla;

-Isixhobo soMbane oPhezulu;

-Isixhobo seMicrowave;

-Optoelectronics;

-Isixhobo soluvo (Inzwa).

2. Inkqubo eDityanisiweyo yokwenziwa kweSekethe

2.1 Ukwenziwa kweChip

Amashumi okanye amashumi amawaka eetshiphusi ezithile anokwenziwa ngaxeshanye kwi-silicon wafer. Inani leetshiphusi kwi-wafer yesilicon ixhomekeke kuhlobo lwemveliso kunye nobukhulu betshiphu nganye.

Amaqhekeza e-silicon adla ngokubizwa ngokuba ngama-substrates. Idayamitha yee-silicone wafers ibisanda ngokuhamba kweminyaka, ukusuka ngaphantsi kwe-intshi e-1 ekuqaleni ukuya kwi-intshizi ezisetyenziswa ngokuqhelekileyo eziyi-12 (malunga ne-300 mm) ngoku, kwaye iphantsi kotshintsho ukuya kwi-intshi ezili-14 okanye ii-intshi ezili-15.

Ukwenziwa kweChip ngokubanzi kwahlulahlulwe ngokwezigaba ezihlanu: ukulungiswa kwe-silicon wafer, ukwenziwa kwesilicon wafer, uvavanyo lwetshiphu/ukuchongwa, ukudibanisa kunye nokupakishwa, kunye novavanyo lokugqibela.

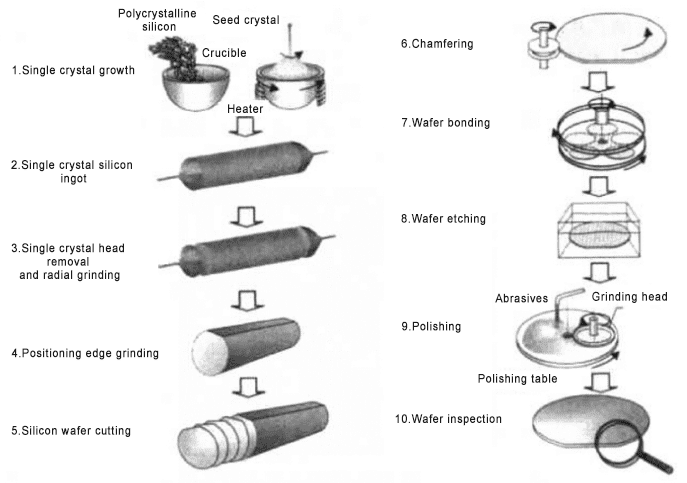

(1)

Ukulungiswa kwe-silicone yesiqhekeza:

Ukwenza izinto eziluhlaza, i-silicon ikhutshwe kwisanti kwaye ihlanjululwe. Inkqubo ekhethekileyo ivelisa i-silicon ingots ye-diameter efanelekileyo. Ii-ingots zisikwa zibe zi-wafers ze-silicon ezibhityileyo zokwenza ii-microchips.

Ii-wafers zilungiselelwe kwiinkcukacha ezithile, ezinje ngeemfuno zomda wobhaliso kunye namanqanaba ongcoliseko.

(2)Ukwenziwa kwe-silicon:

Ikwaziwa njengokwenziwa kwetshiphu, isiqwenga se-silicon esingenanto sifika kwisikhululo sokwenza i-silicon wafer kwaye emva koko sihamba ngeendlela ezahlukeneyo zokucoca, ukwenza ifilimu, ifotolithography, i-etching kunye namanyathelo edoping. Isiqwenga se-silicon esenziweyo sineseti epheleleyo yeesekethe ezidityanisiweyo ezifakwe ngokusisigxina kwi-silicon wafer.

(3)Uvavanyo kunye nokukhethwa kwee-wafers ze-silicon:

Emva kokuba ukuveliswa kwe-silicon kugqityiwe, ii-wafers ze-silicon zithunyelwa kwindawo yovavanyo / yohlobo, apho iitshiphusi zomntu ngamnye ziye zihlolwe kwaye zivavanywe ngombane. Iichips ezamkelekileyo nezingamkelekanga ziyahlelwa, kwaye iitshiphusi ezineziphene ziphawulwe.

(4)INdibano kunye nokupakishwa:

Emva kovavanyo lwe-wafer / ukuhlelwa, ii-wafers zingena kwindibano kunye nesinyathelo sokupakisha ukupakisha iitshiphusi zomntu ngamnye kwipakethi yetyhubhu ekhuselayo. Icala elingasemva le-wafer liphantsi ukunciphisa ubukhulu be-substrate.

Ifilim yeplastiki eshinyeneyo incanyathiselwe ngasemva kwi-wafer nganye, kuze emva koko kusetyenziswe isarha yesarha enencam yedayimane ukwahlula iitshiphusi kwiwafer nganye ecaleni kwemigca yombhali kwicala langaphambili.

Ifilimu yeplastiki engasemva kwe-silicon wafer igcina i-silicon chip ingawi. Kwisityalo sokuhlanganisa, ii-chips ezilungileyo zicinezelwe okanye zikhutshwe ukuze zenze iphakheji yendibano. Kamva, i-chip ivalwe kwigobolondo leplastiki okanye nge-ceramic.

(5)Uvavanyo lokugqibela:

Ukuqinisekisa ukusebenza kwe-chip, isekethe nganye ehlanganisiweyo epakishweyo ivavanywa ukuze ihlangabezane neemfuno zepharamitha yeempawu zombane zomenzi. Emva kovavanyo lokugqibela, i-chip ithunyelwa kumthengi ukuze ahlanganiselwe kwindawo enikezelweyo.

2.2 ICandelo leNkqubo

Iinkqubo zokwenziwa kweesekethe ezidityanisiweyo zohlulwe ngokubanzi zibe:

Ukuphela komphambili: Inkqubo yangaphambili ngokuqhelekileyo ibhekisela kwinkqubo yokwenziwa kwezixhobo ezifana ne-transistors, ngokukodwa kubandakanywa iinkqubo zokuqulunqa ukuhlukaniswa, isakhiwo sesango, umthombo kunye ne-drain, imingxuma yokudibanisa, njl.

Ngasemva-isiphelo: Inkqubo ye-back-end ikakhulu ibhekisela ekubunjweni kwemigca yokudibanisa ekwazi ukuhambisa izibonakaliso zombane kwizixhobo ezahlukahlukeneyo kwi-chip, ngokukodwa kubandakanywa iinkqubo ezifana ne-dielectric deposition phakathi kwemigca yokudibanisa, ukubunjwa komgca wetsimbi, kunye nokubunjwa kwe-lead pad.

Phakathi kwinqanaba: Ukuze kuphuculwe ukusebenza kwee-transistors, ii-node zeteknoloji eziphambili emva kwe-45nm / 28nm zisebenzisa i-dielectrics yesango eliphezulu-k kunye neenkqubo zesango lesinyithi, kunye nokongeza iinkqubo zesango ezitshintshileyo kunye neenkqubo ze-interconnect zasekhaya emva kokuba umthombo we-transistor kunye nesakhiwo se-drain silungiselelwe. Ezi nkqubo ziphakathi kwenkqubo ye-front-end kunye ne-back-end process, kwaye ayisetyenziswa kwiinkqubo zendabuko, ngoko zibizwa ngokuba yi-mid-stage process.

Ngokuqhelekileyo, inkqubo yokulungisa umngxuma wokuqhagamshelana ngumgca wokuhlula phakathi kwenkqubo yangaphambili kunye nenkqubo yokuphela.

Umngxuma woqhagamshelwano: umngxuma omiswe ngokuthe nkqo kwi-silicon wafer ukuqhagamshela umgca woqhagamshelo lwentsimbi yokuqala kunye nesixhobo esisezantsi. Izaliswe ngentsimbi efana ne-tungsten kwaye isetyenziselwa ukukhokelela i-electrode yesixhobo kumaleko oqhagamshelwano lwetsimbi.

NgeHole: Yindlela yokudibanisa phakathi kwemigca emibini esondeleyo yemigca yokudibanisa isinyithi, ebekwe kwi-dielectric layer phakathi kweeleyile ezimbini zetsimbi, kwaye ngokubanzi izaliswe ngeentsimbi ezifana nobhedu.

Ngengqiqo ebanzi:

Inkqubo yangaphambili: Kwingqiqo ebanzi, ukuveliswa kweesekethe ezidibeneyo kufuneka kubandakanye uvavanyo, ukupakishwa kunye namanye amanyathelo. Xa kuthelekiswa novavanyo kunye nokupakishwa, icandelo kunye ne-interconnect production yinxalenye yokuqala yokwenziwa kweesekethe ezidibeneyo, ezibizwa ngokuba ziinkqubo zangaphambili;

Inkqubo yokubuyela emva: Uvavanyo kunye nokupakishwa kubizwa ngokuba ziinkqubo ze-back-end.

3. Isihlomelo

I-SMIF:I-Standard Mechanical Interface

I-AMHS: Inkqubo yokuNika izinto ngokuzenzekela

OHT: Ukudluliselwa kwe-Overhead Hoist

I-FOUP: Ngaphambili Ukuvula iPod eManyeneyo, Ikhethekileyo ukuya kwi-intshi eyi-12 (300mm) iiwafa

Okubaluleke ngakumbi,I-Semicera inokubonelelaiindawo zegraphite, ithambile/iqinile,iinxalenye ze-silicon carbide, CVD iinxalenye zesilicon carbide, kwayeIindawo ezigqunywe yiSiC/TaCngenkqubo epheleleyo ye-semiconductor kwiintsuku ezingama-30.Sijonge ngokunyanisekileyo ukuba liqabane lakho lexesha elide eTshayina.

Ixesha lokuposa: Aug-15-2024