Kwinkqubo yokwenziwa kwesemiconductor,etchingiteknoloji yinkqubo ebalulekileyo esetyenziselwa ukususa ngokuchanekileyo izinto ezingafunekiyo kwi-substrate ukwenza iipatheni zesekethe eziyinkimbinkimbi. Eli nqaku liza kwazisa itekhnoloji ezimbini eziphambili zokudibanisa ngokweenkcukacha - ukudibanisa i-plasma etching (CCP) kunye ne-inductively ye-plasma etching (I-ICP), kwaye baphonononge izicelo zabo ekufakeni izixhobo ezahlukeneyo.

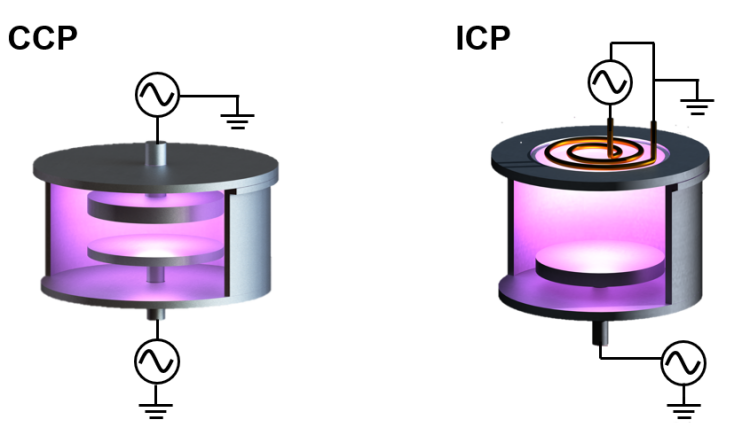

Ugcino lweplasma oludityanisiweyo ngokufanelekileyo (CCP)

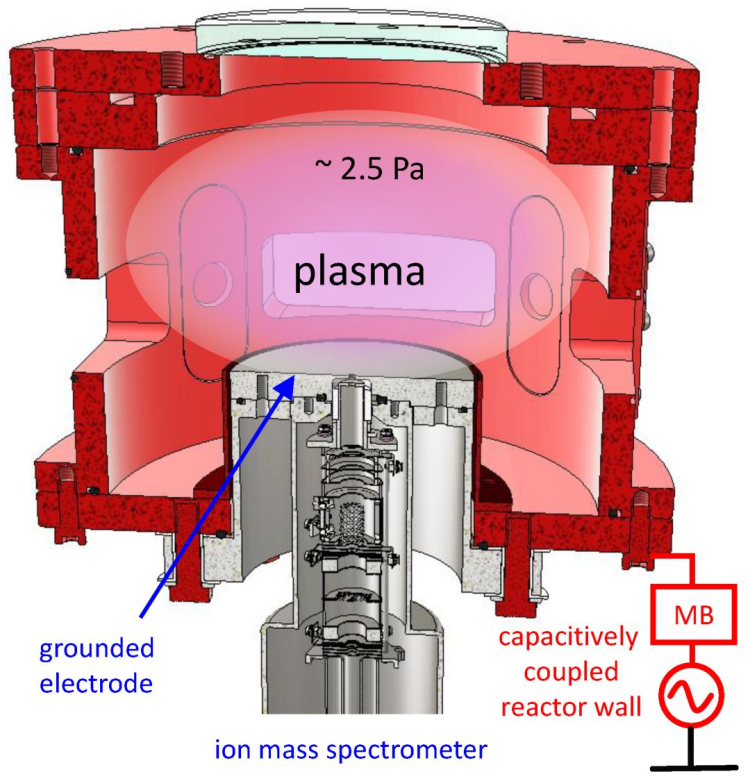

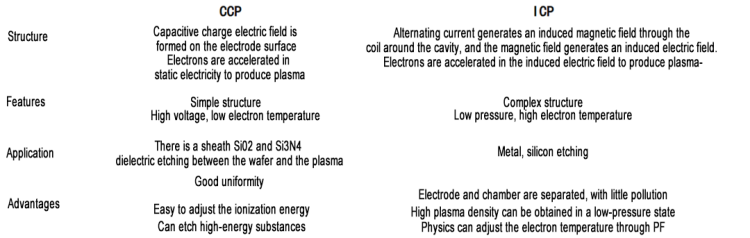

I-Capacitively diced plasma etching (CCP) iphunyezwa ngokusebenzisa amandla ombane e-RF kwiielectrode zeepleyiti ezimbini ezinxuseneyo ngematcher kunye ne-DC blocking capacitor. I-electrode ezimbini kunye neplasma kunye zenza i-capacitor elinganayo. Kule nkqubo, i-voltage ye-RF yenza i-capacitive sheath kufuphi ne-electrode, kwaye umda we-sheath uyatshintsha kunye ne-oscillation ekhawulezayo yombane. Xa ii-electron zifikelela kule sheath eguqukayo ngokukhawuleza, zibonakaliswa kwaye zifumana amandla, nto leyo ebangela ukuhlukana okanye i-ionization yeemolekyuli zegesi ukuba zenze i-plasma. I-CCP etching idla ngokusetyenziswa kwizixhobo ezinamandla okudibanisa iikhemikhali eziphezulu, ezifana ne-dielectrics, kodwa ngenxa yezinga layo elisezantsi lokulinganisa, ifanelekile kwizicelo ezifuna ulawulo oluhle.

I-inductively edityaniswe kwi-plasma etching (ICP)

I-Plasma edityaniswe ngokunyanisekileyoetching(ICP) isekelwe kumgaqo wokuba i-alternating current idlula kwi-coil ukuvelisa i-magnetic field. Ngaphantsi kwesenzo salo mhlaba wamagnetic, ii-electron ezikwigumbi lokuphendula ziyakhawuleza kwaye ziqhubeke zihamba ngokukhawuleza kwintsimi yombane, ekugqibeleni zingqubuzana neemolekyuli zegesi ezisabelayo, ezibangela ukuba iimolekyuli zidibanise okanye i-ionize kwaye zenze iplasma. Le ndlela inokuvelisa izinga eliphezulu le-ionization kwaye ivumele ukuxinana kweplasma kunye namandla ebhomu ukuba ahlengahlengiswe ngokuzimeleyo, okwenzaUkufakwa kwe-ICPifaneleke kakhulu kwizixhobo zokurhweba ezinamandla aphantsi ekhemikhali, njengesilicon kunye nentsimbi. Ukongeza, itekhnoloji ye-ICP ikwabonelela ngokufana okungcono kunye nesantya sokulinganisa.

1. Ukukrolwa kwentsimbi

I-Metal etching isetyenziselwa ukusetyenzwa koqhagamshelo kunye ne-multi-layer metal wiring. Iimfuno zayo zibandakanya: izinga eliphezulu lokuchopha, ukukhetha okuphezulu (ngaphezulu kwe-4: 1 yomaleko wemaski kunye nongaphezulu kwe-20: 1 ye-dielectric ye-interlayer), ukufana okuphezulu, ukulawulwa komgangatho obalulekileyo, akukho monakalo weplasma, ungcoliseko oluncinci, kunye akukho mhlwa kwisinyithi. Ukufakwa kwentsimbi ngokuqhelekileyo kusebenzisa izixhobo zokukrola zeplasma ezidityanisiweyo.

•I-Aluminiyam etching: I-Aluminiyam yeyona nto ibaluleke kakhulu kwi-wire kunye nenqanaba lokwenziwa kwe-chip, kunye neenzuzo zokuxhathisa okuphantsi, ukubeka lula kunye nokubethelwa. Ukufakwa kweAluminiyam ngokuqhelekileyo kusebenzisa iplasma eyenziwe yigesi yekloride (efana neCl2). I-aluminiyam idibana neklorini ukuze ivelise i-aluminiyam chloride eguquguqukayo (AlCl3). Ukongeza, ezinye i-halides ezifana ne-SiCl4, BCl3, BBr3, CCl4, CHF3, njl.

• Ukuqhotyoshwa kweTungsten: Kwizakhiwo zoqhagamshelo lwentsimbi yesinyithi enamaleko amaninzi, i-tungsten sesona sinyithi sisetyenziswa kuqhagamshelo oluphakathi lwetshiphu. I-fluorine-based based or chlorine-based gases ingasetyenziselwa ukufaka i-tungsten yensimbi, kodwa iigesi ezisekelwe kwi-fluorine zinokukhetha okungahambi kakuhle kwe-silicon oxide, ngelixa iigesi ezisekelwe kwi-chlorine (ezifana ne-CCl4) zinokukhetha okungcono. I-nitrojeni idla ngokudityaniswa kwigesi yokusabela ukufumana i-high etching glue selectivity, kunye neoksijini yongezwa ukunciphisa ukubekwa kwekhabhoni. Ukufaka i-tungsten ngegesi esekwe kwiklorine kunokufezekisa i-anisotropic etching kunye nokukhetha okuphezulu. Iigesi ezisetyenziswa kwi-etching eyomileyo ye-tungsten ikakhulu yi-SF6, i-Ar kunye ne-O2, phakathi kwayo i-SF6 inokuboliswa kwi-plasma ukuze ibonelele ngeeathom zefluorine kunye ne-tungsten yokusabela kweekhemikhali ukuvelisa i-fluoride.

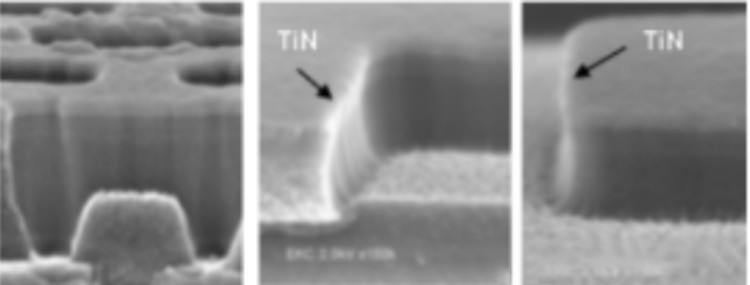

• I-Titanium nitride etching: I-Titanium nitride, njengesixhobo semaski esiqinileyo, ithatha indawo ye-silicon nitride yesiqhelo okanye imaski ye-oxide kwinkqubo emibini yedamascene. I-Titanium nitride etching isetyenziswa ikakhulu kwinkqubo yokuvula imaski enzima, kwaye eyona mveliso yokusabela yi-TiCl4. Ukukhethwa phakathi kwe-mask yendabuko kunye ne-low-k ye-dielectric layer ayikho phezulu, okuya kukhokelela ekubonakaleni kweprofayili ye-arc-shape kwi-top of the low-k-dielectric layer kunye nokwandiswa kobubanzi begroove emva kokuqhawula. Isithuba phakathi kwemigca yentsimbi ediphozithiweyo sincinci kakhulu, ethanda ukuvuza ibhulorho okanye ukonakaliswa ngokuthe ngqo.

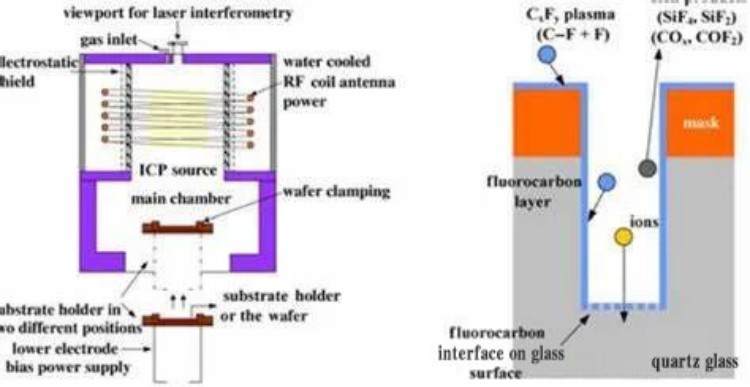

2. I-insulator etching

Into ye-insulator etching idla ngokuba yi-dielectric materials ezifana nesilicon dioxide okanye i-silicon nitride, ezisetyenziswa ngokubanzi ukwenza imingxunya yoqhagamshelwano kunye nemingxuma yesijelo ukudibanisa iileya zesekethe ezahlukeneyo. I-Dielectric etching ihlala isebenzisa i-etcher esekwe kumgaqo-nkqubo wokudibanisa i-plasma etching.

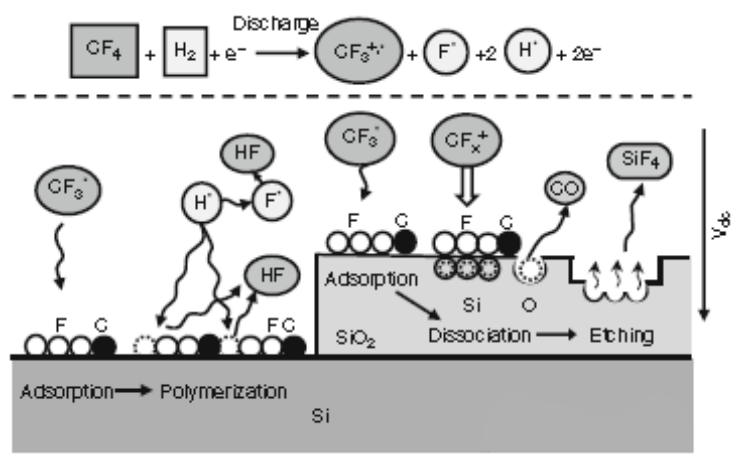

• Ukufakwa kwi-Plasma yefilimu yesilicon dioxide: Ifilim ye-silicon dioxide ikholisa ukumiswa kusetyenziswa iigesi ezifakwayo ezinefluorine, ezifana neCF4, CHF3, C2F6, SF6 kunye neC3F8. Ikhabhoni equlethwe kwirhasi ye-etching inokusabela ngeoksijini ekwi-oxide layer ukuvelisa i-byproducts CO kunye ne-CO2, ngaloo ndlela isusa ioksijini kucwecwe lwe-oxide. I-CF4 yeyona gesi isetyenziswa kakhulu etching. Xa i-CF4 ingqubana nee-electron zamandla aphezulu, ii-ion ezahlukeneyo, iiradicals, iiathom kunye neeradicals zasimahla ziveliswa. I-Fluorine i-radicals yamahhala inokusabela ngokwekhemikhali kunye ne-SiO2 kunye ne-Si ukuvelisa i-silicon eguqukayo ye-tetrafluoride (SiF4).

• Ukufakwa kwi-Plasma yefilimu ye-silicon nitride: Ifilimu ye-Silicon nitride inokufakwa kusetyenziswa i-plasma etching nge-CF4 okanye i-CF4 yegesi exubeneyo (nge-O2, SF6 kunye ne-NF3). Kwifilimu ye-Si3N4, xa i-plasma ye-CF4-O2 okanye enye i-plasma yegesi equkethe i-athomu ye-F isetyenziselwa ukukhangela, izinga lokulinganisa i-silicon nitride linokufikelela kwi-1200Å / min, kwaye i-etching selectivity ingaba phezulu njenge-20: 1. Eyona mveliso iguquguqukayo yesilicon tetrafluoride (SiF4) ekulula ukuyikhupha.

3. I-crystal crystal etching enye

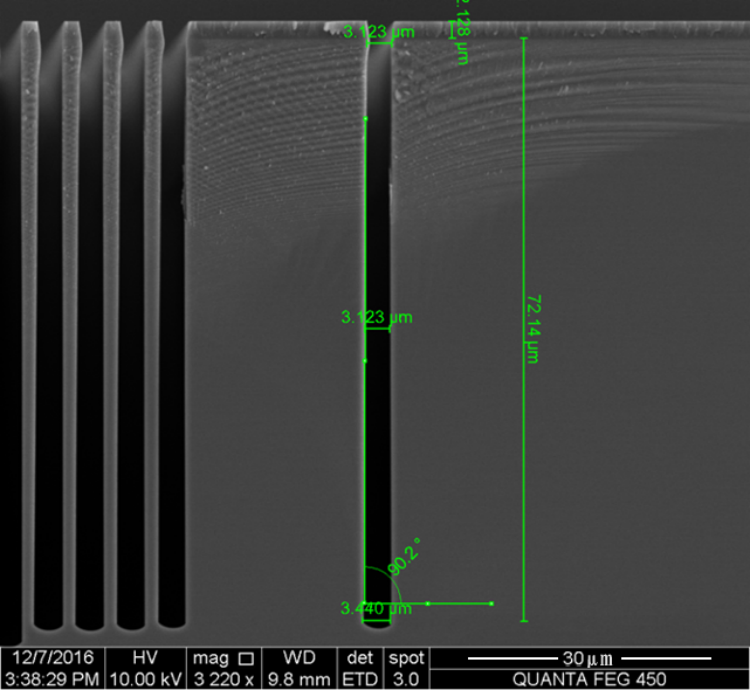

I-crystal silicon etching enye isetyenziswa ikakhulu ukwenza i-shallow trench solation (STI). Le nkqubo idla ngokubandakanya inkqubo yokuphumelela kunye nenkqubo yokubhala engundoqo. Inkqubo yokuphumelela isebenzisa i-SiF4 kunye ne-NF gas ukususa i-oxide layer phezu kwendawo enye ye-crystal silicon ngokusebenzisa i-ion bombardment enamandla kunye nesenzo sekhemikhali yezinto ze-fluorine; i-etching engundoqo isebenzisa i-hydrogen bromide (HBr) njengeyona nto iphambili. I-bromine radicals eboliswe yi-HBr kwindawo ye-plasma isabela nge-silicon ukwenza i-silicon eguqukayo ye-tetrabromide (SiBr4), ngaloo ndlela isusa i-silicon. I-crystal silicon etching enye ihlala isebenzisa umatshini wokukrola weplasma odityanisiweyo.

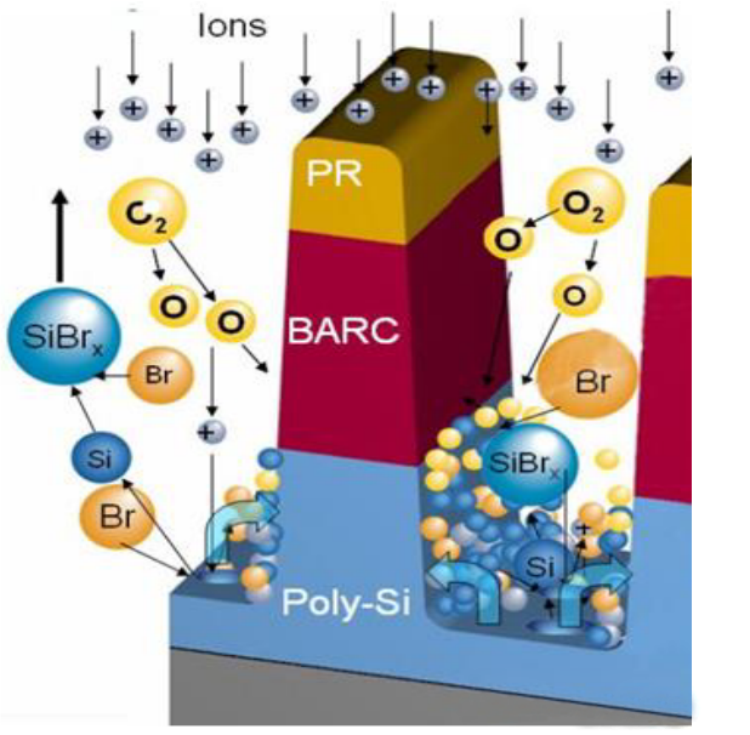

4. I-Polysilicon Etching

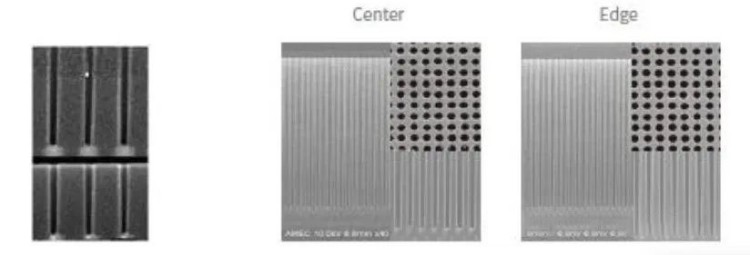

I-Polysilicon etching yenye yeenkqubo eziphambili ezimisela ubungakanani besango le-transistors, kwaye ubukhulu besango buchaphazela ngokuthe ngqo ukusebenza kweesekethe ezidibeneyo. Ukufakwa kwePolysilicon kufuna umlinganiselo olungileyo wokukhetha. Iigesi zeHalogen ezifana neklorini (Cl2) zidla ngokusetyenziselwa ukufikelela kwi-anisotropic etching, kwaye ibe nomlinganiselo omhle wokukhetha (ukuya kwi-10: 1). Iigesi ezisekelwe kwi-Bromine ezifana ne-hydrogen bromide (HBr) zinokufumana umlinganiselo ophezulu wokukhetha (ukuya kwi-100: 1). Umxube we-HBr kunye neklorini kunye ne-oxygen unokunyusa izinga le-etching. Iimveliso zokusabela zegesi ye-halogen kunye ne-silicon zifakwe emacaleni ukuze zidlale indima yokukhusela. I-Polysilicon etching ihlala isebenzisa umatshini wokudibanisa weplasma odibeneyo.

Nokuba idityaniswe ngokufanelekileyo iplasma etching okanye inductively edityaniswe kwiplasma etching, nganye ineengenelo zayo ezizodwa kunye neempawu zobugcisa. Ukukhetha itekhnoloji ye-etching efanelekileyo ayinakuphucula kuphela ukusebenza kakuhle kwemveliso, kodwa nokuqinisekisa isivuno semveliso yokugqibela.

Ixesha lokuposa: Nov-12-2024