Imvelaphi yophando

Ukubaluleka kokusetyenziswa kwesilicon carbide (SiC): Njengomathiriyeli we-semiconductor ebanzi, isilicon carbide itsale ingqalelo enkulu ngenxa yeempawu zayo zombane ezibalaseleyo (ezifana ne-bandgap enkulu, isantya esiphezulu se-electron saturation kunye ne-thermal conductivity). Ezi zakhiwo zenza ukuba isetyenziswe ngokubanzi kwi-high-frequency, iqondo lobushushu eliphezulu kunye nokuveliswa kwezixhobo zamandla aphezulu, ngakumbi kwintsimi yombane wamandla.

Impembelelo ye-crystal defects: Nangona ezi zibonelelo ze-SiC, iziphene kwiikristali zihlala ziyingxaki enkulu ethintela ukuphuhliswa kwezixhobo zokusebenza eziphezulu. Ezi ziphene zisenokubangela ukuthotywa kokusebenza kwesixhobo kwaye kuchaphazele ukuthembeka kwesixhobo.

Itekhnoloji ye-X-ray ye-topological imaging: Ukuze ukwandise ukukhula kwekristale kunye nokuqonda impembelelo yeziphene ekusebenzeni kwesixhobo, kuyimfuneko ukubonakalisa kunye nokuhlalutya ukucwangciswa kwesiphene kwiikristale ze-SiC. I-X-ray ye-topological imaging (ingakumbi isebenzisa i-synchrotron radiation beams) ibe yindlela ebalulekileyo yokubonakalisa iimpawu ezinokuvelisa imifanekiso ephezulu yokulungiswa kwesakhiwo sangaphakathi sekristale.

Izimvo zophando

Ngokusekwe kwithekhnoloji yokulinganisa imitha yokulinganisa: Eli nqaku liphakamisa ukusetyenziswa kwereyi yokulinganisa itekhnoloji yokulinganisa ngokusekwe kwindlela yokuthelekisa yokuthelekisa ukulinganisa umahluko wesiphene obonwa kwimifanekiso yeX-reyi ye-topological. Le ndlela ibonakaliswe njengeyona ndlela isebenzayo yokufunda iimpawu ze-crystal defects kwii-semiconductors ezahlukeneyo.

Ukuphuculwa kobuchwephesha bokulinganisa: Ukuze ukulinganisa ngcono ukuchithwa okuhlukeneyo okubonwa kwi-crystals ye-4H-SiC kunye ne-6H-SiC, abaphandi baphucula iteknoloji yokulinganisa i-ray kunye nokubandakanya imiphumo yokuphumla komphezulu kunye ne-photoelectric absorption.

Umxholo wophando

Uhlalutyo lohlobo lwe-Dislocation: Inqaku liphonononga ngokucwangcisiweyo ukubonakaliswa kweentlobo ezahlukeneyo zokuchithwa (ezifana ne-screw dislocations, i-eddge dislocations, i-dislocations edibeneyo, i-basal plane dislocations kunye ne-Frank-type dislocations) kwiipolytypes ezahlukeneyo ze-SiC (kubandakanywa ne-4H kunye ne-6H) usebenzisa i-ray tracing. iteknoloji yokulinganisa.

Ukusetyenziswa kobuchwephesha bokulinganisa: Ukusetyenziswa kokulinganisa itekhnoloji yokulinganisa imitha phantsi kweemeko zemiqadi ezahlukeneyo ezifana ne-beam topology ebuthathaka kunye ne-plane wave topology, kunye nendlela yokumisela ubunzulu bokungena obusebenzayo bokwahluka ngokulinganisa ubuchwepheshe kuyaphononongwa.

Ukudityaniswa kovavanyo kunye nokulinganisa: Ngokuthelekisa imifanekiso ye-X-ray ye-topological efunyenwe ngovavanyo kunye nemifanekiso efanisiweyo, ukuchaneka kweteknoloji yokulinganisa ekunqumeni uhlobo lokutshatyalaliswa, i-Burgers vector kunye nokusabalalisa kwendawo yokuchithwa kwi-crystal iqinisekisiwe.

Izigqibo zophando

Ukusebenza kwetheknoloji yokulinganisa: Uphononongo lubonisa ukuba iteknoloji yokulinganisa i-ray yindlela elula, engonakalisi kwaye engabonakaliyo yokubonakalisa iimpawu zeentlobo ezahlukeneyo zokuchithwa kwi-SiC kwaye inokuqikelela ngokufanelekileyo ubunzulu bokungena obusebenzayo bokuchithwa.

Uhlalutyo lohlengahlengiso lwe-3D lwe-dislocation: Ngokusebenzisa itekhnoloji yokulinganisa, uhlalutyo lwe-3D yokuchithwa kwe-dislocation kunye nomlinganiselo woxinaniso lunokwenziwa, olubalulekileyo ekuqondeni ukuziphatha kunye ne-evolution ye-dislocation ngexesha lokukhula kwe-crystal.

Usetyenziso lwexesha elizayo: Itekhnoloji yokulinganisa i-ray ilindeleke ukuba isetyenziswe ngakumbi kwi-high-energy topology kunye ne-X-ray topology esekwe elabhoratri. Ukongezelela, le teknoloji inokwandiswa kwi-simulation yeempawu zesiphene zezinye iipolytypes (ezifana ne-15R-SiC) okanye ezinye izinto ze-semiconductor.

Figure Overview

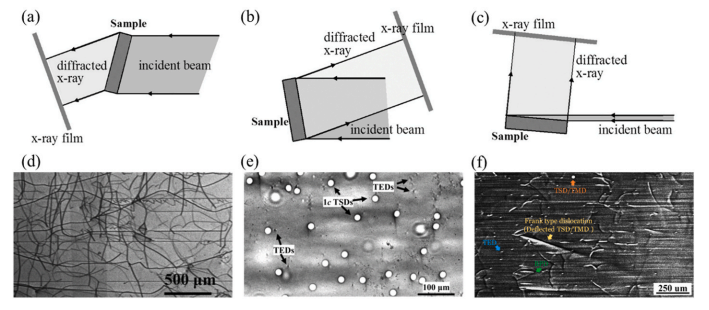

Umzobo woku-1: Umzobo weSchematic we-synchrotron radiation X-ray topological imaging imaging setup, kubandakanywa usasazo (Laue) geometry, ireverse reflection (Bragg) geometry, kunye nejometri yokwenzeka kwedlelo. Ezi geometri zisetyenziswa ikakhulu ukurekhoda imifanekiso ye-X-reyi ye-topological.

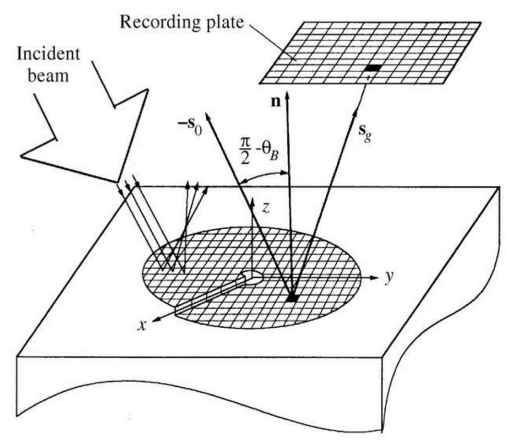

Umzobo 2: I-Schematic diagram ye-X-ray diffraction yendawo egqwethekileyo ejikeleze i-screw dislocation. Lo mzobo uchaza ubudlelwane phakathi kwentsimbi yesiganeko (s0) kunye ne-diffracted beam (sg) kunye nendiza ye-diffraction yendawo eqhelekileyo (n) kunye ne-Bragg angle yendawo (θB).

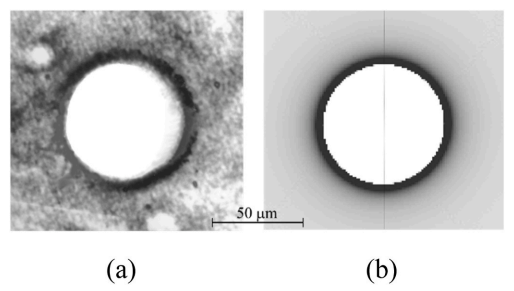

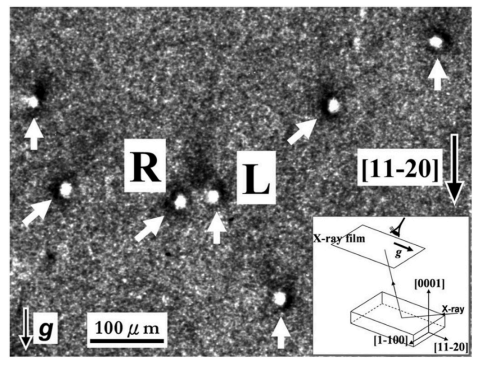

Umzobo 3: Imifanekiso ye-X-ray ye-back-reflection ye-micropipes (MPs) kwi-wafer ye-6H-SiC kunye nokwahlukana kwe-screw dislocation eyenziweyo (b = 6c) phantsi kweemeko ezifanayo zokuphazamiseka.

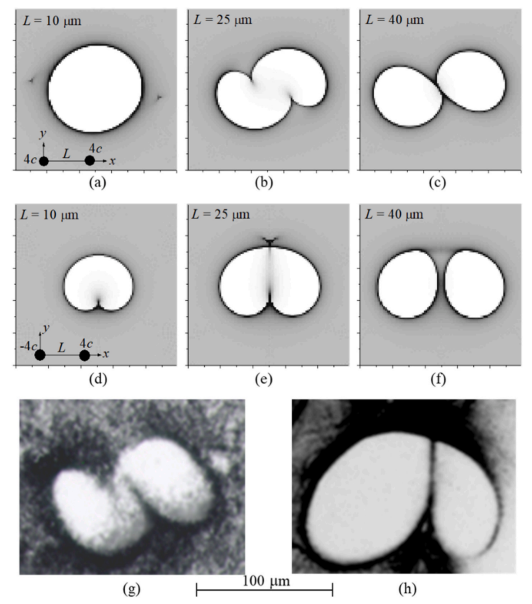

Umzobo 4: Izibini ze-Micropipe kumfanekiso we-back-reflection topography we-6H-SiC wafer. Imifanekiso yamaLungu ePalamente afanayo anezithuba ezahlukeneyo kunye namaLungu ePalamente kumacala achaseneyo aboniswa ngokulinganisa kwe-ray.

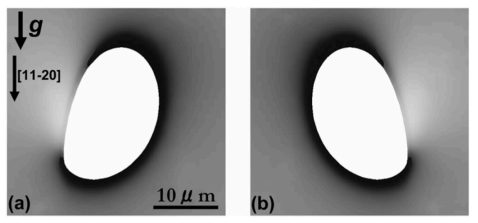

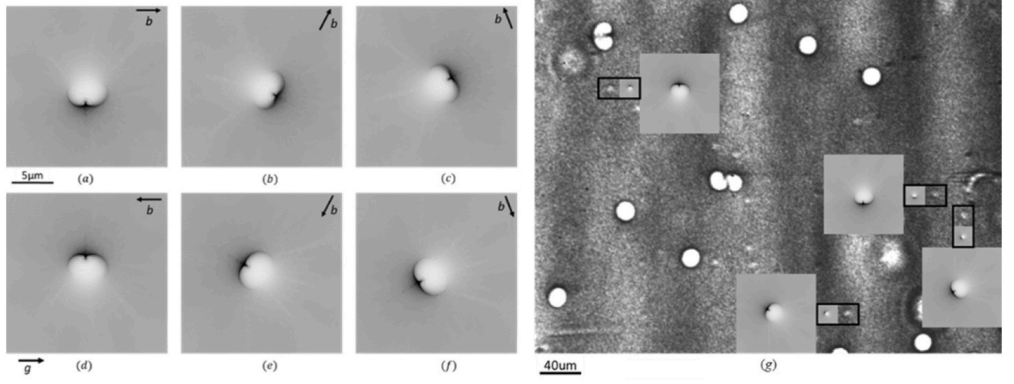

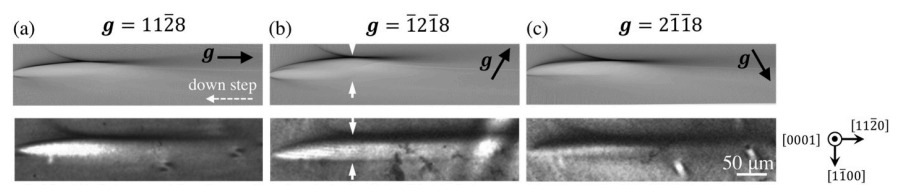

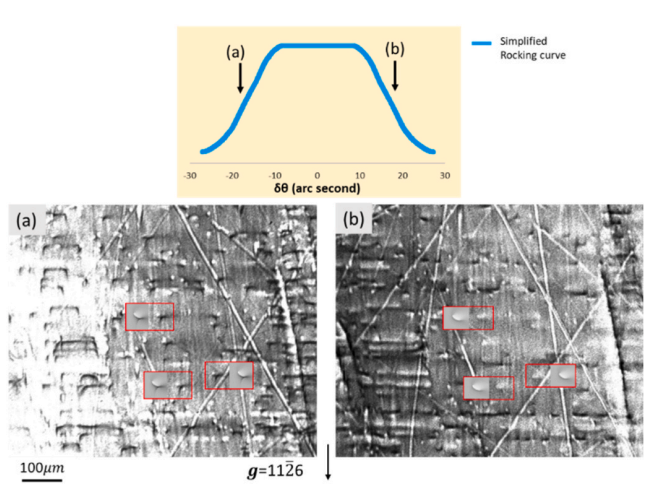

Umzobo 5: Izehlo zokutyisa imfuyo Imifanekiso yeX-reyi yokujonga indawo yokutyela evaliweyo (TSDs) kwi-wafer ye-4H–SiC iyaboniswa. Imifanekiso ibonisa ukomelezwa komphetho umahluko.

Umzobo 6: Ukulinganisa imitha yeziganeko zedlelo Imifanekiso ye-X-reyi yembonakalo yendawo yesandla sasekhohlo kunye nesandla sasekunene se-1c TSDs kwi-wafer ye-4H-SiC iyaboniswa.

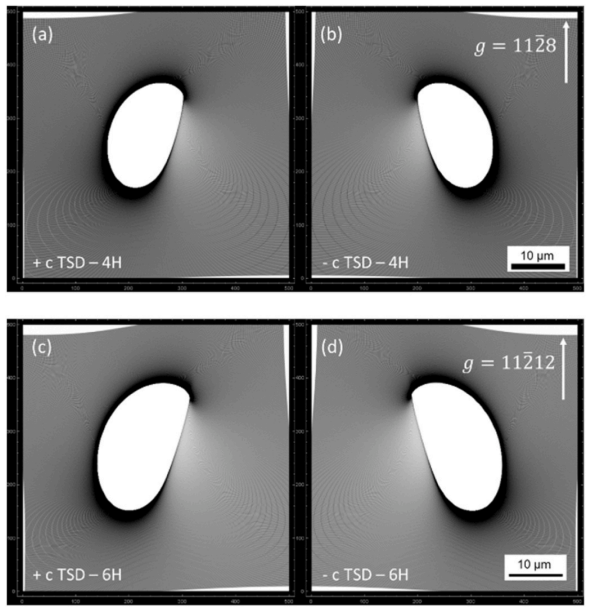

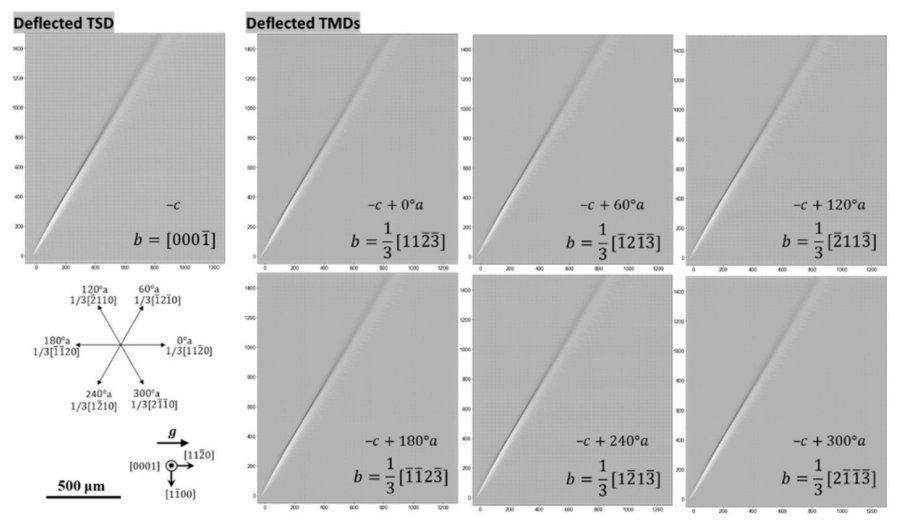

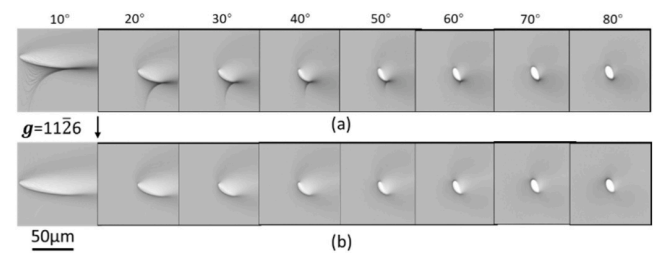

Umzobo we-7: I-Ray tracing simulations ye-TSDs kwi-4H-SiC kunye ne-6H-SiC iboniswa, ibonisa ukuchithwa kunye ne-Burgers vectors eyahlukeneyo kunye ne-polytypes.

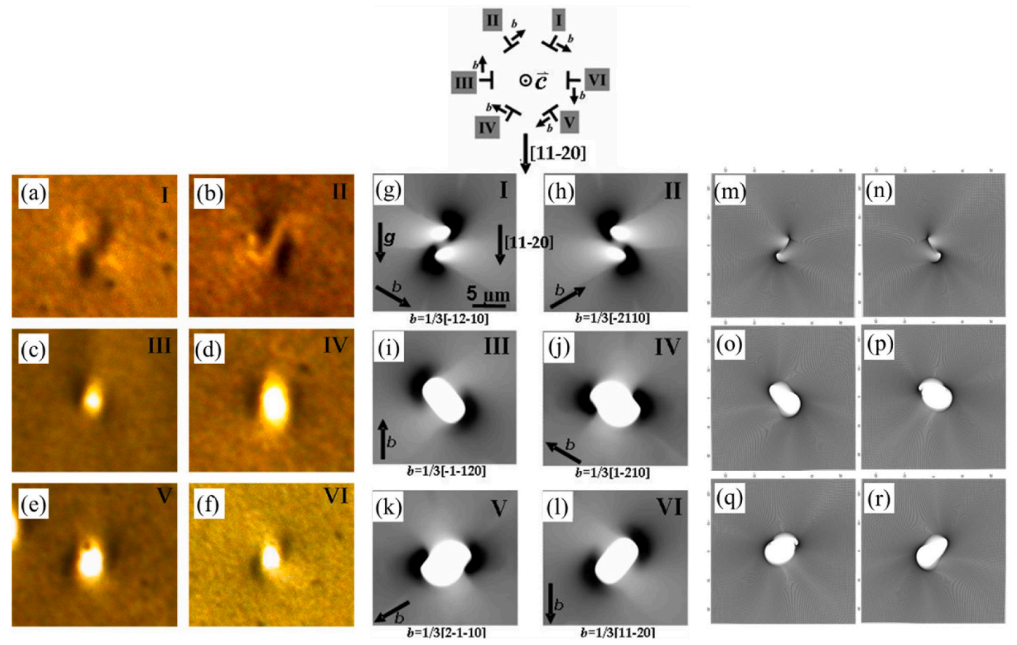

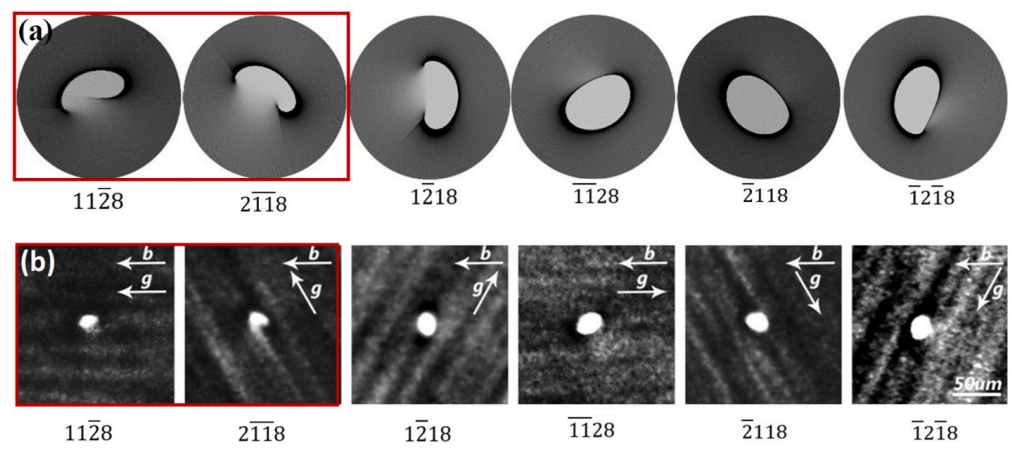

Umzobo 8: Ubonisa iziganeko zedlelo lweX-reyi ye-topological yeentlobo ezahlukeneyo ze-threading edge dislocations (TEDs) kwii-4H-SiC wafers, kunye nemifanekiso ye-TED topological eyenziwe kusetyenziswa indlela yokulandela ireyi.

Umzobo we-9: Ubonisa i-X-ray ye-back-reflection ye-topological imifanekiso yeentlobo ezahlukeneyo ze-TED kwii-wafers ze-4H-SiC, kunye ne-TED efanisiweyo.

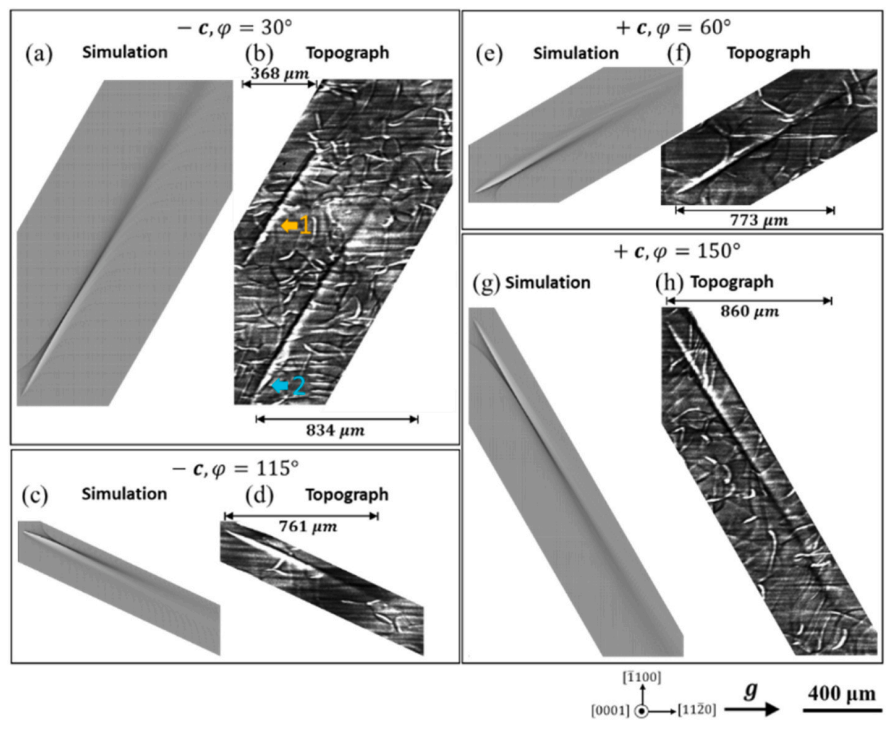

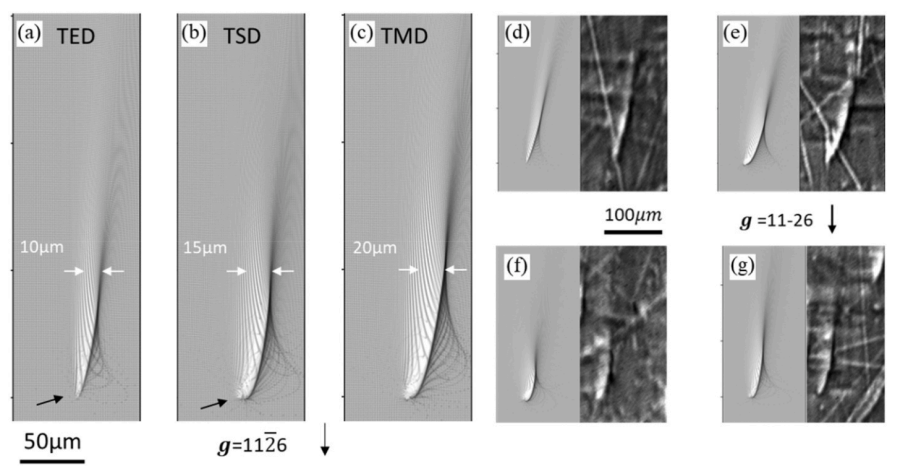

Umzobo we-10: Ubonisa i-ray yokulandelela imifanekiso yokulinganisa i-mixed threading dislocations (TMDs) kunye ne-Burgers vectors ethile, kunye nemifanekiso yovavanyo ye-topological.

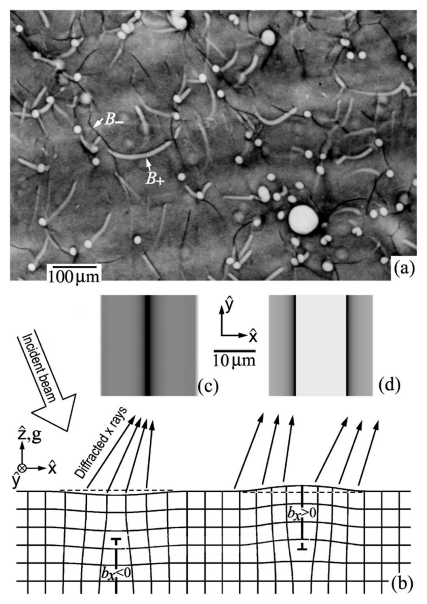

Umzobo we-11: Ubonisa i-back-reflection ye-topological images of basal plane dislocations (BPDs) kwii-wafers ze-4H-SiC, kunye nomzobo we-schematic we-edge edge dislocation eyahlukileyo.

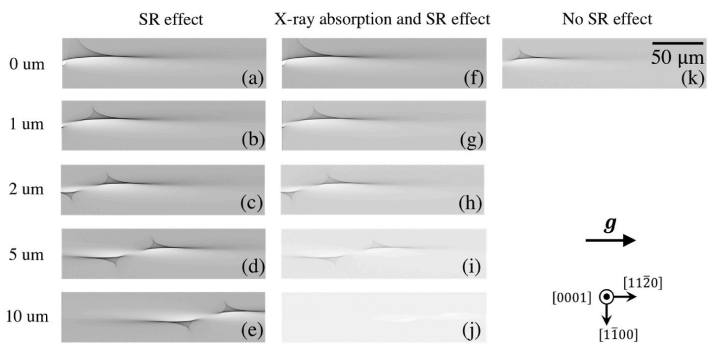

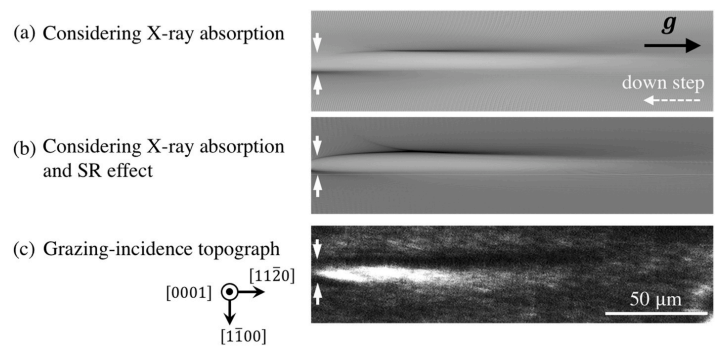

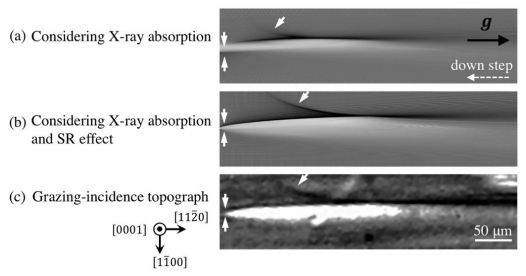

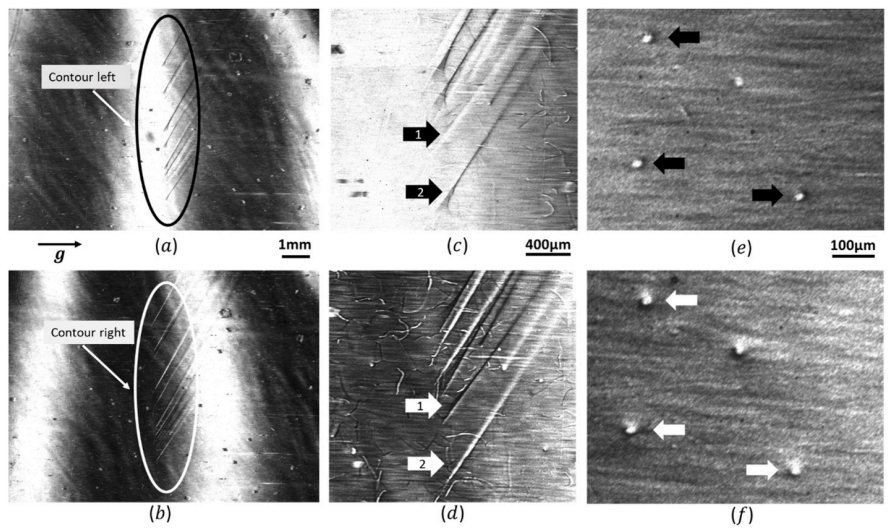

Umzobo we-12: Ubonisa i-ray yokulandelela imifanekiso yokulinganisa ye-BPDs ye-helical yesandla sasekunene kubunzulu obuhlukeneyo ngokuqwalasela ukuphumla komphezulu kunye neziphumo zokufunxa umbane.

Umzobo we-13: Ubonisa imitha yokulinganisa imifanekiso ye-BPDs ye-helical yasekunene kubunzulu obahlukeneyo, kunye nesiganeko sokutya i-X-reyi ye-topological.

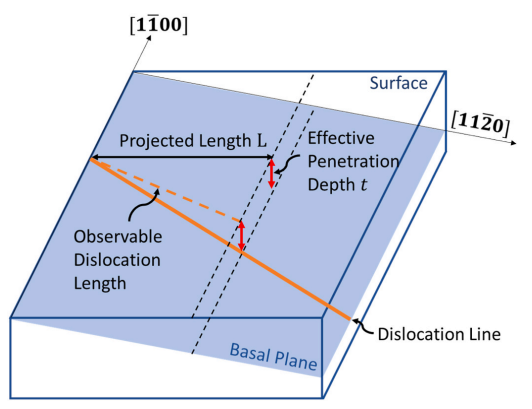

Umzobo we-14: Ubonisa umzobo weskimu sokuchithwa kwe-basal plane kulo naliphi na icala kwii-wafers ze-4H-SiC, kunye nendlela yokumisela ubunzulu bokungena ngokulinganisa ubude bentelekelelo.

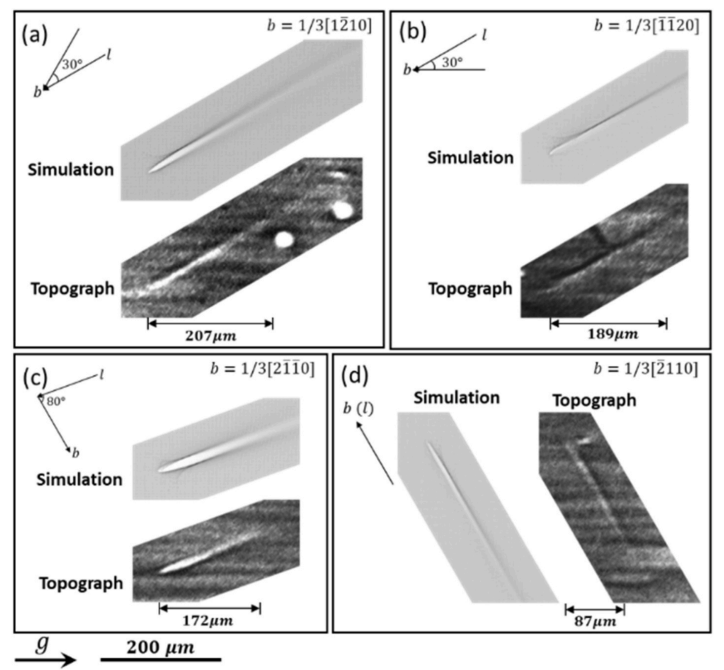

Umzobo we-15: Umahluko we-BPDs kunye ne-Burgers vectors eyahlukeneyo kunye nezalathiso zemigca kwisiganeko sokutyisa imifanekiso ye-X-ray ye-topological, kunye ne-ray ehambelanayo yokulandelela iziphumo zokulinganisa.

Umzobo 16: I-ray tracing simulation image ye-TSD yasekunene ejikisiweyo kwi-4H-SiC wafer, kunye nesiganeko sokutyisa i-X-reyi ye-topological image ibonisiwe.

Umzobo 17: I-ray tracing simulation kunye nomfanekiso wokulinga we-TSD ephambukisiweyo kwi-8 ° offset 4H-SiC wafer ibonisiwe.

Umzobo we-18: I-ray yokulandelela imifanekiso yokulinganisa ye-TSD ephambukisiweyo kunye ne-TMD enee-vectors ezahlukeneyo ze-Burgers kodwa ulwalathiso lomgca ofanayo lubonisiwe.

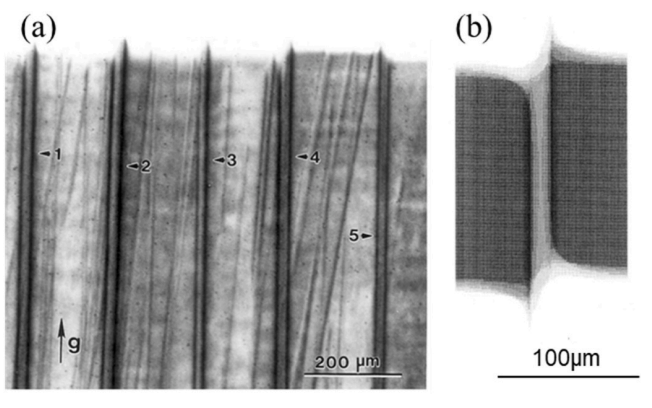

Umfanekiso we-19: I-ray tracing simulation image of Frank-type dislocations, kunye nesiganeko esihambelanayo sokutyisa i-X-ray umfanekiso we-topological uyaboniswa.

Umfanekiso we-20: Umfanekiso ogqithisiweyo we-X-ray we-topological we-micropipe kwi-wafer ye-6H-SiC, kunye ne-ray tracing simulation image ibonisiwe.

Umfanekiso we-21: Isiganeko sokutyisa i-monochromatic X-ray ye-topological sample ye-axially cut sample ye-6H-SiC, kunye ne-ray tracing simulation image ye-BPDs iyaboniswa.

Umzobo we-22: ubonisa i-ray yokulandelela imifanekiso yokulinganisa i-BPDs kwi-6H-SiC i-axially cut samples kwii-angles zesiganeko ezahlukeneyo.

Umzobo we-23: ubonisa i-ray yokulandelela imifanekiso ye-TED, TSD kunye ne-TMD kwi-6H-SiC i-axially cut samples phantsi kwe-geometry yedlelo.

Umzobo we-24: ubonisa imifanekiso ye-X-ray ye-topological ye-TSD ephambukisiweyo kumacala ahlukeneyo omgca we-isoclinic kwi-wafer ye-4H-SiC, kunye ne-ray ehambelanayo yokulandelela imifanekiso yokulinganisa.

Eli nqaku lenzelwe ukwabelana ngezifundo kuphela. Ukuba kukho naluphi na ulwaphulo-mthetho, nceda uqhagamshelane nathi ukuze ulucime.

Ixesha lokuposa: Jun-18-2024