Isishwankathelo seNkqubo yeSemiconductor

Inkqubo ye-semiconductor ngokuyintloko ibandakanya ukusebenzisa i-microfabrication kunye nobuchwepheshe befilimu ukudibanisa ngokupheleleyo iichips kunye nezinye izinto ngaphakathi kwemimandla eyahlukeneyo, efana ne-substrates kunye nezakhelo. Oku kuququzelela ukutsalwa kweetheminali ezikhokelayo kunye ne-encapsulation nge-plastic insulating medium ukwenza yonke into edibeneyo, evezwe njengesakhiwo se-dimensional ezintathu, ekugqibeleni igqibe inkqubo yokupakisha ye-semiconductor. Ingcamango yenkqubo ye-semiconductor ikwabhekiselele kwinkcazo emxinwa yokupakishwa kwe-chip ye-semiconductor. Ukusuka kumbono obanzi, kubhekiselele kubunjineli bokupakisha, okubandakanya ukudibanisa kunye nokulungiswa kwi-substrate, ukuqwalasela izixhobo zombane ezihambelanayo, kunye nokwakha inkqubo epheleleyo kunye nokusebenza okubanzi okunamandla.

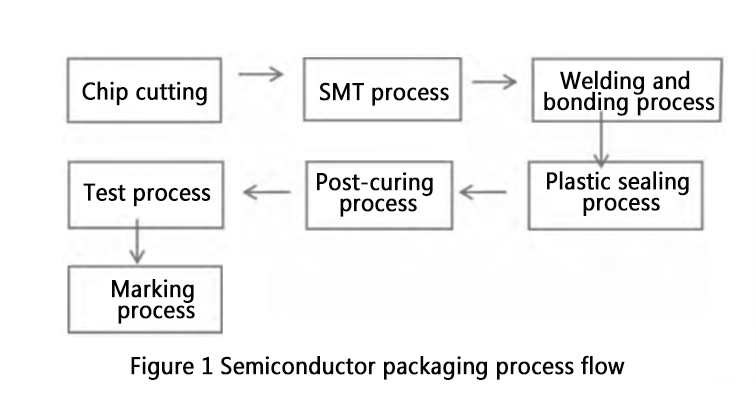

Ukuhamba kweNkqubo yokuPakisha iSemiconductor

Inkqubo yokupakishwa kwe-semiconductor ibandakanya imisebenzi emininzi, njengoko kubonisiwe kwi-Figure 1. Inkqubo nganye ineemfuno ezithile kunye nokuhamba komsebenzi ohambelana ngokusondeleyo, kufuna uhlalutyo olucacileyo ngexesha lesigaba esisebenzayo. Umxholo othile uthi:

1. Ukusika iChip

Kwinkqubo yokupakishwa kwe-semiconductor, ukusika i-chip kubandakanya ukusika ii-wafers ze-silicon kwiichips ezizimeleyo kunye nokususa ngokukhawuleza inkunkuma ye-silicon ukunqanda izithintelo kumsebenzi olandelayo kunye nolawulo lomgangatho.

2. Ukufakwa kweChip

Inkqubo yokuxhoma i-chip igxile ekuphepheni umonakalo wesiphaluka ngexesha lokugaya i-wafer ngokusebenzisa ifilimu ekhuselayo, ngokuqhubekayo igxininisa ukunyaniseka kwesekethe.

3. Inkqubo yoBonding yocingo

Ukulawula umgangatho wenkqubo yokudibanisa intambo kubandakanya ukusebenzisa iintlobo ezahlukeneyo zeengcingo zegolide ukudibanisa i-chip ye-bonding pads kunye ne-frame pads, ukuqinisekisa ukuba i-chip inokuxhuma kwiisekethe zangaphandle kunye nokugcina ukunyaniseka kwenkqubo yonke. Ngokuqhelekileyo, iingcingo zegolide ze-doped kunye neengcingo zegolide ezidibeneyo zisetyenziswa.

Iingcingo zeGolide eziDoped: Iintlobo ziquka i-GS, i-GW, kunye ne-TS, ifanelekile kwi-arc ephezulu (GS: > 250 μm), i-arc ephakathi-phezulu (GW: 200-300 μm), kunye ne-arc ephakathi (TS: 100-200) μm) ukudibanisa ngokulandelelanayo.

Iingcingo zeGolide ezidityanisiweyo: Iintlobo ziquka i-AG2 kunye ne-AG3, ifanelekile kwi-low-arc bonding (70-100 μm).

Izinketho ze-diameter kwezi ngcingo zivela kwi-0.013 mm ukuya kwi-0.070 mm. Ukukhetha uhlobo olufanelekileyo kunye nobubanzi obusekelwe kwiimfuno zokusebenza kunye nemigangatho kubalulekile kulawulo lomgangatho.

4. Inkqubo yokubumba

Iisekethe eziphambili kwizinto zokubumba ziquka i-encapsulation. Ukulawula umgangatho wenkqubo yokubumba ikhusela amacandelo, ngokukodwa kumandla angaphandle abangela amanqanaba ahlukeneyo omonakalo. Oku kubandakanya uhlalutyo olucokisekileyo lweempawu zomzimba zamacandelo.

Iindlela ezintathu eziphambili ezisetyenziswayo ngoku: ukupakishwa kweceramic, ukupakishwa kweplastiki, kunye nokupakishwa kwendabuko. Ukulawula umlinganiselo wohlobo ngalunye lokupakisha kubalulekile ukuhlangabezana neemfuno zemveliso yetshiphu yehlabathi. Ngexesha lenkqubo, izakhono ezibanzi ziyafuneka, njengokutshisa i-chip kunye nesakhelo esikhokelayo ngaphambi kokuba i-encapsulation kunye ne-epoxy resin, ukubumba, kunye nokunyangwa kwe-post-mold.

5. Inkqubo yasemva kokunyanga

Emva kwenkqubo yokubumba, unyango lwe-post-curing luyadingeka, lugxininise ekususeni naziphi na izinto ezigqithisileyo malunga nenkqubo okanye iphakheji. Ukulawulwa komgangatho kubalulekile ukuphepha ukuchaphazela umgangatho wenkqubo jikelele kunye nokubonakala.

6.Inkqubo yoVavanyo

Zakuba zigqityiwe iinkqubo zangaphambili, umgangatho uwonke wenkqubo kufuneka uvavanywe kusetyenziswa ubugcisa bovavanyo olukwinqanaba eliphezulu kunye nezibonelelo. Eli nyathelo libandakanya ukurekhoda okucacileyo kwedatha, kugxininise ukuba i-chip isebenza ngokuqhelekileyo ngokusekelwe kwinqanaba lokusebenza kwayo. Ukunikezelwa kweendleko eziphezulu zezixhobo zokuvavanya, kubalulekile ukugcina ulawulo lomgangatho kuwo onke amanqanaba emveliso, kubandakanywa ukuhlolwa okubonakalayo kunye nokuvavanya ukusebenza kombane.

Uvavanyo lokuSebenza koMbane: Oku kubandakanya uvavanyo lweesekethe ezidibeneyo zisebenzisa izixhobo zovavanyo oluzenzekelayo kunye nokuqinisekisa ukuba isekethe nganye iqhagamshelwe ngokufanelekileyo kuvavanyo lombane.

UHlolo oluBonakalayo: Iingcali zisebenzisa ii-microscopes ukuze zihlole ngokucokisekileyo iitshiphusi ezipakishiweyo ezigqityiweyo ukuqinisekisa ukuba azinaziphene kwaye ziyahlangabezana nemigangatho yomgangatho wokupakishwa kwe-semiconductor.

7. Inkqubo yokuMakisha

Inkqubo yokumakisha ibandakanya ukugqithisela iitshiphusi ezivavanyiweyo kwindawo yokugcina izinto esele zigqityiwe ukuba zisetyenzwe, ukuhlolwa komgangatho, ukupakishwa, kunye nokuthunyelwa kwenqanawa. Le nkqubo ibandakanya amanyathelo amathathu aphambili:

I-1) I-Electroplating: Emva kokwenza izikhokelo, i-anti-corrosion material isetyenziselwa ukuthintela i-oxidation kunye ne-corrosion. Itekhnoloji yokubeka i-Electroplating iqhele ukusetyenziswa kuba uninzi lwezikhokelo zenziwe ngetoti.

I-2) Ukugoba: Izikhokelo ezicwangcisiweyo zibunjwa, kunye nomgca wesiphaluka odibeneyo obekwe kwisixhobo sokwenza i-lead, ukulawula i-lead shape (J okanye uhlobo lwe-L) kunye nokupakishwa kwendawo.

3) Ushicilelo lweLaser: Ekugqibeleni, iimveliso ezenziweyo ziprintwa ngoyilo, olusebenza njengophawu olukhethekileyo lwenkqubo yokupakisha ye-semiconductor, njengoko kubonisiwe kuMfanekiso 3.

Imingeni kunye neeNgcebiso

Uphononongo lweenkqubo zokupakisha ze-semiconductor luqala ngokujonga ngokubanzi itekhnoloji ye-semiconductor ukuqonda imigaqo yayo. Okulandelayo, ukuphonononga ukuhamba kwenkqubo yokupakisha kujolise ekuqinisekiseni ulawulo olucokisekileyo ngexesha lokusebenza, usebenzisa ulawulo olusulungekileyo ukuphepha imiba yesiqhelo. Kwimeko yophuhliso lwangoku, ukuchonga imingeni kwiinkqubo zokupakishwa kwe-semiconductor kubalulekile. Kucetyiswa ukuba kugxininiswe kwiinkalo zolawulo lomgangatho, ukulawula ngokucokisekileyo iingongoma eziphambili ukuze kuphuculwe ngokufanelekileyo umgangatho wenkqubo.

Ukuhlalutya kwimbono yokulawula umgangatho, kukho imingeni ebalulekileyo ngexesha lokuphunyezwa ngenxa yeenkqubo ezininzi ezinomxholo othile kunye neemfuno, nganye ichaphazela enye. Ulawulo olungqongqo luyafuneka ngexesha lemisebenzi eyenziwayo. Ngokwamkela isimo sengqondo esinobuchule bokusebenza kunye nokusebenzisa ubugcisa obuphambili, umgangatho wenkqubo yokupakisha ye-semiconductor kunye namanqanaba obugcisa anokuphuculwa, ukuqinisekisa ukusebenza kakuhle kwesicelo kunye nokuphumeza izibonelelo ezigqwesileyo ngokubanzi.(njengoko kubonisiwe kuMfanekiso 3).

Ixesha lokuposa: May-22-2024