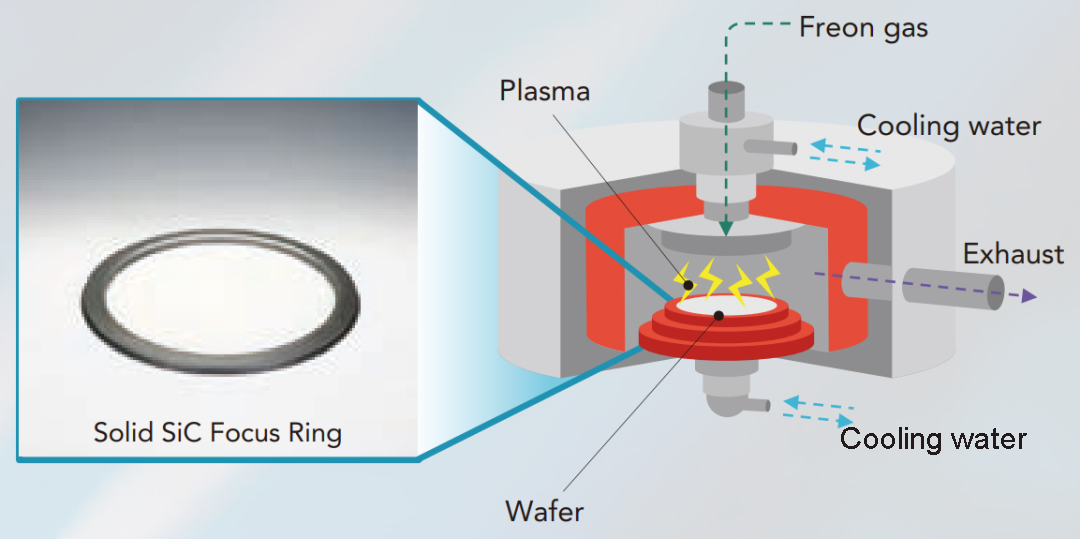

Kwizixhobo ze-plasma etching, amacandelo e-ceramic adlala indima ebalulekileyo, kubandakanywaumsesane wokugxila.I umsesane wokugxila, ibekwe malunga ne-wafer kunye nokunxibelelana ngokuthe ngqo nayo, ibalulekile ekugxininiseni i-plasma kwi-wafer ngokusebenzisa i-voltage kwi-ring. Oku kwandisa ukufana kwenkqubo yokubhala.

Ukusetyenziswa kweeRings zeSiC zokuJonga kwii-Etching Machines

Amacandelo e-SiC CVDkoomatshini etching, ezifanaamakhonkco ogxininiso, iishawara zegesi, iiplatens, kunye neendandatho zomphetho, zithandwa ngenxa ye-reactivity ephantsi ye-SiC kunye ne-chlorine kunye ne-fluorine-based etching gases kunye ne-conductivity yayo, okwenza kube yinto efanelekileyo yezixhobo ze-plasma etching.

Izinto eziluncedo ze-SiC njengesixhobo sokuJonga seRingi

Ngenxa yokuvezwa ngokuthe ngqo kwi-plasma kwigumbi lokuphendula i-vacuum, amakhonkco ekugxilwe kuwo kufuneka enziwe kwizinto ezichasene ne-plasma. Izangqa zokugxila ngokwemveli, ezenziwe ngesilicon okanye iquartz, zinengxaki yokunganyangeki kwi-etching kwi-plasmas esekwe kwi-fluorine, ekhokelela ekudlekeni okukhawulezayo kunye nokuncipha kokusebenza kakuhle.

Uthelekiso phakathi kwe-Si kunye ne-CVD i-SiC yokuJonga iRings:

1. Uxinaniso oluPhezulu:Yehlisa ivolumu yokubhala.

2. Umsantsa obanzi: Ibonelela nge-insulation egqwesileyo.

3. I-Thermal Conductivity ePhezulu kunye ne-Coefficient yoKwandiswa okuPhantsi: Ukumelana nokutshatyalaliswa kwe-thermal.

4. Ukuthamba okuphezulu:Ukuchasana okulungileyo kwimpembelelo yomatshini.

5. Ukuqina okuphezulu: Ukunxiba kunye ne-corrosion-resistant.

I-SiC yabelana ngokusebenza kombane kwe-silicon ngelixa inikezela ukuchasana okuphezulu kwi-ionic etching. Njengoko i-miniaturization yesekethe edityanisiweyo iqhubela phambili, imfuno yeenkqubo zokurhweba ngokufanelekileyo iyanda. Izixhobo zePlasma etching, ngakumbi ezo zisebenzisa i-capacitive coupled plasma (CCP), zifuna amandla aphezulu eplasma,Amakhonkco ekugxilwe kweSiCngokuya ethandwa.

I-Si kunye ne-CVD i-SiC yokuJonga kwiiParamitha zeRingi:

| Ipharamitha | Isilicon (Si) | I-CVD Silicon Carbide (SiC) |

| Ubuninzi (g/cm³) | 2.33 | 3.21 |

| Umsantsa weBand (eV) | 1.12 | 2.3 |

| I-Thermal Conductivity (W/cm°C) | 1.5 | 5 |

| Ukwandiswa kwe-Thermal Coefficient (x10⁻⁶/°C) | 2.6 | 4 |

| I-Elastic Modulus (GPA) | 150 | 440 |

| Ukuqina | Ngasezantsi | Phezulu |

Inkqubo yokuVeliswa kweeRings zeSiC zokuJonga

Kwizixhobo ze-semiconductor, i-CVD (i-Chemical Vapor Deposition) isetyenziswa ngokuqhelekileyo ukuvelisa amacandelo e-SiC. Izangqa zogxininiso zenziwa ngokufaka i-SiC kwiimilo ezithile ngokufaka umphunga, kulandele ukusetyenzwa ngoomatshini ukwenza imveliso yokugqibela. Umlinganiselo wemathiriyeli wokubekwa komphunga ulungisiwe emva kovavanyo olubanzi, ukwenza iiparamitha ezifana nokumelana nokumelana. Nangona kunjalo, izixhobo ezahlukeneyo ze-etching zinokufuna amakhonkco okugxila aneendlela ezahlukeneyo zokuxhathisa, ezifuna iimvavanyo zomlinganiso omtsha wezinto ezichaziweyo kwinkcazo nganye, edla ixesha kunye neendleko.

NgokukhethaAmakhonkco ekugxilwe kweSiCukusukaISemicera Semiconductor, abathengi banokufikelela kwizibonelelo zemijikelezo yokutshintsha ixesha elide kunye nokusebenza okuphezulu ngaphandle kokunyuka okukhulu kweendleko.

Izixhobo ezikhawulezayo zokuLungiswa kweThermal (RTP).

Iipropati zobushushu ezikhethekileyo ze-CVD SiC ziyenza ilungele izicelo ze-RTP. Amacandelo e-RTP, kubandakanywa amakhonkco e-edge kunye neeplatens, inzuzo kwi-CVD SiC. Ngexesha le-RTP, ii-pulses ezitshisa kakhulu zisetyenziswa kwii-wafers zodwa ixesha elifutshane, zilandelwa kukupholisa ngokukhawuleza. I-CVD SiC edge rings, ibe yincinci kwaye ibe nobunzima obuphantsi be-thermal, ayigcini ubushushu obubalulekileyo, ibenza bangachaphazeleki ngokufudumeza ngokukhawuleza kunye neenkqubo zokupholisa.

Amacandelo e-Plasma Etching

Ukumelana nemichiza ephezulu ye-CVD SiC iyenza ilungele ukusetyenziswa kwe-etching. Amagumbi amaninzi e-etching asebenzisa iipleyiti zokuhambisa igesi ye-CVD SiC ukuhambisa iigesi ze-etching, eziqulethe amawaka emingxunya emincinci yokusasazeka kweplasma. Xa kuthelekiswa nezinye izixhobo, i-CVD SiC ine-reactivity ephantsi kunye ne-chlorine kunye neegesi ze-fluorine. Kwi-etching eyomileyo, amacandelo e-CVD SiC afana nezangqa zokugxila, iiplateni ze-ICP, amakhonkco omda, kunye neentloko zeshawari zisetyenziswa ngokuqhelekileyo.

Izangqa ze-SiC, kunye ne-voltage yazo esetyenzisiweyo yokugxila kwi-plasma, kufuneka ibe ne-conductivity eyaneleyo. Ngokuqhelekileyo zenziwe nge-silicon, imisesane yokugxila ibonakaliswe kwiigesi ezisebenzayo eziqulethe i-fluorine kunye ne-chlorine, ekhokelela kwi-corrosion engenakuphepheka. Amakhonkco okugxila e-SiC, kunye nokuxhathisa kwawo okuphezulu, anika ubomi obude xa kuthelekiswa namakhonkco e-silicon.

Uthelekiso lomjikelo wobomi:

Izangqa zeSiC zokuJonga:Itshintshwe rhoqo ngeentsuku ezili-15 ukuya kwezingama-20.

Izangqa zeSilicon zokuJonga:Itshintshwe rhoqo ngeentsuku ezili-10 ukuya kwezili-12.

Nangona amakhonkco e-SiC abe ngama-2 ukuya kwamaxesha e-3 abiza kakhulu kunezangqa ze-silicon, umjikelo owandisiweyo wokutshintsha unciphisa iindleko ezipheleleyo zokutshintshwa kwecandelo, njengoko zonke iinxalenye zokunxiba kwigumbi zitshintshwa ngaxeshanye xa igumbi livulelwa ukutshintshwa kweringi.

Izangqa zeSemicera Semiconductor yeSiC yokuJonga

I-Semicera Semiconductor inikezela ngamakhonkco okugxilwa kwe-SiC kumaxabiso akufutshane nalawo amakhonkco e-silicon, kunye nexesha eliphambili leentsuku ezingama-30. Ngokudibanisa iindandatho ze-SiC ze-Semicera kwizixhobo zokujonga i-plasma, ukusebenza kakuhle kunye nokuphila ixesha elide kuphuculwe kakhulu, ukunciphisa iindleko zokulondolozwa kunye nokuphucula ukusebenza kakuhle kwemveliso. Ukongeza, i-Semicera inokwenza ngokwezifiso ukuxhathisa kwamakhonkco okugxila ukuhlangabezana neemfuno ezithile zabathengi.

Ngokukhetha amakhonkco e-SiC avela kwi-Semicera Semiconductor, abathengi banokufikelela kwizibonelelo zemijikelezo emide yokutshintsha kunye nokusebenza okuphezulu ngaphandle kokunyuka okukhulu kweendleko.

Ixesha lokuposa: Jul-10-2024