Amakhulu eenkqubo ezifunekayo ukujika aiqhekezana lesonkakwi semiconductor. Enye yezona nkqubo zibalulekileyoetching- oko kukuthi, ukukrola iipateni zesekethe ezintle kwiiqhekezana lesonka. Impumelelo yeetchinginkqubo ixhomekeke ekulawuleni ezahlukeneyo phakathi koluhlu lonikezelo iseti, kunye nesixhobo etching ngalinye kufuneka zilungiselelwe ukusebenza phantsi kweemeko ezingcono. Iinjineli zethu zenkqubo ye-etching zisebenzisa itekhnoloji yokuvelisa egqwesileyo ukugqiba le nkqubo ineenkcukacha.

Iziko leendaba le-SK Hynix lidlan'indlebe namalungu e-Icheon DRAM Front Etch, i-Middle Etch, kunye ne-End Etch amaqela obugcisa ukuze afunde ngakumbi ngomsebenzi wabo.

I-Etch: Uhambo lokuPhucula iMveliso

Kwimveliso ye-semiconductor, i-etching ibhekisa kwiipateni zokukrola kwiifilimu ezincinci. Iipateni zitshizwa kusetyenziswa iplasma ukwenza ulwandlalo lokugqibela lwenyathelo ngalinye lenkqubo. Injongo yayo ephambili kukubonisa ngokugqibeleleyo iipatheni ezichanekileyo ngokwendlela yokubeka kunye nokugcina iziphumo ezifanayo phantsi kwazo zonke iimeko.

Ukuba iingxaki zenzeka kwi-deposition okanye inkqubo ye-photolithography, ziyakwazi ukusombululwa ngeteknoloji ekhethiweyo ye-etching (Etch). Nangona kunjalo, ukuba kukho into engahambi kakuhle ngexesha lenkqubo ye-etching, imeko ayikwazi ukuguqulwa. Oku kungenxa yokuba izinto ezifanayo azinakuzaliswa kwindawo ekroliweyo. Ke ngoko, kwinkqubo yokwenziwa kwe-semiconductor, i-etching ibalulekile ukumisela isivuno esipheleleyo kunye nomgangatho wemveliso.

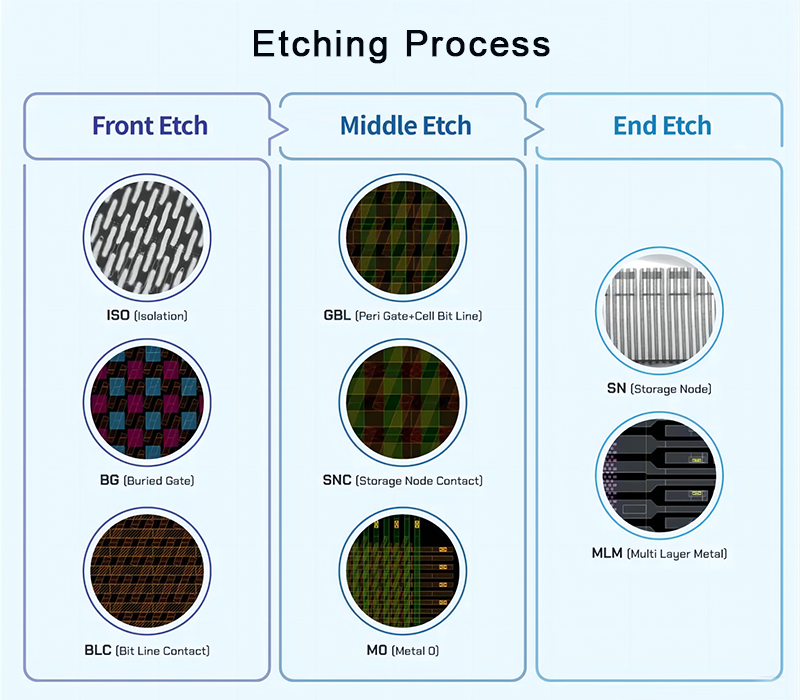

Inkqubo ye-etching ibandakanya amanyathelo asibhozo: ISO, BG, BLC, GBL, SNC, M0, SN kunye neMLM.

Okokuqala, i-ISO (Isolation) yeqonga etches (Etch) isilicon (Si) kwi-wafer ukudala indawo yeseli esebenzayo. Inqanaba le-BG (iSango eliNgcwabileyo) lenza umgca wedilesi yomqolo (Umgca weLizwi) 1 kunye nesango lokudala itshaneli yombane. Emva koko, isigaba se-BLC (uQhagamshelwano lweBit Line) senza uxhulumaniso phakathi kwe-ISO kunye nomgca wedilesi yekholomu (Bit Line) 2 kwindawo yeseli. Isigaba se-GBL (i-Peri Gate + Cell Bit Line) siya kwenza ngexesha elifanayo umgca wedilesi yekholomu yeseli kunye nesango kwi-periphery 3.

Isigaba se-SNC (iSivumelwano se-Storage Node) siyaqhubeka nokudala uxhulumaniso phakathi kwendawo esebenzayo kunye ne-node yokugcina 4. Emva koko, isigaba se-M0 (i-Metal0) senza iindawo zokudibanisa ze-peripheral S / D (I-Storage Node) 5 kunye neendawo zokuxhuma. phakathi komgca wedilesi yekholomu kunye nendawo yokugcina. Isigaba se-SN (i-Storage Node) siqinisekisa umthamo weyunithi, kwaye i-MLM elandelayo (i-Multi Layer Metal) idala ukunikezelwa kwamandla angaphandle kunye ne-wiring yangaphakathi, kwaye yonke inkqubo yobunjineli be-etching (Etch) igqityiwe.

Ngenxa yokuba i-etching (Etch) i-technicians inoxanduva ngokuyinhloko kwipatheni ye-semiconductors, isebe le-DRAM lihlulwe libe ngamaqela amathathu: I-Front Etch (ISO, BG, BLC); I-Middle Etch (GBL, SNC, M0); I-Etch Etch (SN, MLM). La maqela nawo ahlulwe ngokwezikhundla zokuvelisa kunye nezixhobo zokusebenza.

Izikhundla zokuvelisa zinoxanduva lokulawula nokuphucula iinkqubo zemveliso yeeyunithi. Izikhundla zokuvelisa zidlala indima ebaluleke kakhulu ekuphuculeni isivuno kunye nomgangatho wemveliso ngolawulo oluguquguqukayo kunye namanye amanyathelo okuphucula imveliso.

Izikhundla zezixhobo zinoxanduva lokulawula kunye nokomeleza izixhobo zokuvelisa ukuphepha iingxaki ezinokuthi zenzeke ngexesha lenkqubo yokubhala. Olona xanduva lwezikhundla zezixhobo kukuqinisekisa ukusebenza ngokupheleleyo kwezixhobo.

Nangona uxanduva lucacile, onke amaqela asebenza ngenjongo efanayo - oko kukuthi, ukulawula nokuphucula iinkqubo zokuvelisa kunye nezixhobo ezinxulumene nokuphucula imveliso. Ukuza kuthi ga ngoku, iqela ngalinye labelana ngempumelelo yalo kunye nemimandla yokuphucula, kwaye liyasebenzisana ukuphucula ukusebenza kweshishini.

Uhlangabezana njani nemingeni yetekhnoloji ye-miniaturization

I-SK Hynix iqale ukuveliswa kobunzima beemveliso ze-8Gb LPDDR4 DRAM zenkqubo yeklasi ye-10nm (1a) ngoJulayi ka-2021.

Iipateni zeesekethe ze-Semiconductor zesekethe ziye zangena kwixesha le-10nm, kwaye emva kokuphuculwa, i-DRAM enye inokuthatha malunga neeseli ze-10,000. Ke ngoko, nakwinkqubo yokubhala, umda wenkqubo ayanelanga.

Ukuba umngxuma owenziweyo (I-Hole) 6 incinci kakhulu, ingabonakala "ingavulwanga" kwaye ivimbele indawo engezantsi ye-chip. Ukongeza, ukuba umngxuma owenziweyo mkhulu kakhulu, "ibhuloho" inokwenzeka. Xa umsantsa phakathi kwemingxunya emibini ungonelanga, “ibhuloho” iyenzeka, nto leyo ekhokelela kwiingxaki zokubambelela ngokulinganayo kumanyathelo alandelayo. Njengoko i-semiconductors iya icocwa ngakumbi, uluhlu lwamaxabiso obungakanani bomngxuma luye luncipha ngokuthe ngcembe, kwaye le mingcipheko iya kupheliswa ngokuthe ngcembe.

Ukusombulula ezi ngxaki zingentla, iingcali zetekhnoloji ye-etching ziyaqhubeka nokuphucula inkqubo, kubandakanya nokuguqula iresiphi yenkqubo kunye ne-algorithm ye-APC7, kunye nokwazisa ubuchwepheshe obutsha be-etching njenge-ADCC8 kunye ne-LSR9.

Njengoko iimfuno zabathengi ziye zahluka ngakumbi, kuye kwavela omnye umngeni - umkhwa wokuveliswa kweemveliso ezininzi. Ukuhlangabezana neemfuno ezinjalo zabathengi, iimeko zenkqubo ephuculweyo yemveliso nganye kufuneka zibekwe ngokwahlukeneyo. Lo ngumceli mngeni okhethekileyo kwiinjineli kuba kufuneka zenze itekhnoloji yemveliso yobuninzi ihlangabezane neemfuno zazo zombini iimeko ezimiselweyo kunye neemeko ezahlukeneyo.

Ukuza kuthi ga ngoku, iinjineli ze-Etch zazisa itekhnoloji ye- "APC offset" ye-10 yokulawula i-derivatives eyahlukeneyo esekelwe kwiimveliso eziphambili (iiMveliso eziPhambili), kwaye yaseka kwaye yasebenzisa "inkqubo ye-T-index" ukulawula ngokubanzi iimveliso ezahlukeneyo. Ngale nzame, inkqubo iye yaphuculwa ngokuqhubekayo ukuhlangabezana neemfuno zemveliso yeemveliso ezininzi.

Ixesha lokuposa: Jul-16-2024