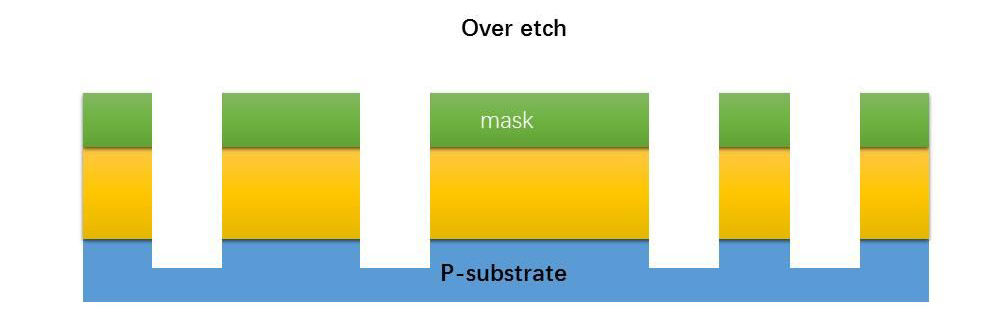

Inkqubo eyomileyo yokuhombisa idla ngokuba neendawo ezine ezisisiseko: phambi kokukrolwa, ukukrolwa ngokuyinxenye, ukukrolwa nje, kunye nokukrolwa ngaphezulu. Ezona mpawu ziphambili zizireyithi zokuchopha, ukukhetha, ubungakanani obubalulekileyo, ukufana, kunye nokubhaqwa kokuphela.

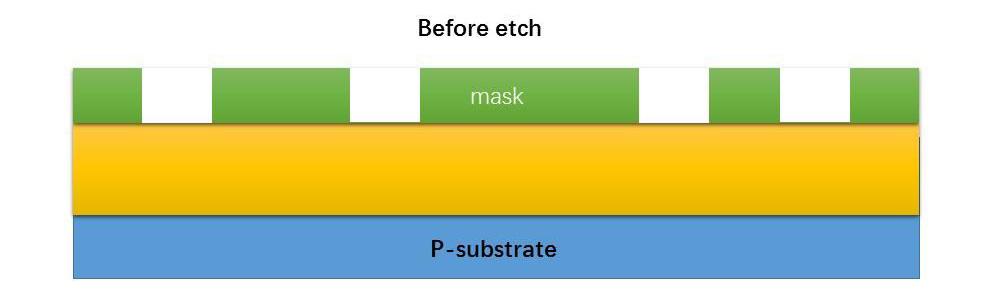

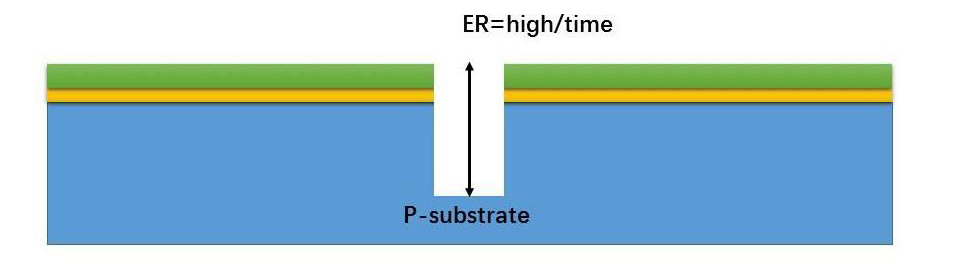

Umzobo 1 Phambi kokuchongwa

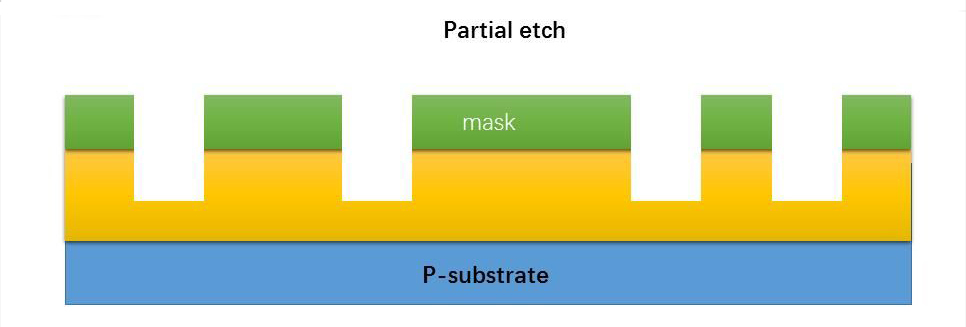

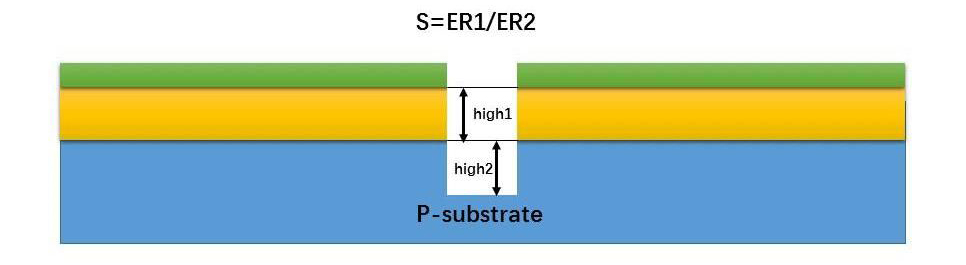

Umzobo 2 Ukufakwa ngokuyinxenye

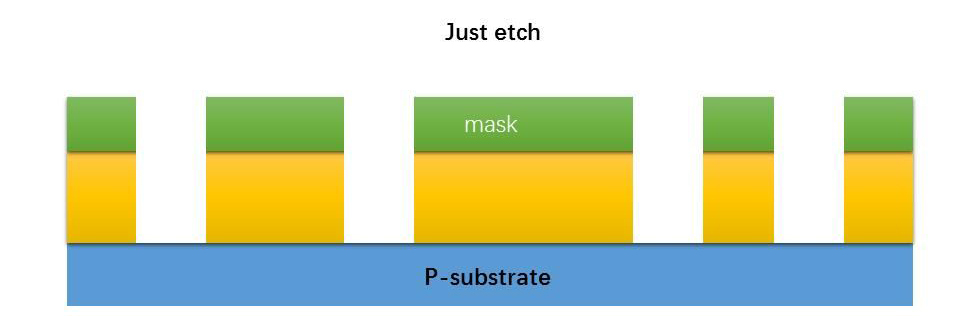

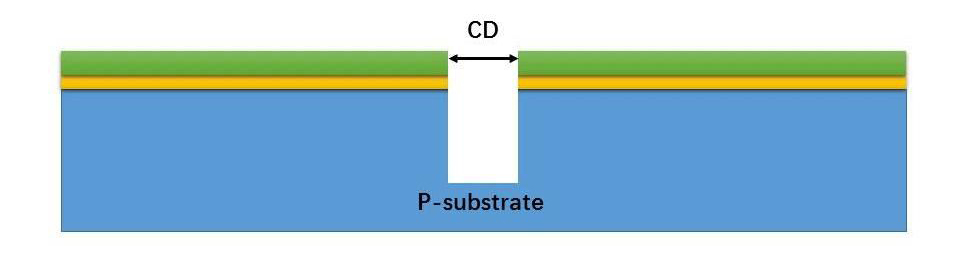

Umzobo 3 Ukukrola nje

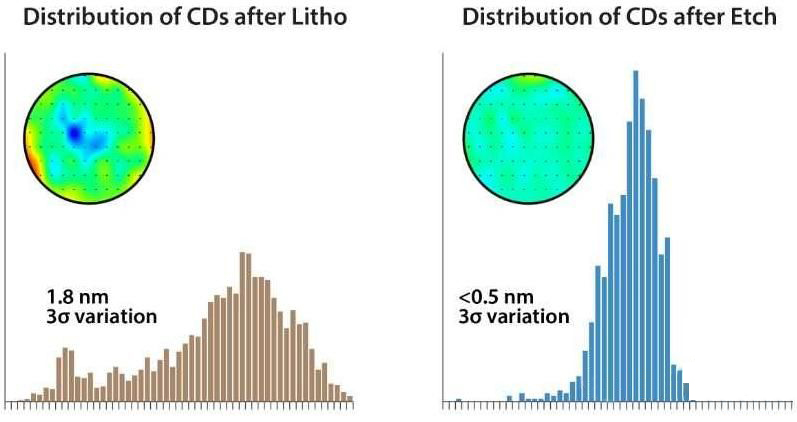

Umzobo 4 Ukuhombisa ngaphezulu

(1) Isantya sokuqhafaza: ubunzulu okanye ubukhulu bezinto ezifakiweyo ezisusiweyo ngexesha leyunithi.

Umzobo 5 Umzobo we-Etching rate diagram

2

Umzobo 6 Umzobo wokukhetha

(3) Umlinganiselo obalulekileyo: ubungakanani bepateni kwindawo ethile emva kokugqitywa kwe-etching.

Umzobo 7 Umzobo womlinganiselo obalulekileyo

(4) Ukulingana: ukulinganisa ukufana kwe-critical etching dimension (CD), ngokuqhelekileyo ibonakaliswe yimephu epheleleyo ye-CD, ifomula yile: U = (Max-Min) / 2 * AVG.

Umzobo we-8 Uniformity Schematic Diagram

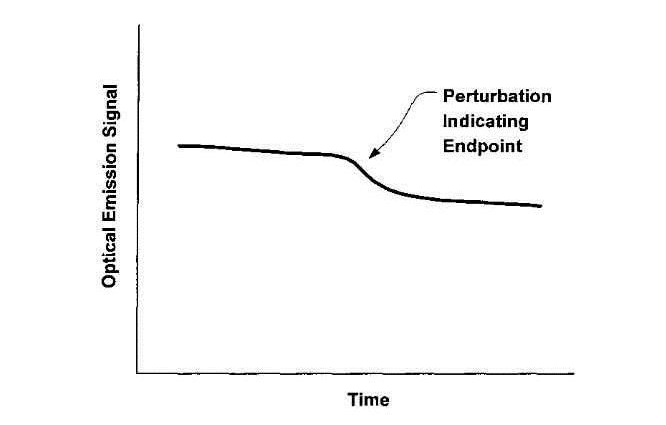

(5) Ukubona indawo yokuphela: Ngethuba lenkqubo yokubhala, utshintsho lokukhanya kokukhanya luhlala lubonwa. Xa ukukhanya okuthile kunyuka okanye kuhla ngokuphawulekayo, i-etching iyanqanyulwa ukuphawula ukugqitywa komgangatho othile wefilimu.

Isazobe 9 Isiphelo sedayagram yeskim

Kwi-etching eyomileyo, igesi ivuyiswa yi-frequency ephezulu (ikakhulukazi i-13.56 MHz okanye i-2.45 GHz). Kuxinzelelo lwe-1 ukuya kwi-100 Pa, indlela yayo ekhululekileyo iphakathi kweemilimitha ezininzi ukuya kwiisentimitha ezininzi. Kukho iintlobo ezintathu eziphambili zokuhombisa okomileyo:

•Etching ngokomzimba owomileyo: amasuntswana akhawulezayo anxiba ngokwasemzimbeni umphezulu we-wafer

•Chemical etching owomileyo: Irhasi iphendula ngokwekhemikhali kunye nomphezulu we-wafer

•Chemical ukomisa etching ngokomzimba: inkqubo yokubhala ngokomzimba kunye neempawu zeekhemikhali

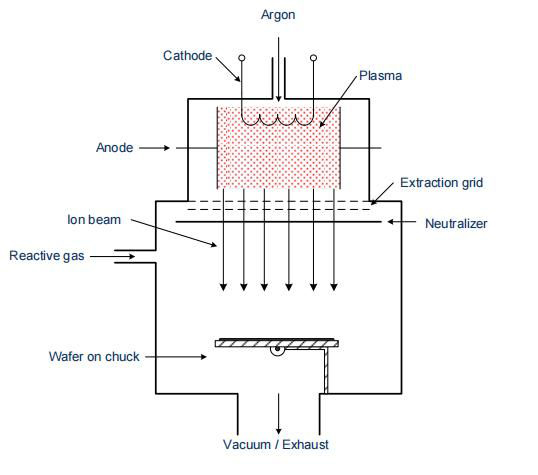

1. Ukukrolwa kwe-ion beam

Ion beam etching (Ion Beam Etching) yinkqubo eyomileyo yomzimba esebenzisa i-argon ion beam ephezulu yamandla ngamandla amalunga ne-1 ukuya kwi-3 keV ukukhupha umphezulu wezinto. Amandla e-ion beam abangela ukuba ichaphazele kwaye isuse izinto ezingaphezulu. Inkqubo ye-etching i-anisotropic kwimeko ye-ion beams ye-on ethe nkqo okanye e-oblique. Nangona kunjalo, ngenxa yokungabikho kokukhetha, akukho mahluko acacileyo phakathi kwezixhobo kumanqanaba ahlukeneyo. Iigesi eziveliswayo kunye nezinto ezidibeneyo ziphelile yimpompo yokucoca, kodwa ekubeni iimveliso zokuphendula azikho iigesi, iinqununu zifakwe kwi-wafer okanye iindonga zegumbi.

Ukuthintela ukubunjwa kweengqungquthela, igesi yesibini ingangeniswa kwigumbi. Le gesi iya kusabela kunye ne-argon ion kwaye ibangele inkqubo yokubhala ngokomzimba kunye neekhemikhali. Inxalenye yerhasi iya kusabela kunye nezinto ezingaphezulu, kodwa iya kuphinda iphendule ngamasuntswana aphucukileyo ukwenza i-gaseous byproducts. Phantse zonke iintlobo zemathiriyeli zinokubhalwa ngale ndlela. Ngenxa yemitha ethe nkqo, ukunxiba kwiindonga ezithe nkqo kuncinci kakhulu (i-anisotropy ephezulu). Nangona kunjalo, ngenxa yokukhethwa kwayo okuphantsi kunye nesantya sokucotha, le nkqubo ayifane isetyenziswe kwimveliso ye-semiconductor yangoku.

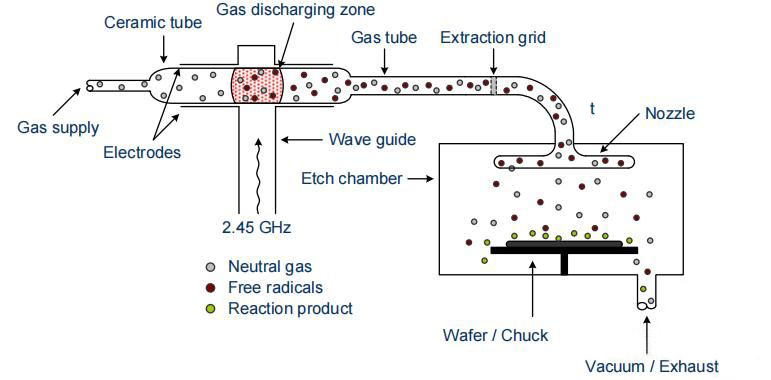

2. Ukufakwa kwePlasma

I-Plasma etching yinkqubo yokufakwa kweekhemikhali ngokupheleleyo, eyaziwa ngokuba yikhemikhali eyomileyo. Inzuzo yayo kukuba ayibangeli umonakalo we-ion kwi-wafer surface. Ekubeni iintlobo ezisebenzayo kwi-gas ye-etching zikhululekile ukuhamba kwaye inkqubo ye-etching is isotropic, le ndlela ifanelekile ukususa yonke ifilimu yefilimu (umzekelo, ukucoca icala elingasemva emva kwe-oxidation ye-thermal).

I-reactor esezantsi luhlobo lwe-reactor edla ngokusetyenziswa kwi-plasma etching. Kule reactor, i-plasma iveliswa yi-ionization yempembelelo kwintsimi yombane ye-high-frequency ye-2.45GHz kwaye ihlukaniswe kwi-wafer.

Kwindawo yokukhutshwa kwegesi, iinqununu ezahlukahlukeneyo zenziwa ngenxa yempembelelo kunye nokuvuselela, kuquka i-radicals yamahhala. I-radicals yamahhala i-athomu engathathi hlangothi okanye iiathomu ezinee-electron ezingaxutywanga, ngoko ke zisebenza kakhulu. Kwinkqubo ye-plasma etching, ezinye iigesi ezingathathi hlangothi, ezifana ne-tetrafluoromethane (CF4), zihlala zisetyenziswa, ezingeniswa kwindawo yokukhupha igesi ukuvelisa iintlobo ezisebenzayo nge-ionization okanye ukubola.

Ngokomzekelo, kwigesi ye-CF4, ifakwe kwindawo yokukhupha igesi kwaye ibole ibe yi-fluorine radicals (F) kunye ne-carbon difluoride molekyuli (CF2). Ngokufanayo, i-fluorine (F) inokubola kwi-CF4 ngokudibanisa i-oxygen (O2).

2 CF4 + O2 —> 2 COF2 + 2 F2

Imolekyuli yefluorine inokwahlulwa ibe ziiathom ezimbini ezizimeleyo zefluorine phantsi kwamandla ommandla wokukhupha irhasi, nganye apho iyi-fluorine radical free. Ekubeni i-athomu nganye ye-fluorine inee-electron ezisixhenxe ze-valence kwaye ithande ukufikelela kwi-electronic configuration ye-inert gas, zonke zisebenza kakhulu. Ukongeza kwi-radicals yamahhala ye-fluorine engathathi hlangothi, kuya kubakho iinqununu ezihlawuliswayo ezifana ne-CF + 4, CF + 3, CF + 2, njl njl kwindawo yokukhupha igesi. Emva koko, onke la masuntswana kunye neeradicals zasimahla zingeniswa kwigumbi lokutsala ngetyhubhu yeceramic.

Iinqununu ezihlawuliswayo zingavalwa ngokukhupha i-gratings okanye ziphinde zihlanganiswe kwinkqubo yokwenza iamolekyu ezingathathi hlangothi ukulawula ukuziphatha kwazo kwigumbi lokudibanisa. Iiradicals zasimahla zeFluorine nazo ziyakuphinda zidityaniswe ngokuyinxenye, kodwa zisasebenza ngokwaneleyo ukuba zingene kwigumbi lokuqhafaza, zisabela ngokwekhemikhali kumphezulu we-wafer kwaye zibangele ukuhlutywa kwezinto. Amanye amasuntswana angathathi hlangothi awathathi nxaxheba kwinkqubo yokubhala kwaye adliwe kunye neemveliso zokusabela.

Imizekelo yeefilimu ezibhityileyo ezinokuthi zifakwe kwi-plasma etching:

• I-Silicon: Si + 4F—> SiF4

• Isilicon dioxide: SiO2 + 4F—> SiF4 + O2

• I-Silicon nitride: Si3N4 + 12F—> 3SiF4 + 2N2

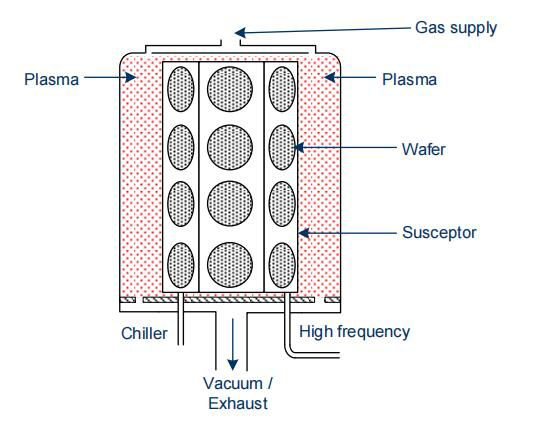

3.I-ion etching esebenzayo (RIE)

I-ion etching esebenzayo yinkqubo yekhemikhali ye-etching enokulawula ngokuchanekileyo ukukhethwa, iprofayili ye-etching, ireyithi ye-etching, ukufana kunye nokuphindaphinda. Inokufikelela kwiiprofayili ze-isotropic kunye ne-anisotropic etching kwaye ke yenye yezona nkqubo zibalulekileyo zokwakha iifilimu ezibhityileyo ezahlukeneyo kwimveliso ye-semiconductor.

Ngexesha le-RIE, i-wafer ifakwe kwi-electrode ephezulu-frequency (i-HF electrode). Ngokusebenzisa i-ionization yempembelelo, i-plasma yenziwa apho ii-electron zamahhala kunye neeoni ezihlawuliswa kakuhle zikhona. Ukuba i-voltage esebenzayo isetyenziswe kwi-electrode ye-HF, ii-electron zamahhala ziqokelela kwi-electrode surface kwaye azikwazi ukushiya i-electrode kwakhona ngenxa yobudlelwane be-electron. Ngoko ke, i-electrodes ihlawuliswa kwi--1000V (i-voltage ye-bias) ukwenzela ukuba i-ion ecothayo ingakwazi ukulandela intsimi yombane eguqukayo ngokukhawuleza kwi-electrode ehlawuliswa kakubi.

Ngexesha le-ion etching (RIE), ukuba indlela ekhululekileyo ye-ion iphezulu, ibetha umphezulu we-wafer kwicala eliphantse libe yi-perpendicular. Ngale ndlela, ii-ion ezikhawulezayo zikhupha izinto kwaye zenze ukusabela kweekhemikhali ngokufaka umzimba. Ekubeni i-sidewalls esecaleni ayichaphazeleki, iphrofayili ye-etch ihlala i-anisotropic kwaye i-surface wear incinci. Nangona kunjalo, ukhetho aluphezulu kakhulu ngenxa yokuba inkqubo ye-etching yomzimba iyenzeka. Ukongeza, ukukhawuleziswa kwee-ion kubangela umonakalo kwi-wafer surface, efuna i-thermal annealing ukulungisa.

Inxalenye yekhemikhali yenkqubo yokudibanisa igqitywe ngama-radicals amahhala asabela kunye nomphezulu kunye neeonini ezibethela izinto eziphathekayo ukuze zingaphindi zifake kwi-wafer okanye kwiindonga zegumbi, ukuphepha ukuphindaphinda kwesiganeko esifana ne-ion beam etching. Xa unyusa uxinzelelo lwegesi kwigumbi lokuqhafaza, intsingiselo yendlela yasimahla ye-ion iyancitshiswa, eyandisa inani lokungqubana phakathi kwe-ion kunye ne-athomu yegesi, kwaye i-ion ihlakazekile kwiindlela ezahlukeneyo. Oku kubangela ukuba i-etching encinci ye-directional, iyenze inkqubo ye-etching more chemical.

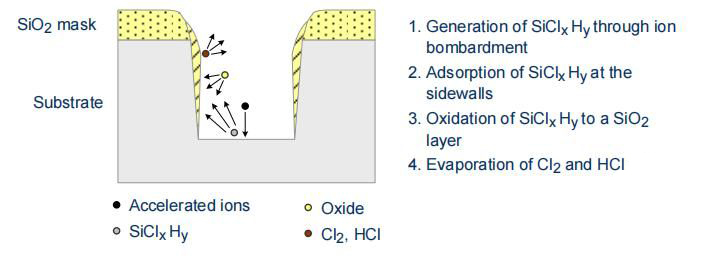

Iiprofayili ze-anisotropic etch zifezekiswa ngokudlula ama-sidewall ngexesha lokufakwa kwe-silicon. Ioksijini ingeniswa kwigumbi lokukrola, apho idibana nesilicon emisiweyo ukwenza isilicon dioxide, efakwa emacaleni asecaleni. Ngenxa yebhobho ye-ion, i-oxide layer kwiindawo ezithe tye iyasuswa, ivumela ukuba inkqubo ye-lateral etching iqhubeke. Le ndlela inokulawula imilo yeprofayili ye-etch kunye nokunyuka kwee-sidewalls.

Isantya se-etch sichatshazelwa zizinto ezinje ngoxinzelelo, amandla ejeneretha ye-HF, inkqubo yegesi, isantya sokuhamba kwerhasi eyiyo kunye nobushushu be-wafer, kunye noluhlu lwalo lokutshintsha lugcinwe ngaphantsi kwe-15%. I-Anisotropy iyanda ngokunyuka kwamandla e-HF, ukuncipha koxinzelelo kunye nokwehla kobushushu. Ukufana kwenkqubo ye-etching kunqunywe yigesi, isithuba se-electrode kunye nezinto ze-electrode. Ukuba umgama we-electrode uncinci kakhulu, i-plasma ayikwazi ukusabalalisa ngokulinganayo, okubangelwa ukungafani. Ukwandisa umgama we-electrode kunciphisa izinga lokubetha ngenxa yokuba i-plasma isasazwa kumthamo omkhulu. I-Carbon yinto ekhethwayo ye-electrode kuba ivelisa i-plasma edibeneyo efanayo ukwenzela ukuba umgca we-wafer uchaphazeleke ngendlela efanayo neziko le-wafer.

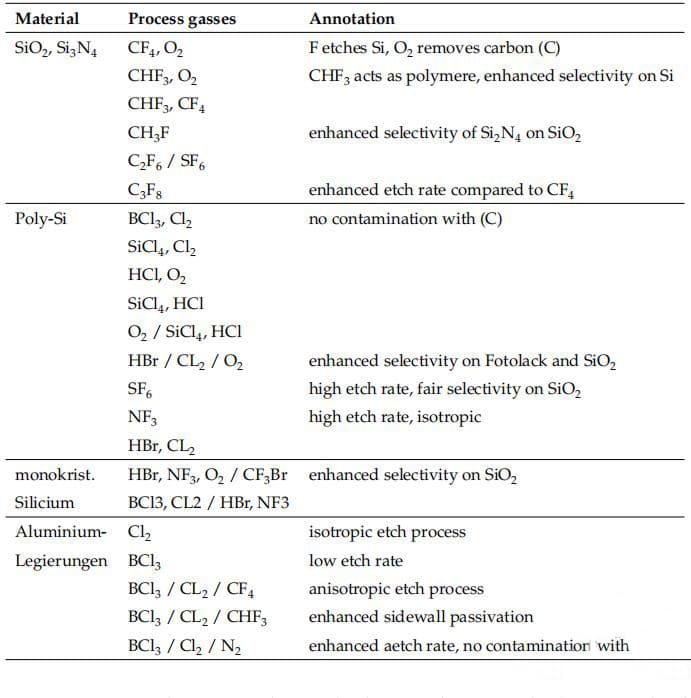

Igesi yenkqubo idlala indima ebalulekileyo ekukhetheni kunye nesantya se-etching. Kwi-silicon kunye neekhompawundi ze-silicon, i-fluorine kunye neklorini zisetyenziswa ikakhulu ukuphumeza ukufakwa. Ukukhetha igesi efanelekileyo, ukulungelelanisa ukuhamba kwegesi kunye noxinzelelo, kunye nokulawula ezinye iiparitha ezifana nobushushu kunye namandla kwinkqubo inokufikelela kwinqanaba elifunekayo le-etch, ukhetho, kunye nokufana. Ukulungiswa kwezi parameters ngokuqhelekileyo kuhlengahlengiswa kwizicelo ezahlukeneyo kunye nezixhobo.

Inkqubo ye-etching ayikhawulelwanga kwi-gas enye, umxube wegesi, okanye iiparamitha zenkqubo esisigxina. Ngokomzekelo, i-oxide yendalo kwi-polysilicon inokususwa kuqala ngezinga eliphezulu le-etch kunye nokukhetha okuphantsi, ngelixa i-polysilicon inokuthi ifakwe kamva kunye nokukhethwa okuphezulu ngokumalunga nemigangatho engaphantsi.

————————————————————————————————————————————————— ————————————

I-Semicera inokubonelelaiindawo zegraphite, uthambile/uqinile, iinxalenye ze-silicon carbide,CVD iinxalenye zesilicon carbide, kwayeIindawo ezigqunywe yiSiC/TaC nge 30 iintsuku.

Ukuba unomdla kwezi mveliso zesemiconductor zingasentla,nceda ungathandabuzi ukuqhagamshelana nathi okokuqala.

Umnxeba: +86-13373889683

Whatsap:+86-15957878134

Email: sales01@semi-cera.com

Ixesha lokuposa: Sep-12-2024