Izixhobo zamandla ze-Semiconductor zithatha indawo ephambili kwiinkqubo zombane zamandla, ngokukodwa kumxholo wokuphuhliswa ngokukhawuleza kobuchwepheshe obufana nobukrelekrele bokufakelwa, unxibelelwano lwe-5G kunye nezithuthi zamandla amatsha, iimfuno zokusebenza kwazo ziphuculwe.

I-silicon carbide(I-4H-SiC) iye yaba yinto efanelekileyo yokuvelisa izixhobo zamandla ze-semiconductor ezisebenza kakhulu ngenxa yeenzuzo zayo ezifana ne-bandgap ebanzi, i-conductivity ephezulu ye-thermal, amandla e-high breakdown field, i-saturation drift rate, ukuzinza kweekhemikhali kunye nokumelana nemitha. Nangona kunjalo, i-4H-SiC inobulukhuni obuphezulu, i-brittleness ephezulu, i-inertness eqinile yeekhemikhali, kunye nobunzima bokucubungula okuphezulu. Umgangatho womphezulu we-wafer ye-substrate yayo ubalulekile kusetyenziso lwesixhobo esikhulu.

Ngoko ke, ukuphucula umgangatho womgangatho we-4H-SiC substrate wafers, ngokukodwa ukususa umaleko owonakalisiweyo kwi-wafer processing surface, isitshixo ekufezekiseni ukusebenza kakuhle, ilahleko ephantsi kunye nekhwalithi ephezulu ye-4H-SiC substrate processing.

Zama

Uvavanyo lusebenzisa i-4-intshi ye-N-uhlobo lwe-4H-SiC ingot ekhuliswe yindlela yokuthutha umphunga womzimba, ecutshungulwa ngokusikwa kwecingo, ukugawula, ukugawula, ukugaya okulungileyo kunye nokupolisha, kwaye irekhoda ukugqithiswa kobuso be-C kunye ne-Si surface. kunye nobukhulu bokugqibela be-wafer kwinkqubo nganye.

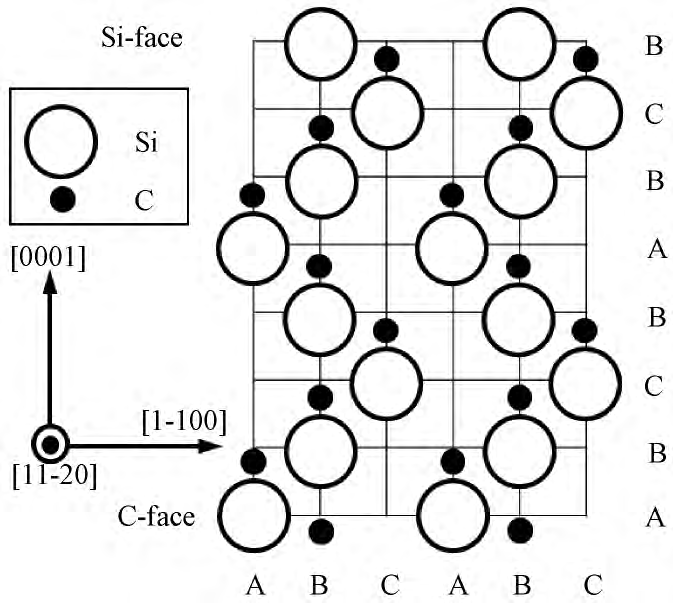

Umzobo we-1 Umzobo weSchematic we-4H-SiC isakhiwo se-crystal

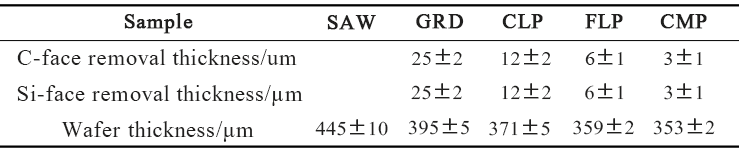

Umzobo 2 Ukutyeba kususiwe kwicala le-C kunye ne-Si-side ye-4H-Iqhekeza leSiCemva kwamanyathelo ahlukeneyo okucubungula kunye nobukhulu be-wafer emva kokulungiswa

Ubukhulu, ubume bomphezulu, uburhabaxa kunye neempawu zomatshini zewafer ziphawulwe ngokupheleleyo ngesivavanyi separamitha yejiyometri, umahluko wokuphazamiseka kwemakroskopu, i-atomic force microscope, isixhobo sokulinganisa uburhabaxa kunye ne-nanoindenter. Ukongeza, i-X-ray ye-diffractometer enesisombululo esiphezulu isetyenziselwe ukuvavanya umgangatho wekristale we-wafer.

La manyathelo okulinga kunye neendlela zovavanyo zibonelela ngenkxaso yobuchwephesha eneenkcukacha zokufunda ireyithi yokususa izinto kunye nomgangatho womphezulu ngexesha lokusetyenzwa kwe-4H-Iifafa zeSiC.

Ngokusebenzisa iimvavanyo, abaphandi bahlalutya utshintsho kwireyithi yokususa izinto (MRR), i-morphology yomhlaba kunye noburhabaxa, kunye neempawu zomatshini kunye nomgangatho wekristale we-4H-Iifafa zeSiCkumanyathelo okusebenza ahlukeneyo (ukusika ucingo, ukugaya, ukugawula, ukugaya kakuhle, ukupolisha).

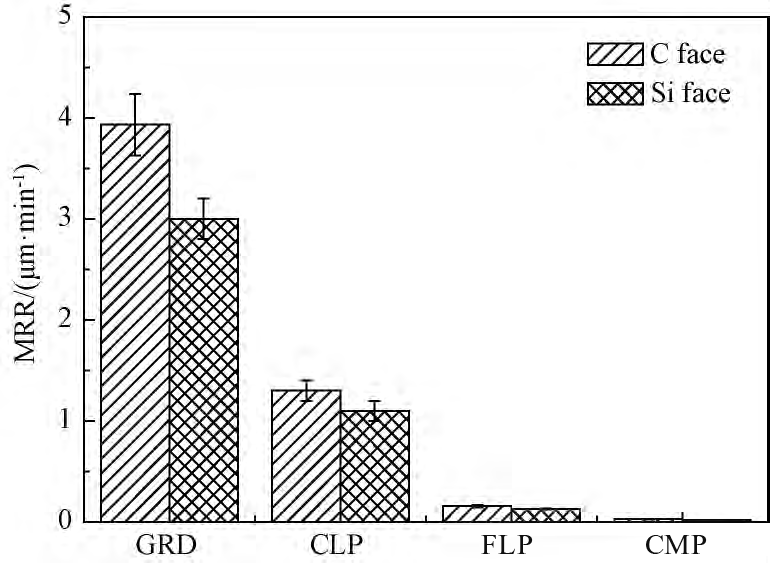

Umzobo 3 Izinga lokususwa kwezinto ezibonakalayo ze-C-face kunye ne-Si-face ye-4H-Iqhekeza leSiCkumanyathelo ahlukeneyo okuqhuba

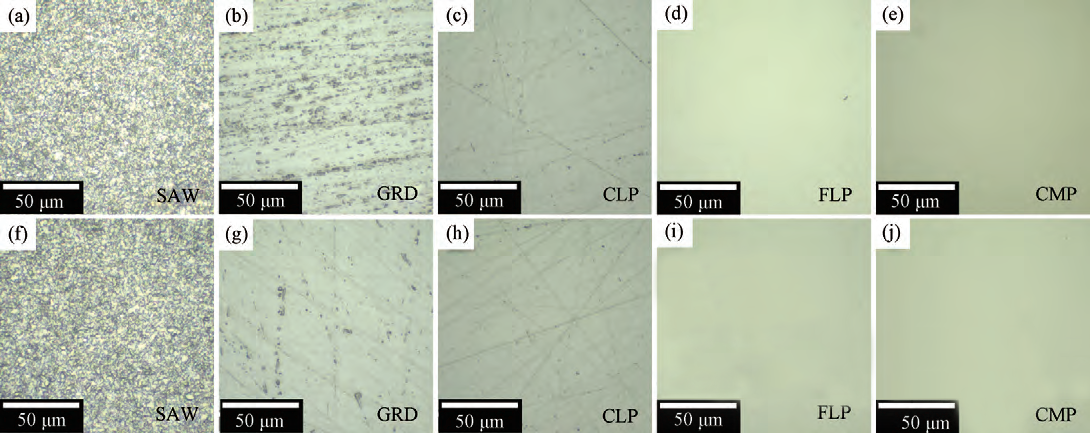

Uphononongo lufumene ukuba ngenxa ye-anisotropy yezinto eziphathekayo zobuso obuhlukeneyo be-crystal ye-4H-SiC, kukho umehluko kwi-MRR phakathi kwe-C-face kunye ne-Si-face phantsi kwenkqubo efanayo, kwaye i-MRR ye-C-face iphezulu kakhulu leyo kaSi-face. Ngokuqhubela phambili kwamanyathelo okucubungula, i-morphology yomhlaba kunye noburhabaxa be-4H-SiC wafers ngokuthe ngcembe iphuculwa. Emva kokupholisa, i-Ra ye-C-face yi-0.24nm, kwaye i-Ra ye-Si-face ifikelela kwi-0.14nm, enokuthi ihlangabezane neemfuno zokukhula kwe-epitaxial.

Umzobo 4 Imifanekiso ye-microscope yokubona yobuso be-C (a~e) kunye nomgangatho we-Si (f~j) we-4H-SiC wafer emva kwamanyathelo ahlukeneyo okucubungula.

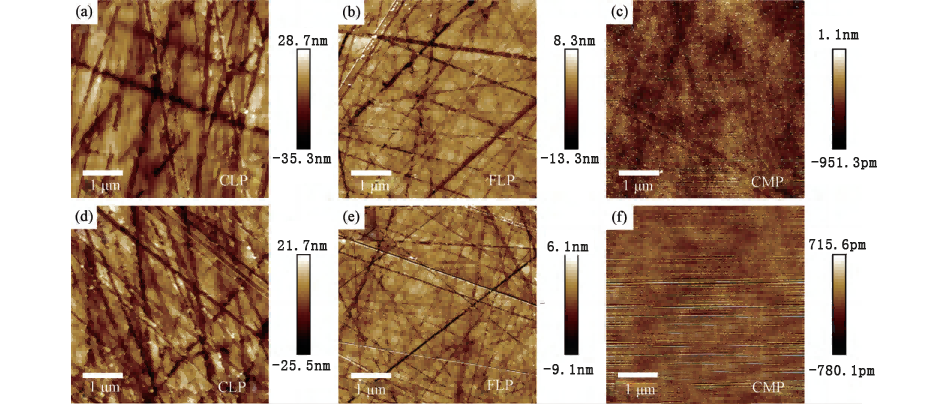

Umfanekiso we-5 Imifanekiso ye-atomic yamandla e-atom yobuso be-C (a~c) kunye ne-Si surface (d~f) ye-4H-SiC yangasese emva kwe-CLP, i-FLP kunye namanyathelo okucubungula e-CMP

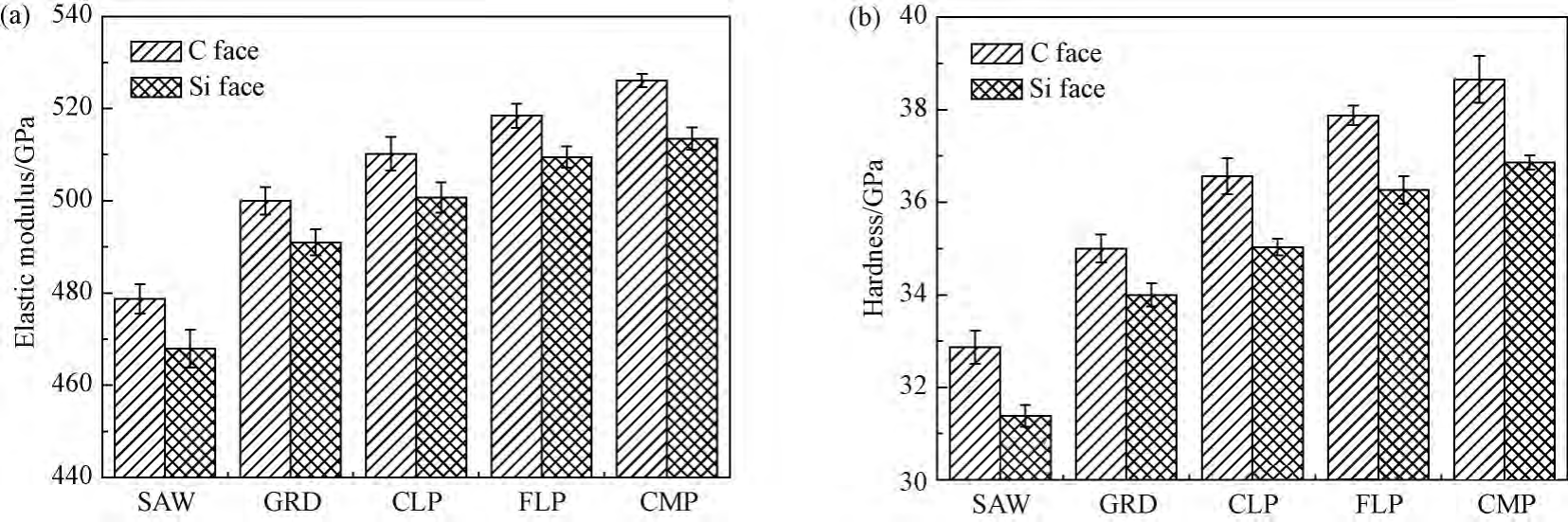

Umzobo 6 (a) imodyuli elastiki kunye (b) nokuqina kobuso be-C kunye nobuso be-Si be-4H-SiC wafer emva kwamanyathelo okusebenza ahlukeneyo

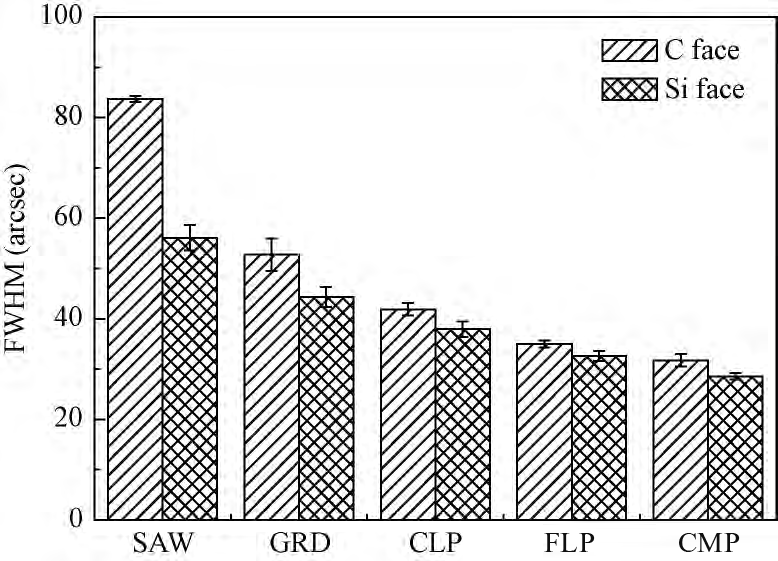

Uvavanyo lwepropathi yoomatshini lubonisa ukuba umphezulu we-C we-wafer unokuqina okulambathayo kunemathiriyeli yomphezulu we-Si, iqondo elikhulu lokuqhekeka kwe-brittle ngexesha lokusetyenzwa, ukususwa kwemathiriyeli ngokukhawuleza, kunye ne-morphology yomphezulu engalunganga kunye noburhabaxa. Ukususa umaleko owonakalisiweyo kwindawo esetyenzisiweyo sisitshixo sokuphucula umgangatho womgangatho we-wafer. Ububanzi besiqingatha sobude be-4H-SiC (0004) ye-rocking curve ingasetyenziselwa ukubonakalisa intuitively kunye ngokuchanekileyo kunye nokuhlalutya umgangatho womonakalo ophezulu we-wafer.

Umzobo we-7 (0004) ijika elijikajikayo ububanzi besiqingatha sobuso be-C kunye ne-Si-face ye-4H-SiC wafer emva kwamanyathelo ahlukeneyo okucubungula

Iziphumo zophando zibonisa ukuba umaleko womonakalo ongaphezulu we-wafer unokususwa ngokuthe ngcembe emva kokulungiswa kwe-wafer ye-4H-SiC, ephucula ngokufanelekileyo umgangatho we-wafer kunye nokubonelela ngereferensi yobugcisa bokusebenza okuphezulu, ilahleko ephantsi kunye nomgangatho ophezulu wokusetyenzwa. ye-4H-SiC substrate wafers.

Abaphandi bacubungula ii-wafers ze-4H-SiC ngokusebenzisa amanyathelo ahlukeneyo okucutshungulwa okufana nokusika ucingo, ukugaya, ukugaya, ukugaya okulungileyo kunye nokupholisa, kwaye bafunde iziphumo zezi nkqubo kumgangatho ophezulu we-wafer.

Iziphumo zibonisa ukuba ngokuhambela phambili kwamanyathelo okulungisa, i-morphology yomhlaba kunye noburhabaxa be-wafer buphuculwa ngokuthe ngcembe. Emva kokupholisa, ubukhali be-C-face kunye ne-Si-face bufikelela kwi-0.24nm kunye ne-0.14nm ngokulandelanayo, ehlangabezana neemfuno zokukhula kwe-epitaxial. I-C-face ye-wafer inokuqina okungahambi kakuhle kune-Si-face material, kwaye ithanda kakhulu ukuphuka kwe-brittle ngexesha lokulungiswa, okukhokelela ku-morphology yomgangatho ophantsi kunye noburhabaxa. Ukususa umaleko womonakalo ongaphezulu wendawo esetyenzisiweyo sisitshixo sokuphucula umgangatho we-wafer. Ububanzi besiqingatha se-4H-SiC (0004) ijika eligungqileyo liyakwazi ukubonakalisa intuitively kwaye ngokuchanekileyo umaleko womonakalo ongaphezulu we-wafer.

Uphando lubonisa ukuba umaleko owonakalisiweyo kumphezulu we-4H-SiC wafers unokususwa ngokuthe ngcembe nge-4H-SiC wafer processing, ngokufanelekileyo ukuphucula umgangatho womhlaba we-wafer, ukubonelela ngereferensi yobugcisa ekusebenzeni okuphezulu, ilahleko ephantsi, kunye ne-high- ukulungiswa komgangatho we-4H-SiC substrate wafers.

Ixesha lokuposa: Jul-08-2024