Iindlela zokwaleka zefotoresist zidla ngokuhlulwa zibe yi-spin coating, idiphu yokwaleka kunye ne-roll coating, phakathi kwayo i-spin coating isetyenziswa kakhulu. Ngokugquma kwe-spin, i-photoresist ithontsizwa kwi-substrate, kwaye i-substrate inokujikelezwa ngesantya esiphezulu ukufumana ifilimu ye-photoresist. Emva koko, ifilimu eqinile inokufumaneka ngokufudumeza kwisitya esishushu. I-Spin coating ifanelekile ukugquma kwiifilimu ezi-ultra-thin (malunga ne-20nm) ukuya kwiifilimu ezishinyeneyo malunga ne-100um. Iimpawu zayo zihambelana kakuhle, ubukhulu befilimu obufanayo phakathi kwama-wafers, iziphene ezimbalwa, njl.

Inkqubo yokwaleka iSpin

Ngexesha lokugquma kwe-spin, isantya esiphambili sokujikeleza kwe-substrate sinquma ubukhulu befilimu ye-photoresist. Ubudlelwane phakathi kwesantya sokujikeleza kunye nobukhulu befilimu buhamba ngolu hlobo lulandelayo:

Spin=kTn

Kwifomula, iSpin sisantya sokujikeleza; T bubunzima befilimu; k kunye no-n zizigxina.

Izinto ezichaphazela inkqubo yokwaleka kwe-spin

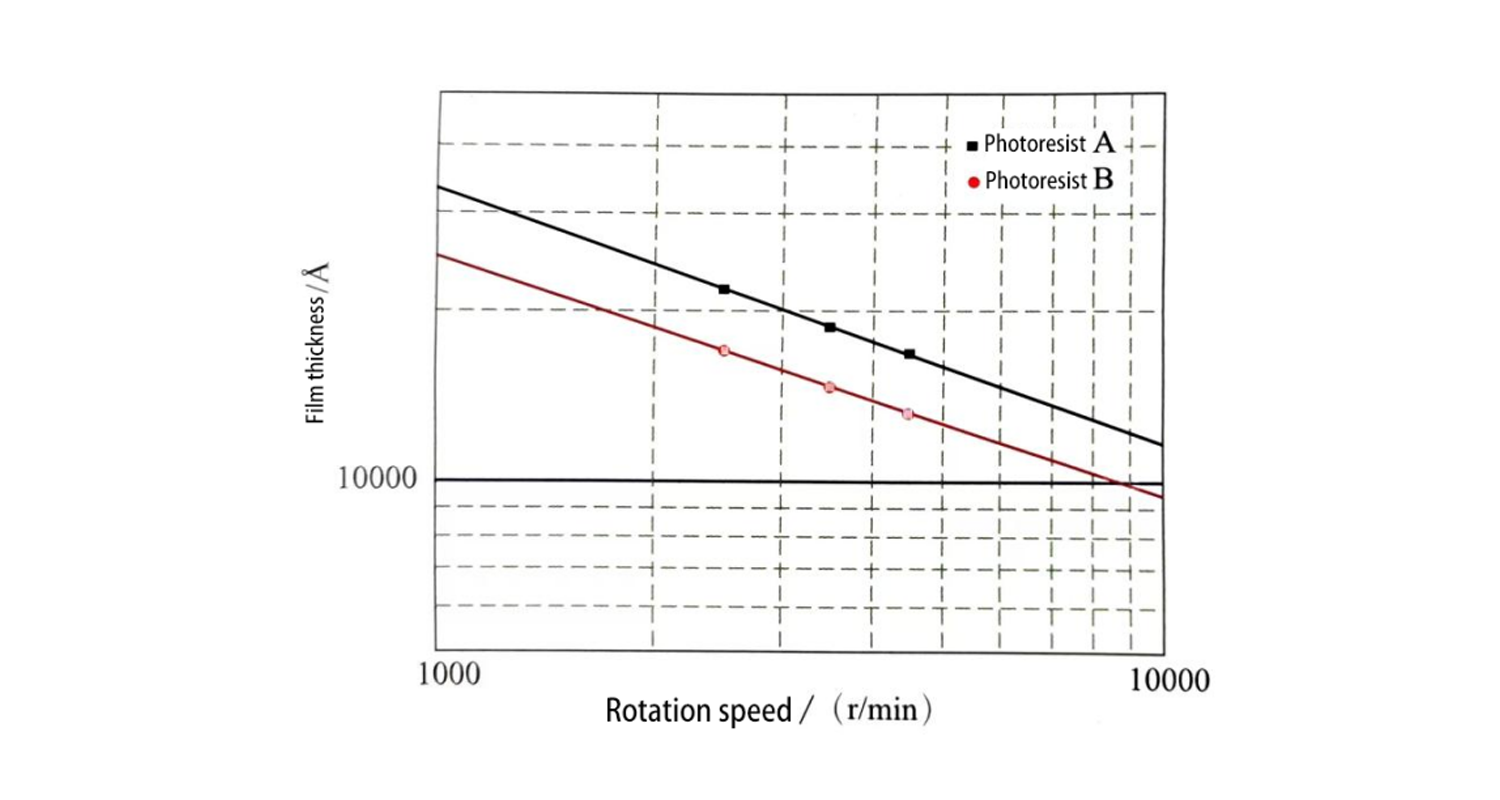

Nangona ubukhulu befilimu buchongwa ngesantya esiphambili sokujikeleza, sikwanxulumene nobushushu begumbi, ukufuma, i-photoresist viscosity kunye nohlobo lwe-photoresist. Ukuthelekiswa kweentlobo ezahlukeneyo ze-photoresist coating curves kuboniswe kwi-Figure 1.

Umzobo 1: Ukuthelekiswa kweentlobo ezahlukeneyo ze-photoresist coating curves

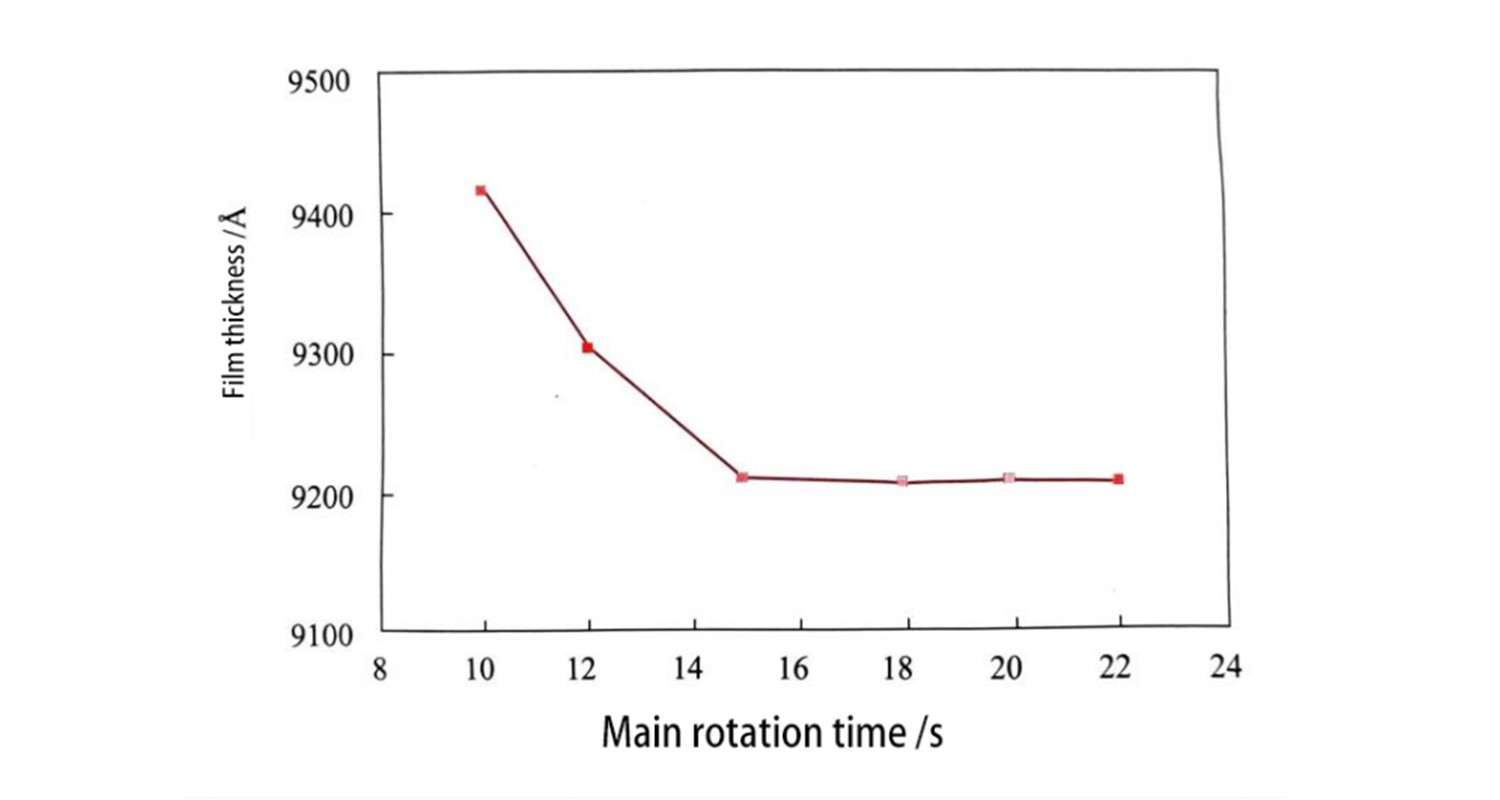

Impembelelo yexesha eliphambili lokujikeleza

Imfutshane ixesha eliphambili lokujikeleza, ukutyeba kwefilimu. Xa ixesha eliphambili lokujikeleza linyuswa, ifilimu iba yincinci. Xa idlula i-20s, ubukhulu befilimu buhlala bungatshintshi. Ngoko ke, ixesha eliphambili lokujikeleza lidla ngokukhethwa ukuba libe ngaphezu kwemizuzwana engama-20. Ubudlelwane phakathi kwexesha eliphambili lokujikeleza kunye nobukhulu befilimu buboniswe kuMfanekiso 2.

Umzobo 2: Ubudlelwane phakathi kwexesha eliphambili lokujikeleza kunye nobukhulu befilimu

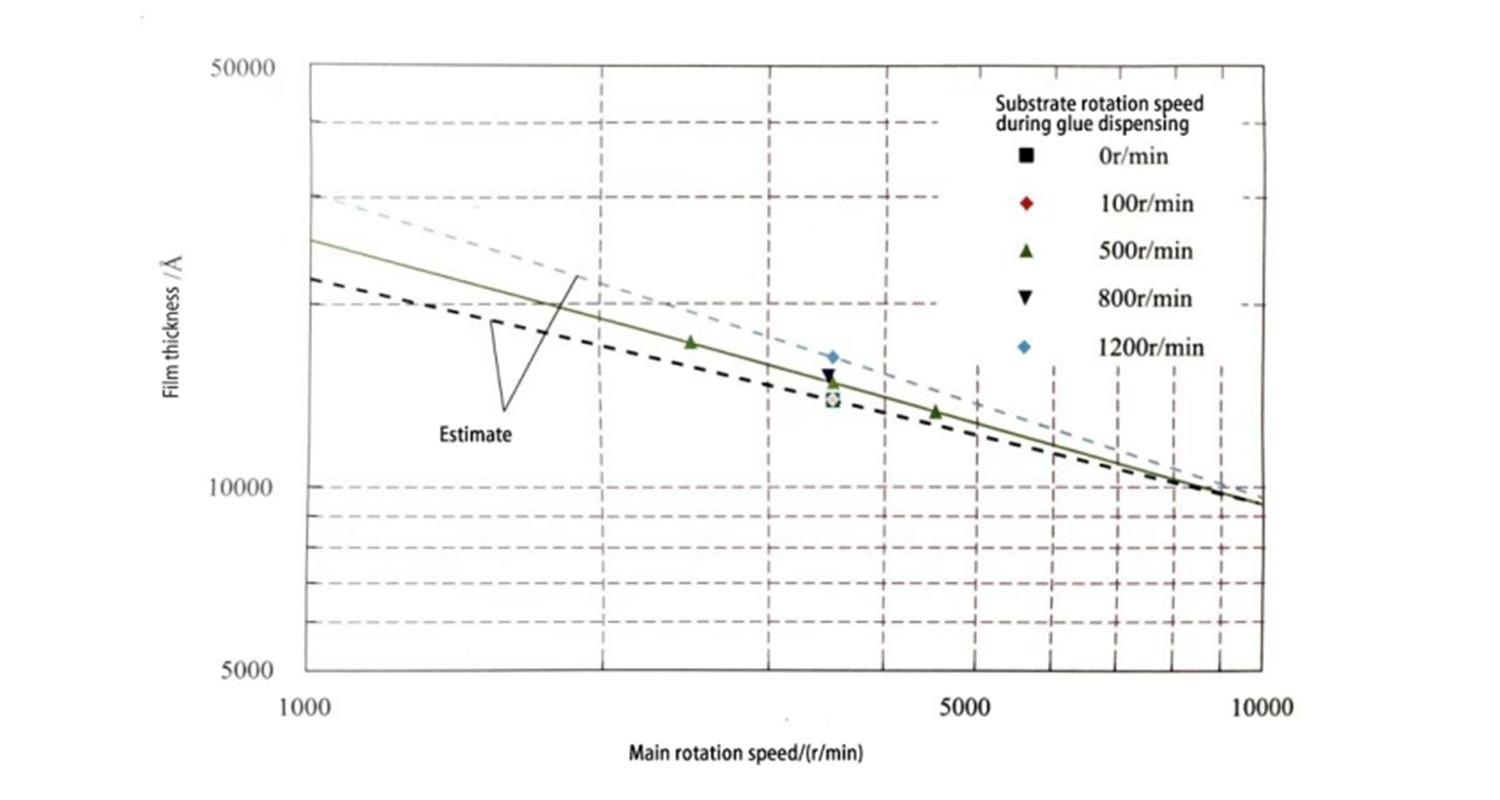

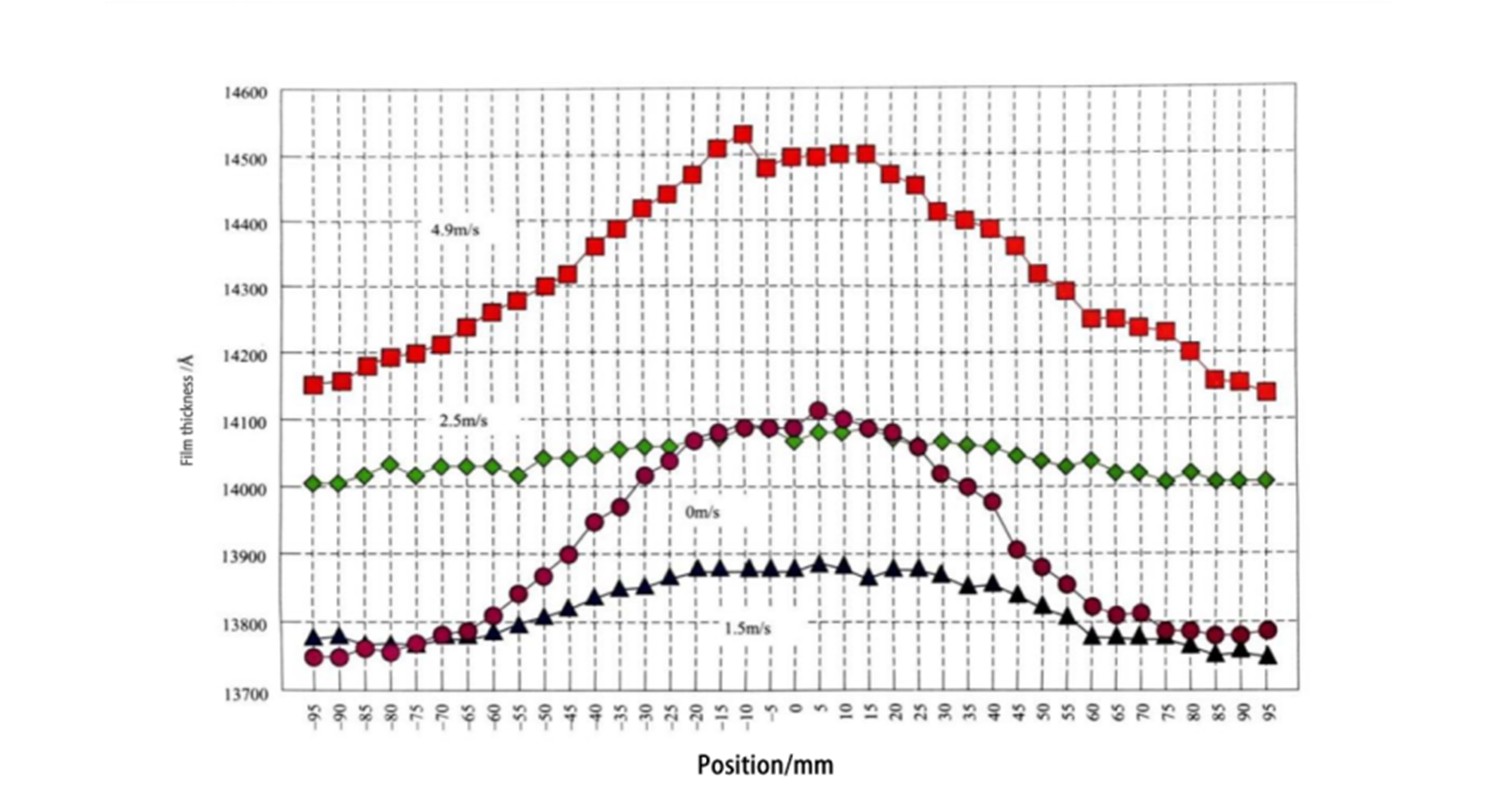

Xa i-photoresist ithontsizwa kwi-substrate, nokuba isantya esihamba phambili sokujikeleza siyafana, isantya sokujikeleza se-substrate ngexesha lokuthontsiza kuya kuchaphazela ubukhulu befilimu bokugqibela. Ubukhulu befilimu ye-photoresist buyanda kunye nokwanda kwesantya sokujikeleza kwe-substrate ngexesha lokuthontsiza, okubangelwa yimpembelelo ye-solvent evaporation xa i-photoresist ityhilwa emva kokuvuza. Umzobo 3 ubonisa ubudlelwane phakathi kobukhulu befilimu kunye nesantya esiphambili sokujikeleza kwizantya ezahlukeneyo zokujikeleza kwe-substrate ngexesha lokuvuza kwefotoresist. Inokubonwa kumzobo ukuba ngokunyuka kwesantya sokujikeleza kwe-substrate ethontsizayo, ubukhulu befilimu butshintsha ngokukhawuleza, kwaye umahluko ubonakala ngakumbi kwindawo enesantya esisezantsi sokujikeleza.

Umzobo 3: Ubudlelwane phakathi kobukhulu befilimu kunye nesantya esiphambili sokujikeleza kwizantya ezahlukeneyo zokujikeleza kwe-substrate ngexesha lokusasaza kwefotoresist.

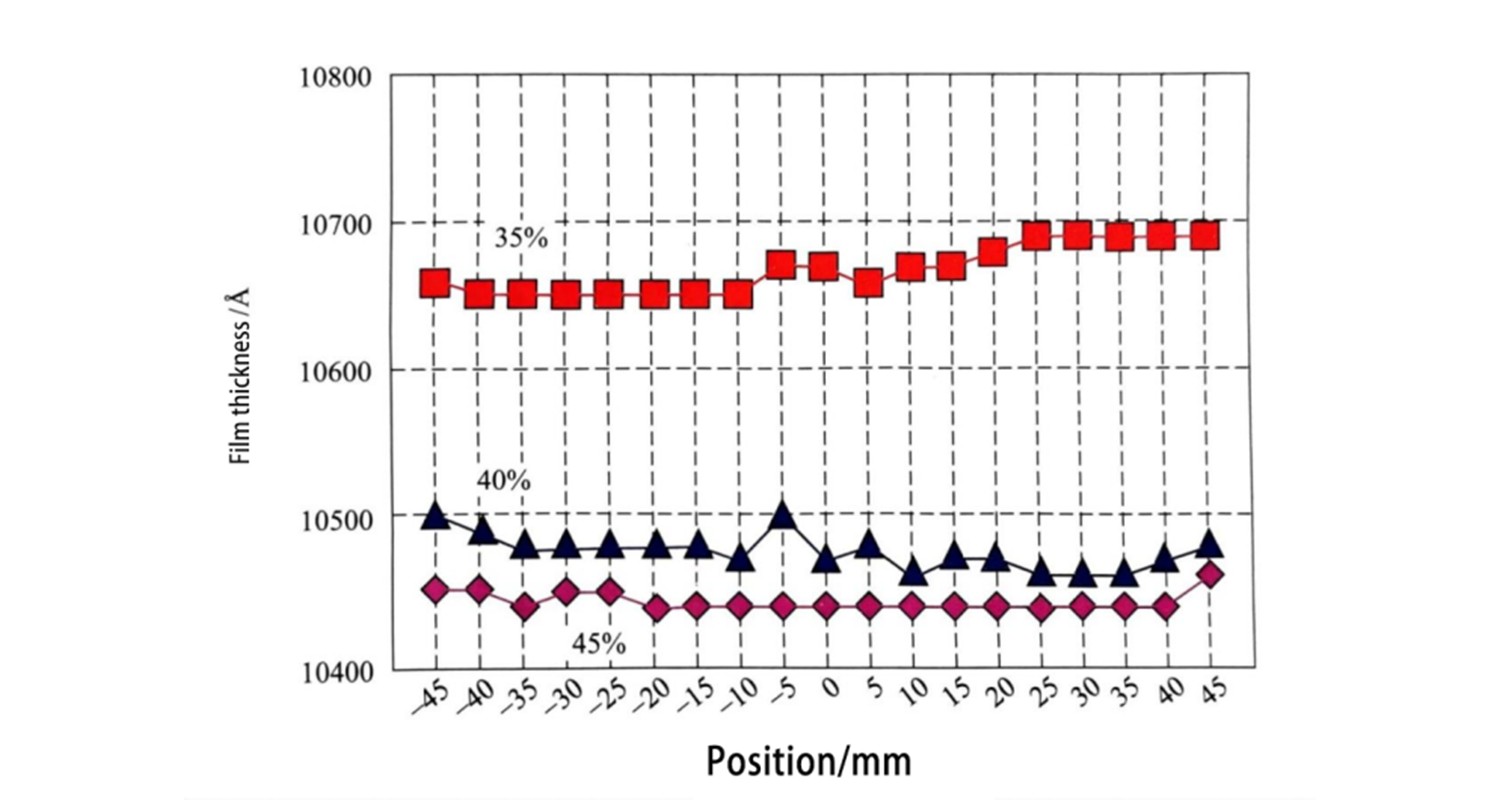

Isiphumo sokufuma ngexesha lokwaleka

Xa umswakama uyancipha, ubukhulu befilimu buyanda, kuba ukuhla komswakama kukhuthaza ukukhuphuka kwe-solvent. Nangona kunjalo, ukusabalalisa ubukhulu befilimu akutshintshi kakhulu. Umzobo we-4 ubonisa ubudlelwane phakathi kokufuma kunye nokusabalalisa ubukhulu befilimu ngexesha lokwaleka.

Umzobo 4: Ubudlelwane phakathi kokufuma kunye nokusabalalisa ubukhulu befilimu ngexesha lokwaleka

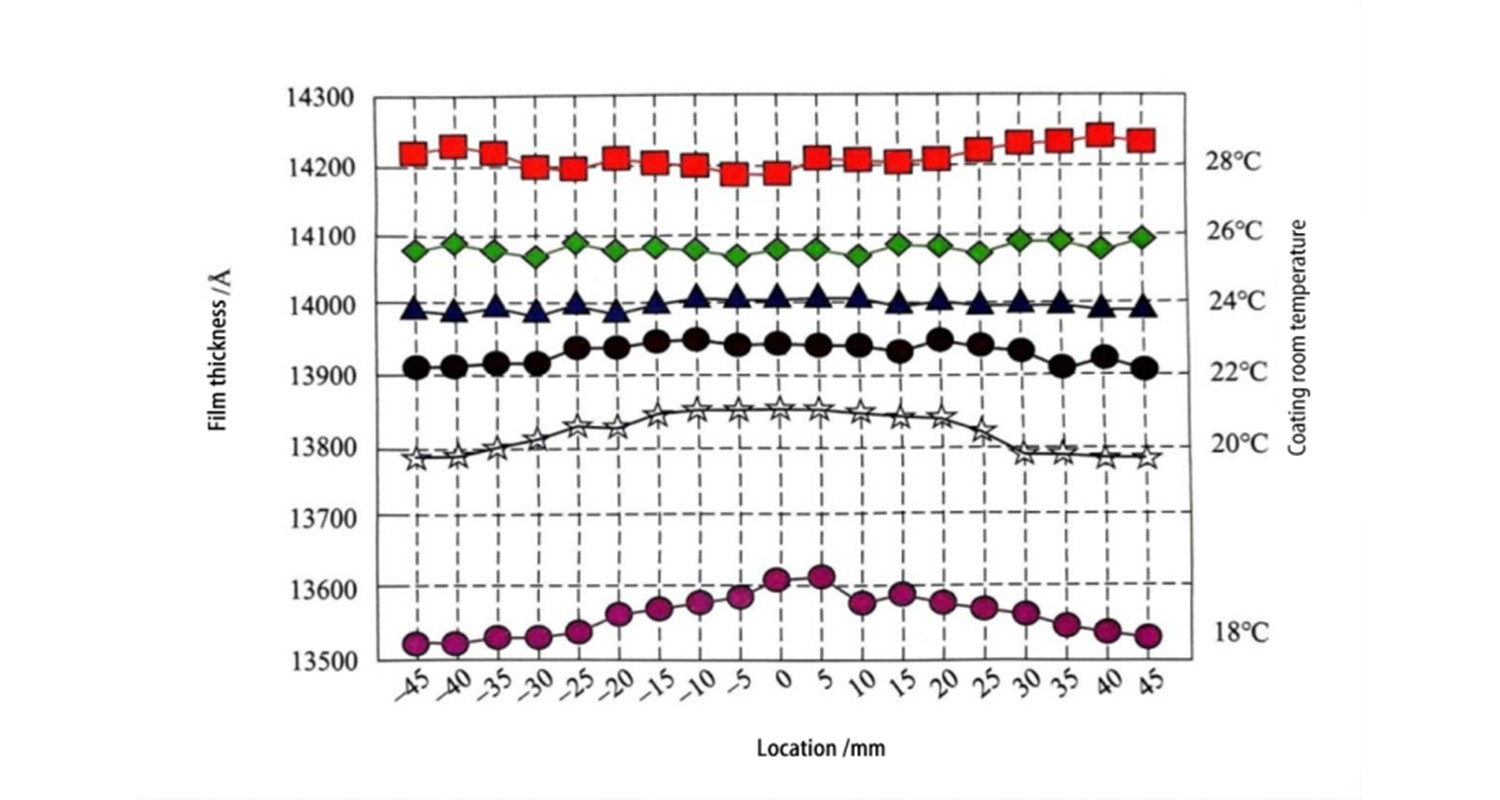

Impembelelo yobushushu ngexesha lokwaleka

Xa ukushisa kwangaphakathi kuphakama, ubukhulu befilimu buyanda. Inokubonwa kuMfanekiso 5 ukuba ukuhanjiswa kwefilimu yefotoresist ubukhulu butshintsha ukusuka kwiconvex ukuya kwiconcave. Ijika elisemfanekisweni likwabonisa ukuba ukufana okuphezulu kufumaneka xa ubushushu bangaphakathi bungama-26 ° C kunye nobushushu befotoresist bungama-21 ° C.

Umzobo 5: Ubudlelwane phakathi kobushushu kunye nokusabalalisa ubukhulu befilimu ngexesha lokwaleka

Impembelelo yesantya sokukhupha ngexesha lokugquma

Umzobo we-6 ubonisa ubudlelwane phakathi kwesantya sokukhupha kunye nokusabalalisa ubukhulu befilimu. Ukungabikho kokuphuma, kubonisa ukuba umbindi we-wafer uvame ukujiya. Ukwandisa isantya sokukhupha kuya kuphucula ukufana, kodwa ukuba kunyuswe kakhulu, ukufana kuya kuncipha. Ingabonwa ukuba kukho ixabiso elifanelekileyo lesantya sokukhupha.

Umzobo 6: Ubudlelwane phakathi kwesantya sokukhupha kunye nokusabalalisa ubukhulu befilimu

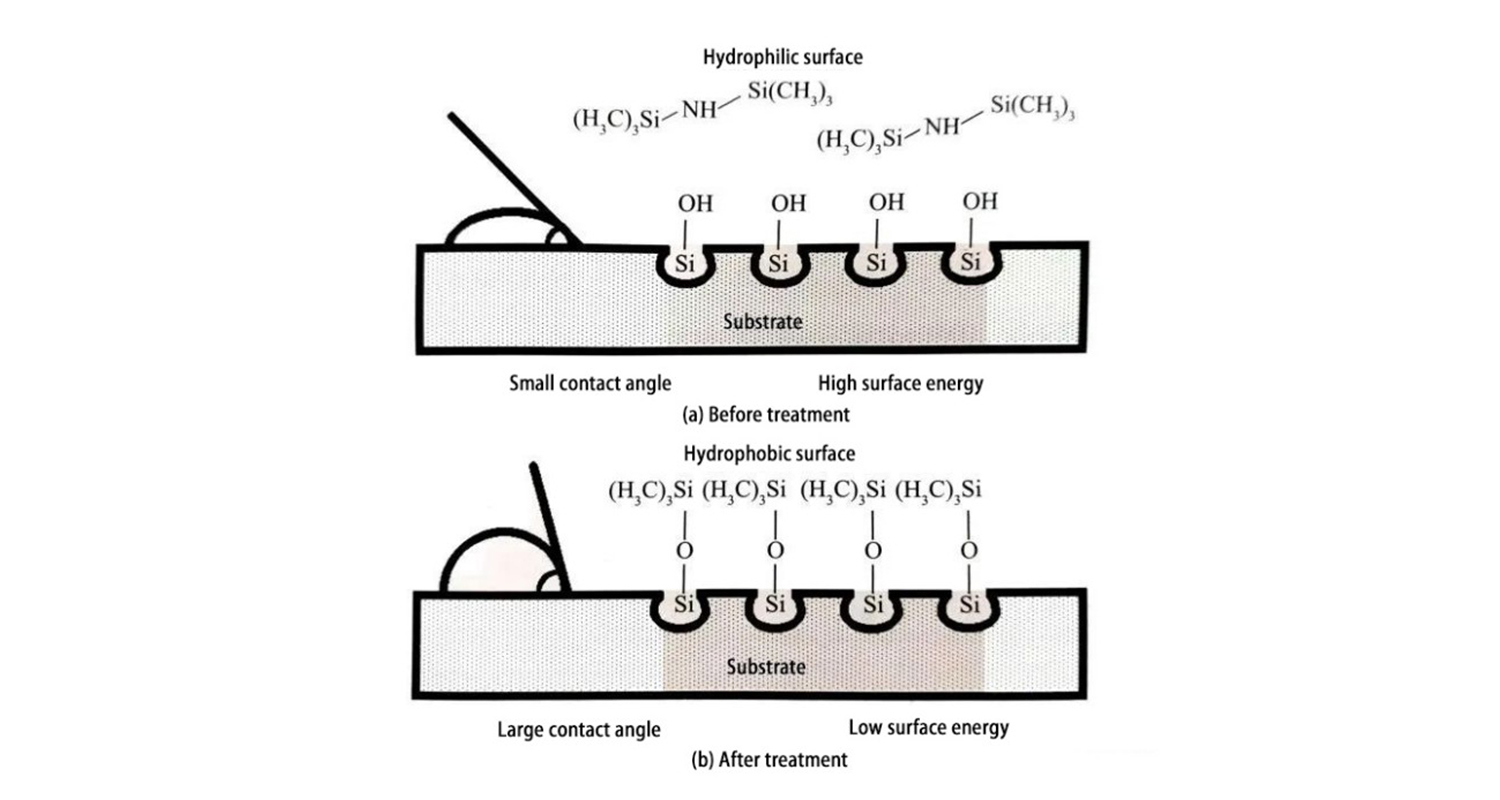

Unyango lwe-HMDS

Ukuze wenze i-photoresist inxibe ngakumbi, iwafer kufuneka inyangwe nge-hexamethyldisilazane (HMDS). Ngokukodwa xa umswakama unamathele kumphezulu wefilimu ye-Si oxide, i-silanol yenziwe, eyanciphisa ukunamathela kwe-photoresist. Ukuze kususwe umswakama kunye nokubola kwe-silanol, i-wafer idla ngokufudumeza ukuya kwi-100-120 ° C, kwaye i-HMDS yenkungu iqaliswa ukuba ibangele ukusabela kweekhemikhali. Indlela yokusabela iboniswa kuMzobo 7. Ngonyango lwe-HMDS, umphezulu we-hydrophilic kunye ne-angle yokudibanisa encinci iba yindawo ye-hydrophobic ene-angle enkulu yoqhagamshelwano. Ukufudumeza i-wafer kunokufumana ukunamathela okuphezulu kwe-photoresist.

Umzobo 7: Indlela yokusabela ye-HMDS

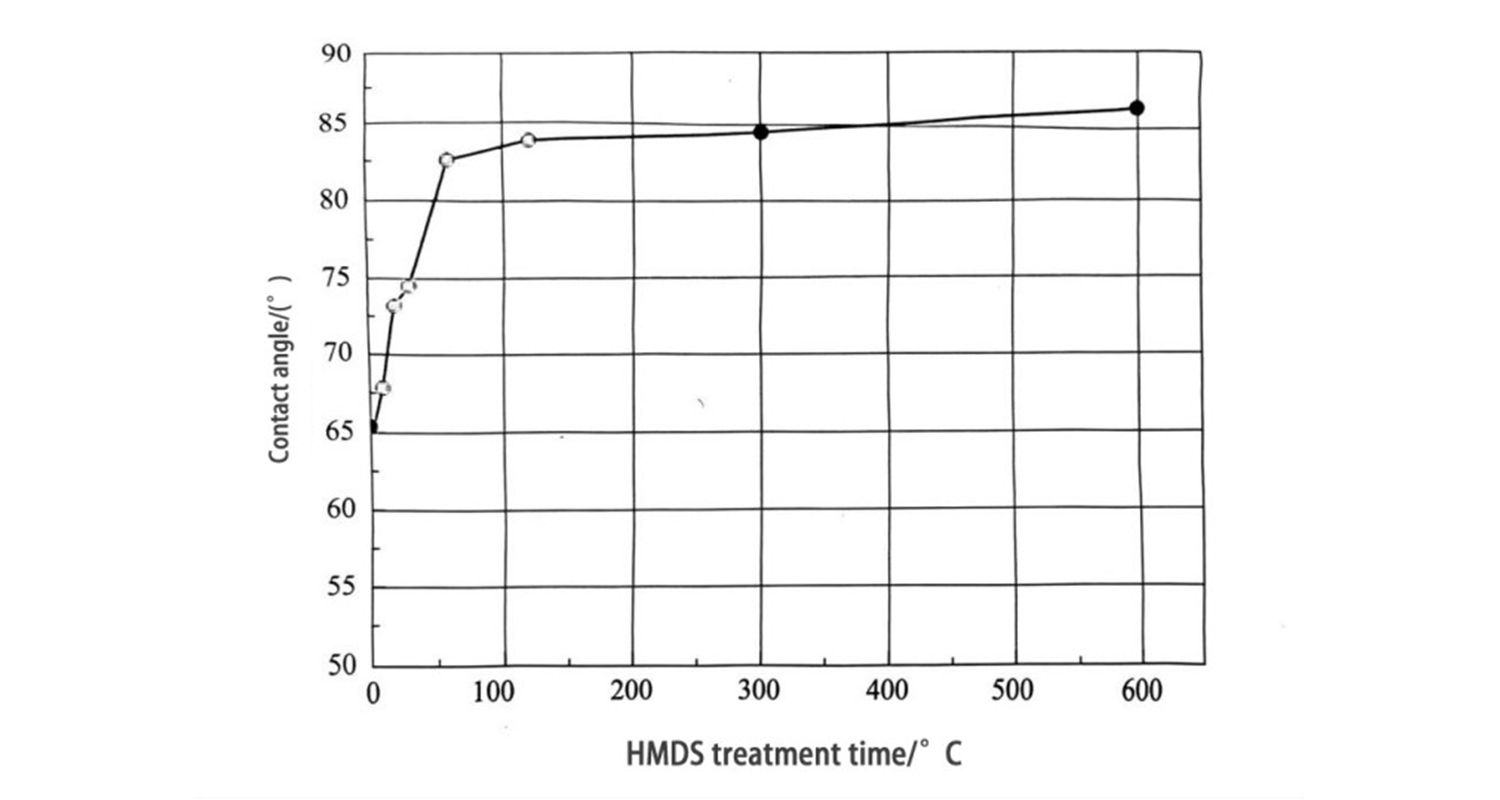

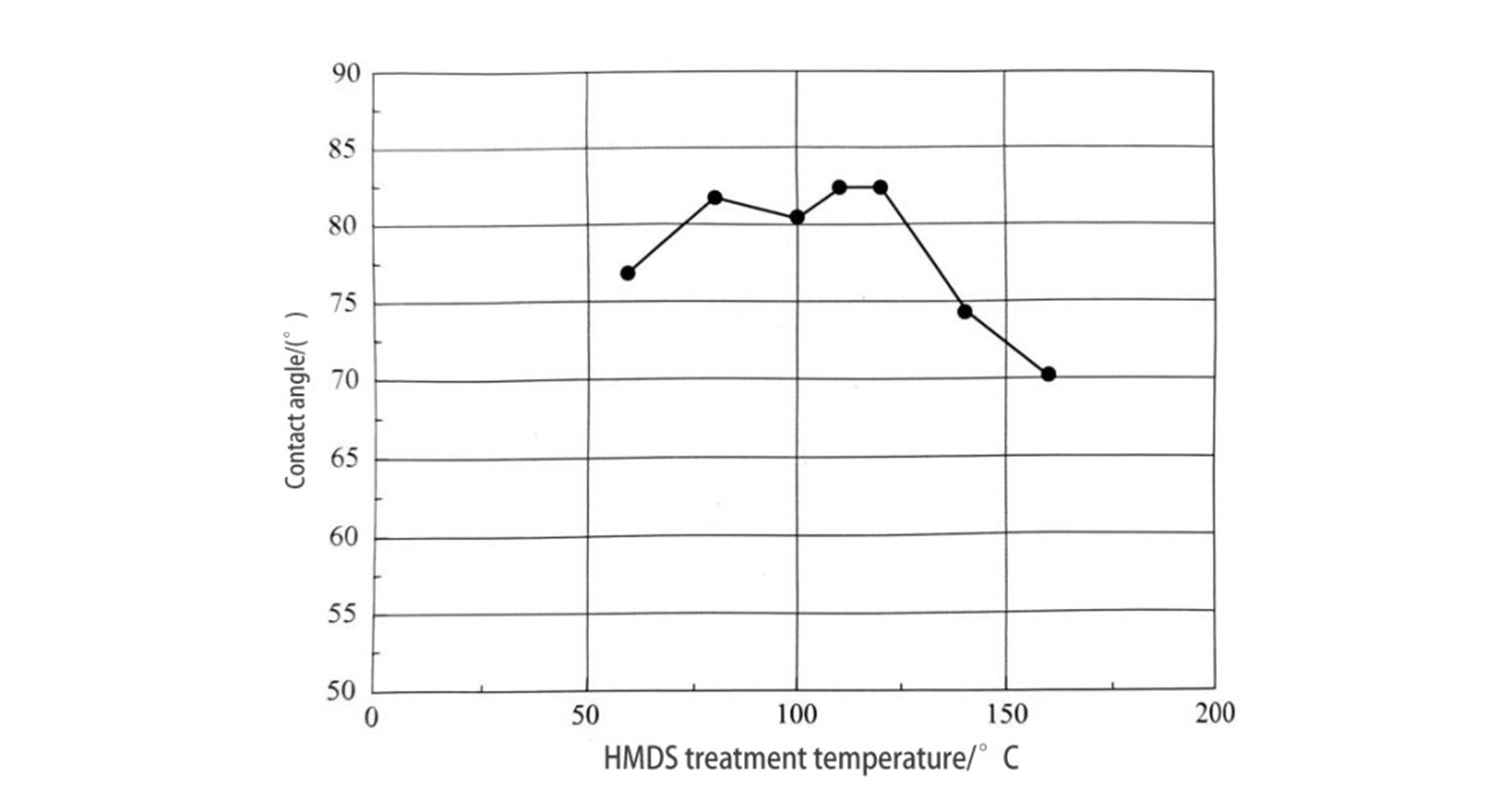

Isiphumo sonyango lwe-HMDS sinokubonwa ngokulinganisa i-angle yoqhagamshelwano. Umzobo we-8 ubonisa ubudlelwane phakathi kwexesha lonyango lwe-HMDS kunye ne-angle yoqhagamshelwano (iqondo lokushisa lonyango 110 ° C). I-substrate yi-Si, ixesha lonyango lwe-HMDS likhulu kune-1min, i-angle yoqhagamshelwano inkulu kune-80 °, kwaye umphumo wonyango uzinzile. Umzobo we-9 ubonisa ubudlelwane phakathi kweqondo lokushisa lonyango lwe-HMDS kunye ne-angle yoqhagamshelwano (ixesha lonyango 60s). Xa iqondo lobushushu lidlula i-120℃, i-engile yoqhagamshelwano iyancipha, ebonisa ukuba i-HMDS iyabola ngenxa yobushushu. Ngoko ke, unyango lwe-HMDS ludla ngokuqhutywa kwi-100-110 ℃.

Umzobo 8: Ubudlelwane phakathi kwexesha lonyango lwe-HMDS

kunye ne-engile yoqhagamshelwano (ubushushu bonyango 110℃)

Umzobo 9: Ubudlelwane phakathi kweqondo lokushisa lonyango lwe-HMDS kunye ne-angle yoqhagamshelwano (ixesha lonyango 60s)

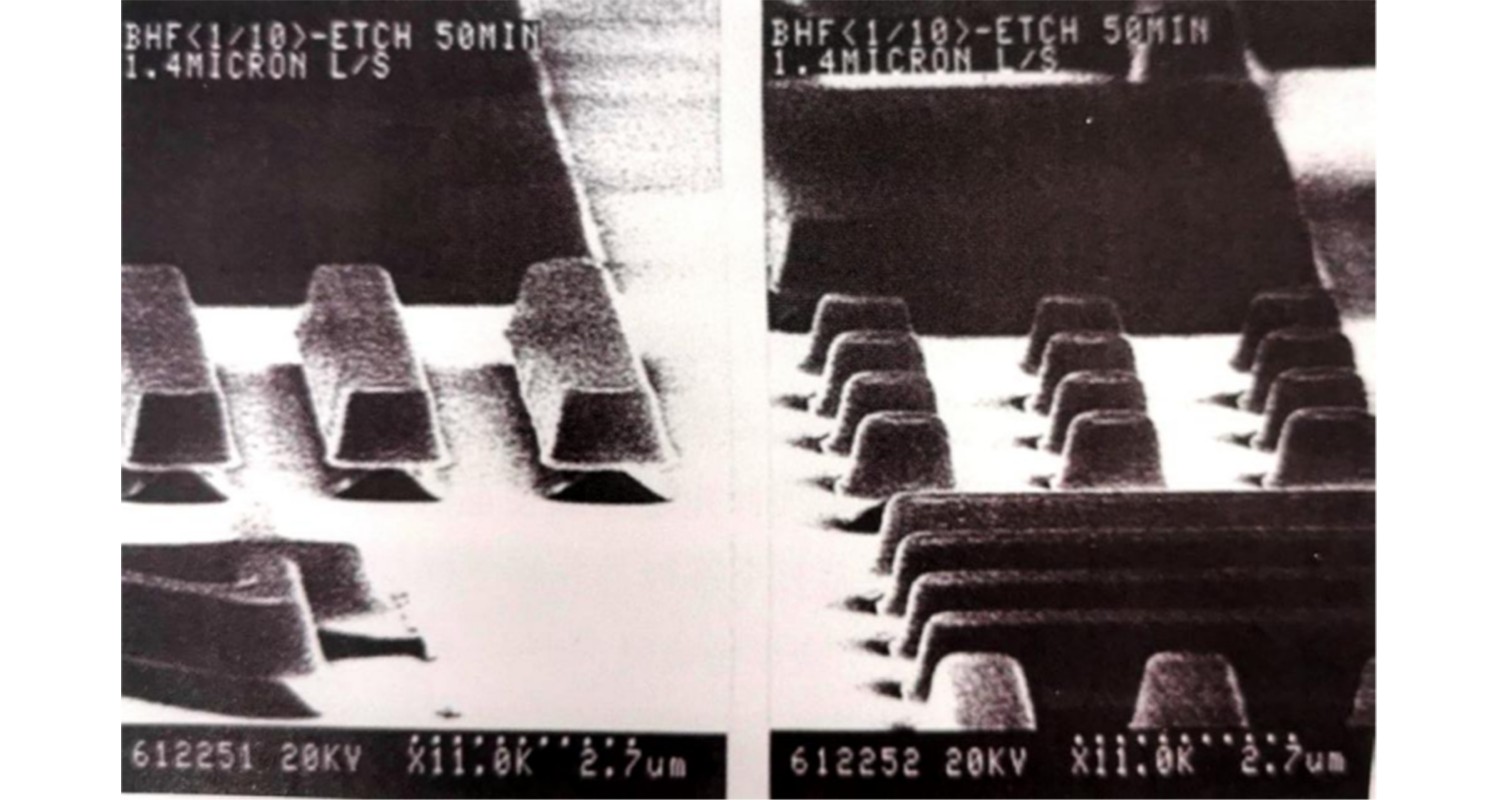

Unyango lwe-HMDS lwenziwa kwi-silicon substrate kunye nefilimu ye-oxide ukwenza ipateni ye-photoresist. Ifilimu ye-oxide ifakwe kwi-hydrofluoric acid kunye ne-buffer eyongeziweyo, kwaye kufunyenwe ukuba emva konyango lwe-HMDS, ipateni ye-photoresist ingagcinwa ekuweni. Umzobo we-10 ubonisa umphumo wonyango lwe-HMDS (ubungakanani bepatheni yi-1um).

Umzobo 10: Isiphumo sonyango lwe-HMDS (ubungakanani bepatheni yi-1um)

Ukubhaka kwangaphambili

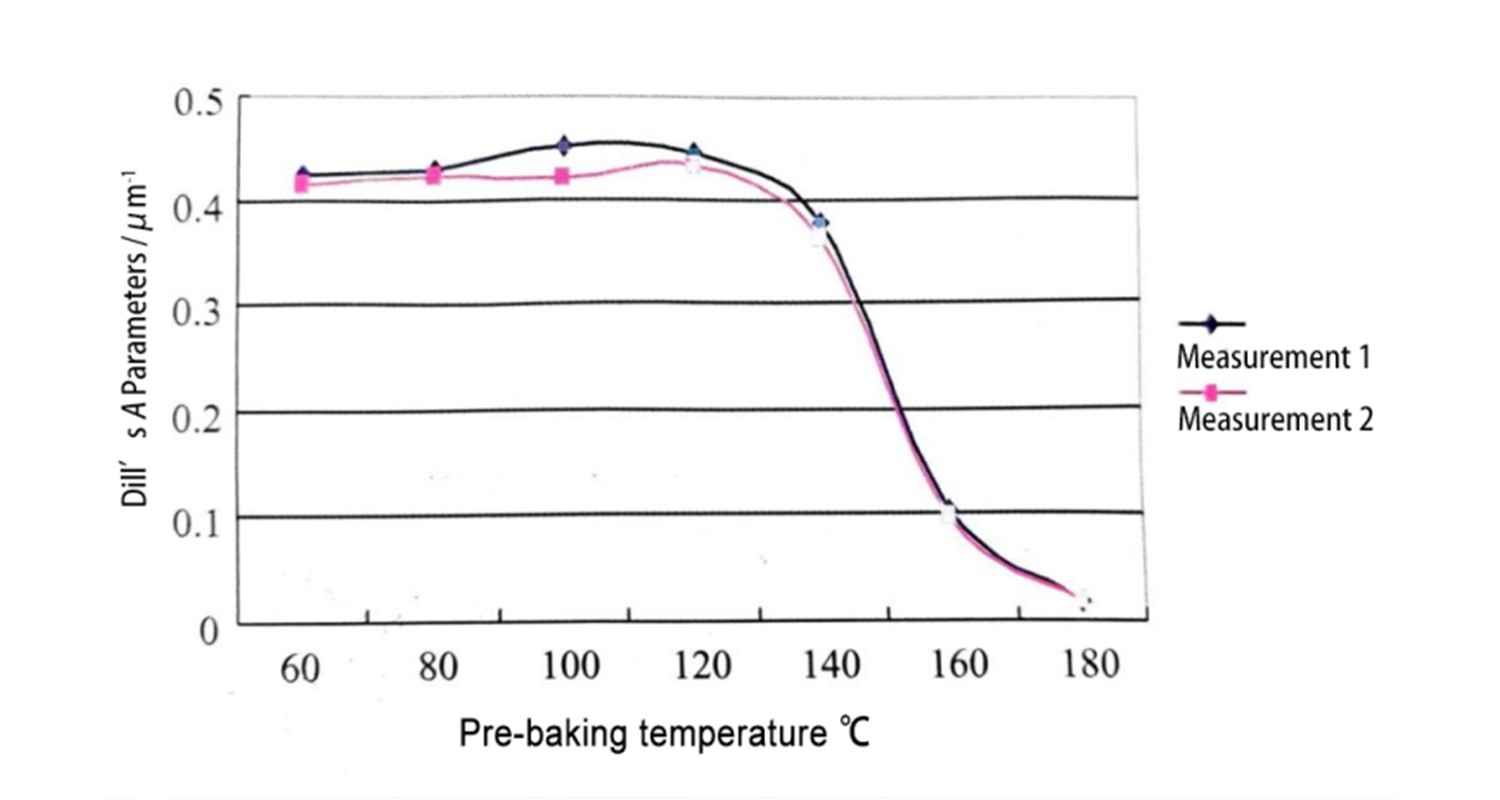

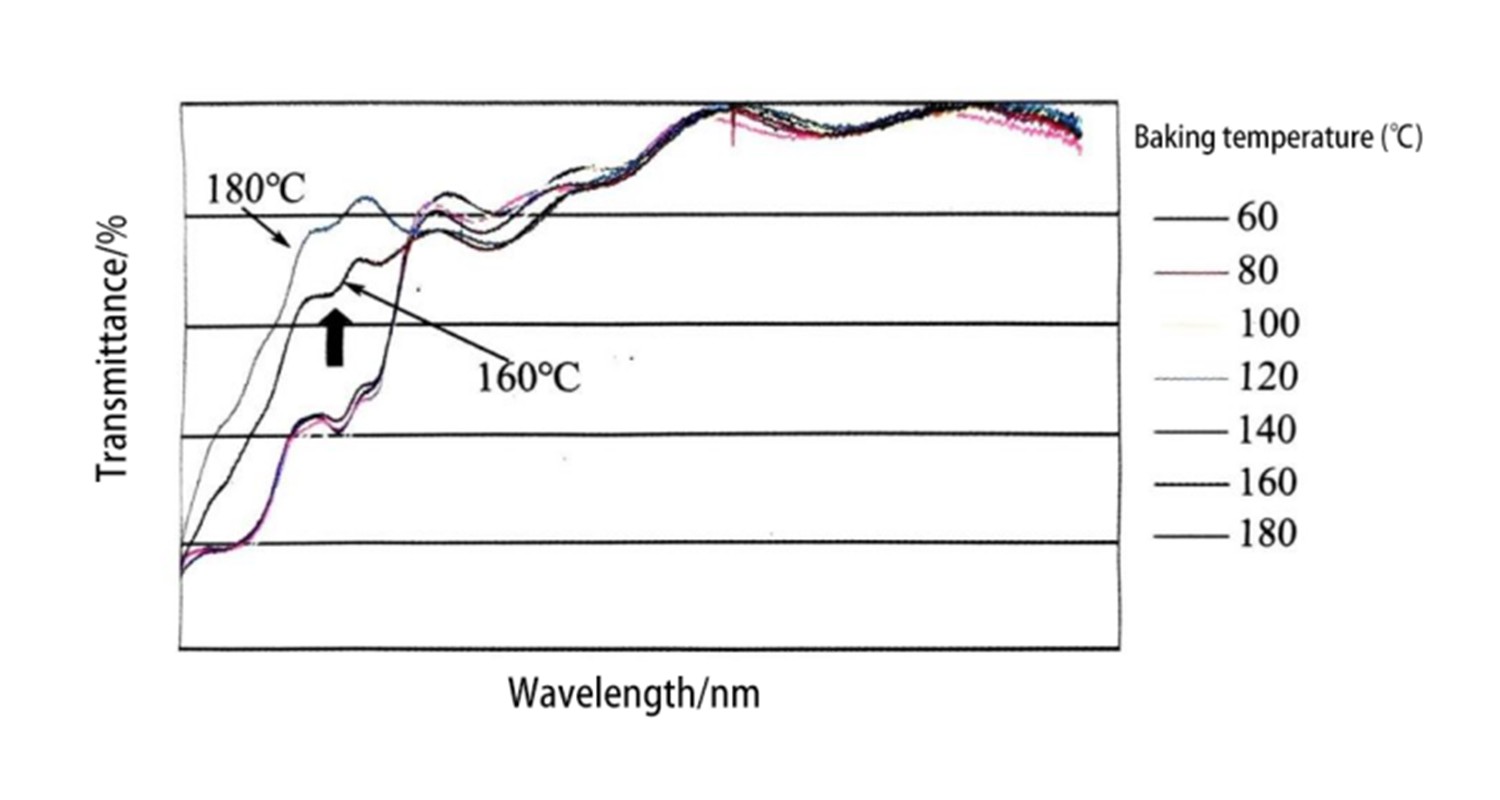

Ngesantya esifanayo sokujikeleza, kokukhona ubushushu bokubhaka buphezulu, kokukhona buncinci ukutyeba kwefilim, nto leyo ebonisa ukuba phezulu iqondo lobushushu lokubhaka, kokukhona isinyibilikisi siphuma sibe ngumphunga, sibangele ukutyeba kwefilim encinane. Umzobo we-11 ubonisa ubudlelwane phakathi kobushushu bokubhaka kwangaphambili kunye ne-Dill's A parameter. Iparamitha ye-A ibonisa ukuxinana kwe-agent ye-photosensitive. Njengoko kunokubonwa kumfanekiso, xa ukushisa kwangaphambi kokubhaka kuphakama ngaphezu kwe-140 ° C, i-parameter ye-A iyancipha, ebonisa ukuba i-agent ye-photosensitive ibola kwiqondo lokushisa eliphezulu kunale. Umzobo we-12 ubonisa ukuhanjiswa kwe-spectral kumaqondo ahlukeneyo okushisa kwangaphambili. Kwi-160 ° C kunye ne-180 ° C, ukunyuka kwe-transmittance kunokubonwa kwi-wavelength range ye-300-500nm. Oku kuqinisekisa ukuba i-agent ye-photosensitive iyabhaka kwaye ibolile kumaqondo aphezulu. Ukushisa kwangaphambi kokubhaka kunexabiso elifanelekileyo, elichongwa yimpawu zokukhanya kunye novakalelo.

Umzobo 11: Ubudlelwane phakathi kokushisa kwangaphambi kokubhaka kunye neDill's A parameter

(ixabiso elilinganisiweyo le-OFPR-800/2)

Umzobo 12: Ukuhanjiswa kweSpectral kumaqondo obushushu ahlukeneyo aphambi kokubhaka

(OFPR-800, 1um ubukhulu befilimu)

Ngamafutshane, indlela yokugubungela i-spin ineenzuzo ezizodwa ezifana nokulawulwa ngokuchanekileyo kobunzima befilimu, ukusebenza kweendleko eziphezulu, iimeko zenkqubo ethambileyo, kunye nokusebenza okulula, ngoko kunemiphumo ebalulekileyo ekunciphiseni ukungcola, ukonga amandla, kunye nokuphucula ukusebenza kweendleko. Kwiminyaka yakutshanje, i-spin coating ifumana ingqalelo ekhulayo, kwaye ukusetyenziswa kwayo kuye kwasasazeka kwiindawo ezahlukeneyo.

Ixesha lokuposa: Nov-27-2024