Kwimveliso ye-semiconductor, kukho ubuchule obubizwa ngokuba yi-"etching" ngexesha lokulungiswa kwe-substrate okanye ifilimu encinci eyenziwe kwi-substrate. Uphuhliso lwetekhnoloji ye-etching ludlale indima ekuqondeni uqikelelo olwenziwa ngumseki we-Intel uGordon Moore ngo-1965 ukuba "ukuxinana kokudibanisa kwee-transistors kuya kuphinda kabini kwi-1.5 ukuya kwi-2 iminyaka" (eyaziwa ngokuba ngu "Moore's Law").

I-Etching ayiyonkqubo "eyongezelelweyo" efana ne-deposition okanye i-bonding, kodwa yinkqubo "yokuthabatha". Ukongezelela, ngokweendlela ezahlukeneyo zokukrazula, ihlulwe ibe ngamacandelo amabini, oko kukuthi "i-wet etching" kunye "ne-dry etching". Ukuyibeka ngokulula, eyokuqala yindlela yokunyibilika kwaye le yokugqibela yindlela yokumba.

Kule nqaku, siza kuchaza ngokufutshane iimpawu kunye nokwahluka kweteknoloji nganye ye-etching, i-etching emanzi kunye ne-etching eyomileyo, kunye neendawo zesicelo apho ngamnye ufanelekile.

Isishwankathelo senkqubo yokubhala

Itekhnoloji ye-Etching kuthiwa yaqala eYurophu phakathi kwinkulungwane ye-15. Ngelo xesha, iasidi yayigalelwa kwipleyiti yobhedu ekroliweyo ukuze idle ubhedu olungenanto, yenze i-intaglio. Ubuchule bonyango obuphezulu obusebenzisa iziphumo zokubola zaziwa ngokubanzi njenge "etching."

Injongo yenkqubo ye-etching kwi-semiconductor yokuvelisa ukusika i-substrate okanye ifilimu kwi-substrate ngokomzobo. Ngokuphinda amanyathelo okulungiselela ukubunjwa kwefilimu, i-photolithography, kunye ne-etching, isakhiwo seplani sicutshungulwa kwisakhiwo sesithathu-dimensional.

Umahluko phakathi kwe-etching emanzi kunye ne-etching eyomileyo

Emva kwenkqubo ye-photolithography, i-substrate evezwayo imanzi okanye yomile ifakwe kwinkqubo yokubhala.

Ukuchongwa okumanzi kusebenzisa isisombululo ukukrola kunye nokukhuhla umphezulu. Nangona le ndlela inokuqwalaselwa ngokukhawuleza kwaye ngexabiso eliphantsi, ukusilela kwayo kukuba ukuchaneka kokulungiswa kusezantsi kancinci. Ke ngoko, i-etching eyomileyo yazalwa malunga no-1970. I-etching eyomileyo ayisebenzisi isisombululo, kodwa isebenzisa igesi ukubetha i-substrate surface ukuyikrwempa, ebonakala ngokuchaneka okuphezulu.

"Isotropy" kunye "neAnisotropy"

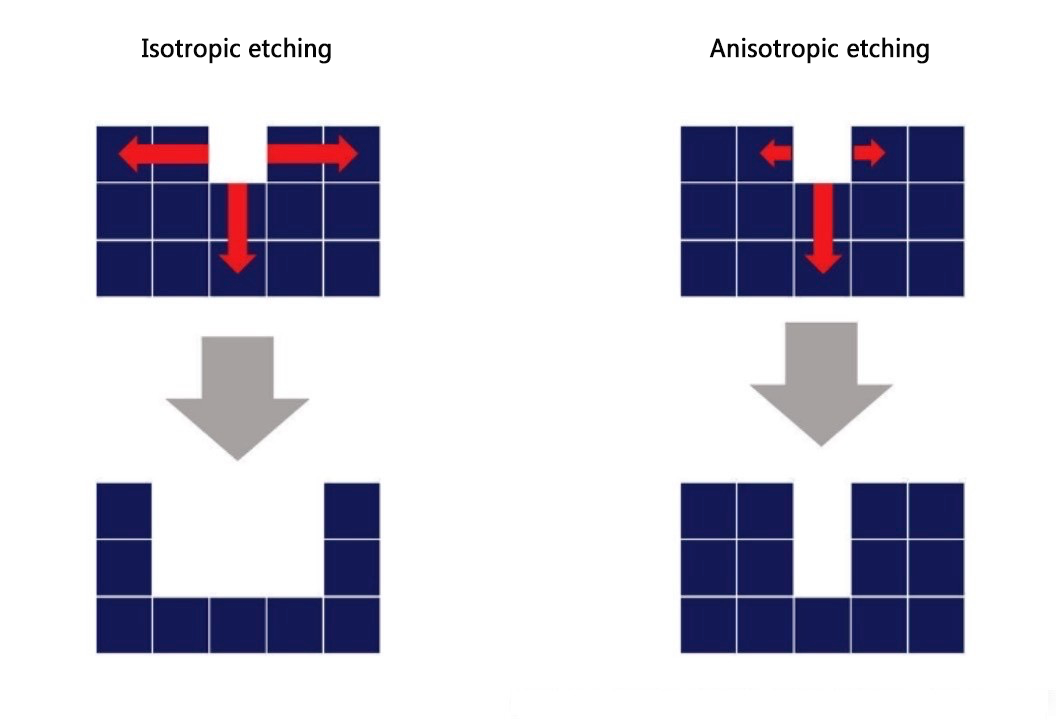

Xa uzisa umahluko phakathi kwe-etching emanzi kunye ne-etching eyomileyo, amagama abalulekileyo "isotropic" kunye ne "anisotropic". I-Isotropy ithetha ukuba iipropathi ezibonakalayo ze-matter kunye nendawo aziguquki ngesikhokelo, kwaye i-anisotropy ithetha ukuba iimpawu ezibonakalayo ze-matter kunye nendawo ziyahluka ngokwalathiso.

I-Isotropic etching ithetha ukuba i-etching iqhubeka ngexabiso elifanayo malunga nendawo ethile, kwaye i-anisotropic etching ithetha ukuba ukuthungwa kuqhubeka kumacala ahlukeneyo malunga nendawo ethile. Umzekelo, kwi-etching ngexesha lokwenziwa kwe-semiconductor, i-anisotropic etching ihlala ikhethwa ukuze kuphela i-directional ekujoliswe kuyo ikhutshiwe, ishiya enye indlela.

Imifanekiso ye "Isotropic Etch" kunye ne "Anisotropic Etch"

Imifanekiso ye "Isotropic Etch" kunye ne "Anisotropic Etch"

Ukucheba okumanzi usebenzisa imichiza.

Ukuchongwa okumanzi kusebenzisa ukusabela kweekhemikhali phakathi kwekhemikhali kunye ne-substrate. Ngale ndlela, i-anisotropic etching ayinakwenzeka, kodwa inzima kakhulu kune-isotropic etching. Kukho izithintelo ezininzi kwindibaniselwano yezisombululo kunye nezixhobo, kunye neemeko ezinje ngeqondo lobushushu le-substrate, ukugxininiswa kwesisombululo, kunye nesixa esongezelelweyo kufuneka silawulwe ngokungqongqo.

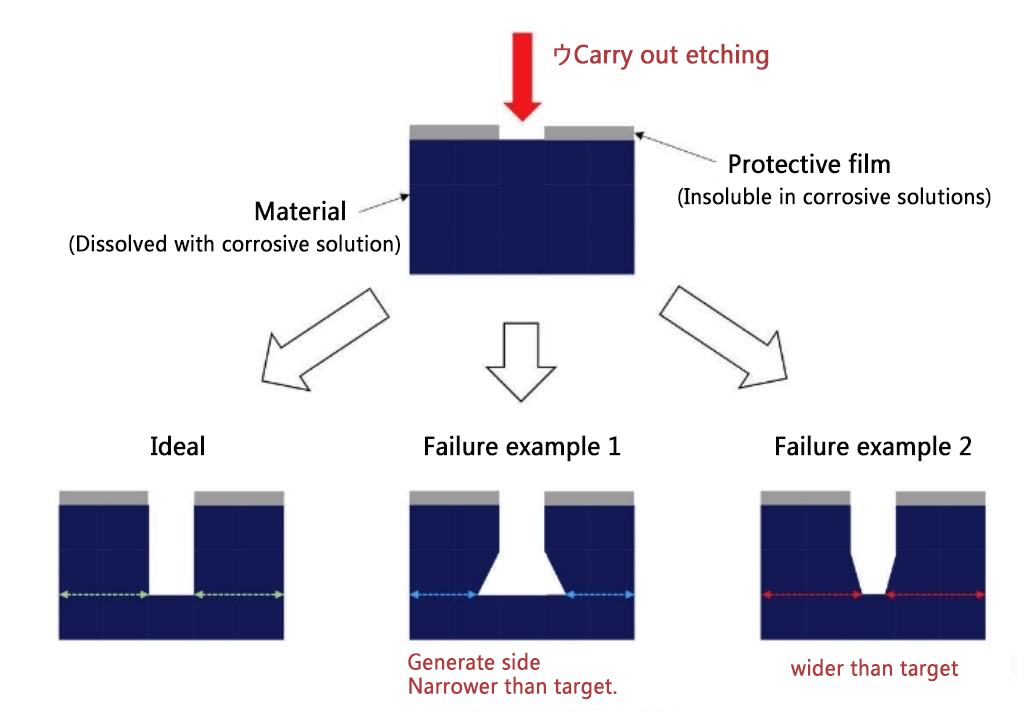

Kungakhathaliseki ukuba iimeko zilungelelaniswe kakuhle kangakanani, ukufakwa okumanzi kunzima ukufezekisa ukulungiswa kakuhle ngaphantsi kwe-1 μm. Esinye isizathu soku yimfuneko yokulawula ukuchetywa kwecala.

Ukusika ngaphantsi yinto eyaziwa ngokuba yi-undercutting. Nokuba kunethemba lokuba izinto ziya kunyibilika kuphela kwicala elithe nkqo (ulwalathiso olunzulu) ngokufakwa okumanzi, akunakwenzeka ukuthintela ngokupheleleyo isisombululo ekubetheni amacala, ngoko ke ukuchithwa kwezinto ngendlela efanayo kuya kuqhubekeka. . Ngenxa yesi siganeko, ukuthungwa okumanzi ngokungaqhelekanga kuvelisa amacandelo amancinci kunobubanzi obujoliswe kuyo. Ngale ndlela, xa kusetyenzwa iimveliso ezifuna ulawulo oluchanekileyo lwangoku, ukuveliswa kwakhona kuphantsi kwaye ukuchaneka akuthembeki.

Imizekelo yokusilela okunokwenzeka kwi-Wet Etching

Imizekelo yokusilela okunokwenzeka kwi-Wet Etching

Kutheni i-etching eyomileyo ifanelekile kwi-micromachining

Inkcazo ye-Related Art Dry etching efanelekileyo kwi-anisotropic etching isetyenziswe kwiinkqubo zokuvelisa ze-semiconductor ezifuna ukucocwa okuphezulu. I-etching eyomileyo idla ngokubizwa ngokuba yi-reactive ion etching (RIE), enokuthi iquke i-plasma etching kunye ne-sputter etching ngendlela ebanzi, kodwa eli nqaku liza kugxila kwi-RIE.

Ukucacisa ukuba kutheni i-anisotropic etching ilula ngokukrola okomileyo, makhe sijonge ngakumbi inkqubo yeRIE. Kulula ukuyiqonda ngokwahlula inkqubo yokukrola okomileyo kunye nokukrazula i-substrate ibe ziindidi ezimbini: "ikhemikhali ye-chemical etching" kunye "ne-physical etching".

Ukufakwa kweekhemikhali kwenzeka ngamanyathelo amathathu. Okokuqala, iigesi ezisebenzayo zibhengezwa kumphezulu. Iimveliso zokusabela zenziwa ukusuka kwi-reaction gas kunye ne-substrate material, kwaye ekugqibeleni iimveliso zokusabela zichithwa. Kwi-etching yomzimba elandelayo, i-substrate ifakwe ngokuthe nkqo ezantsi ngokufaka igesi ye-argon ngokuthe nkqo kwi-substrate.

Ukufakwa kweekhemikhali kwenzeka ngokwe-isotropically, ngelixa ukufakwa ngokwasemzimbeni kunokuthi kwenzeke nge-anisotropically ngokulawula icala lokusetyenziswa kwerhasi. Ngenxa yolu gcino lomzimba, ukomisa okomileyo kuvumela ulawulo olungaphezulu kwisalathiso se-etching kune-etching emanzi.

I-etching eyomileyo kunye nemanzi nayo ifuna iimeko ezingqongqo ezifanayo njenge-etching emanzi, kodwa inokuphindaphinda okuphezulu kunokonakalisa okumanzi kwaye inezinto ezininzi ekulula ukuzilawula. Ke ngoko, akukho mathandabuzo ukuba ukomisa okomileyo kuluncedo ngakumbi kwimveliso yamashishini.

Kutheni i-Wet Etching isafuneka

Nje ukuba uqonde i-etching ebonakala inamandla onke, unokuzibuza ukuba kutheni i-etching emanzi isekhona. Nangona kunjalo, isizathu silula: i-etching emanzi yenza imveliso ingabizi kakhulu.

Umahluko omkhulu phakathi kwe-etching eyomileyo kunye ne-etching emanzi yindleko. Iikhemikhali ezisetyenziswa kwi-etching emanzi azibizi kangako, kwaye ixabiso lesixhobo ngokwalo kuthiwa limalunga ne-1/10 yezixhobo zokuhombisa ezomileyo. Ukongezelela, ixesha lokucubungula lifutshane kwaye i-substrates ezininzi zinokucutshungulwa ngexesha elifanayo, ukunciphisa iindleko zokuvelisa. Ngenxa yoko, sinokugcina iindleko zemveliso ziphantsi, zisinika inzuzo ngaphezu kwabakhuphisana nabo. Ukuba iimfuno zokuchaneka kokusetyenzwa azikho phezulu, iinkampani ezininzi ziya kukhetha i-etching emanzi kwimveliso yobunzima.

Inkqubo ye-etching yaziswa njengenkqubo edlala indima kwi-teknoloji ye-microfabrication. Inkqubo etching yahlulahlulwe ngokurhabaxa ibe etching emanzi kunye ne-etching eyomileyo. Ukuba iindleko zibalulekile, yangaphambili ingcono, kwaye ukuba i-microprocessing engaphantsi kwe-1 μm iyadingeka, le yokugqibela ingcono. Ngokufanelekileyo, inkqubo inokukhethwa ngokusekelwe kwimveliso eza kuveliswa kunye neendleko, kunokuba yintoni enye engcono.

Ixesha lokuposa: Apr-16-2024