Ukukhula okukhawulezayo kweSiC eNye Crystal UkusebenzisaCVD-SiC UbuninziUmthombo ngeNdlela yokuNcitshiswa

Ngokusetyenziswa ngokutshaIibhloko zeCVD-SiCnjengomthombo we-SiC, i-crystals ye-SiC yakhuliswa ngempumelelo kwizinga le-1.46 mm / h ngokusebenzisa indlela ye-PVT. I-micropipe yekristale ekhulileyo kunye noxinzelelo lwe-dislocation lubonisa ukuba nangona izinga eliphezulu lokukhula, umgangatho wekristale ugqwesile.

I-silicon carbide (SiC)Yisemiconductor ene-wide-bandgap eneempawu ezigqwesileyo zokusetyenziswa kumbane ophezulu, amandla aphezulu, kunye namaza aphezulu. Imfuno yayo ikhule ngokukhawuleza kwiminyaka yakutshanje, ngakumbi kwintsimi ye-semiconductor yamandla. Kwizicelo zamandla e-semiconductor yamandla, iikristale ze-SiC enye zikhuliswa ngokunciphisa umthombo we-SiC wobunyulu obuphezulu kwi-2100-2500 ° C, emva koko uphinda uhlaziywe kwikristale yembewu usebenzisa indlela yokuthutha umphunga womzimba (PVT), ilandelwa kukucubungula ukufumana i-crystal substrates enye kwii-wafers. . Ngokwemveli,Iikristale zeSiCzikhuliswe kusetyenziswa indlela ye-PVT kwizinga lokukhula kwe-0.3 ukuya kwi-0.8 mm / h ukulawula i-crystallinity, ehamba kancinane xa kuthelekiswa nezinye izinto ze-crystal ezisetyenziselwa izicelo ze-semiconductor. Xa i-crystals ye-SiC ikhulile kumazinga aphezulu okukhula ngokusebenzisa indlela ye-PVT, ukuthotywa komgangatho kubandakanywa ne-carbon inclusions, ukuhlambuluka okuncitshisiweyo, ukukhula kwe-polycrystalline, ukubunjwa komda wengqolowa, kunye nokuchithwa kunye nokukhubazeka kwe-porosity akuzange kukhutshwe. Ke ngoko, ukukhula okukhawulezayo kwe-SiC akuzange kuphuhliswe, kwaye isantya sokukhula kancinci kwe-SiC ibe ngumqobo omkhulu kwimveliso ye-SiC substrates.

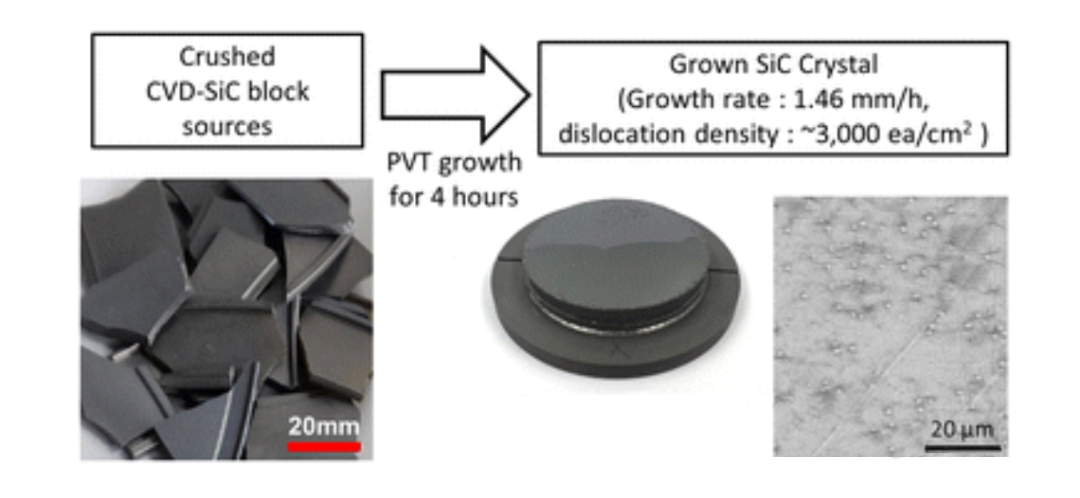

Ngakolunye uhlangothi, iingxelo zamva nje malunga nokukhula okukhawulezayo kwe-SiC ziye zasebenzisa iindlela eziphezulu zokushisa i-chemical vapor deposition (HTCVD) kunendlela ye-PVT. Indlela ye-HTCVD isebenzisa umphunga oqulethe i-Si kunye no-C njengomthombo we-SiC kwi-reactor. I-HTCVD ayikasetyenziswa kwimveliso emikhulu ye-SiC kwaye ifuna uphando olongezelelweyo kunye nophuhliso lwentengiso. Kuyathakazelisa ukuba, nakwizinga eliphezulu lokukhula ~ 3 mm / h, i-crystals ye-SiC enye inokukhuliswa ngomgangatho omhle we-crystal usebenzisa indlela ye-HTCVD. Okwangoku, amacandelo e-SiC asetyenziswe kwiinkqubo ze-semiconductor phantsi kweemeko ezinzima ezifuna ulawulo lwenkqubo yococeko oluphezulu kakhulu. Kwizicelo zenkqubo ye-semiconductor, ~ 99.9999% (∼6N) i-purity SiC components zidla ngokulungiswa yinkqubo ye-CVD esuka kwi-methyltrichlorosilane (CH3Cl3Si, MTS). Nangona kunjalo, nangona ubunyulu obuphezulu bezinto ze-CVD-SiC, ziye zalahlwa emva kokusetyenziswa. Kungekudala, amacandelo e-CVD-SiC alahliweyo athathwa njengemithombo ye-SiC yokukhula kwekristale, nangona ezinye iinkqubo zokubuyisela ezibandakanya ukutyumza kunye nokuhlanjululwa zisafuneka ukuhlangabezana neemfuno eziphezulu zomthombo wokukhula kwekristale. Kwesi sifundo, sasebenzisa iibhloko ze-CVD-SiC ezilahliweyo ukuze siphinde sisebenzise izinto njengomthombo wokukhulisa iikristale ze-SiC. Iibhloko ze-CVD-SiC zokukhula kwekristale enye zalungiswa njengeebhloko ezityumkileyo ezilawulwa ubungakanani, zihluke kakhulu kwimilo kunye nobukhulu xa kuthelekiswa ne-powder ye-SiC yorhwebo esetyenziswa ngokuqhelekileyo kwinkqubo ye-PVT, ngoko ke ukuziphatha kwe-SiC yokukhula kwekristale enye kulindeleke ukuba kube kakhulu. ezahlukeneyo. Ngaphambi kokuqhuba iimvavanyo zokukhula kwekristale enye ye-SiC, ukulinganisa kwekhompyuter kwenziwa ukuphumeza amazinga aphezulu okukhula, kwaye indawo eshushu yacwangciswa ngokufanelekileyo ngokukhula kwekristale enye. Emva kokukhula kwekristale, iikristale ezikhulileyo zavavanywa nge-tomography yamacandelo, i-micro-Raman spectroscopy, i-high-resolution X-ray diffraction, kunye ne-synchrotron white beam X-ray topography.

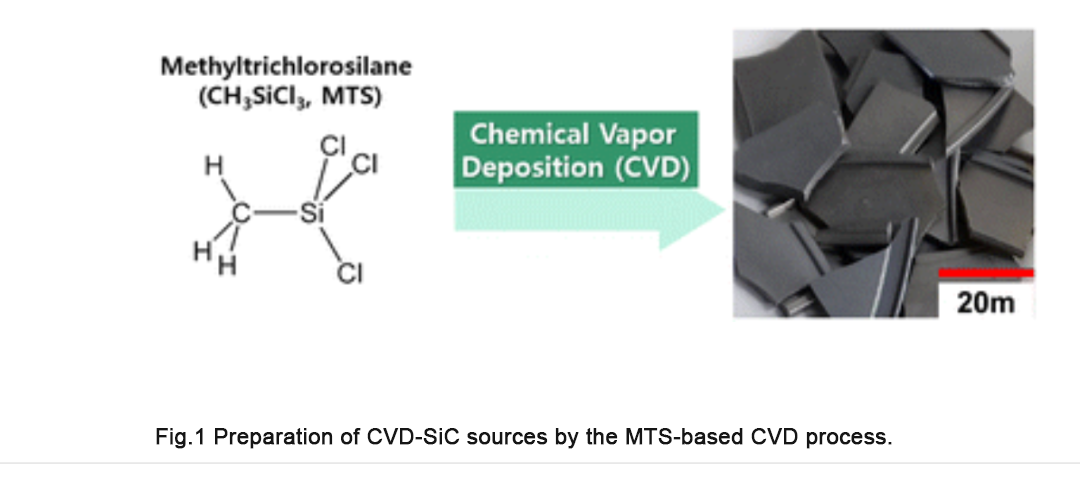

Umzobo we-1 ubonisa umthombo we-CVD-SiC osetyenziselwa ukukhula kwe-PVT ye-crystals ye-SiC kolu cwaningo. Njengoko kuchazwe kwintshayelelo, amacandelo e-CVD-SiC adityaniswe kwi-MTS ngenkqubo ye-CVD kwaye abunjwe ukusetyenziswa kwe-semiconductor ngokulungiswa komatshini. I-N yafakwa kwinkqubo ye-CVD ukuphumeza ukuhanjiswa kwezicelo zenkqubo ye-semiconductor. Emva kokusetyenziswa kwiinkqubo ze-semiconductor, amacandelo e-CVD-SiC atyunyuziwe ukulungiselela umthombo wokukhula kwekristale, njengoko kuboniswe kwi-Figure 1. Umthombo we-CVD-SiC wawulungiselelwe njengamacwecwe kunye nobukhulu obuphakathi kwe ~ 0.5 mm kunye nobukhulu be-particle 49.75 mm.

Umzobo 1: Umthombo we-CVD-SiC olungiselelwe yinkqubo ye-CVD esekelwe kwi-MTS.

Umzobo 1: Umthombo we-CVD-SiC olungiselelwe yinkqubo ye-CVD esekelwe kwi-MTS.

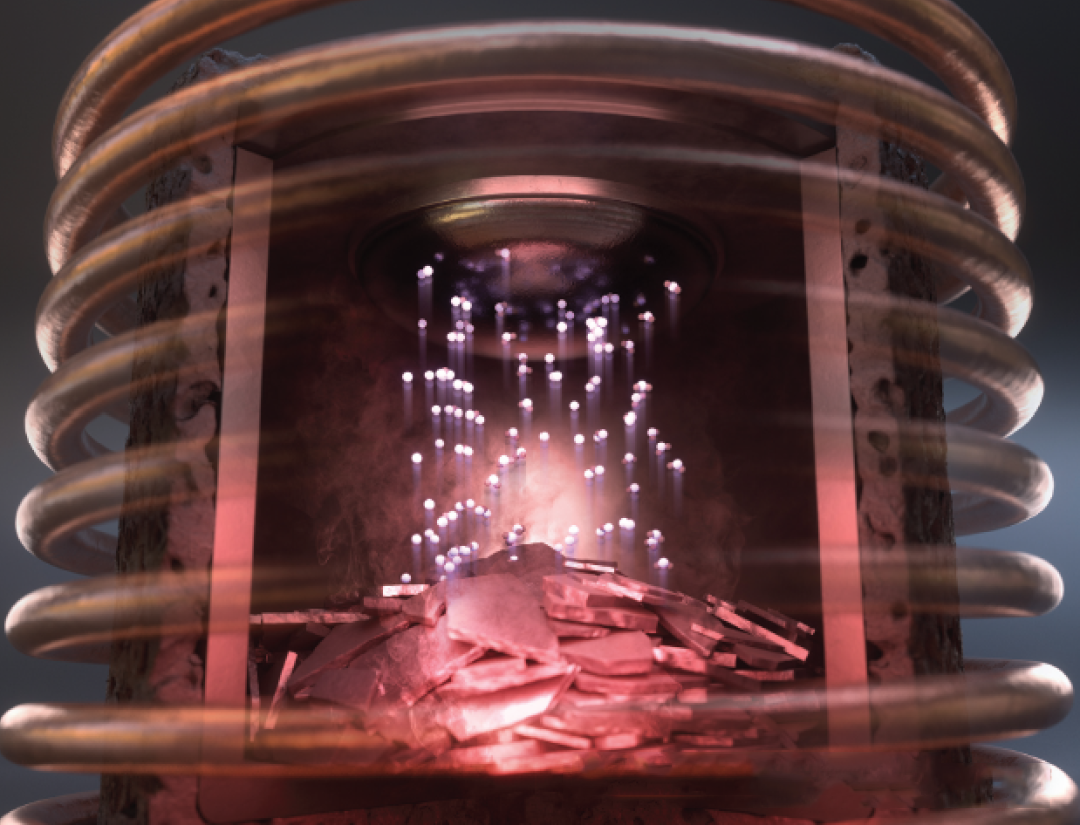

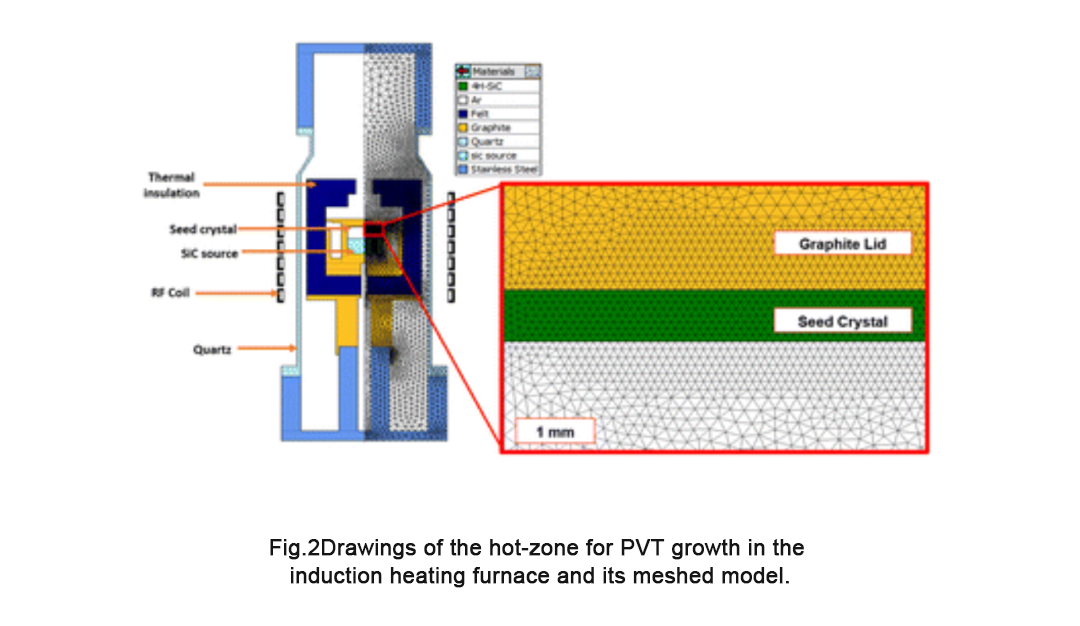

Ukusebenzisa umthombo we-CVD-SiC oboniswe kwi-Figure 1, iikristale ze-SiC zakhuliswa ngendlela ye-PVT kwisithando sokufudumala sokufudumala. Ukuvavanya ukuhanjiswa kweqondo lokushisa kwindawo ye-thermal, ikhowudi yokulinganisa yorhwebo VR-PVT 8.2 (STR, Republic of Serbia) yasetyenziswa. I-reactor ene-thermal zone yakhiwe njengemodeli ye-axisymmetric ye-2D, njengoko kubonisiwe kuMfanekiso 2, kunye nemodeli ye-mesh yayo. Zonke izinto ezisetyenziselwa ukulinganisa ziboniswe kwi-Figure 2, kwaye iipropati zabo zidweliswe kwiThebhile 1. Ngokusekelwe kwiziphumo zokulinganisa, iikristali ze-SiC zakhuliswa kusetyenziswa indlela ye-PVT kwiqondo lokushisa le-2250-2350 ° C kwi-Aratmosphere. 35 Torr iiyure ezi-4. I-4° off-axis 4H-SiC wafer yasetyenziswa njengembewu yeSiC. Iikristale ezikhulileyo zavavanywa nge-micro-Raman spectroscopy (Witec, UHTS 300, Germany) kunye nesisombululo esiphezulu se-XRD (HRXRD, X'Pert-PROMED, PANalytical, Netherlands). Ukugxininiswa kokungcola kwiikristale ze-SiC ezikhulile zavavanywa kusetyenziswa i-ion mass spectrometry eguqukayo (i-SIMS, i-Cameca IMS-6f, eFransi). Uxinaniso lwe-dislocation yeekristale ezikhulileyo zavavanywa kusetyenziswa i-synchrotron white beam X-ray topography kwi-Pohang Light Source.

Umzobo 2: Idayagram yendawo ye-Thermal kunye nemodeli ye-mesh yokukhula kwe-PVT kwisithando sokufudumala sokufudumala.

Umzobo 2: Idayagram yendawo ye-Thermal kunye nemodeli ye-mesh yokukhula kwe-PVT kwisithando sokufudumala sokufudumala.

Ekubeni i-HTCVD kunye neendlela ze-PVT zikhula iikristale phantsi kwe-gas-solid phase equilibrium kwi-front front yokukhula, ukukhula ngokukhawuleza kwe-SiC ngendlela ye-HTCVD kubangele umngeni wokukhula ngokukhawuleza kwe-SiC nge-PVT indlela kolu cwaningo. Indlela ye-HTCVD isebenzisa umthombo wegesi olawulwa ngokulula, ngelixa indlela ye-PVT isebenzisa umthombo oqinileyo ongalawuli ngokuthe ngqo ukuhamba. Isantya sokuhamba esibonelelwe phambili ekukhuleni kwindlela ye-PVT inokulawulwa ngesantya se-sublimation yomthombo oqinileyo ngokulawulwa kokusabalalisa ukushisa, kodwa ukulawulwa ngokuchanekileyo kokusasazwa kweqondo lokushisa kwiinkqubo zokukhula eziphathekayo akulula ukufikelela.

Ngokunyusa izinga lokushisa lomthombo kwi-reactor ye-PVT, izinga lokukhula kwe-SiC linganyuswa ngokunyusa izinga lokunciphisa umthombo. Ukufezekisa ukukhula kwekristale okuzinzileyo, ulawulo lobushushu kwindawo yokukhula lubalulekile. Ukwandisa izinga lokukhula ngaphandle kokwenza i-polycrystals, i-gradient ephezulu yokushisa kufuneka ifezekiswe kwinqanaba lokukhula, njengoko kuboniswe ukukhula kwe-SiC ngendlela ye-HTCVD. Ukunganelanga kobushushu obuthe nkqo ukuya ngasemva komnqwazi kufuneka buchithe ubushushu obuqokelelweyo kwindawo yokukhula ngaphambili ngemitha ye-thermal ukuya kumphezulu wokukhula, okukhokelela kukwakheka kwemiphezulu engaphezulu, oko kukuthi, ukukhula kwepolycrystalline.

Zombini iinkqubo zokudlulisa ubunzima kunye ne-recrystallization kwindlela ye-PVT zifana kakhulu nendlela ye-HTCVD, nangona zihluke kumthombo we-SiC. Oku kuthetha ukuba ukukhula okukhawulezayo kwe-SiC kuyafezekiswa xa izinga lokuthotywa kwe-SiC umthombo liphezulu ngokwaneleyo. Nangona kunjalo, ukufezekisa iikristale ezikumgangatho ophezulu ze-SiC phantsi kweemeko zokukhula okuphezulu ngendlela ye-PVT kunemingeni emininzi. Umgubo worhwebo udla ngokuqulatha umxube wamasuntswana amancinci namakhulu. Ngenxa yokungafani kwamandla omhlaba, iincinci ezincinci zinemilinganiselo ephezulu yokungcola kunye ne-sublimate phambi kweengqungquthela ezinkulu, ezikhokelela ekugxilweni kokungcola okuphezulu kwizigaba zokuqala zokukhula kwe-crystal. Ukongeza, njengoko i-SiC eyomeleleyo ibola kwiintlobo zomphunga ezifana ne-C kunye ne-Si, i-SiC2 kunye ne-Si2C kumaqondo aphezulu, i-C eqinileyo iyabumba xa umthombo we-SiC uthomalalisa kwindlela ye-PVT. Ukuba i-C eqinile eyenziwe yi-C incinci kwaye ilula ngokwaneleyo, phantsi kweemeko zokukhula ngokukhawuleza, iincinci ezincinci ze-C, ezibizwa ngokuba yi "C dust," zinokuthuthelwa kwi-crystal surface ngokudluliswa kobunzima obunamandla, okubangelwa ukufakwa kwi-crystal ekhulile. Ngoko ke, ukunciphisa ukungcola kwesinyithi kunye nothuli lwe-C, ubukhulu beqhekeza lomthombo we-SiC kufuneka ngokuqhelekileyo balawulwe ukuya kububanzi obungaphantsi kwe-200 μm, kwaye izinga lokukhula akufanele lidlule ~ ~ 0.4 mm / h ukugcina ukuhanjiswa kobunzima kunye nokungabandakanyi ukudada. C uthuli. Ukungcola kwesinyithi kunye nothuli lwe-C lukhokelela ekuthotyweni kweekristale ze-SiC ezikhulileyo, eziyimiqobo ephambili yokukhula ngokukhawuleza kwe-SiC ngendlela ye-PVT.

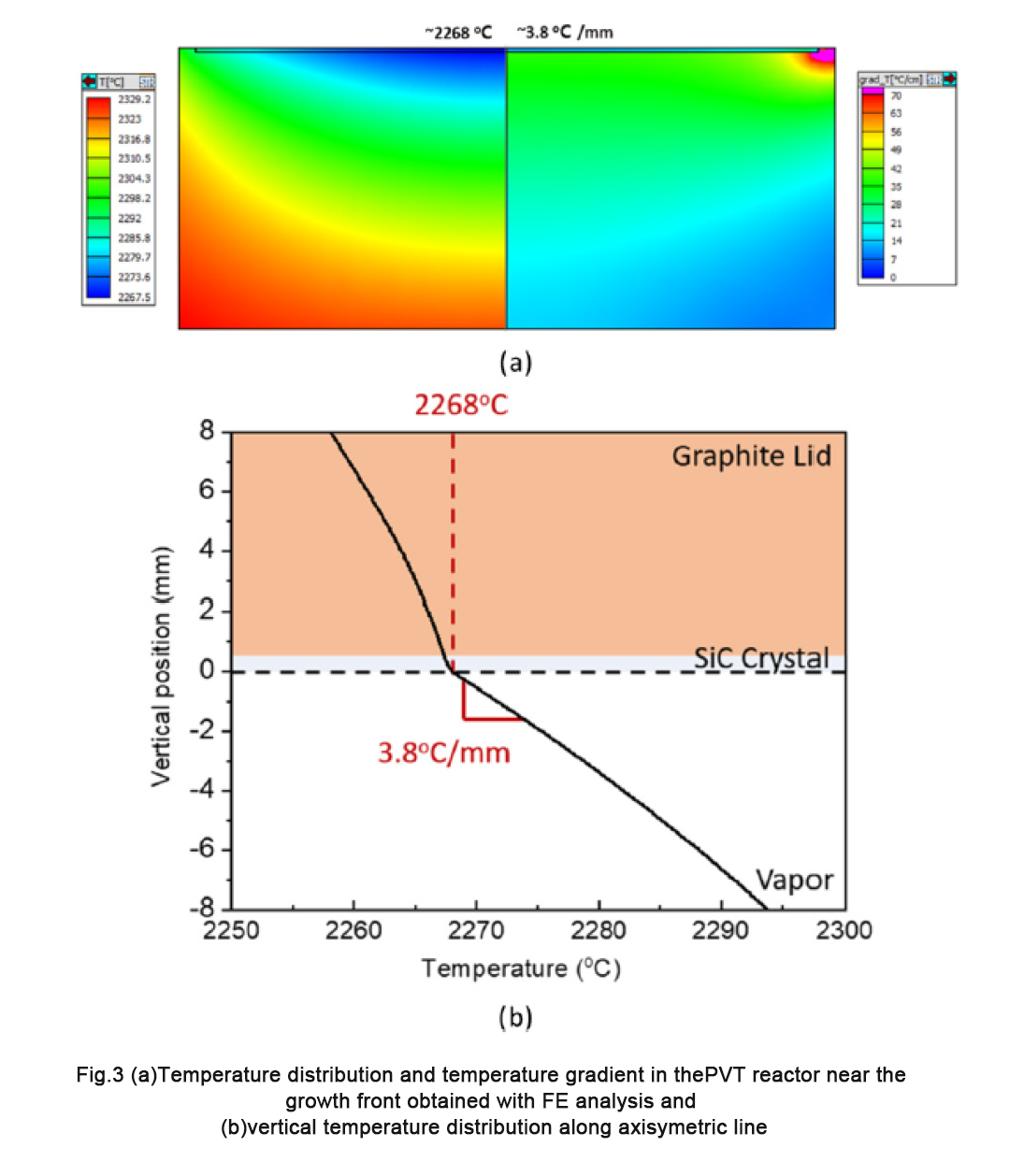

Kolu phononongo, imithombo ye-CVD-SiC echotshoziweyo ngaphandle kwamaqhekeza amancinci asetyenzisiweyo, ukuphelisa uthuli oludadayo lwe-C phantsi kokudluliselwa kobunzima obunamandla. Ngaloo ndlela, isakhiwo sommandla we-thermal senziwe sisebenzisa i-multiphysics-based simulation-based PVT indlela yokufezekisa ukukhula ngokukhawuleza kwe-SiC, kunye nokusabalalisa ubushushu obufanayo kunye ne-gradient yokushisa kuboniswe kuMfanekiso 3a.

Umzobo 3: (a) Ukuhanjiswa kobushushu kunye neqondo lobushushu kufutshane nomphambili wokukhula kwe-PVT ireactor efunyenwe ngohlahlelo lwento ephelelisiweyo, kunye (b) nokusabalalisa ubushushu obuthe nkqo ecaleni komgca we-axisymmetric.

Xa kuthelekiswa nemimiselo yeendawo zokufudumala eziqhelekileyo zokukhulisa iikristale ze-SiC kwizinga lokukhula kwe-0.3 ukuya kwi-0.8 mm / h phantsi kweqondo lokushisa elincinci elingaphantsi kwe-1 ° C / mm, iisetingi zendawo ye-thermal kule sifundo zineqondo lokushisa elikhulu kakhulu ~ 3.8 °C/mm kubushushu bokukhula obungu-∼2268°C. Ixabiso le-gradient yeqondo lokushisa kule sifundo lifaniswa nokukhula ngokukhawuleza kwe-SiC kwisantya se-2.4 mm / h usebenzisa indlela ye-HTCVD, apho i-gradient yokushisa ibekwe kwi-∼14 ° C / mm. Ukususela ekuhanjisweni kweqondo lokushisa elithe tye eliboniswe kwi-Figure 3b, siye saqinisekisa ukuba akukho mgangatho we-reverse gradient onokuthi wenze i-polycrystals ekhoyo kufuphi nokukhula kwangaphambili, njengoko kuchazwe kwiincwadi.

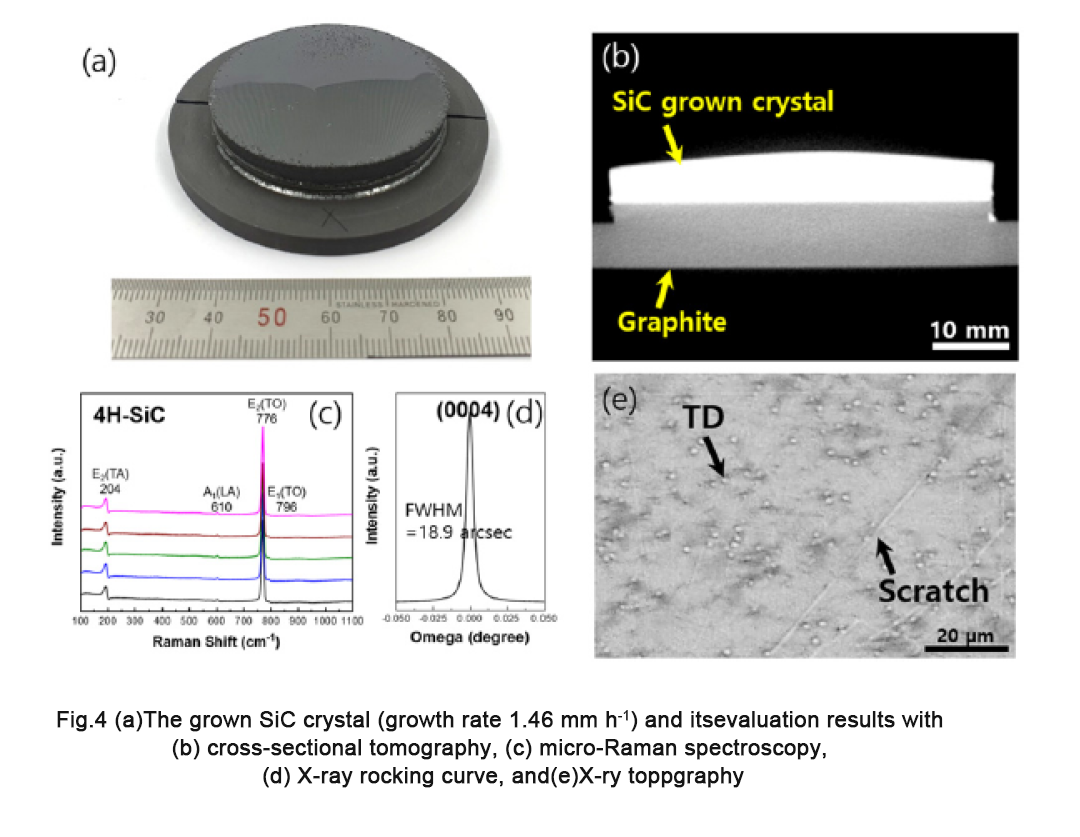

Ukusebenzisa inkqubo ye-PVT, i-crystals ye-SiC yakhuliswa ukusuka kumthombo we-CVD-SiC kwiiyure ze-4, njengoko kuboniswe kwiMifanekiso 2 kunye ne-3. Ummeli we-SiC crystal ukukhula kwi-SiC ekhulile iboniswe kuMfanekiso 4a. Ubunzima kunye nezinga lokukhula kwe-crystal ye-SiC eboniswe kwi-Figure 4a yi-5.84 mm kunye ne-1.46 mm / h, ngokulandelanayo. Impembelelo yomthombo we-SiC kumgangatho, i-polytype, i-morphology, kunye nokuhlanzeka kwe-crystal ye-SiC ekhulile eboniswe kwi-Figure 4a iphandwa, njengoko kuboniswe kwiMifanekiso 4b-e. Umfanekiso we-tomography we-cross-sectional ku-Figure 4b ubonisa ukuba ukukhula kwekristale kwakuyi-convex-shaped ngenxa yeemeko zokukhula ezingaphantsi. Nangona kunjalo, i-micro-Raman spectroscopy kwi-Figure 4c ichonge i-crystal ekhulile njengesigaba esisodwa se-4H-SiC ngaphandle kwe-polytype inclusions. Ixabiso le-FWHM ye-(0004) efunyenwe kwi-X-ray ye-rocking curve analysis yayingu-18.9 arcseconds, ekwaqinisekisa umgangatho omhle we-crystal.

Umzobo 4: (a) I-crystal ye-SiC ekhulile (izinga lokukhula kwe-1.46 mm / h) kunye neziphumo zovavanyo lwayo kunye (b) ne-tomography ye-cross-sectional, (c) i-micro-Raman spectroscopy, (d) i-X-ray rocking curve, kunye ( e) I-X-reyi yokuma komhlaba.

Umzobo we-4e ubonisa umqadi omhlophe we-X-reyi indawo echaza imikrwelo kunye nentambo yokudityaniswa kwi-wafer ekhazimlisiweyo yekristale ekhulileyo. Uxinaniso lwe-dislocation ye-crystal ekhulileyo yalinganiselwa ukuba ~ 3000 ea / cm², iphakamileyo kancinane kunoxinaniso lwe-dislocation ye-crystal yembewu, eyayiyi-∼2000 ye-cm². Ikristale ekhulileyo yaqinisekiswa ukuba inoxinaniso oluphantsi lokususwa, xa kuthelekiswa nomgangatho wekristale yeewafers zorhwebo. Kuyathakazelisa ukuba ukukhula okukhawulezayo kweekristale ze-SiC kwaphunyezwa ngokusebenzisa indlela ye-PVT kunye nomthombo otyumkileyo we-CVD-SiC phantsi kweqondo lokushisa elikhulu. Ugxininiso lwe-B, Al, kunye ne-N kwikristale ekhulileyo yayiyi-2.18 × 10¹⁶, 7.61 × 10¹⁵, kunye ne-1.98 × 10¹⁹ athomu/cm³, ngokulandelelanayo. Ukuxinwa kwe-P kwi-crystal ekhulileyo yayingaphantsi komda wokufumanisa (<1.0 × 10¹⁴ athomu / cm³). Ukugxininiswa kokungcola kwakuphantsi ngokwaneleyo kubathwali bentlawulo, ngaphandle kwe-N, eyayifakwe ngenjongo ngexesha lenkqubo ye-CVD.

Nangona ukukhula kwekristal kolu cwaningo kwakuyinto encinci yokuqwalasela iimveliso zorhwebo, ukubonakaliswa okuphumelelayo kokukhula kwe-SiC ngokukhawuleza kunye nomgangatho omhle we-crystal usebenzisa umthombo we-CVD-SiC ngokusebenzisa indlela ye-PVT ineempembelelo ezibalulekileyo. Ekubeni imithombo ye-CVD-SiC, nangona iipropati zabo ezintle, zikhuphisana ngeendleko ngokuphinda zisetyenziswe izinto ezilahliweyo, silindele ukusetyenziswa kwazo ngokubanzi njengomthombo we-SiC othembisayo ukutshintsha imithombo ye-SiC powder. Ukusebenzisa imithombo ye-CVD-SiC yokukhula ngokukhawuleza kwe-SiC, ukulungelelanisa ukuhanjiswa kweqondo lokushisa kwinkqubo ye-PVT kuyadingeka, kubangele imibuzo eyongezelelweyo yophando lwexesha elizayo.

Ukuqukumbela

Kule sifundo, umboniso ophumeleleyo wokukhula kwe-crystal ye-SiC ngokukhawuleza usebenzisa iibhloko ze-CVD-SiC ezichotshoziweyo phantsi kweemeko ze-gradient yobushushu obuphezulu ngokusebenzisa indlela ye-PVT ifunyenwe. Okubangel 'umdla kukuba, ukukhula ngokukhawuleza kweekristale ze-SiC kwaqondwa ngokutshintsha umthombo we-SiC kunye nendlela ye-PVT. Le ndlela ilindeleke ukuba ikhulise kakhulu ukuveliswa kwemveliso enkulu ye-crystals ye-SiC enye, ekugqibeleni iyancipha indleko yeyunithi yee-substrates ze-SiC kunye nokukhuthaza ukusetyenziswa ngokubanzi kwezixhobo zombane eziphezulu.

Ixesha lokuposa: Jul-19-2024