I-Silicon carbide (i-SiC) substrates ineziphene ezininzi ezithintela ukuqhutyelwa ngqo. Ukwenza ii-chip wafers, ifilimu ethile ye-crystal eyodwa kufuneka ikhuliswe kwi-substrate ye-SiC ngokusebenzisa inkqubo ye-epitaxial. Le filimu yaziwa ngokuba yi-epitaxial layer. Phantse zonke izixhobo ze-SiC zibonwa kwizinto ze-epitaxial, kunye nekhwalithi ephezulu ye-homoepitaxial SiC izinto zenza isiseko sophuhliso lwesixhobo se-SiC. Ukusebenza kwezixhobo ze-epitaxial kugqiba ngokuthe ngqo ukusebenza kwezixhobo ze-SiC.

Izixhobo ze-SiC zangoku eziphezulu kunye nokuthembeka okuphezulu zibeka iimfuno ezingqongqo kwi-morphology yomphezulu, ukuxinana kwesiphene, ukufana kwe-doping, kunye nokulingana kobunzimaepitaxializixhobo. Ukufezekisa ubungakanani obukhulu, ukuxinana kwesiphene esisezantsi, kunye ne-uniformity ephezulu ye-SiC epitaxy kuye kwaba yinto ebalulekileyo kuphuhliso lweshishini le-SiC.

Ukuvelisa umgangatho ophezulu we-SiC epitaxy kuxhomekeke kwiinkqubo eziphambili kunye nezixhobo. Okwangoku, eyona ndlela isetyenziswa kakhulu yokukhula kwe-SiC epitaxial yiUkubekwa kweMichiza yoMphunga (CVD).I-CVD inikezela ngolawulo oluchanekileyo malunga nobukhulu befilimu ye-epitaxial kunye nokugxilwa kwe-doping, ukuxinana kwe-defect ephantsi, izinga lokukhula eliphakathi, kunye nokulawulwa kwenkqubo ezenzekelayo, okwenza kube yiteknoloji ethembekileyo kwizicelo eziphumelelayo zorhwebo.

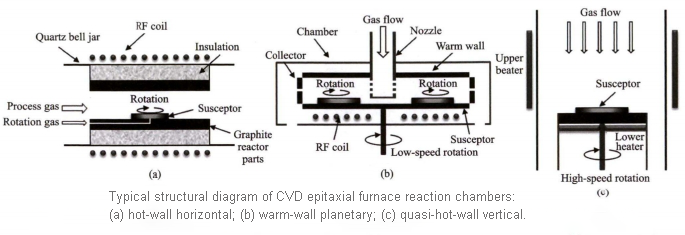

I-SiC CVD epitaxyngokubanzi usebenzisa udonga olushushu okanye izixhobo ezishushu ze-CVD. Amaqondo okushisa aphezulu okukhula (1500-1700 ° C) aqinisekisa ukuqhubeka kwefom ye-crystalline ye-4H-SiC. Ngokusekelwe kubudlelwane phakathi kolwalathiso lokuhamba kwegesi kunye ne-substrate surface, amagumbi okusabela kwezi nkqubo ze-CVD anokuthi ahlelwe kwizakhiwo ezithe tye kunye nezithe nkqo.

Umgangatho we-SiC epitaxial furnaces ujongwa ikakhulu kwimiba emithathu: ukukhula kwe-epitaxial ukukhula (kubandakanya ukufana kobukhulu, ukufana kwe-doping, inqanaba lesiphene, kunye nesantya sokukhula), ukusebenza kobushushu besixhobo (kubandakanya amazinga okufudumeza / okupholisa, ubushushu obuninzi, kunye nokulingana kobushushu. ), kunye nokusebenza kakuhle kweendleko (kubandakanya ixabiso leyunithi kunye nomthamo wemveliso).

Umahluko phakathi kweentlobo ezintathu zeSiC Epitaxial Growth Furnaces

1.Iinkqubo zeCVD eziHolizonti zodonga:

-Iimbonakalo:Ibonisa ngokubanzi iinkqubo zokukhula ze-wafer ezinobungakanani obukhulu obuqhutywa kukujikeleziswa kwegesi ejikelezayo, ukufikelela kwi-intra-wafer metrics ezigqwesileyo.

-Imodeli emeleyo:I-LPE's Pe1O6, ekwaziyo ukulayisha/ukukhulula iwafer ezenzekelayo kwi-900°C. Yaziwa ngamazinga aphezulu okukhula, imijikelo emifutshane ye-epitaxial, kunye ne-intra-wafer engaguqukiyo kunye nokusebenza kwe-inter-run.

-Ukusebenza:Kwi-4-6 intshi ye-4H-SiC epitaxial wafers ezinobunzima ≤30μm, ifikelela intra-wafer thick non-uniformity ≤2%, i-doping concentration i-non-uniformity ≤5%, ingxinano yesiphako somphezulu ≤1 cm-², kwaye ayinasiphako indawo yomhlaba (2mm×2mm iiseli) ≥90%.

-Abavelisi basekhaya: Iinkampani ezifana ne-Jingsheng Mechatronics, i-CETC 48, iNorth Huachuang, kunye ne-Nasset Intelligent ziye zavelisa izixhobo ezifanayo ze-SiC ze-epitaxial ezifanayo kunye nemveliso ye-scaled-up.

2.Iinkqubo zePlanethi yeCVD ezifudumeleyo:

-Iimbonakalo:Sebenzisa iziseko zokucwangciswa kweeplanethi zokukhula kwe-wafer ezininzi ngebhetshi nganye, uphucula kakhulu ukusebenza kakuhle kwemveliso.

-Iimodeli ezimele:I-AIXG5WWC ye-Aixtron (8x150mm) kunye ne-G10-SiC (9x150mm okanye i-6x200mm) series.

-Ukusebenza:Kwi-6-intshi ye-4H-SiC epitaxial wafers kunye nobukhulu ≤10μm, ifezekisa ukutenxa phakathi kwe-wafer ubukhulu ± 2.5%, intra-wafer thick non-uniformity 2%, inter-wafer doping deviation ± 5%, kunye ne-intra-wafer doping ukugxininiswa okungafaniyo <2%.

-Imingeni:Ukwamkelwa okulinganiselweyo kwiimarike zasekhaya ngenxa yokunqongophala kwedatha yokuvelisa ibhetshi, izithintelo zobugcisa kubushushu kunye nolawulo lwentsimi yokuhamba, kunye ne-R & D eqhubekayo ngaphandle kokuphunyezwa okukhulu.

3. IiNkqubo ze-CVD ezithe nkqo ezikwi-Quasi-hot-wall:

- Iimbonakalo:Sebenzisa uncedo lwangaphandle lomatshini wokujikeleza kwe-substrate ye-speed-speed, ukunciphisa umda womda wobunzima kunye nokuphucula izinga lokukhula kwe-epitaxial, kunye neenzuzo zemvelo kulawulo lwesiphene.

- Iimodeli ezimele:I-wafer enye ye-Nuflare i-EPIREVOS6 kunye ne-EPIREVOS8.

-Ukusebenza:Ifezekisa amazinga okukhula ngaphezu kwe-50μm/h, ulawulo loxinano lweziphene kumphezulu ongaphantsi kwe-0.1 cm-², kunye nobukhulu be-intra-wafer kunye nogxininiso lwe-doping non-uniformity ye-1% kunye ne-2.6%, ngokulandelelanayo.

-Uphuhliso lwasekhaya:Iinkampani ezifana ne-Xingsandai kunye ne-Jingsheng Mechatronics ziye zayila izixhobo ezifanayo kodwa azifikeleli kusetyenziso olukhulu.

Isishwankathelo

Nganye kwiintlobo ezintathu zesakhiwo se-SiC epitaxial yezixhobo zokukhula zineempawu ezahlukileyo kwaye zihlala kumacandelo athile emarike ngokusekelwe kwiimfuno zesicelo. I-CVD ethe tyaba eludongeni olushushu ibonelela ngamazinga okukhula akhawulezayo kunye nomgangatho olungeleleneyo kunye nokufana kodwa inomgangatho ophantsi wemveliso ngenxa yokusetyenzwa kwe-wafer enye. I-CVD yeplanethi yodonga olufudumeleyo yonyusa kakhulu ukusebenza kakuhle kwemveliso kodwa ijongene nemingeni kulawulo lokungaguquguquki kwezinto ezininzi. I-Quasi-hot-wall ethe nkqo i-CVD iyagqwesa kulawulo lwesiphene kunye nesakhiwo esinzima kwaye ifuna ukugcinwa okubanzi kunye namava okusebenza.

Njengoko ishishini likhula, ukuphuculwa okuphindaphindwayo kunye nokuphuculwa kwezi zakhiwo zezixhobo kuya kukhokelela kulungelelwaniso oluphucukileyo, ludlala indima ebalulekileyo ekuhlangabezaneni nemigangatho eyahlukeneyo ye-epitaxial wafer yobunzima kunye neemfuno zesiphene.

Izinto eziluncedo kunye nezingeloncedo kwii-SiC Epitaxial Growth Furnaces ezahlukeneyo

| Uhlobo lwesithando somlilo | Iingenelo | Iingxaki | Abavelisi abaMele |

| Udonga olushushu oluthe tye CVD | Isantya sokukhula ngokukhawuleza, isakhiwo esilula, ukugcinwa lula | Umjikelo omfutshane wolondolozo | I-LPE (eItali), TEL (eJapan) |

| Warm-wall Planetary CVD | Umthamo ophezulu wemveliso, osebenzayo | Ulwakhiwo oluntsonkothileyo, ulawulo lokungaguquguquki olunzima | Aixtron (eJamani) |

| Quasi-hot-wall nkqo CVD | Ulawulo lwesiphako olugqwesileyo, umjikelo wolondolozo olude | Isakhiwo esiyinkimbinkimbi, kunzima ukusigcina | I-Nuflare (eJapan) |

Ngophuhliso oluqhubekayo loshishino, ezi ntlobo zintathu zezixhobo ziya kuphinda ziphuculwe kwaye ziphuculwe, ezikhokelela kuhlengahlengiso olusandayo oluhambelana neenkcukacha ezahlukeneyo ze-epitaxial wafer zobunzima kunye neemfuno zesiphene.

Ixesha lokuposa: Jul-19-2024