I-silicon carbide (SiC)Izinto eziphathekayo zineenzuzo zebhendi ebanzi, ukuhanjiswa kwe-thermal ephezulu, ukomelela okuphezulu kwebala lokuqhekeka okukhulu, kunye nesantya esiphezulu se-electron drift drift, isenza ukuba sithembise kakhulu kwindawo yokwenziwa kwe-semiconductor. Iikristale enye ye-SiC iveliswa ngokubanzi ngendlela yokuthutha umphunga womzimba (PVT). Amanyathelo athile ale ndlela abandakanya ukubeka i-SiC powder phantsi kwe-graphite crucible kunye nokubeka i-crystal yembewu ye-SiC phezulu kwi-crucible. Igraphitei-crucibleishushu kwiqondo lobushushu le-sublimation ye-SiC, ibangela ukuba i-SiC powder ibole ibe yizinto zesigaba somphunga ezifana ne-Si vapor, i-Si2C, kunye ne-SiC2. Ngaphantsi kwempembelelo ye-axial yeqondo lobushushu, ezi zinto zenziwe ngumphunga zithomalalisa phezulu kwi-crucible kwaye zijike kumphezulu we-SiC yekristale yembewu, ikhazimle kwiikristale ze-SiC enye.

Okwangoku, ububanzi bekristale yembewu busetyenziswa kuyoUkukhula kwekristale enye yeSiCidinga ukutshatisa idiamitha yekristale ekujoliswe kuyo. Ngethuba lokukhula, i-crystal yembewu igxininiswe kumnini wembewu phezulu kwi-crucible usebenzisa i-adhesive. Nangona kunjalo, le ndlela yokulungisa i-crystal yembewu inokukhokelela kwimiba efana ne-voids kwi-adhesive layer ngenxa yezinto ezifana nokuchaneka kwendawo yomnini wembewu kunye nokufana kwe-adhesive coating, enokubangela ukuba kubekho iziphene ze-hexagonal void. Ezi ziquka ukuphucula ukuthambeka kwepleyiti yegraphite, ukwandisa ukufana kobungqingqwa bomaleko wokuncamathelisa, kunye nokongeza umaleko webuffer oguqukayo. Nangona le migudu, kusekho imiba ngobuninzi bomgca wokunamathela, kwaye kukho umngcipheko we-crystal detachment yembewu. Ngokwamkela indlela yokudibanisa iiqhekezana lesonkakwiphepha le-graphite kwaye ligqithise phezulu kwi-crucible, ubuninzi be-adhesive layer bunokuphuculwa, kwaye i-detachment ye-wafer inokuthintelwa.

1. ISkimu soMfuniselo:

Iziphaluka ezisetyenzisiweyo kuvavanyo ziyafumaneka kurhweboIi-intshi ezi-6 ze-N-uhlobo lwe-SiC wafers. Ifotoresist isetyenziswa kusetyenziswa i-spin coater. Ukubambelela kufezekiswa ngokusebenzisa i-self-developed seed hot-press furnace.

1.1 Inkqubo yokuLungisa iCrystal yeMbewu:

Okwangoku, i-SiC seed crystal adhesion schemes inokwahlulwa ibe ngamacandelo amabini: uhlobo lwe-adhesive kunye nohlobo lokumiswa.

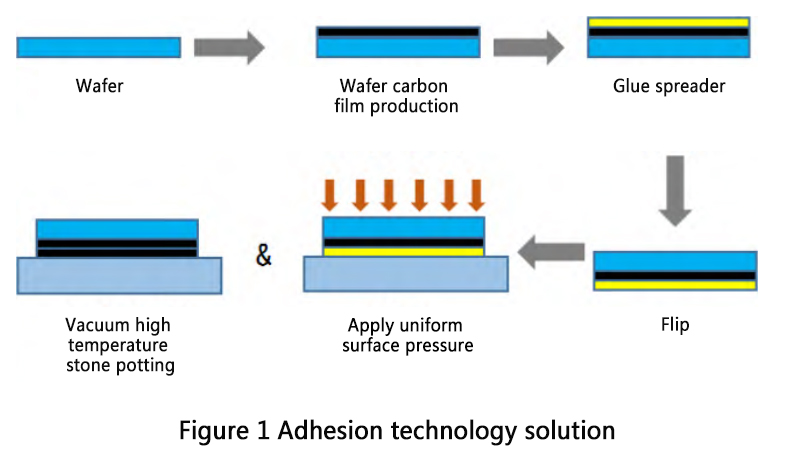

I-Adhesive Type Scheme (Umfanekiso 1): Oku kubandakanya ukudibanisa iIqhekeza leSiCkwipleyiti yegraphite kunye umaleko wephepha legraphite njengomaleko buffer ukuphelisa izithuba phakathiIqhekeza leSiCkunye nepleyiti yegraphite. Kwimveliso yangempela, amandla okubambisana phakathi kwephepha legraphite kunye neplate yegraphite ayinamandla, ekhokelela ekudibaneni kwe-crystal yembewu rhoqo ngexesha lenkqubo yokukhula kobushushu obuphezulu, okubangela ukungaphumeleli kokukhula.

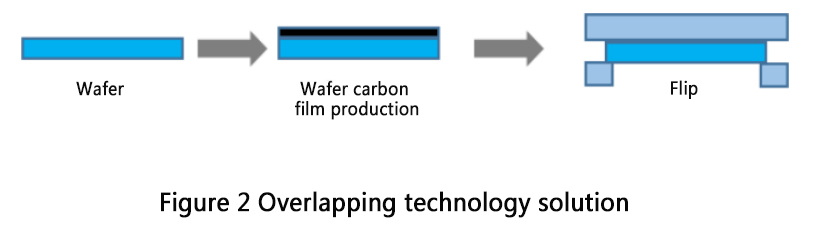

ISikimu soHlobo lokuSuspension (Umfanekiso 2): Ngokuqhelekileyo, ifilimu yekhabhoni exineneyo yenziwa kwindawo yokudibanisa i-SiC wafer usebenzisa i-glue carbonization okanye iindlela zokugqoka. IIqhekeza leSiCemva koko ibotshwe phakathi kweepleyiti ezimbini zegraphite kwaye ibekwe phezulu kwi-crucible yegraphite, iqinisekisa uzinzo ngelixa ifilimu yekhabhoni ikhusela i-wafer. Nangona kunjalo, ukudala ifilimu yekhabhoni ngokusebenzisa i-coating kubiza kwaye ayifanelekanga ukuveliswa kwemveliso. Indlela yeglue ye-carbonization ivelisa umgangatho wefilimu ye-carbon engahambelaniyo, okwenza kube nzima ukufumana ifilimu ye-carbon exineneyo ngokubambelela ngokuqinileyo. Ukongezelela, ukubethelela iipleyiti zegraphite kunciphisa indawo yokukhula esebenzayo ye-wafer ngokuthintela inxalenye yobuso bayo.

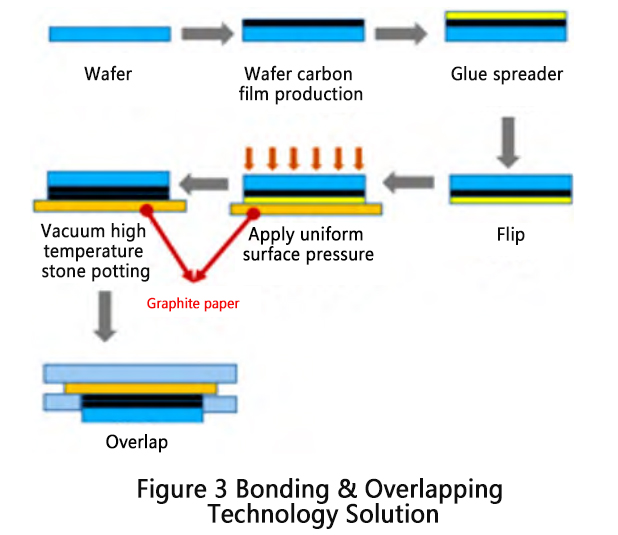

Ngokusekwe kwezi zikimu zimbini zingentla, icebo elitsha lokuncamathelisa kunye nokugqithelana liyacetywa (Umfanekiso 3):

Ifilimu yekhabhoni eshinyeneyo yenziwe kumphezulu wokudibanisa we-SiC wafer usebenzisa indlela yeglue carbonization, iqinisekisa ukuba akukho kuvuza okukhulu kokukhanya phantsi kokukhanya.

I-wafer ye-SiC egqunywe ngefilimu yekhabhoni idityaniswe kwiphepha legraphite, kunye nomphezulu wokubopha icala lefilimu yekhabhoni. I-adhesive layer kufuneka ibonakale imnyama ngokufanayo phantsi kokukhanya.

Iphepha le-graphite linyanzeliswa ngamacwecwe e-graphite kwaye lixhonywe ngaphezu kwe-graphite crucible yokukhula kwekristale.

1.2 Ukuncamathelisa:

I-viscosity ye-photoresist ichaphazela kakhulu ukufana kwefilimu. Ngesantya esifanayo se-spin, i-viscosity esezantsi iphumela kwiifilim ezincinci kunye nezincamathelayo ezifanayo. Ngoko ke, i-photoresist ephantsi ye-viscosity ikhethwa ngaphakathi kweemfuno zesicelo.

Ngethuba lovavanyo, kwafunyaniswa ukuba i-viscosity ye-adhesive carbonizing ichaphazela amandla okudibanisa phakathi kwefilimu ye-carbon kunye ne-wafer. I-viscosity ephezulu yenza kube nzima ukufaka isicelo ngokulinganayo usebenzisa i-spin coater, ngelixa i-viscosity ephantsi iphumela kumandla obuthakathaka obuthakathaka, okukhokelela ekuqhekekeni kwefilimu yekhabhoni ngexesha leenkqubo zokubambisana ezilandelayo ngenxa yokuhamba kwe-adhesive kunye noxinzelelo lwangaphandle. Ngophando lovavanyo, i-viscosity ye-adhesive carbonizing inqunywe ukuba ibe yi-100 mPa · s, kwaye i-viscosity ye-adhesive edibeneyo ibekwe kwi-25 mPa · s.

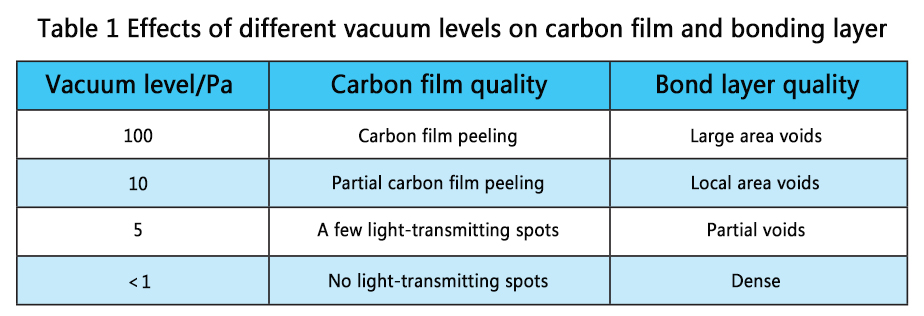

1.3 Ivacuum esebenzayo:

Inkqubo yokudala ifilimu ye-carbon kwi-wafer ye-SiC ibandakanya i-carbonizing i-adhesive layer kwi-wafer surface ye-SiC, ekufuneka yenziwe kwi-vacuum okanye i-argon-protected environment. Iziphumo zovavanyo zibonisa ukuba indawo ekhuselweyo ye-argon inceda kakhulu ekudalweni kwefilimu yekhabhoni kunendawo ephezulu yevacuum. Ukuba indawo ye-vacuum isetyenzisiwe, inqanaba le-vacuum kufuneka libe yi-≤1 Pa.

Inkqubo yokudibanisa i-crystal yembewu ye-SiC ibandakanya ukudibanisa i-wafer ye-SiC kwi-graphite plate / iphepha legraphite. Ukuqwalasela umphumo we-oxygen erosive kwizinto zegraphite kumaqondo okushisa aphezulu, le nkqubo kufuneka iqhutywe phantsi kweemeko ze-vacuum. Impembelelo yamanqanaba ahlukeneyo e-vacuum kwi-adhesive layer yafundwa. Iziphumo zovavanyo ziboniswa kwiThebhile 1. Ingabonwa ukuba phantsi kweemeko ze-vacuum ephantsi, iamolekyu ze-oksijini emoyeni azisuswanga ngokupheleleyo, ezikhokelela kwiimpawu zokunamathela ezingaphelelanga. Xa inqanaba le-vacuum lingaphantsi kwe-10 Pa, i-erosive effect ye-oksijini ye-oxygen kwi-adhesive layer iyancipha kakhulu. Xa inqanaba lokucoca lingaphantsi kwe-1 Pa, umphumo we-erosive upheliswe ngokupheleleyo.

Ixesha lokuposa: Jun-11-2024