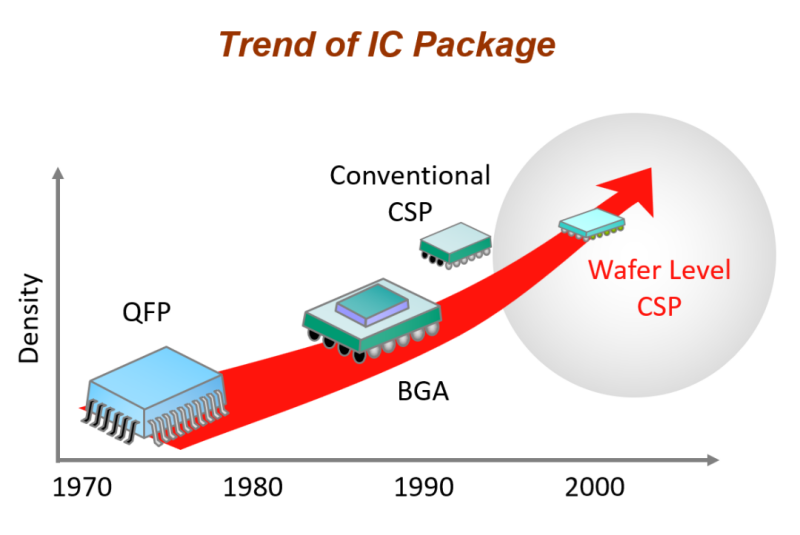

Itekhnoloji yokupakisha yenye yezona nkqubo zibaluleke kakhulu kwishishini le-semiconductor. Ngokwemilo yephakheji, inokwahlulwa ibe yiphakheji yesokhethi, iphakheji ye-socket, iphakheji ye-BGA, iphakheji yesayizi ye-chip (CSP), iphakheji yemodyuli ye-chip eyodwa (SCM, isithuba phakathi kwe-wiring kwibhodi yesekethe eprintiweyo (PCB) kunye nesekethe edityanisiweyo (IC) yebhodi yeematshisi zebhodi), iphakheji yemodyuli ye-chip ezininzi (MCM, enokudibanisa iitshiphusi ezingafaniyo), iphakheji yenqanaba le-wafer (WLP, kubandakanywa iphakheji yenqanaba le-fan-out wafer level (FOWLP), i-micro surface mount amacandelo (microSMD), njl.), iphakheji ye-three-dimensional (i-micro bump interconnect package, i-TSV interconnect package, njl.), iphakheji yenkqubo (SIP), inkqubo ye-chip (SOC).

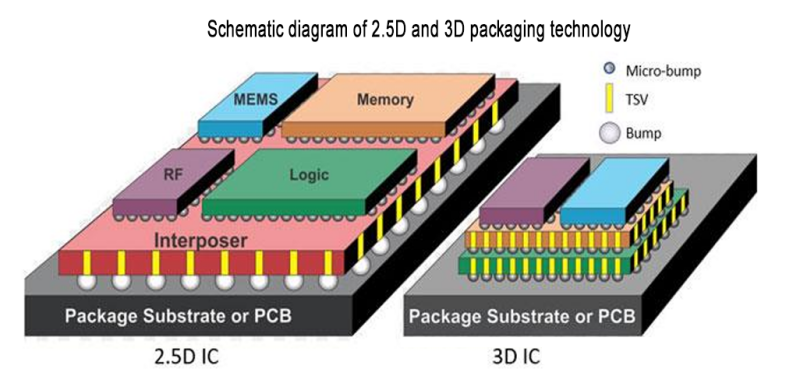

Iifom zokupakishwa kwe-3D zahlulwe kakhulu zibe ziindidi ezintathu: uhlobo olungcwatyiweyo (ukungcwaba isixhobo kucingo olunomaleko oluninzi okanye kungcwatywa kwi-substrate), uhlobo lwesubstrate esebenzayo (ukuhlanganiswa kwe-silicon wafer: okokuqala hlanganisa amacandelo kunye ne-wafer substrate ukwenza i-substrate esebenzayo. Emva koko ulungelelanise imigca yoqhagamshelo olunemigangatho emininzi, kwaye udibanise ezinye iitshiphusi okanye izinto kumaleko angaphezulu) kunye nohlobo olupakishweyo (iziqwenga ze-silicon ezipakishwe ngee-silicone wafers, iichips). zifakwe kwi-silicon wafers, kunye neetshiphusi ezipakishwe ngeetships).

Iindlela zokudibanisa i-3D ziquka i-wire bonding (WB), i-flip chip (FC), nge-silicon nge-(TSV), umqhubi wefilimu, njl.

I-TSV ibona uqhagamshelo oluthe nkqo phakathi kweetshiphusi. Kuba umgca woqhagamshelo othe nkqo unowona mgama umfutshane kunye namandla aphezulu, kulula ukuyiqonda i-miniaturization, uxinaniso oluphezulu, ukusebenza okuphezulu, kunye ne-multifunctional heterogeneous structure package. Kwangaxeshanye, inokudibanisa iitshiphusi zezixhobo ezahlukeneyo;

okwangoku, kukho iintlobo ezimbini zeteknoloji yokuvelisa i-microelectronics usebenzisa inkqubo ye-TSV: ukupakishwa kweesekethe ezintathu-ntathu (ukuhlanganiswa kwe-3D IC) kunye nokupakishwa kwe-silicon ye-3D (ukuhlanganiswa kwe-3D Si).

Umahluko phakathi kwezi fom zimbini kukuba:

(1) Ukupakishwa kwesekethe ye-3D kufuna ukuba i-electrode ye-chip ilungiswe ibe ngamaqhuma, kwaye amaqhuma aqhagamshelwe (adityaniswe ngokubopha, ukudibanisa, ukuwelda, njl.), ngelixa ukupakishwa kwe-silicon ye-3D kukunxibelelana ngokuthe ngqo phakathi kweetshiphusi (ukudibanisa phakathi kwee-oksidi kunye neCu). -Cu bonding).

(2) Itekhnoloji yokudibanisa isekethe ye-3D inokufezekiswa ngokudibanisa phakathi kwee-wafers (i-3D ukupakishwa kwesekethe, ukupakishwa kwe-silicon ye-3D), ngelixa i-chip-to-chip bonding kunye ne-chip-to-wafer bonding inokufezekiswa kuphela ngokupakishwa kwesekethe ye-3D.

(3) Kukho izikhewu phakathi kwee-chips ezidityaniswe yinkqubo yokupakishwa kwesekethe ye-3D, kunye nezixhobo ze-dielectric kufuneka zizaliswe ukulungelelanisa i-conductivity ye-thermal kunye ne-coefficient yokwandisa i-thermal yenkqubo ukuqinisekisa ukuzinza kweempawu zomatshini kunye nombane wenkqubo; akukho zithuba phakathi kweetshiphusi ezidityaniswe yinkqubo yokupakisha ye-silicon ye-3D, kunye nokusetyenziswa kwamandla, umthamo, kunye nobunzima be-chip zincinci, kwaye ukusebenza kombane kuhle kakhulu.

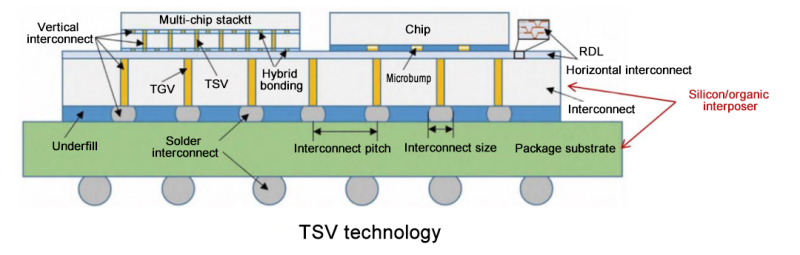

Inkqubo ye-TSV inokwakha umendo wesignali othe nkqo kwi-substrate kwaye udibanise i-RDL phezulu nasezantsi kwi-substrate ukwenza indlela yomqhubi we-dimensional-dimensional. Ngoko ke, inkqubo ye-TSV yenye yeembombo ezibalulekileyo zokwakhiwa kwesakhiwo sesixhobo esinemilinganiselo emithathu.

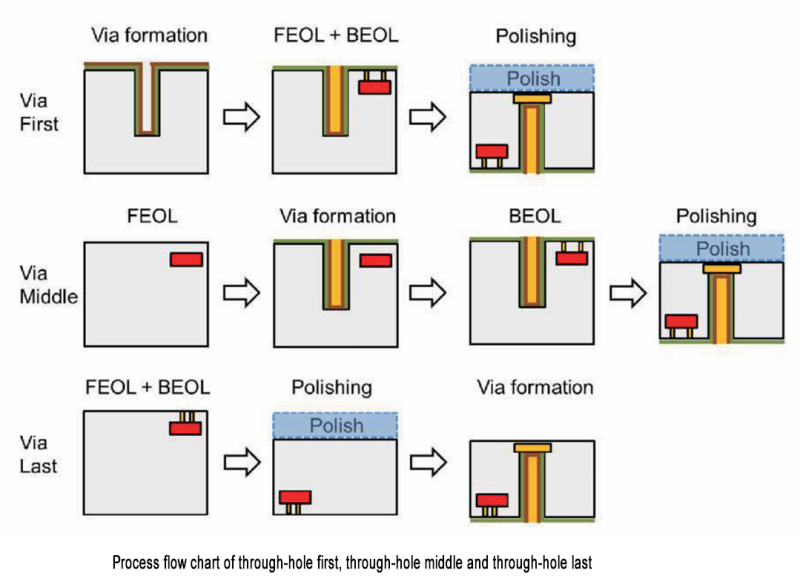

Ngokomyalelo phakathi kwesiphelo sangaphambili somgca (FEOL) kunye nesiphelo sangasemva somgca (BEOL), inkqubo ye-TSV inokwahlulwa ibe ziinkqubo ezintathu zokuvelisa eziqhelekileyo, ezizezi, ngeyokuqala (i-ViaFirst), nge-middle (Via Middle) kunye ngeyokugqibela (Ngendlela yokugqibela), njengoko kubonisiwe kumzobo.

1. Ngenkqubo etching

Inkqubo ye-etching isitshixo sokwenziwa kwesakhiwo se-TSV. Ukukhetha inkqubo yokubhala efanelekileyo kunokuphucula ngokufanelekileyo amandla oomatshini kunye neepropathi zombane ze-TSV, kwaye zinxulumene ngakumbi nokuthembeka okupheleleyo kwezixhobo ze-TSV ezithathu.

Okwangoku, kukho ezine eziphambili ze-TSV ngeenkqubo ze-etching: I-Deep Reactive Ion Etching (DRIE), i-etching emanzi, i-photo-assisted electrochemical etching (PAECE) kunye ne-laser drilling.

(1) Ukufakela i-Ion eNxibeleleyo

I-ion etching enzulu, ekwabizwa ngokuba yinkqubo ye-DRIE, yeyona nkqubo iqhele ukusetyenziswa ye-TSV etching, esetyenziswa ikakhulu ukuqonda i-TSV ngokusebenzisa izakhiwo ezinomlinganiselo ophezulu. Iinkqubo zesiqhelo zokuchongwa kweplasma zinokufikelela kuphela ubunzulu be-etching yee-microns ezininzi, kunye nesantya esisezantsi sokuchopha kunye nokungabikho kokukhetha imaski. UBosch wenze uphuculo lwenkqubo ehambelanayo kwesi siseko. Ngokusebenzisa i-SF6 njengerhasi esebenzayo kunye nokukhulula igesi ye-C4F8 ngexesha lenkqubo yokubhala njengokhuseleko lokugqitha kwiindonga zecala, inkqubo ye-DRIE ephuculweyo ifanelekile ukubethelwa kwe-aspect ratio vias. Ke ngoko, ikwabizwa ngokuba yinkqubo yeBosch emva komqambi wayo.

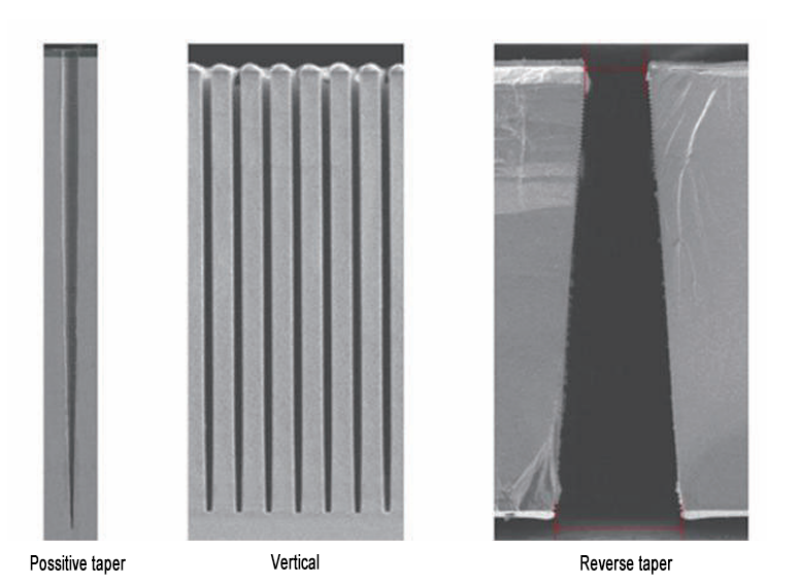

Lo mzobo ungezantsi yifoto yomlinganiso ophezulu owenziwe ngokucofa inkqubo yeDRIE.

Nangona inkqubo ye-DRIE isetyenziswa ngokubanzi kwinkqubo ye-TSV ngenxa yokulawulwa kwayo kakuhle, ukusilela kwayo kukuba i-sidewall flatness ihlwempuzekile kwaye iziphene zokushwabana ezimilise okwescallop ziya kwenziwa. Esi siphene sibaluleke ngakumbi xa ubhala umlinganiselo ophezulu we-aspect ratio.

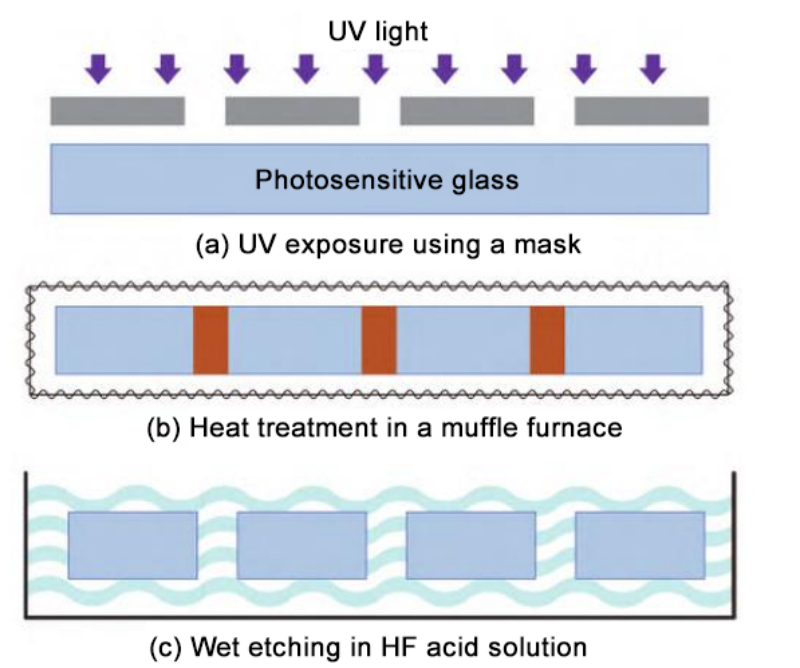

(2) Ukurhabula okumanzi

Ukuchongwa okumanzi kusebenzisa indibaniselwano yemaski kunye nekhemikhali yokukrola ukukrola emingxunyeni. Esona sisombululo siqhele ukusetyenziswa yi-KOH, enokuthi ifake izikhundla kwi-silicon substrate engakhuselwanga sisigqubuthelo sobuso, ngokwenza oko yenze ulwakhiwo olufunwayo lokuphumela kumngxuma. Ukujongwa okumanzi yeyona nkqubo yokuqala yokukrolwa komngxuma ephuhlisiwe. Ekubeni amanyathelo ayo enkqubo kunye nezixhobo ezifunekayo zilula, zifanelekile ukuveliswa kobuninzi be-TSV ngexabiso eliphantsi. Nangona kunjalo, indlela yayo yokufaka iikhemikhali imisela ukuba umngxuma owenziwe yile ndlela uya kuchatshazelwa kukuqhelaniswa nekristale yesiqwenga se-silicon, esenza ukuba umngxuma uphume umngxuma ungagungqiyo kodwa ubonise into ecacileyo yomphezulu obanzi kunye nomzantsi omxinwa. Esi siphene sinciphisa ukusetyenziswa kwe-etching emanzi kwi-TSV yokuvelisa.

(3) Ifoto encediswa yi-electrochemical etching (PAECE)

Umgaqo osisiseko we-photo-assisted electrochemical etching (PAECE) kukusebenzisa ukukhanya kwe-ultraviolet ukukhawulezisa ukuveliswa kwee-electron-hole pairs, ngaloo ndlela kukhawulezisa inkqubo ye-electrochemical etching. Xa kuthelekiswa nenkqubo ye-DRIE esetyenziswa ngokubanzi, inkqubo ye-PAECE ifaneleke ngakumbi ukukrola i-Ultra-large aspect ratio nge-hole izakhiwo ezingaphezu kwe-100: 1, kodwa ukungabikho kwayo kukuba ukulawulwa kobunzulu be-etching buthathaka kune-DRIE, kwaye iteknoloji yayo zifuna uphando olongezelelweyo kunye nokuphuculwa kwenkqubo.

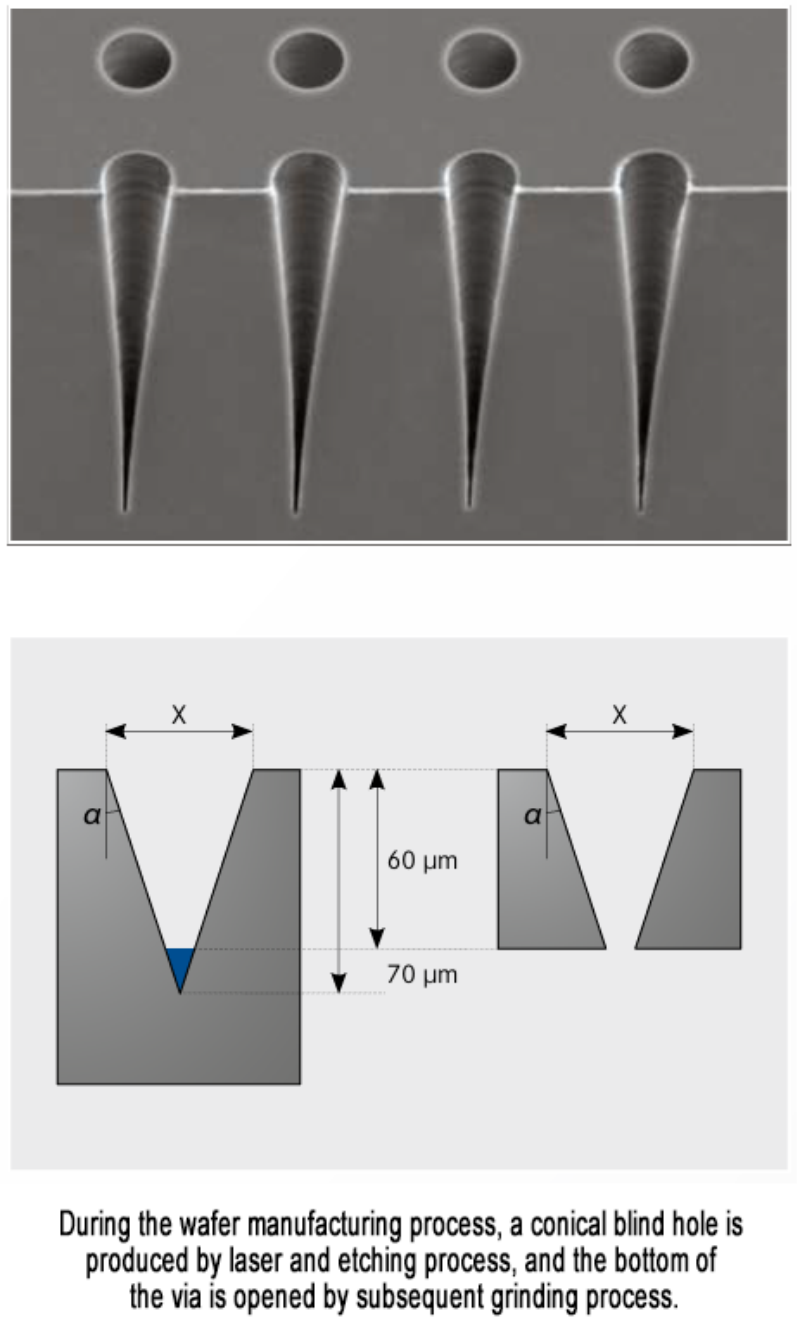

(4) Ukugrunjwa kweLaser

Yahlukile kwezi ndlela zintathu zingasentla. Indlela yokomba yelaser yindlela yokwenyama kuphela. Isebenzisa ubukhulu becala i-laser irradiation ene-eneji ephezulu ukunyibilika kunye nokukhupha imathiriyeli yesubstrate kwindawo echaziweyo ukuqonda ngokwasemzimbeni ukwakhiwa komngxuma wokutyhutyha we-TSV.

Umngxuma wokutyhutyha owenziwe ngokugrumba i-laser unomlinganiselo ophezulu we-aspect ratio kwaye i-sidewall ngokusisiseko ithe nkqo. Nangona kunjalo, kuba ukugrumba nge-laser ngenene kusebenzisa ukufudumeza kwendawo ukwenza umngxuma wokutyhutyha, udonga lomngxuma we-TSV luya kuchatshazelwa kakubi ngumonakalo oshushu kunye nokunciphisa ukuthembeka.

2. Inkqubo yokubeka umaleko womgca

Obunye ubuchwephesha obuphambili bokwenza i-TSV yinkqubo yokubeka i-liner layer.

Inkqubo yokubeka i-liner layer yenziwa emva kokuba umngxuma wokutyhutyha ufakiwe. Umaleko womgca ogciniweyo ngokuqhelekileyo uyi-oxide efana ne-SiO2. I-liner layer ibekwe phakathi komqhubi wangaphakathi we-TSV kunye ne-substrate, kwaye idlala indima enkulu yokuhlukanisa ukuvuza kwangoku kwe-DC. Ukongeza ekufakeni i-oxide, umqobo kunye neengqimba zembewu nazo ziyafuneka ukuze umqhubi azalise inkqubo elandelayo.

Umaleko we-liner owenziweyo kufuneka uhlangabezane nezi mfuno zimbini zilandelayo:

(1) amandla ombane wokuqhawuka komgangatho we-insulating kufuneka ahlangabezane neemfuno zokwenene zokusebenza ze-TSV;

(2) iileya ezidiphozithiweyo zihambelana kakhulu kwaye zinamathele kakuhle omnye komnye.

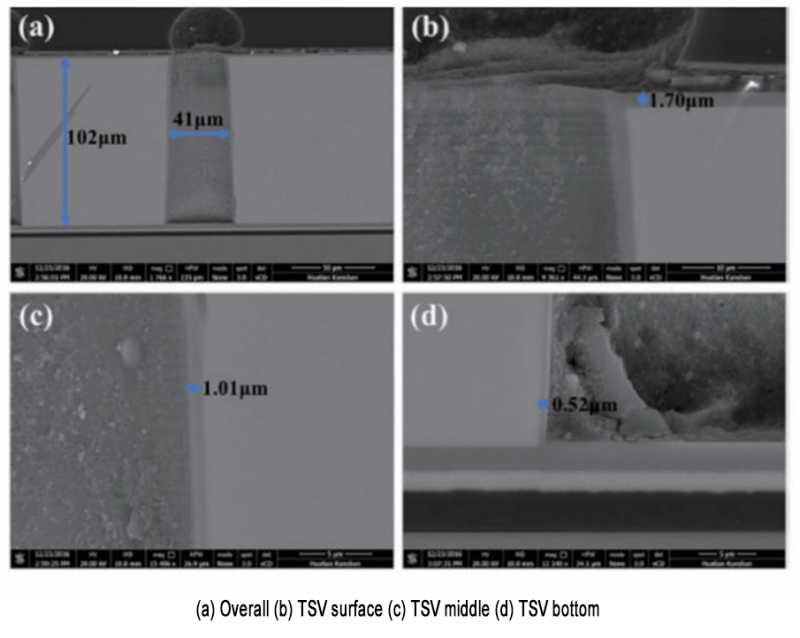

Lo mzobo ulandelayo ubonisa ifoto yomaleko we-liner ofakwe kwi-plasma ephuculweyo ye-chemical vapor deposition (PECVD).

Inkqubo yokubekwa kufuneka ihlengahlengiswe ngokufanelekileyo kwiinkqubo ezahlukeneyo zokwenziwa kwe-TSV. Kwinkqubo ye-front through-hole, inkqubo yokubeka ubushushu obuphezulu ingasetyenziselwa ukuphucula umgangatho we-oxide layer.

Ukubekwa okuqhelekileyo kobushushu obuphezulu kunokusekwa kwi-tetraethyl orthosilicate (TEOS) edityaniswe nenkqubo ye-oxidation ye-thermal ukuze yenze i-SiO2 yomgangatho ophezulu we-insulating layer. Kumngxuma ophakathi kunye nenkqubo yokubuyela umva, ekubeni inkqubo ye-BEOL igqityiwe ngexesha lokubekwa, indlela yobushushu obuphantsi iyafuneka ukuze kuqinisekiswe ukuhambelana nezinto ze-BEOL.

Ngaphantsi kwalo mqathango, ukushisa kwe-deposit kufuneka kukhawulelwe kwi-450 °, kubandakanywa nokusetyenziswa kwe-PECVD ukufaka i-SiO2 okanye i-SiNx njenge-insulating layer.

Enye indlela eqhelekileyo kukusebenzisa i-atomic layer deposition (ALD) ukufaka i-Al2O3 ukufumana i-denser insulating layer.

3. Inkqubo yokuzaliswa kwesinyithi

Inkqubo yokuzaliswa kwe-TSV iqhutyelwa ngokukhawuleza emva kwenkqubo yokubeka i-liner, enye iteknoloji ebalulekileyo emisela umgangatho we-TSV.

Izinto ezinokuzaliswa zibandakanya i-polysilicon ye-doped, i-tungsten, i-carbon nanotubes, njl kuxhomekeke kwinkqubo esetyenzisiweyo, kodwa eyona nto ixhaphakileyo iseyi-copper e-electroplated, kuba inkqubo yayo ikhulile kwaye i-conductivity yayo yombane kunye ne-thermal iphezulu.

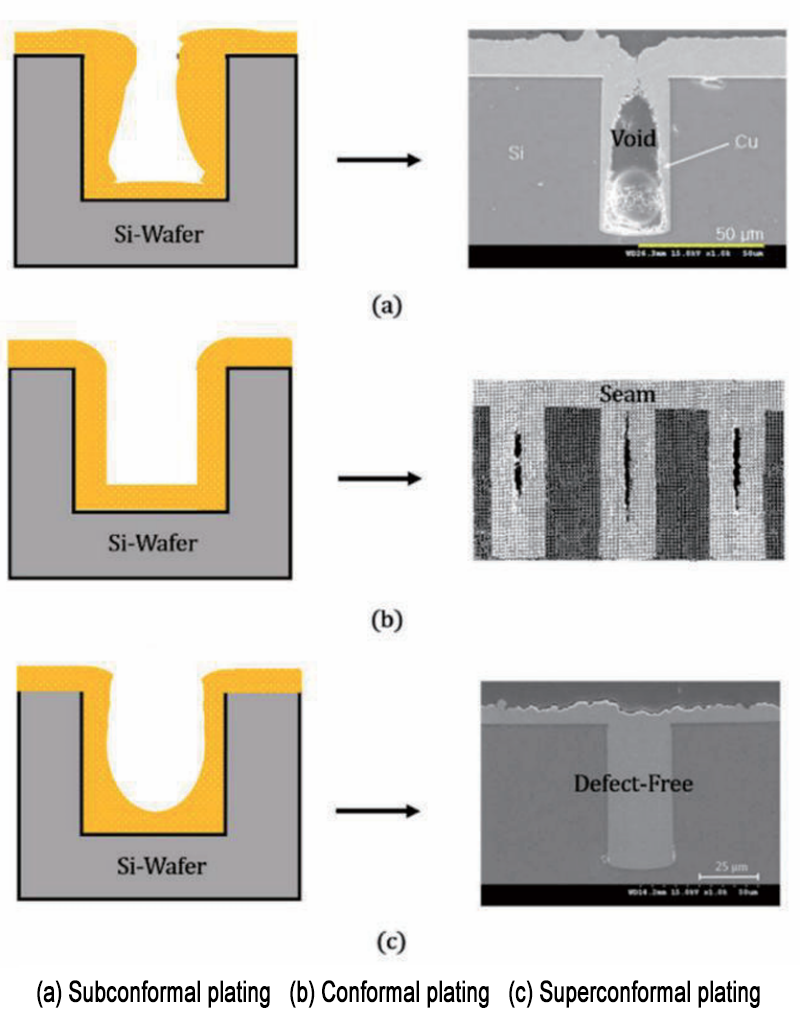

Ngokomahluko wokusasazwa kwereyithi yokulinganisa i-electroplating kumngxuma odlulayo, inokwahlulwa ikakhulu ibe yi-subconformal, conformal, superconformal kunye ne-bottom-up-electroplating iindlela, njengoko kubonisiwe kulo mfanekiso.

I-subconformal electroplating yayisetyenziswa ikakhulu kwinqanaba lokuqala lophando lwe-TSV. Njengoko kuboniswe kuMzobo (a), i-Cu ions ebonelelwa nge-electrolysis igxininiswe phezulu, ngelixa i-bottom is insufficiently supplemented, okubangela ukuba izinga le-electroplating liphezulu kwi-hole-hole libe liphezulu kunokuba lingaphantsi phezulu. Ke ngoko, umphezulu womngxuma wokutyhutyha uya kuvalwa kwangaphambili ngaphambi kokuba uzaliswe ngokupheleleyo, kwaye isithuba esikhulu siya kwenziwa ngaphakathi.

Umzobo weskim kunye nefoto yendlela yokulinganisa i-electroplating iboniswe kuMzobo (b). Ngokuqinisekisa ukongezwa okufanayo kwe-Cu ion, isantya se-electroplating kwindawo nganye kumngxuma wokutyhutyha ngokusisiseko siyafana, ngoko ke i-seam kuphela iya kusala ngaphakathi, kwaye umthamo ongenanto uncinci kakhulu kunendlela ye-subconformal electroplating. isetyenziswa ngokubanzi.

Ukuze uqhubele phambili ukufezekisa umphumo wokuzaliswa kwe-void-free, indlela ye-superconformal electroplating yacetywayo yokwandisa indlela ye-electroplating ehambelanayo. Njengoko kubonisiwe kuMfanekiso (c), ngokulawula unikezelo lwe-Cu ions, izinga lokuzalisa ezantsi liphezulu kancinane kunezinye izikhundla, ngaloo ndlela kunyuswa inqanaba lenqanaba lokuzalisa ukusuka ezantsi ukuya phezulu ukuphelisa ngokupheleleyo umthungo osekhohlo. ngendlela ye-electroplating ehambelanayo, ukuze kufezekiswe ukuzaliswa kobhedu olungenanto ngokupheleleyo.

Indlela ye-electroplating esezantsi-phezulu ingaqwalaselwa njengemeko ekhethekileyo yendlela ephezulu-conformal. Kule meko, izinga le-electroplating ngaphandle kwezantsi linyanzeliswa kwi-zero, kwaye kuphela i-electroplating iqhutyelwa ngokuthe ngcembe ukusuka ezantsi ukuya phezulu. Ukongeza kwi-void-free advantage ye-conformal electroplating method, le ndlela inokunciphisa ngokufanelekileyo ixesha elipheleleyo le-electroplating, ngoko ifundwe ngokubanzi kwiminyaka yamuva.

4. Iteknoloji yenkqubo yeRDL

Inkqubo ye-RDL yitekhnoloji esisiseko eyimfuneko kwinkqubo yokupakisha enemigangatho emithathu. Ngale nkqubo, ukudityaniswa kwesinyithi kunokuveliswa kumacala omabini e-substrate ukufezekisa injongo yokusasazwa kwezibuko okanye ukudibanisa phakathi kweepakethe. Ngoko ke, inkqubo ye-RDL isetyenziswa ngokubanzi kwiinkqubo zokupakisha i-fan-in-fan-out okanye i-2.5D/3D.

Kwinkqubo yokwakha izixhobo ezine-dimensional ezintathu, inkqubo ye-RDL idla ngokusetyenziselwa ukunxibelelanisa i-TSV ukufezekisa ulwakhiwo lwesixhobo esinamacala amathathu.

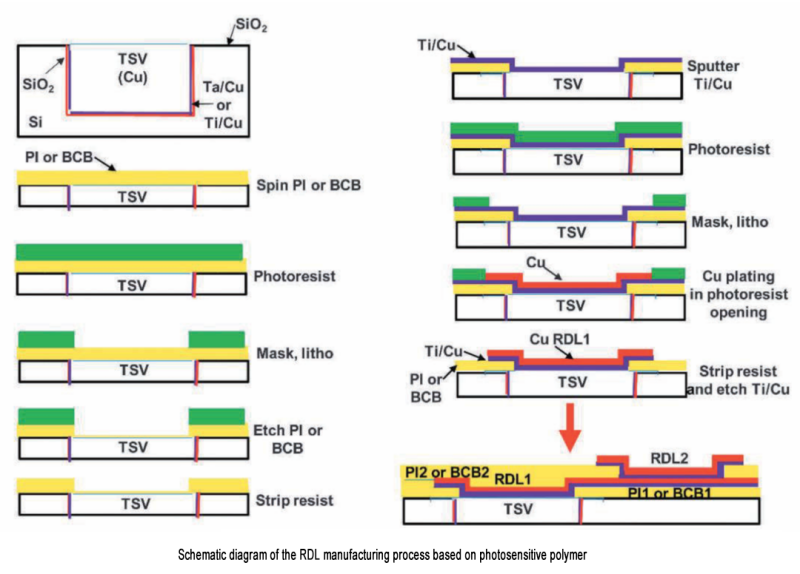

Okwangoku kukho iinkqubo ezimbini eziphambili zeRDL. Eyokuqala isekelwe kwiipolymers ze-photosensitive kwaye idibaniswe ne-electroplating yobhedu kunye neenkqubo ze-etching; enye iphunyezwa ngokusebenzisa inkqubo yeCu Damasko edityaniswe ne-PECVD kunye nenkqubo yokupholisa ngamachiza ekhemikhali (CMP).

Oku kulandelayo kuya kwazisa iindlela eziphambili zenkqubo yezi RDL zimbini ngokulandelelanayo.

Inkqubo ye-RDL esekelwe kwi-polymer ye-photosensitive iboniswe kumzobo ongentla.

Okokuqala, i-glue ye-PI okanye ye-BCB ifakwe phezu kwe-wafer ngokujikeleza, kwaye emva kokufudumeza kunye nokunyanga, inkqubo ye-photolithography isetyenziselwa ukuvula imingxuma kwindawo efunwayo, kwaye emva koko i-etching yenziwa. Okulandelayo, emva kokususa i-photoresist, i-Ti kunye ne-Cu zichithwa kwi-wafer ngokusebenzisa inkqubo yokubeka umphunga womzimba (PVD) njengoluhlu lwesithintelo kunye noluhlu lwembewu, ngokulandelanayo. Emva koko, uluhlu lokuqala lwe-RDL luveliswa kwinqanaba le-Ti / Cu eliveziweyo ngokudibanisa i-photolithography kunye neenkqubo ze-electroplating Cu, kwaye emva koko i-photoresist isusiwe kwaye i-Ti kunye ne-Cu eyongezelelweyo ikhutshwe. Phinda la manyathelo angasentla ukwenza i-multi-layer ye-RDL. Le ndlela ngoku isetyenziswa ngokubanzi kushishino.

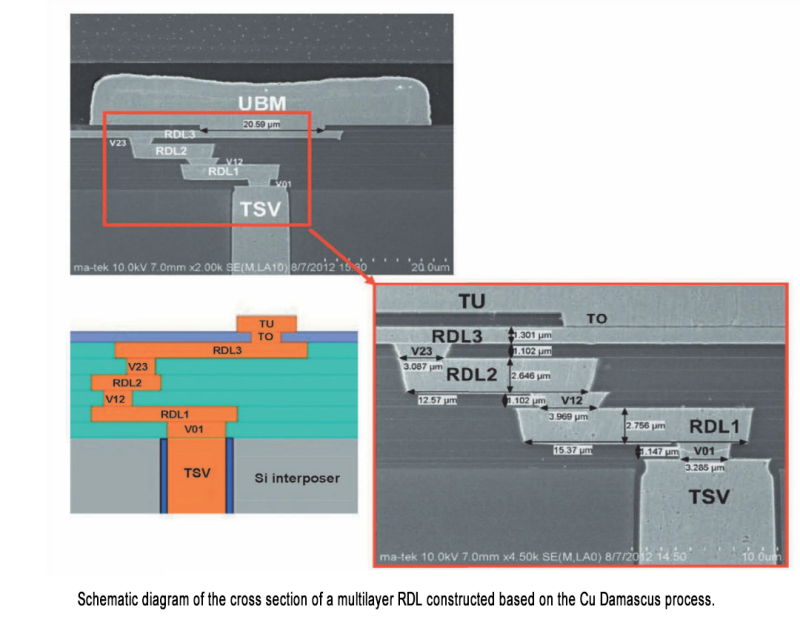

Enye indlela yokuvelisa i-RDL isekelwe ikakhulu kwinkqubo yeCu Damasko, edibanisa i-PECVD kunye neenkqubo zeCMP.

Umahluko phakathi kwale ndlela kunye nenkqubo ye-RDL esekelwe kwi-polymer ye-photosensitive kukuba kwinqanaba lokuqala lokuvelisa umaleko ngamnye, i-PECVD isetyenziselwa ukufaka i-SiO2 okanye i-Si3N4 njenge-insulating layer, kwaye emva koko ifestile yenziwa kwi-insulating layer nge-photolithography kunye i-ion etching esebenzayo, kunye nesithintelo se-Ti/Cu / umaleko wembewu kunye nobhedu lwe-conductor ziyafafazwa ngokulandelelana, emva koko umaleko we-conductor ucuthwe ukuya kubukhulu obufunekayo. Inkqubo ye-CMP, oko kukuthi, umaleko we-RDL okanye umngxuma womngxuma wenziwa.

Lo mzobo ulandelayo ngumzobo weskimu kunye nesithombe somnqamlezo we-multi-layer RDL eyakhiwe ngokusekelwe kwinkqubo yeCu Damasko. Inokuqatshelwa ukuba i-TSV iqale iqhagamshelwe kumngxunya we-V01, kwaye emva koko ibekwe ukusuka ezantsi ukuya phezulu ngokolandelelwano lwe-RDL1, umaleko womngxuma we-V12, kunye ne-RDL2.

Umaleko ngamnye we-RDL okanye umngxuma womngxuma wenziwa ngokulandelelana ngokwendlela engentla.Ekubeni inkqubo ye-RDL idinga ukusetyenziswa kwenkqubo ye-CMP, iindleko zayo zokuvelisa ziphezulu kunenkqubo ye-RDL esekelwe kwi-polymer ye-photosensitive, ngoko ke isicelo sayo siphantsi.

5. IPD inkqubo yeteknoloji

Ukwenziwa kwezixhobo ezine-dimensional-dimensional, ngaphezu kokuhlanganiswa ngokuthe ngqo kwi-chip kwi-MMIC, inkqubo ye-IPD inika enye indlela yobugcisa eguquguqukayo.

Izixhobo ezidityanisiweyo ze-passive, ezikwaziwa ngokuba yinkqubo ye-IPD, zidibanisa nayiphi na indibaniselwano yezixhobo zokwenziwa eziquka i-inductors, i-capacitors, resistors, i-balun converters, njl. Ukubizwa ngokuguquguqukayo ngokweemfuno zoyilo.

Ekubeni kwinkqubo ye-IPD, izixhobo ezisetyenziswayo zenziwa kwaye zidityaniswe ngokuthe ngqo kwibhodi yokudlulisa, ukuhamba kwayo kwenkqubo kulula kwaye kungabizi kakhulu kunokuhlanganiswa kwe-ICs kwi-chip, kwaye inokuveliswa ngobuninzi kwangaphambili njengelayibrari yesixhobo sokwenziwa.

Kwi-TSV yokwenziwa kwesixhobo esine-dimensional three-dimensional passive, i-IPD inokuphelisa ngokufanelekileyo umthwalo weendleko zeenkqubo zokupakisha ezinomacala amathathu kuquka i-TSV kunye ne-RDL.

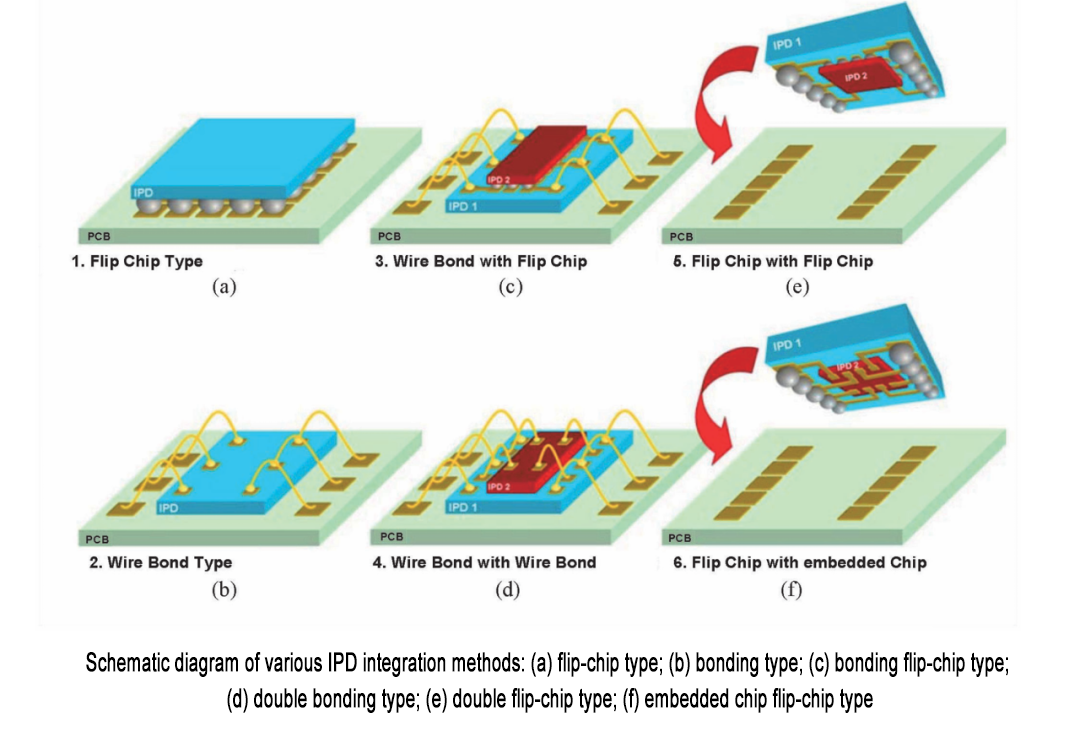

Ukongeza kwiinzuzo zeendleko, enye inzuzo ye-IPD kukuguquguquka kwayo okuphezulu. Enye yokuguquguquka kwe-IPD ibonakaliswe kwiindlela ezahlukeneyo zokudibanisa, njengoko kuboniswe kumzobo ongezantsi. Ukongeza kwiindlela ezimbini ezisisiseko zokudibanisa ngokuthe ngqo i-IPD kwi-substrate ye-package ngokusebenzisa inkqubo ye-flip-chip njengoko kuboniswe kuMzobo (a) okanye inkqubo yokudibanisa njengoko kuboniswe kuMzobo (b), enye i-IPD inokudibaniswa kwinqanaba elinye. ye-IPD njengoko kubonisiwe kwiMifanekiso (c)-(e) ukuphumeza uluhlu olubanzi lwendibaniselwano yesixhobo sokwenziwa.

Ngexesha elifanayo, njengoko kuboniswe kuMzobo (f), i-IPD ingasetyenziselwa ngakumbi njengebhodi ye-adapter ukungcwaba ngokuthe ngqo i-chip edibeneyo kuyo ukwakha ngokuthe ngqo inkqubo yokupakisha ephezulu.

Xa usebenzisa i-IPD ukwakha izixhobo ezine-dimensional passive, inkqubo ye-TSV kunye nenkqubo ye-RDL nayo ingasetyenziswa. Ukuhamba kwenkqubo ngokusisiseko kufana nendlela yokudibanisa kwi-chip ekhankanywe ngasentla, kwaye ayiyi kuphinda iphindwe; Umahluko kukuba ekubeni into yokudibanisa itshintshiwe ukusuka kwi-chip ukuya kwibhodi ye-adapter, akukho mfuneko yokuqwalasela impembelelo yenkqubo yokupakisha ye-three-dimensional kwindawo esebenzayo kunye ne-interconnection layer. Oku kukhokelela ngakumbi kwelinye i-flexibility engundoqo ye-IPD: izinto ezahlukeneyo ze-substrate zingakhethwa ngokuguquguqukayo ngokweemfuno zoyilo lwezixhobo zokungena.

Izixhobo ze-substrate ezikhoyo kwi-IPD azikho nje izinto eziqhelekileyo ze-semiconductor substrate ezifana ne-Si kunye ne-GaN, kodwa kunye neekeramics ze-Al2O3, i-low-temperature / high-temperature co-fired ceramics, i-glass substrates, njl. izixhobo ezidityaniswe yi IPD.

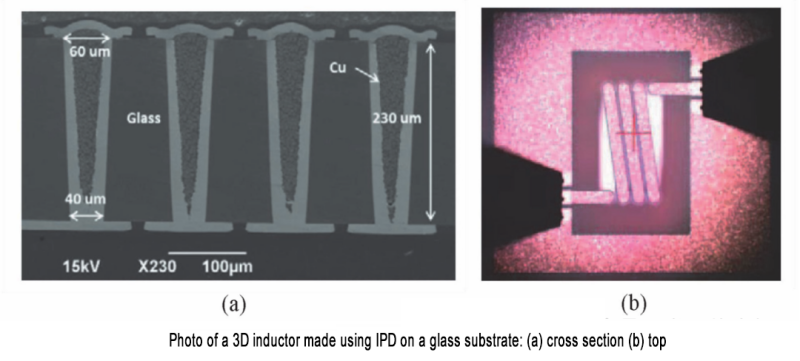

Ngokomzekelo, isakhiwo se-inductor esine-dimensional-dimensional passive inductor esidityaniswe yi-IPD sinokusebenzisa i-substrate yeglasi ukuphucula ngokufanelekileyo ukusebenza kwe-inductor. Ngokuchaseneyo nombono we-TSV, imingxunya eyenziwe kwi-substrate yeglasi ikwabizwa ngokuba yi- through-glass vias (TGV). Ifoto ye-inductor ene-dimensional-dimensional eyenziwe ngokusekelwe kwi-IPD kunye neenkqubo ze-TGV iboniswe kumzobo ongezantsi. Ekubeni i-resistivity ye-substrate yeglasi iphezulu kakhulu kuneyezinto eziqhelekileyo ze-semiconductor ezifana ne-Si, i-TGV i-inductor ye-three-dimensional inductor ineempawu ezingcono zokugquma, kunye nelahleko yokufakela okubangelwa yi-substrate parasitic effect kwi-frequencies ephezulu incinci kakhulu kuneyo i-TSV eqhelekileyo i-inductor enamacala amathathu.

Kwelinye icala, i-metal-insulator-metal (MIM) i-capacitors nayo inokuveliswa kwi-IPD yeglasi ephantsi ngenkqubo yokubeka ifilimu ebhityileyo, kwaye idityaniswe ne-TGV i-inductor ene-dimensional-dimensional ukwenza i-three-dimensional passive filter structure. Ke ngoko, inkqubo ye-IPD inamandla osetyenziso olubanzi kuphuhliso lwezixhobo ezitsha ezinamacala amathathu okwenziwa.

Ixesha lokuposa: Nov-12-2024