Ezona zizathu zichaphazela ukufana kwe-radial resistivity yeekristale enye kukuthambeka kojongano olululwelo oluqinileyo kunye nefuthe lendiza encinci ngexesha lokukhula kwekristale.

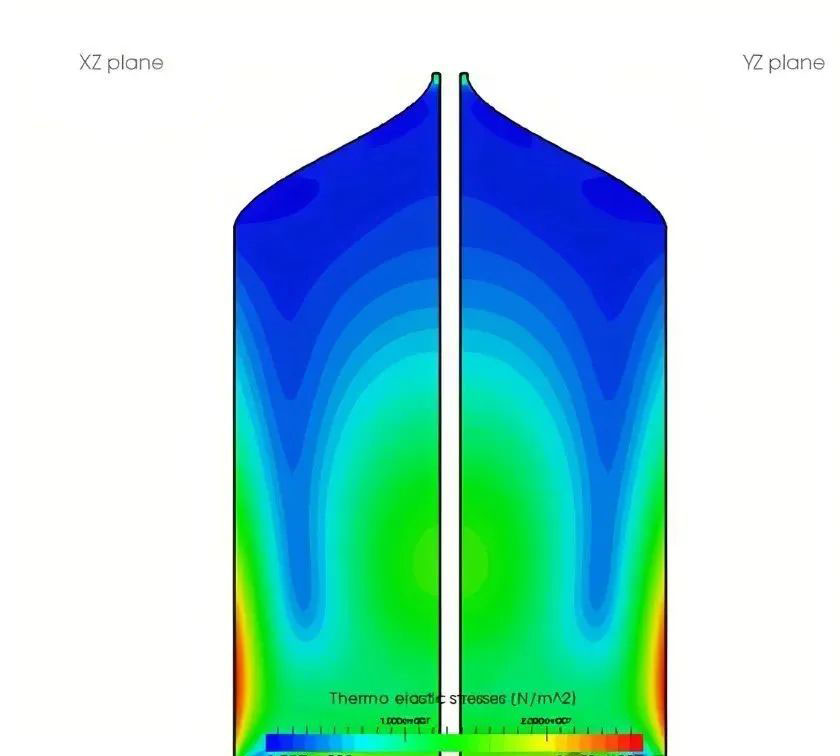

Impembelelo ye-flatness ye-solid-liquid interface Ngexesha lokukhula kwekristale, ukuba inyibilika ishukunyiswa ngokulinganayo, umgangatho wokumelana olinganayo ujongano oluqinileyo-olwelwelo (i-concentration yokungcola kwi-melting yahlukile kwi-crystal concentration, ngoko ke ukuxhathisa kwahlukile, kwaye ukuxhathisa kuyalingana kuphela kwi-interface eqinileyo-emanzi). Xa ukungcola K<1, i-interface convex kwi-melt iya kubangela ukuba i-resistivity ye-radial ibe phezulu embindini kwaye iphantsi emphethweni, ngelixa i-interface concave kwi-melt ichasene. I-radial resistivity uniformity yojongano olusicaba olululwelo lungcono. Ubume be-solid-liquid interface ngexesha lokutsalwa kwe-crystal kuchongwa zizinto ezifana nokusabalalisa intsimi ye-thermal kunye ne-crystal growth parameters yokusebenza. Kwi-crystal edibeneyo edibeneyo, imilo ye-slid-liquid surface iyisiphumo sesiphumo esidibeneyo sezinto ezifana nokusabalalisa ukushisa kwesithando somlilo kunye nokutshatyalaliswa kokushisa kwe-crystal.

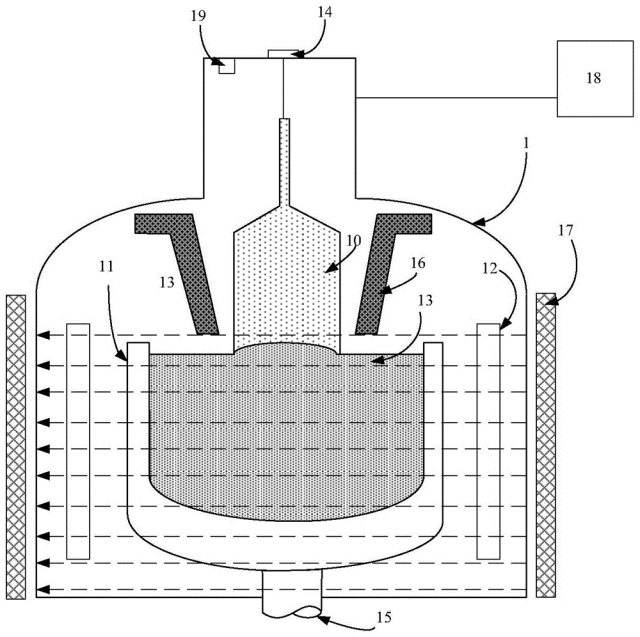

Xa utsala iikristale, kukho iindidi ezine eziphambili zokutshintshiselana kobushushu kumdibaniso oqinileyo wolwelo:

▪ Ubushushu obufihlakeleyo bokutshintsha kwesigaba bukhutshwa kukuqiniswa kwesilicon etyhidiweyo

▪ Ukuqhutywa kobushushu bokunyibilika

Ubushushu bunyuke ngekristale

▪ Ubushushu bemitha buphuma ngaphandle ngekristale

Ubushushu obufihliweyo bufana ne-interface yonke, kwaye ubungakanani bayo abutshintshi xa izinga lokukhula lihlala lihlala. (Ukuqhuba ubushushu okukhawulezayo, ukupholisa ngokukhawuleza, kunye nesantya esongeziweyo sokuqina)

Xa intloko yekristale ekhulayo ikufutshane nentonga yekristale epholileyo yamanzi yesithando somlilo sekristale enye, iqondo lobushushu kwikristale likhulu, nto leyo eyenza ukuba ukuqhutywa kobushushu bekristale kube kukhulu kunobushushu bomhlaba, ngoko ke ujongano oluqinileyo-olwelo olujikekileyo ukuya kwinyibilika.

Xa ikristale ikhula ukuya embindini, i-longitudinal heat conduction ilingana nobushushu obuphezulu bemitha, ngoko ke ujongano luthe tye.

Emsileni wekristale, ukuqhutywa kobushushu bexesha elide kungaphantsi kobushushu obuphezulu bemitha, okwenza ujongano olululwelo oluqinileyo lujike lunyibilike.

Ukuze ufumane i-crystal enye kunye ne-resistivity ye-radial efanayo, i-solid-liquid interface kufuneka iphakanyiswe.

Iindlela ezisetyenziswayo zezi:

①Lungisa inkqubo ye-crystal yokukhula kwe-thermal ukunciphisa i-radial yeqondo lokushisa kwintsimi ye-thermal.

②Lungisa iiparamitha zokusebenza zokutsalwa kwekristale. Umzekelo, kwi-convex yojongano ukuya kwinyibilika, yongeza isantya sokutsala ukunyusa izinga lokuqina kwekristale. Ngeli xesha, ngenxa yokwanda kwe-crystallization latent heat ekhutshwe kwi-interface, iqondo lokushisa lokunyibilika kufuphi ne-interface liyenyuka, okukhokelela ekunyibilikeni kwenxalenye yekristale kwi-interface, okwenza ujongano lube tyaba. Ngokuchasene noko, ukuba i-interface yokukhula i-concave ukuya kwi-melt, isantya sokukhula sinokuncitshiswa, kwaye inyibilika iya kuqinisa umthamo ohambelanayo, okwenza ujongano lokukhula lube flat.

③ Lungisa isantya sokujikeleza kwekristale okanye i-crucible. Ukwandisa isantya sokujikeleza kwekristale kuya kwandisa ukuhamba kwamanzi obushushu obuphezulu ukusuka ezantsi ukuya phezulu kujongano oluqinileyo olumanzi, okwenza ujongano lutshintshe ukusuka kwiconvex ukuya kwiconcave. Isalathiso sokuhamba kwamanzi okubangelwa ukujikeleza kwe-crucible kufana ne-convection yendalo, kwaye umphumo uchasene ngokupheleleyo ne-crystal rotation.

④ Ukwandisa umlinganiselo we-diameter yangaphakathi ye-crucible ukuya kububanzi be-crystal kuya kuthoba i-interface e-slid-liquid, kwaye kunokunciphisa ukuxinana kwe-dislocation kunye nomxholo we-oksijini kwi-crystal. Ngokuqhelekileyo, i-diameter ye-crucible: ububanzi be-crystal = 3 ~ 2.5: 1.

Impembelelo yempembelelo yendiza encinci

Ujongano oluqinileyo-ulwelo lokukhula kwekristale luhlala lugobile ngenxa yokuthintelwa kwe-isotherm enyibilikayo kwi-crucible. Ukuba ikristale iphakanyiswe ngokukhawuleza ngexesha lokukhula kwekristale, inqwelomoya encinci ethe tyaba iya kuvela kwindawo eqinileyo yolwelo lwe (111) yegermanium kunye nesilicon iikristale enye. Yi (111) inqwelomoya evaleleke ngeathom, edla ngokubizwa ngokuba yinqwelomoya encinci.

Ukugxininiswa kokungcola kwindawo encinci yendiza ihluke kakhulu kwindawo engeyincinci yendiza. Lo mcimbi wokusasazwa okungaqhelekanga kokungcola kwindawo yenqwelomoya encinci ibizwa ngokuba yimpembelelo yendiza encinci.

Ngenxa yempembelelo encinci yendiza, ukuxhatshazwa kwendawo encinci yendiza kuya kuncipha, kwaye kwiimeko ezinzima, iinqununu zepayipi ezingcolileyo ziya kubonakala. Ukuze kupheliswe i-radial resistivity inhomogeneity ebangelwa yimpembelelo yendiza encinci, ujongano oluqinileyo olumanzi kufuneka lubekwe kwinqanaba.

Wamkelekile nabaphi na abathengi abavela kwihlabathi liphela ukuba basindwendwele kwingxoxo eyongezelelekileyo!

https://www.semi-cera.com/

https://www.semi-cera.com/tac-coating-monocrystal-growth-parts/

https://www.semi-cera.com/cvd-coating/

Ixesha lokuposa: Jul-24-2024